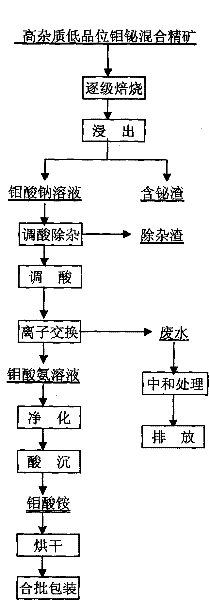

Method for producing ammonium molybdate from molybdenum-bismuth bulk concentrates of high impurity content and low grade

A mixed concentrate, low-grade technology, applied in the direction of improving process efficiency, can solve problems such as low calcine leaching rate and low molybdenum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Take 1 ton of high-impurity and low-grade molybdenum-bismuth mixed concentrate, and continuously roast it step by step in a reverberatory furnace at 200°C to 700°C for 9 hours; the solid / liquid ratio is 1:3.5, add 500kg of mixed alkali, and leach at 70°C for 2 hours; the leachate is processed with concentrated hydrochloric acid Adjust the pH value to 7.0, stir for 30 minutes; filter; the filtrate is adsorbed on the weak base anion resin for about 75 minutes; add industrial MgCl to the molybdenum analysis solution according to 2 times the stoichiometric amount 2 In addition to P and Si, after holding at 50°C for 30 minutes, cool down to 40°C and filter; add industrial concentrated nitric acid crystal ammonium molybdate to the filtrate at 55°C according to 1.05 times of stoichiometric measurement, and produce ammonium molybdate with high-impurity and low-grade molybdenum-bismuth mixed concentrate The result (%) is as follows:

[0011]

Embodiment 2

[0013] Take 1.5 tons of high-impurity and low-grade molybdenum-bismuth mixed concentrate, and continuously roast it step by step in a reverberatory furnace at 200°C to 700°C for 10 hours, with a solid / liquid ratio of 1:4, add 700kg of mixed alkali, and leach at 80°C for 2 hours. Adjust the pH value to 8.0, and filter after stirring for 20 minutes; the filtrate is adsorbed on the weak base anion resin and the contact time is about 80 minutes. 2 In addition to P and Si, after 40 minutes of heat preservation, the temperature was lowered to 40 ° C and filtered, and the filtrate was added to 1.05 times of stoichiometric measurement at 50 ° C to add industrial concentrated nitric acid to crystallize ammonium molybdate, and the results of producing ammonium molybdate with high impurities and low grade molybdenum and bismuth mixed concentrates ( %)as follows:

[0014]

[0015] Ammonium molybdate

Embodiment 3

[0017] Take 3 tons of high-impurity and low-grade molybdenum-bismuth mixed concentrate, and continuously roast it step by step in a reverberatory furnace at 200°C to 700°C for 12 hours, with a solid / liquid ratio of 1:5, add 1100kg of mixed alkali, and leach at 90°C for 1.5 hours. Adjust the pH value to 6.5 with hydrochloric acid, filter after stirring for 50 minutes; the filtrate is adsorbed on a weak base anion resin for about 70 minutes, and the molybdenum analysis solution is added to industrial MgCl at 48 ° C according to 1.5 times the stoichiometric amount. 2 In addition to P and Si, after holding for 25 minutes, cool down to 45°C and filter, add industrial concentrated nitric acid to crystallize ammonium molybdate at 40°C according to 1.06 times of stoichiometric measurement, the result of producing ammonium molybdate from molybdenum-bismuth mixed concentrate with high impurities and low grade (%)as follows:

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com