Capacitive level probe

A level meter, capacitive technology, applied to the liquid level indicator, measuring device, instrument and other directions of physical variable measurement, can solve the problems of high manufacturing cost, reduce storage space, enhance mechanical performance, and simplify manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

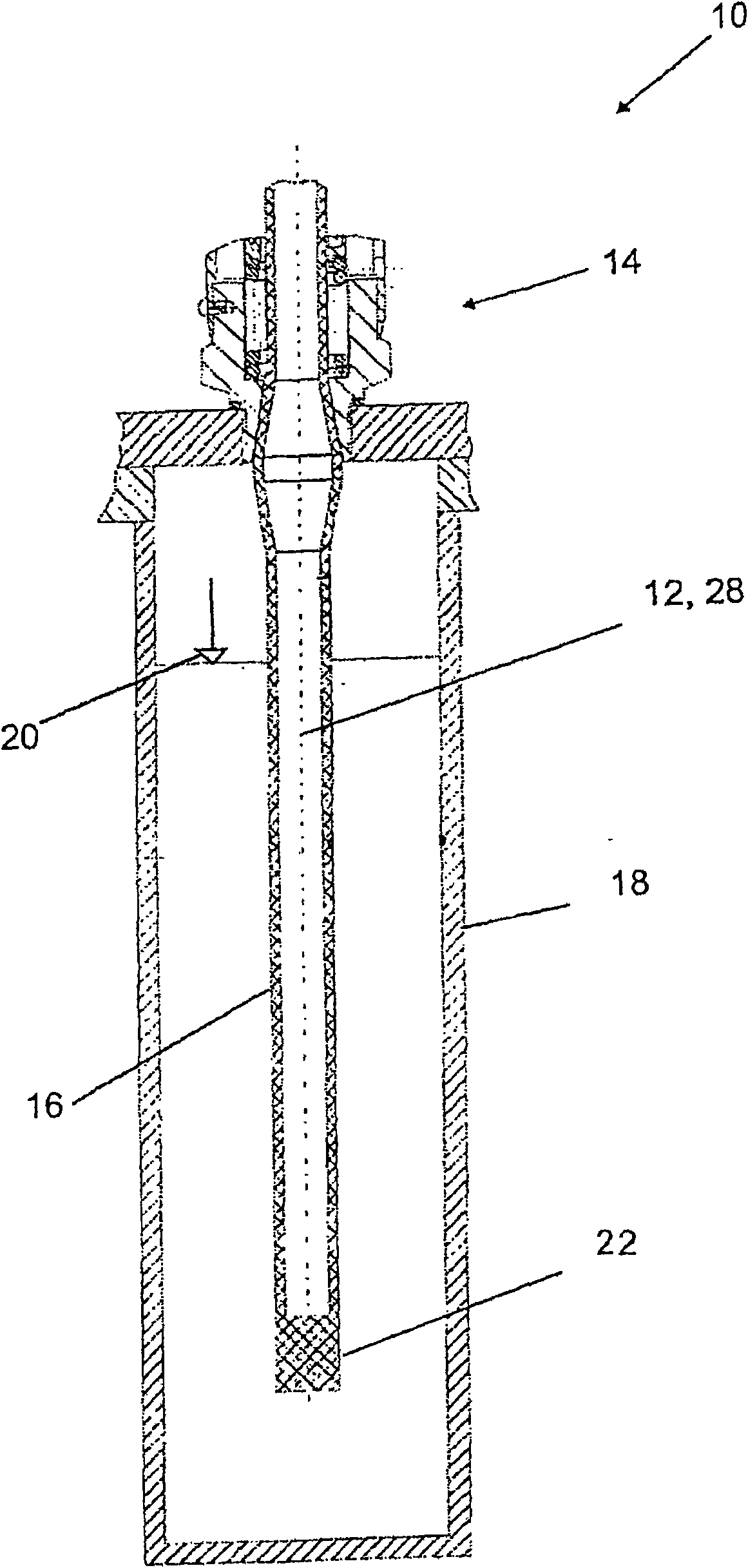

[0051] figure 1 A level gauge 10 according to the prior art is illustrated. The level gauge includes an electrode 12 , a connecting portion 14 and an insulating sleeve 16 . The electrodes 12 protrude into a container 18 with a liquid medium (not shown), the filling level of which is to be determined. The fill level of the liquid medium at the maximum fill level is indicated by arrow 20 . The electrode 12 comprises a substantially cylindrical metal tube radially completely surrounded by an insulating sleeve 16 .

