Patents

Literature

40results about How to "Improve the stability of bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

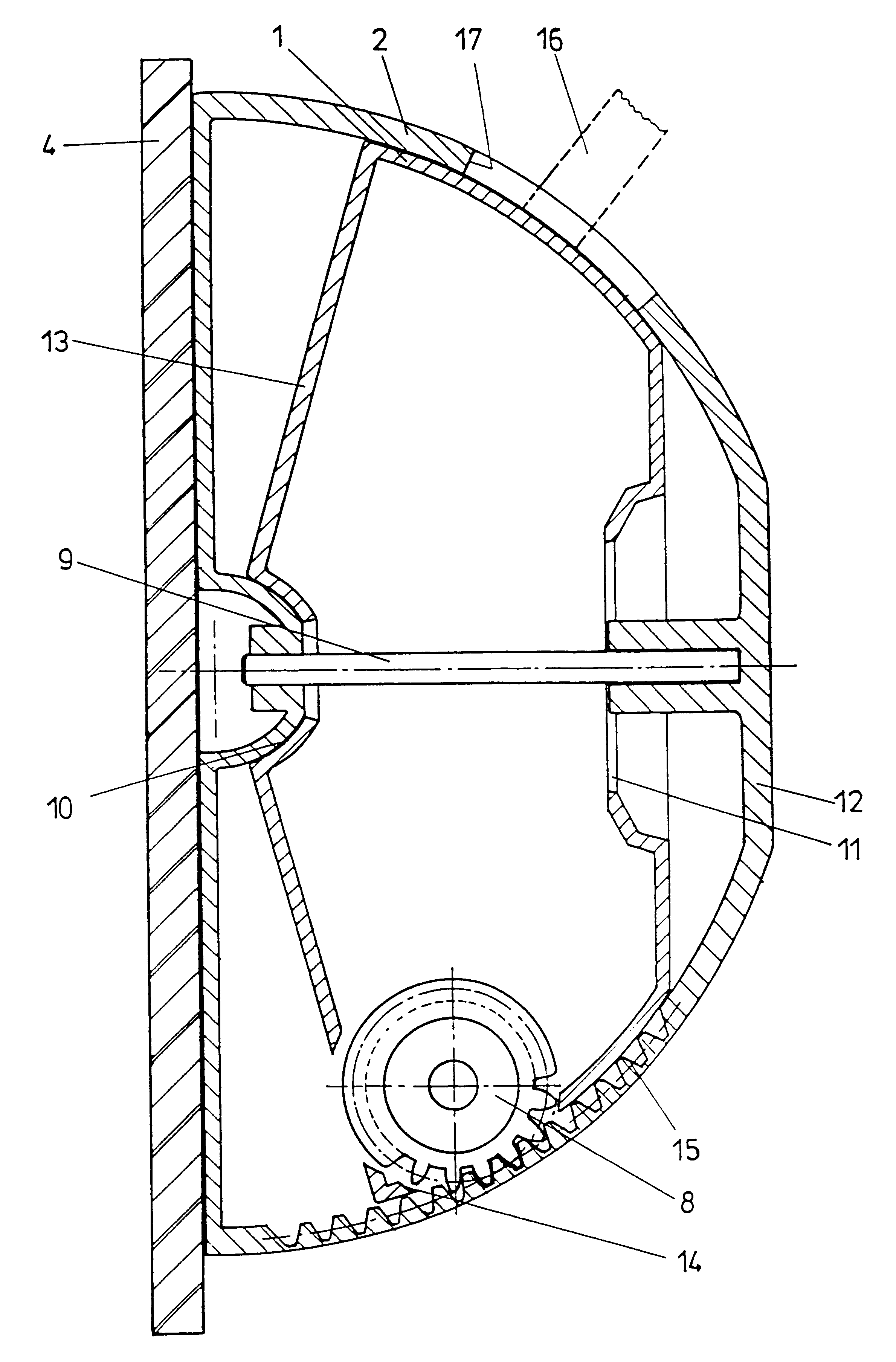

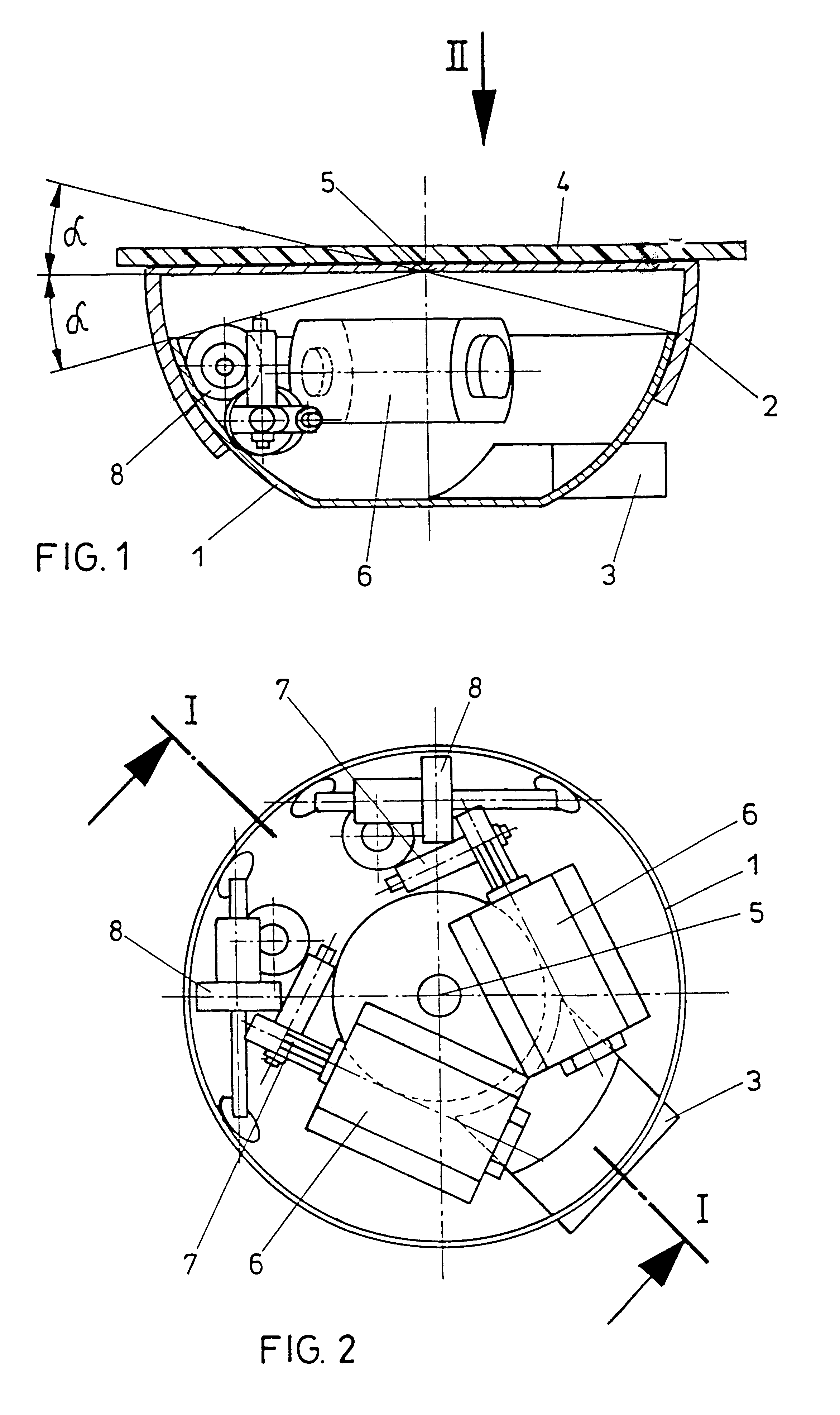

