Injection moulding technology for remote controller housing

An injection molding process and remote control technology, applied in the coating and other directions, can solve the problems of difficult to remove moisture, poor plastic plate uniformity, oxidative discoloration of raw materials, etc., to achieve the effect of enhancing strength and hardness and avoiding oxidative discoloration and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

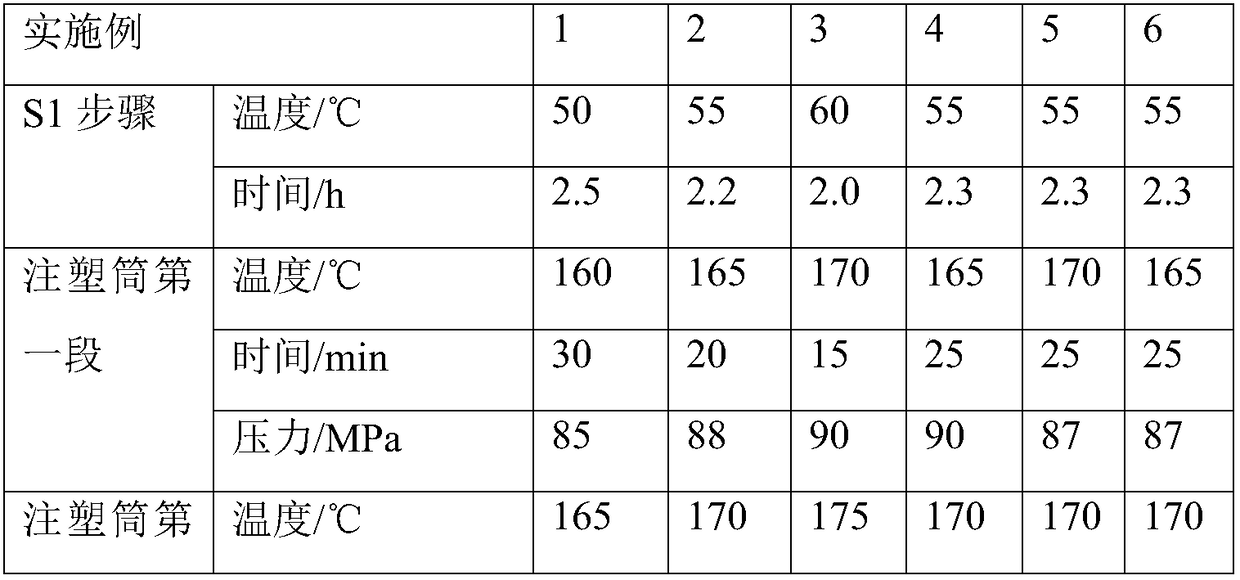

[0064] The specific process parameters of embodiment 1-embodiment 6 are as shown in table 1, wherein embodiment 1-embodiment 4 is the technical parameter defined in the present invention, the pressure in embodiment 5 is the same, and the monomer ratio is different in embodiment 6 .

[0065]

[0066]

