Method for arranging roadways on coal-pillar-free stope

A technology for mining working face and roadway layout, which is applied in surface mining, earthwork drilling, underground mining, etc., and can solve problems such as increasing the engineering volume of boundary return air lanes, affecting mining continuity, and increasing the preparation time of working faces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

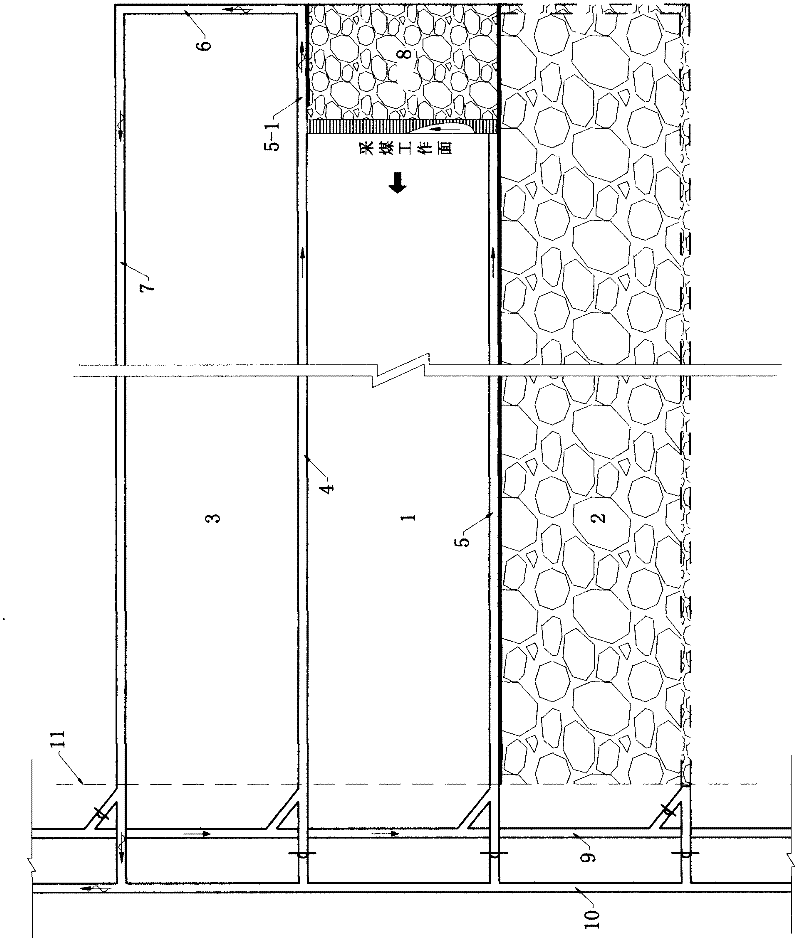

[0021] refer to figure 1 Shown: A roadway layout method for a coal-pillar-free mining face, which is carried out according to the following steps:

[0022] 1) Two roadways are arranged on both sides of the coal mining face, one of which is the newly excavated roadway 4 on the side of the existing coal mining face 1, and the other is the gobside roadway 5 of the already mined working face 2 as the air inlet roadway;

[0023] 2), before the mining of the replacement coal mining face 3, a roadway 7 is excavated in advance on one side of the replacement working face 3 as a return air roadway, and a cut hole 6 is excavated in advance at one end of the roadway 7;

[0024] 3), the cutout 6 communicates with the new excavation roadway 4 of the existing coal mining face 1;

[0025] 4), there is a reserved roadway 5-1 during the recovery of the existing coal mining face;

[0026] 5), take over the roadway 7 and the cutout 6 of the working face 3 as the boundary return airway of the wo...

Embodiment 2

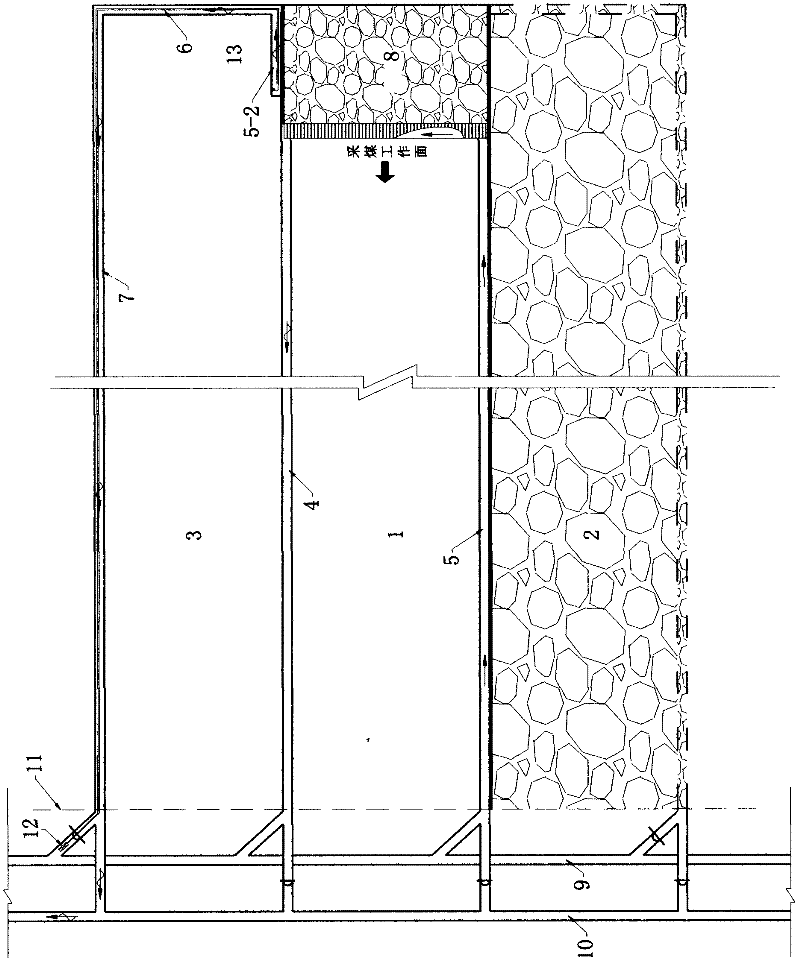

[0033] refer to figure 2 As shown: there are three parallel mining working faces arranged on one side of the transportation road 9 and the return air road 10, namely, the existing coal mining face 1, the already mined working face 2, the replacement working face 3, and the existing coal mining face 1 There are two roadways, that is, the newly dug roadway 4 and the gob-side roadway 5. Before the mining of the existing coal mining face 1, the replacement working face 3 adjacent to the existing coal mining face 1 is pre-excavated with the incision 6 and the roadway 7. Roadway 5, newly excavated roadway 4 and the roadway 7 of the replacement working face intersect with the transportation roadway 9 and the return air roadway 10 respectively. Help pour a concrete wall, and lag behind the working face 100-300m to paste the concrete wall to form a gob-side tunneling roadway 5-2 in the replacement working face 3. The current coal mining face 1 adopts "U" type ventilation, along Durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com