Low-permeability soft coal seam extra-thin layer water jetting exploiting permeability increasing method

A layered mining and water jet technology, applied in the fields of mining fluids, mining equipment, earthwork drilling, etc., can solve the problems of increasing the risk of coal and gas outburst, high hydraulic cutting pressure, uneven stress distribution, etc., to increase the coal seam. The effect of air permeability, increasing the extraction radius and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

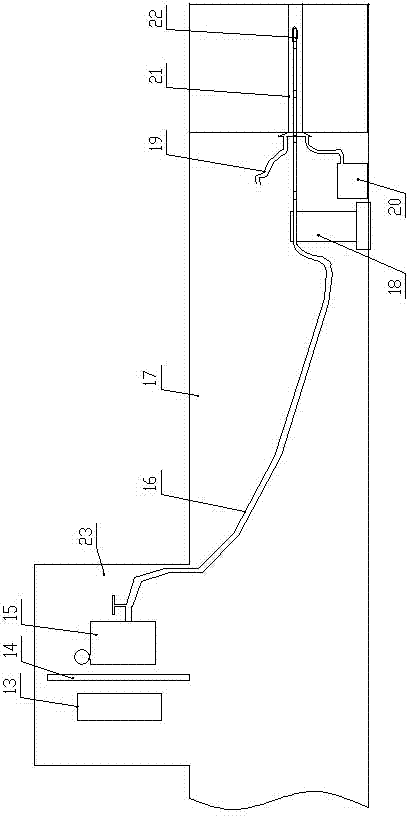

[0052] The anti-permeability method for ultra-thin stratified water jet mining of low-permeability soft coal seams of the present invention comprises the following specific steps:

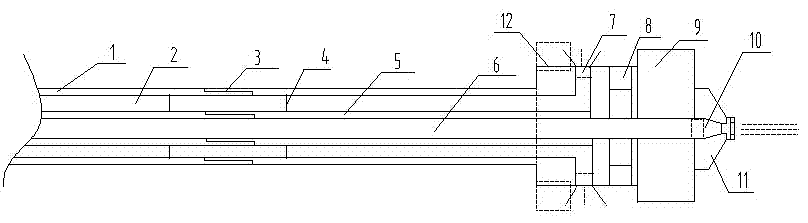

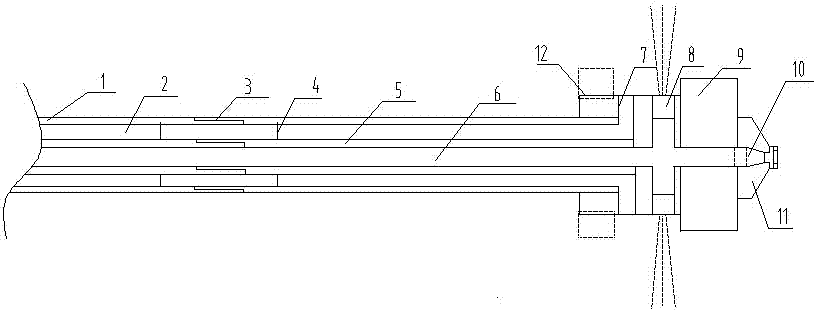

[0053] (1) Design the mining parameters of ultra-thin layer water jet, process and test the ultra-thin layer water jet mining device;

[0054] Mining parameters include ultra-thin layer mining layer, ultra-thin layer mining thickness, bedding drilling construction parameters and hydraulic jet parameters, hydraulic jet parameters include jet pressure, flow rate and nozzle moving speed; mining equipment includes orifice casing, Coal and gas water separation transportation system, jet-guided drilling-shotcrete solid hole-jet mining integrated equipment, drilling rig, water recycling system, high-pressure water supply system and other supporting facilities.

[0055] The hardness coefficient of soft coal is generally between 0.1 and 0.6, and the water jet mining layer should be arranged in the soft coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com