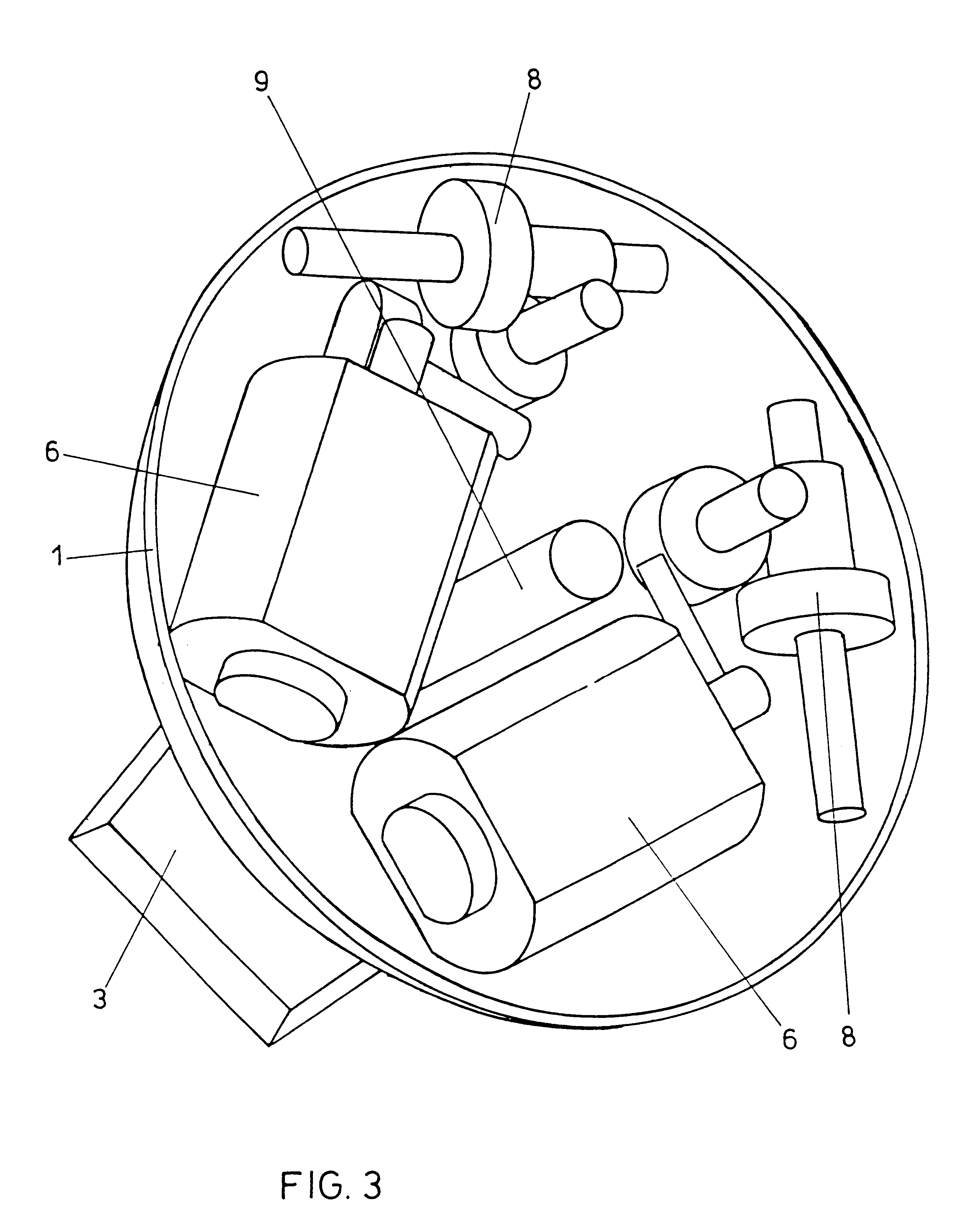

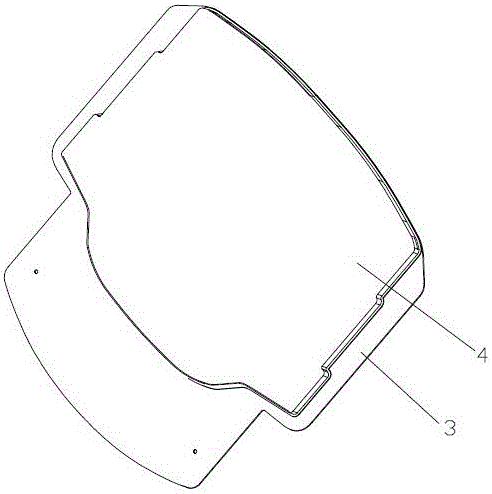

