Testing structure, forming method of testing structure and washing time judging method of washing process

A technology of test structure and judgment method, which is applied in semiconductor/solid-state device testing/measurement, electrical components, electric solid-state devices, etc., can solve the problems of semiconductor device yield decline, thin-film material property degradation, and inability to detect manufacturing processes, etc., to achieve Form the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

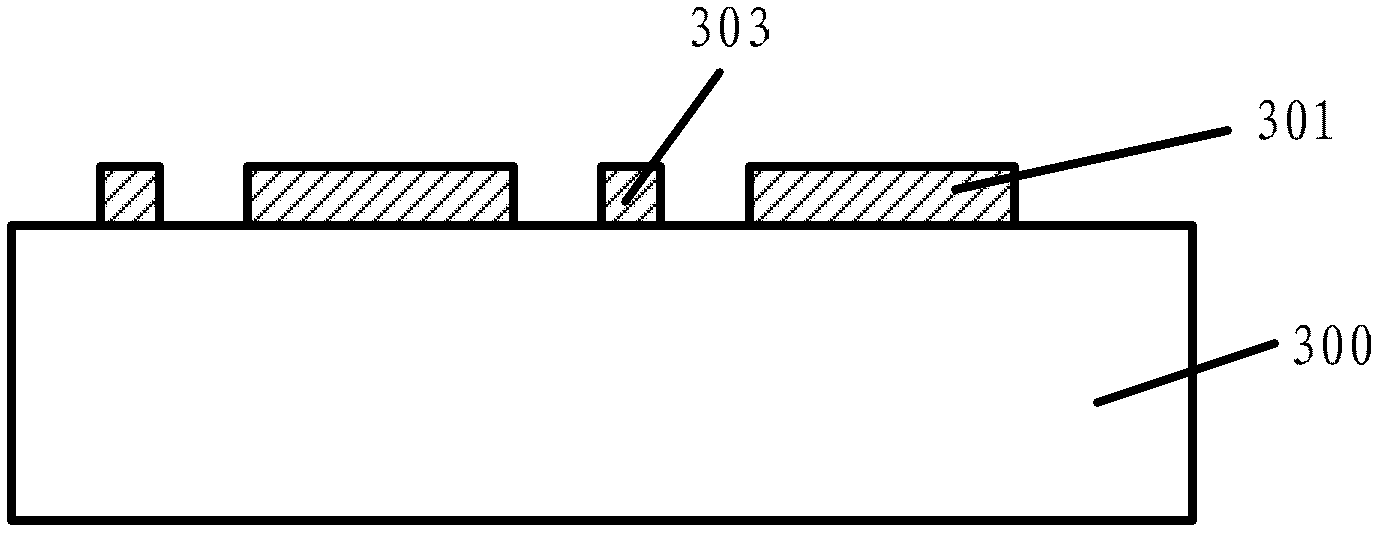

[0067] Please refer to Figure 6 , the long side of the first pattern 301 is greater than 100 microns, the short side is greater than 25 microns, the long side of the second pattern 303 is greater than 100 microns, and the short side is greater than 25 microns, the first pattern 301 and the second pattern 303 The distance between them is less than or equal to 5 microns.

[0068] In Example 1 of the present invention, the long side of the first pattern 301 is 150 microns, the short side is 100 microns, the long side of the second pattern 303 is 110 microns, and the short side is 80 microns, the first The distance between the pattern 301 and the second pattern 303 is 3 microns. In the test structure formed subsequently in Example 1, cracks are more likely to appear in the corresponding areas between the first pattern 301 and the second pattern 303 .

example 2

[0070] Please refer to Figure 7 , the long side of the first pattern 301 is greater than 100 microns, the short side is greater than 25 microns, the area of the second pattern 303 is less than 1 square micron, and the distance between the first pattern 301 and the second pattern 303 is less than or equal to 5 microns.

[0071] In Example 1 of the present invention, the long side of the first pattern 301 is 150 microns, the short side is 100 microns, the long side of the second pattern 303 is 0.8 microns, and the short side is 0.5 microns, the first The distance between the pattern 301 and the second pattern 303 is 2 microns. In the test structure formed subsequently in Example 2, cracks are more likely to appear in the corresponding areas between the first pattern 301 and the second pattern 303 . Since the distance between the first graphic 301 and the second graphic 303 in Example 2 is small, cracks are more likely to appear in the corresponding areas between the first g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com