Method for ensuring fully-mechanized top coal caving recovery rate of three-soft thick coal seam roadway tunneling along top

A technology of tunneling along the top and thick coal seam is applied in the field of fully mechanized caving mining along the top of the roadway with three soft and thick coal seams to ensure the recovery rate. Coal production output, economic and social benefits are significant, and the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

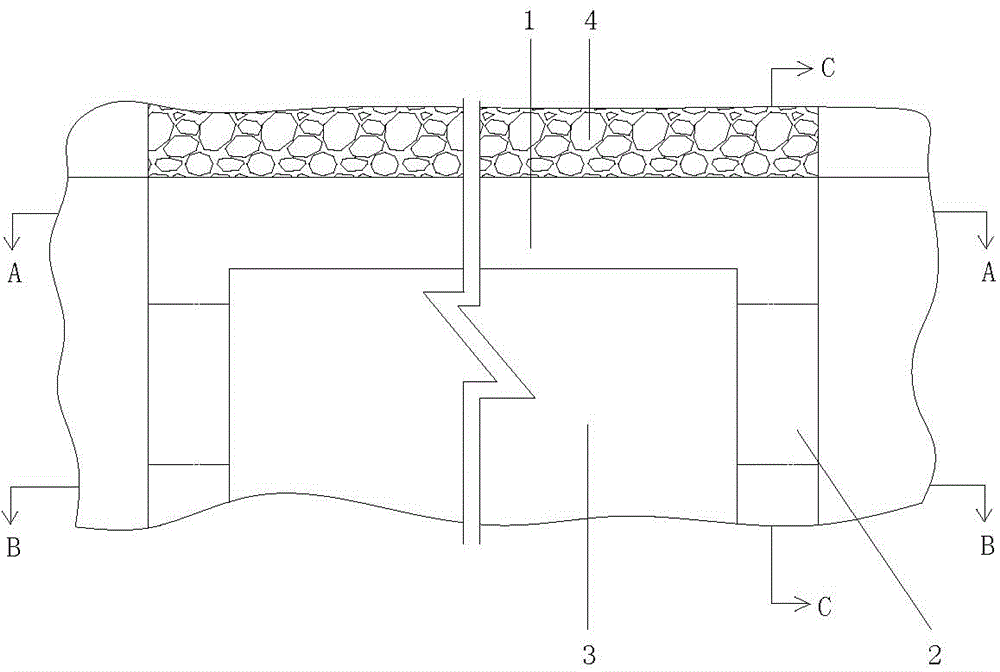

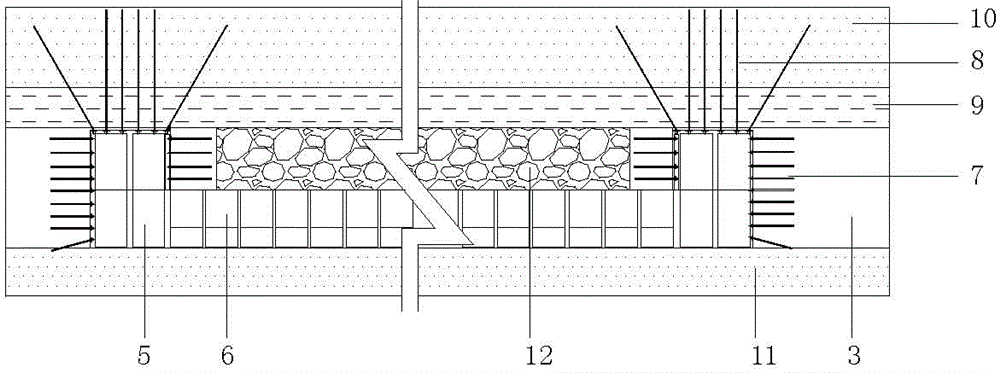

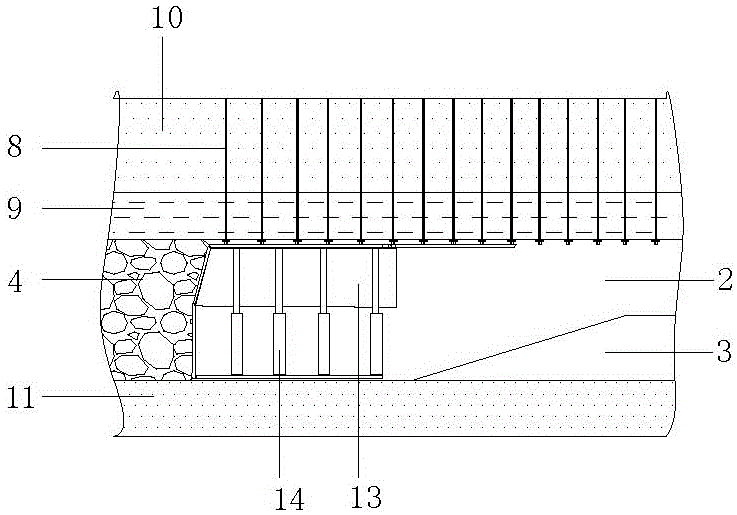

[0019] Depend on Figure 1-4 Shown, the present invention is realized by the following steps in concrete implementation:

[0020] (1) Set up the coal mining face roadway: Excavate a rectangular cross-section roadway with a width of 4.0m. The roadway is excavated along the roof of the coal seam and the height of the roadway is 3.0m. Behind the coal mining face 1 is the goaf 4. In the coal seam 3, there is an advance bottom digging section 2 connected with the coal mining face (see figure 1 As shown), then the roadway is supported by anchor net cables, the method is to excavate the roadway 15 with the bottom coal along the direct roof 9 on both sides of the coal mining face of the coal seam 3, and the roadway 15 with the bottom coal is installed on both sides for The anchor rod 7 supporting the roadway, the roof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com