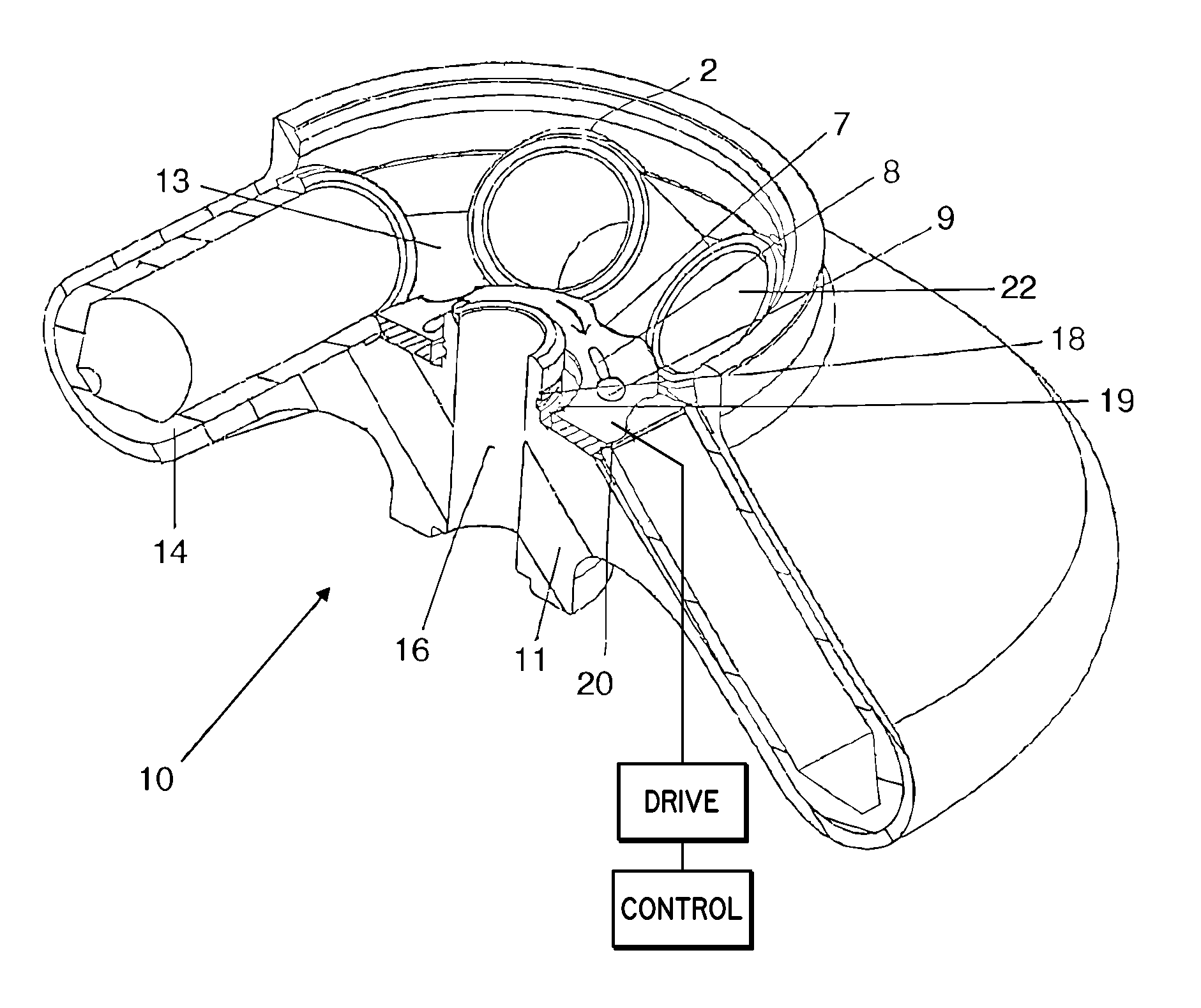