[0067] Table 1

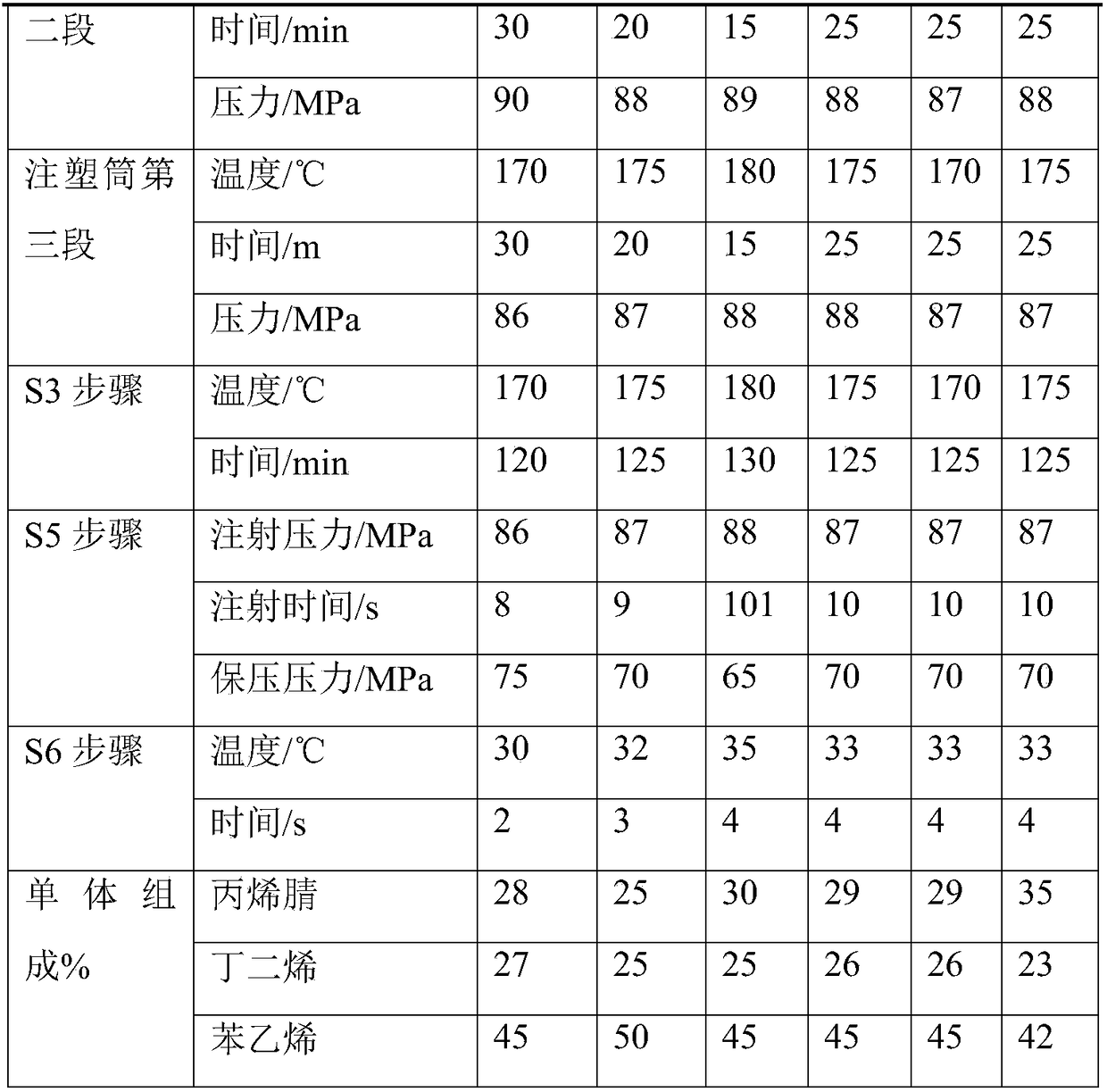

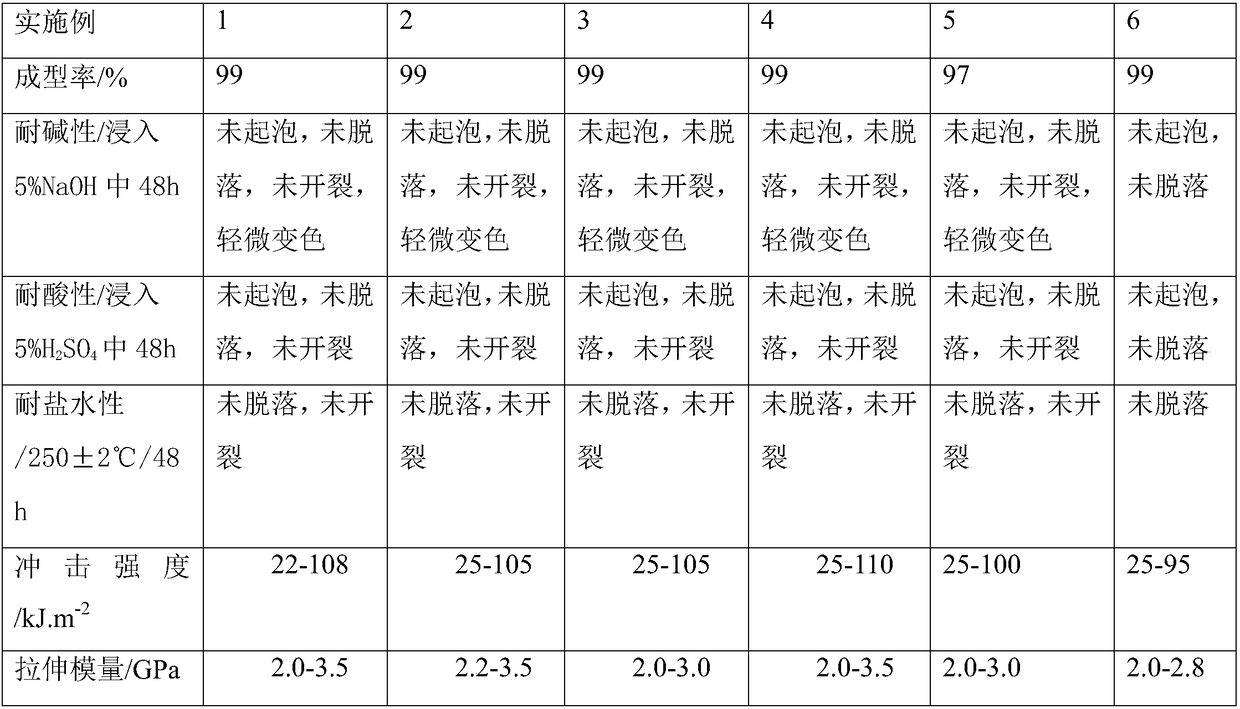

[0068] The performance parameter of the plastic plate that embodiment 1-embodiment 6 prepares is as shown in table 2, and wherein embodiment 1-embodiment 4 is the technical parameter defined in the present invention, and the pressure in embodiment 5 is identical, and in embodiment 6 Monomer ratios are different.

[0069]

[0070] Table 2

[0071] It can be seen from the data in Table 2 that the performance parameters of Embodiment 1-Example 4 are excellent, and are better than those of Embodiment 5-Example 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com