[0052] In the lowest position, that is to say at the point where the fluid immersion ends last as the filling height decreases, the insulating sleeve 16 is welded to the closing part 22 in such a way that the insulating sleeve 16 is pressure-tight.

[0053] The insulating sleeve 16 extends partially around the connection portion 14 and substantially completely surrounds the electrode 12 .

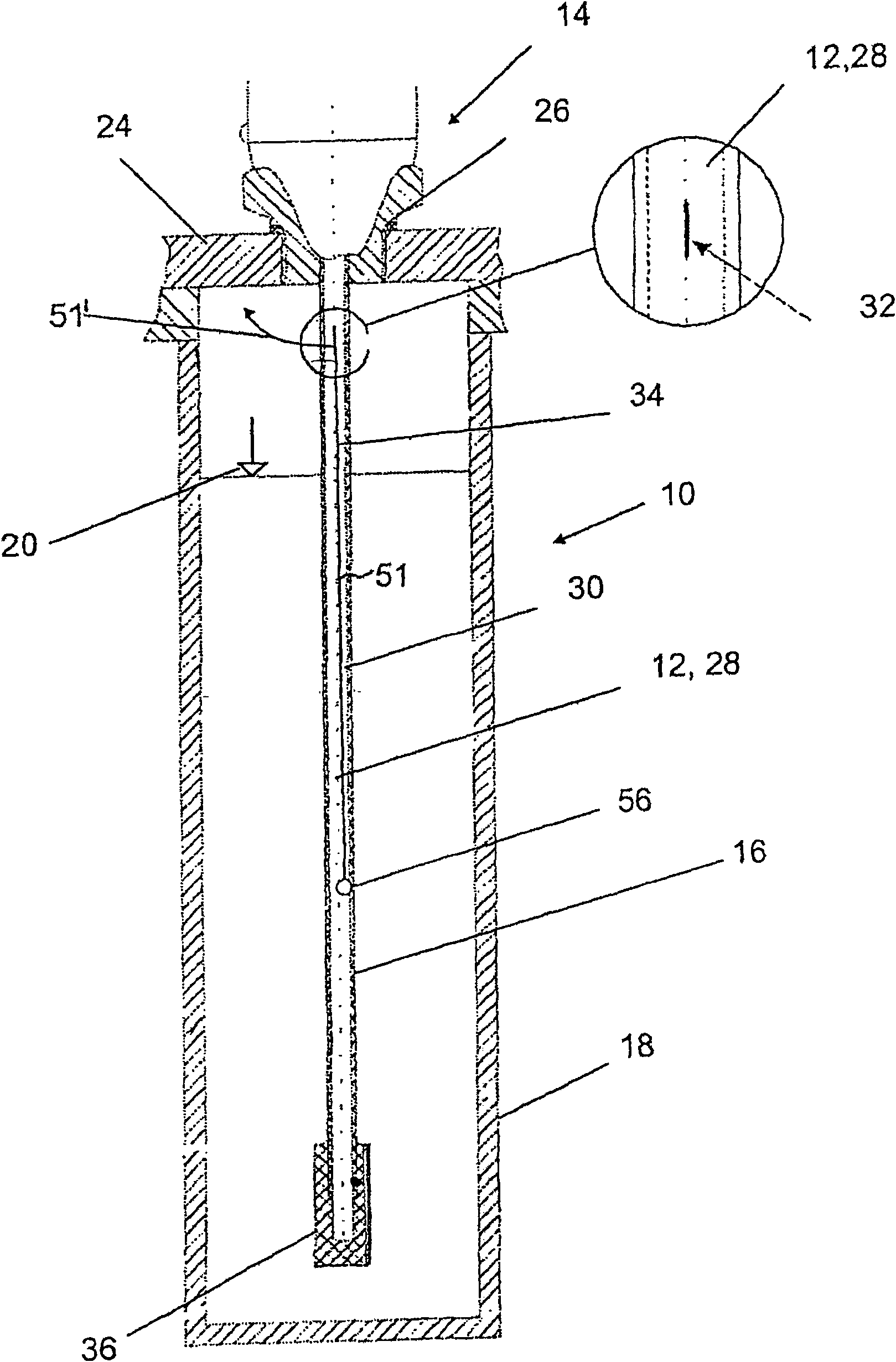

[0054] figure 2 A level gauge 10 according to the invention is illustrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com