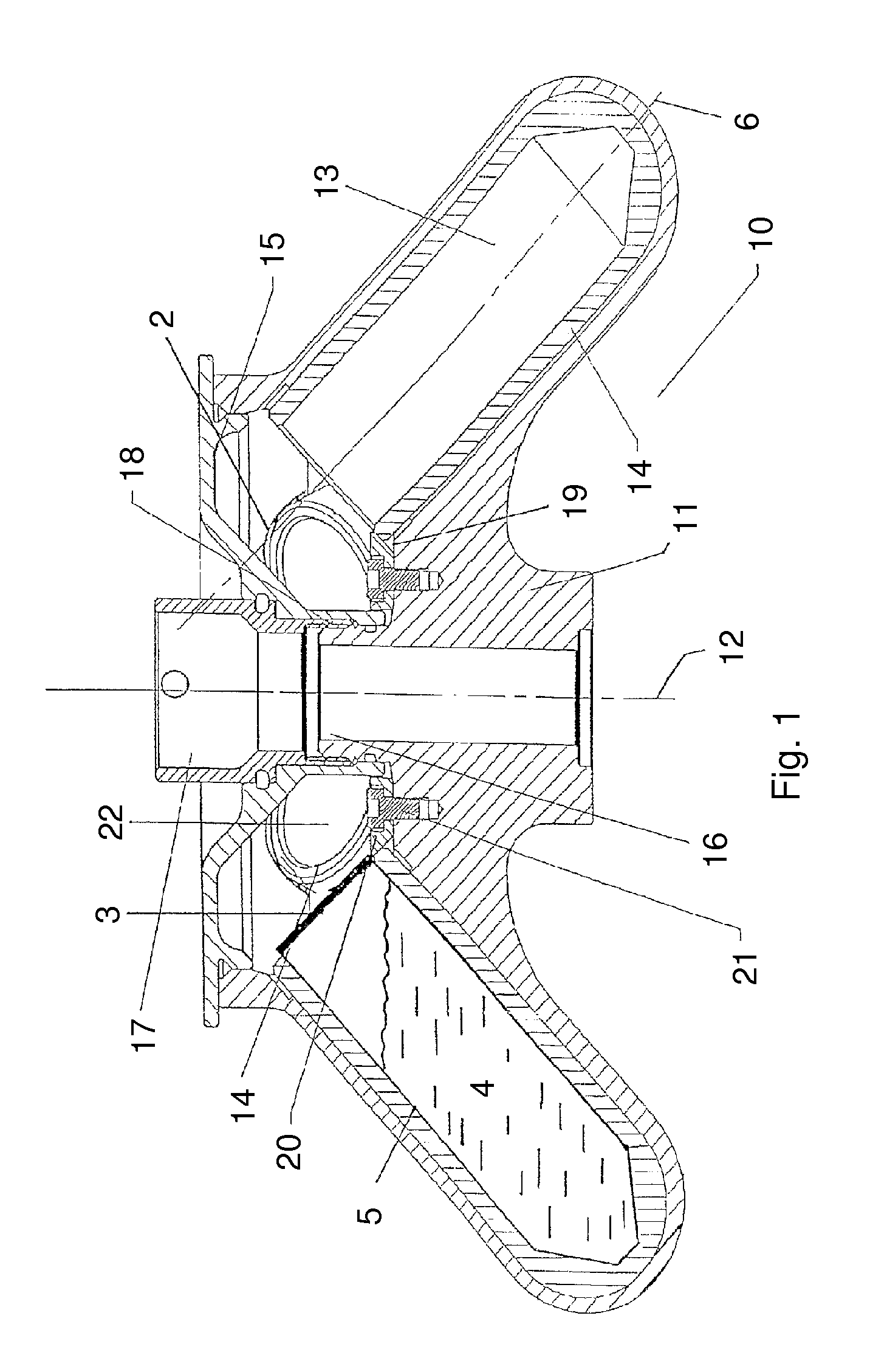

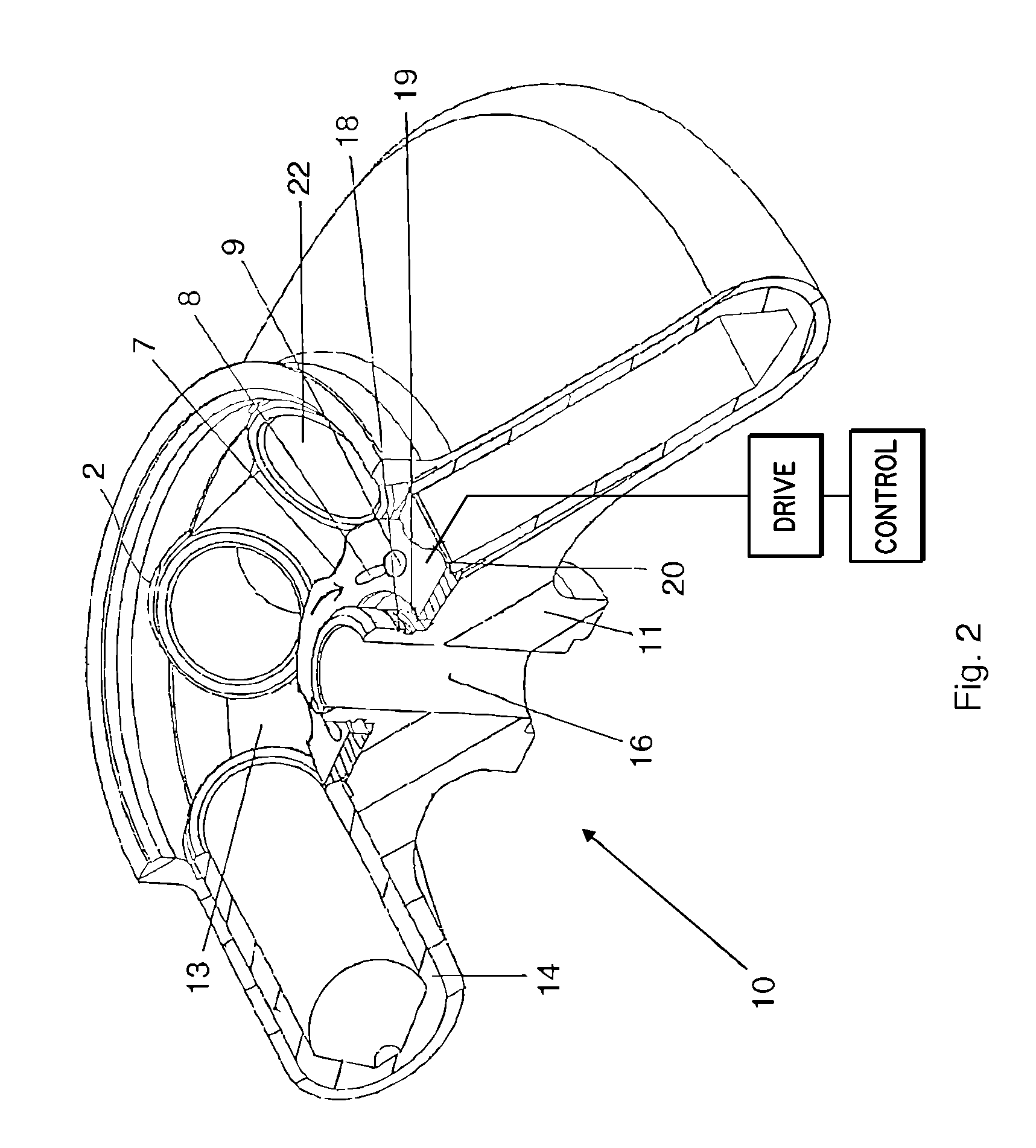

