Method for pumping out gas from mining coal layer roof

A coal seam roof and gas drainage technology, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of poor air permeability of the original coal seam, reduce gas, and gas concentration exceeds the limit, and achieve obvious technical advantages and promotion and application prospects , Ensure safe production and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

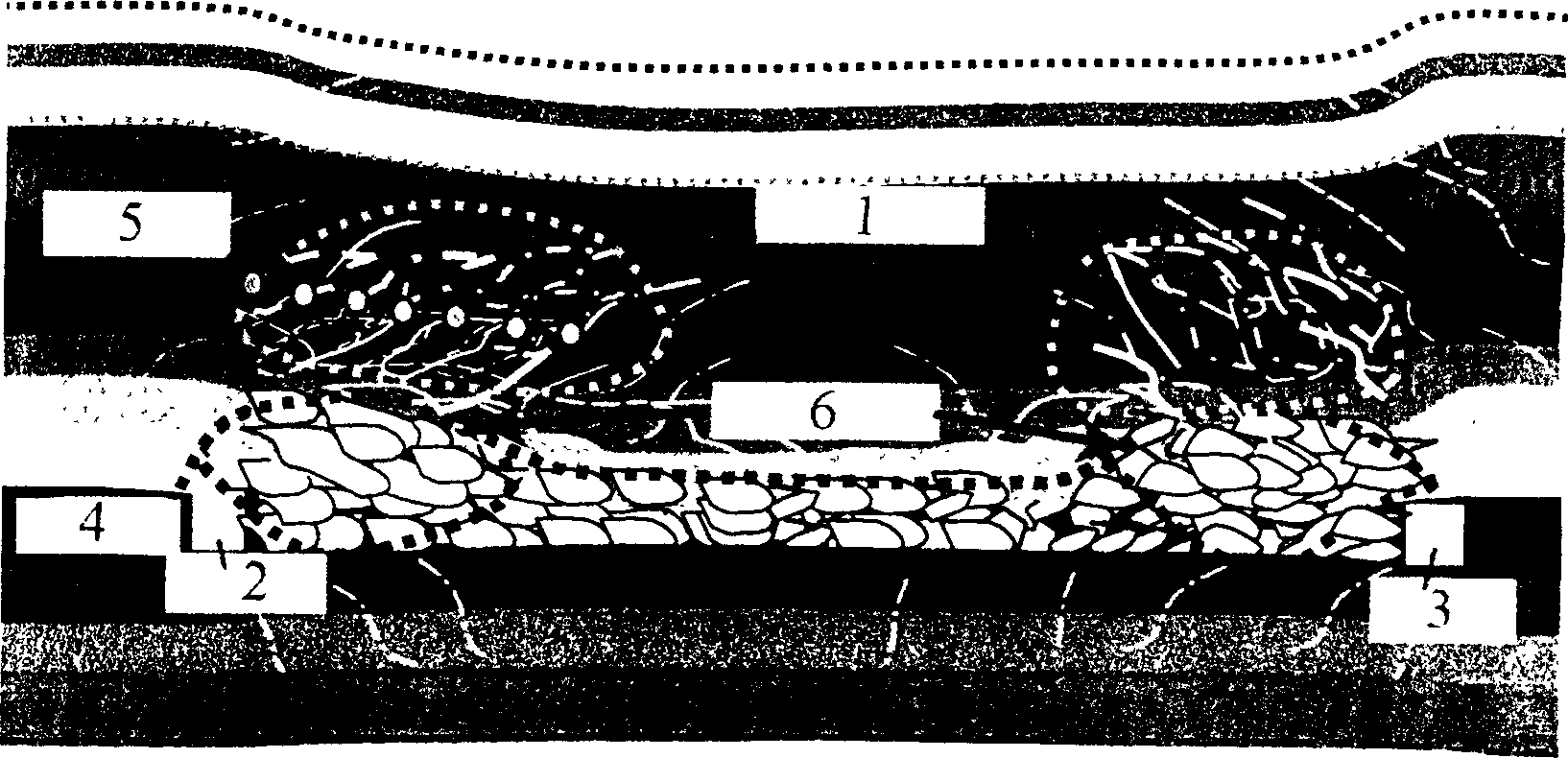

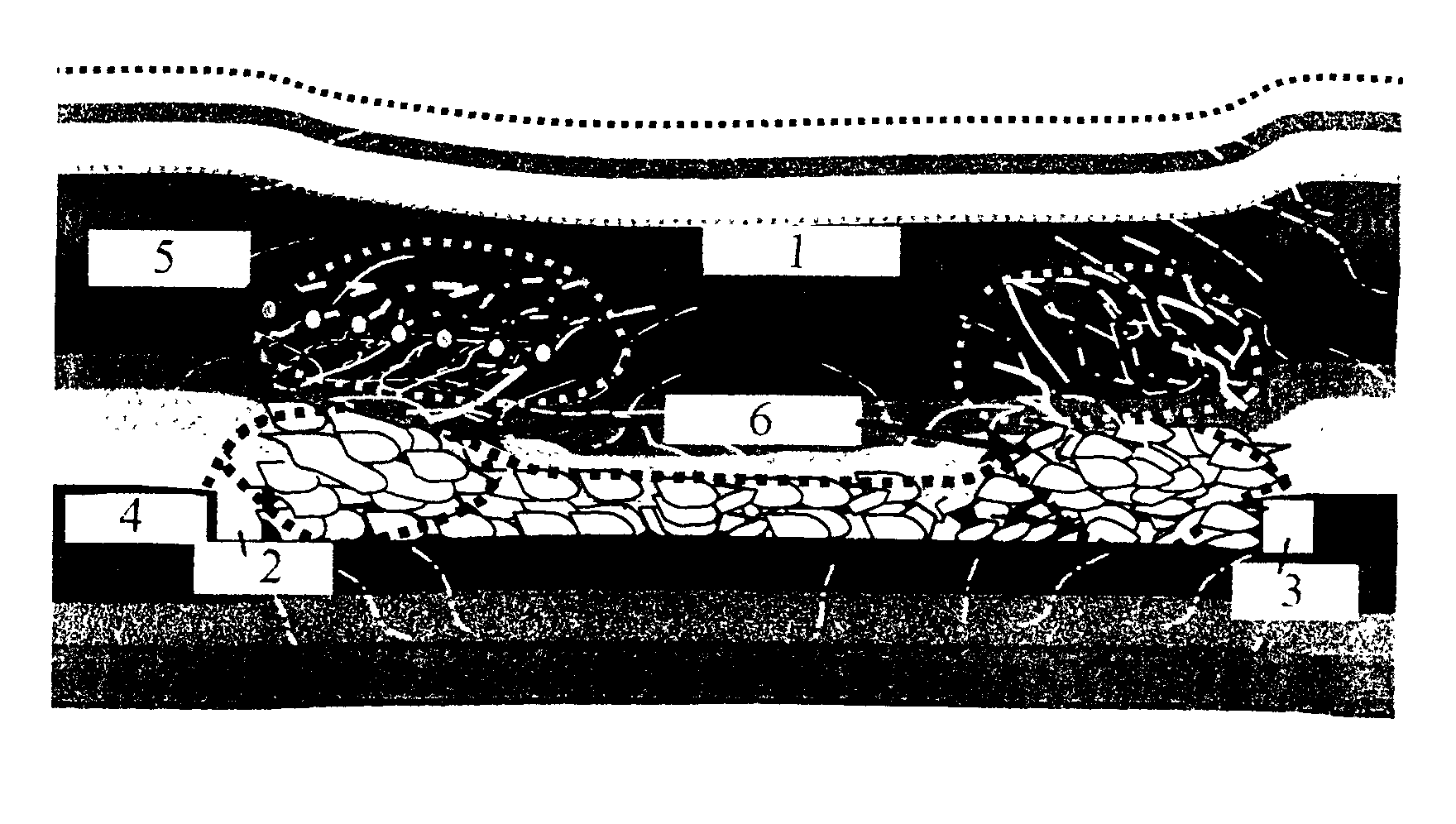

[0012] The method of the present invention is on the roof of the mining coal seam, for the desorption gas collected in the "annular fissure circle" from the mining and pressure relief coal seam through the crack channel formed by the overlying strata in the goaf affected by mining, the gas is arranged in the "annular fissure circle" The "annular fissure circle" is located in the abscission fracture zone above the roof caving zone of the goaf near the return airway and the air inlet roadway in the coal mining face.

[0013] In specific implementation, since the coal mining face generally has a certain inclination and is ventilated upwards, the gas will rise and float when the gas and air coexist. The drainage roadway is located in the "annular fissure circle" of the inner roof of the upwind roadway on the side of the working face, and the gas is drained from the goaf or the decompression and desorption gas from the adjacent layer to solve the gas overrun problem in the upper cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com