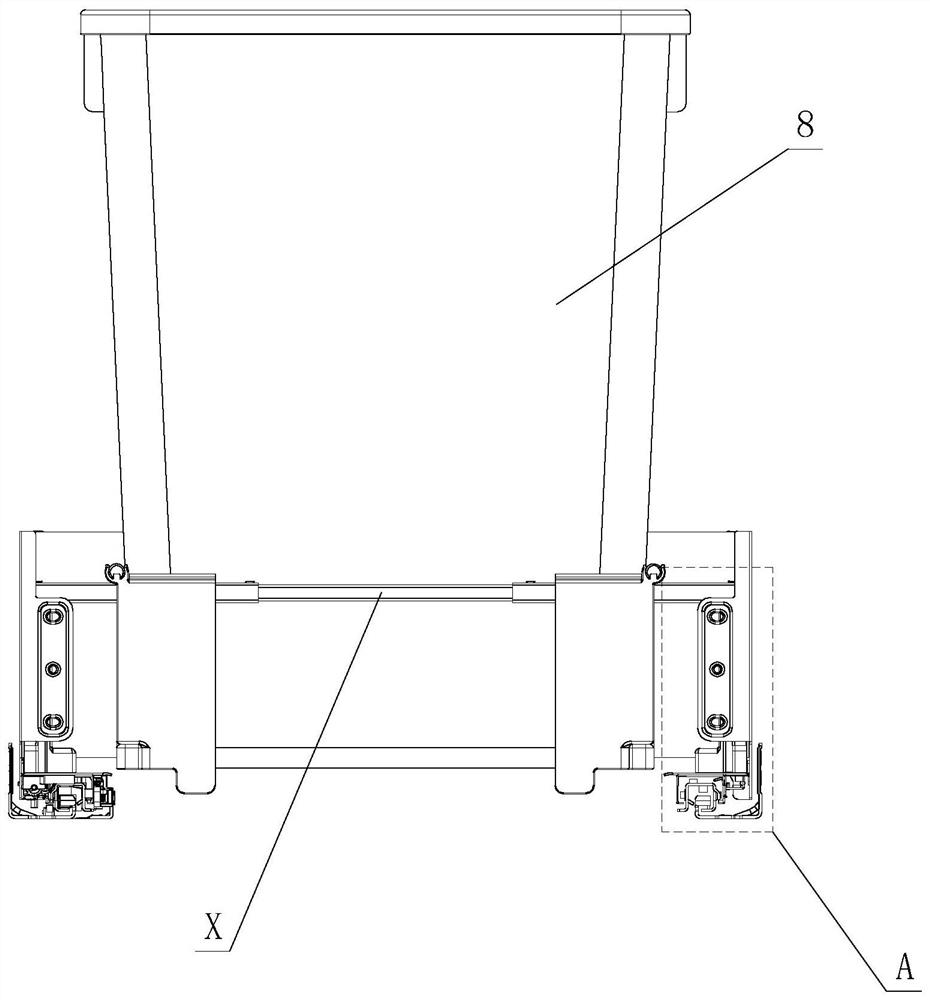

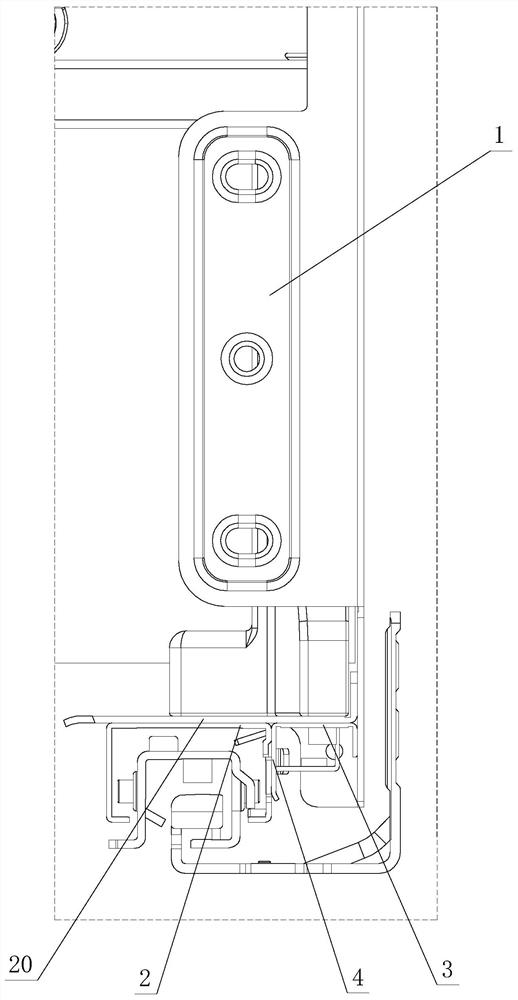

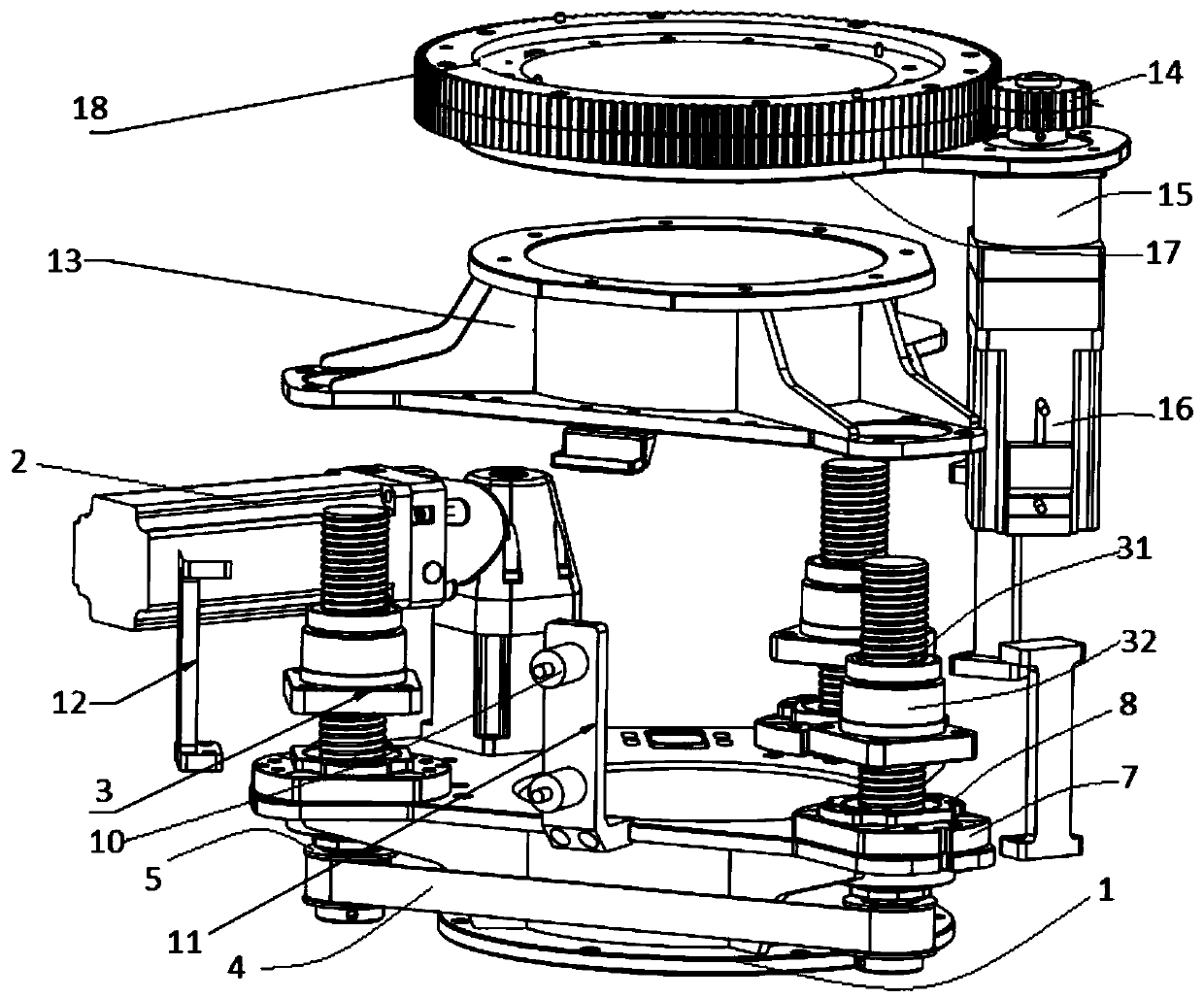

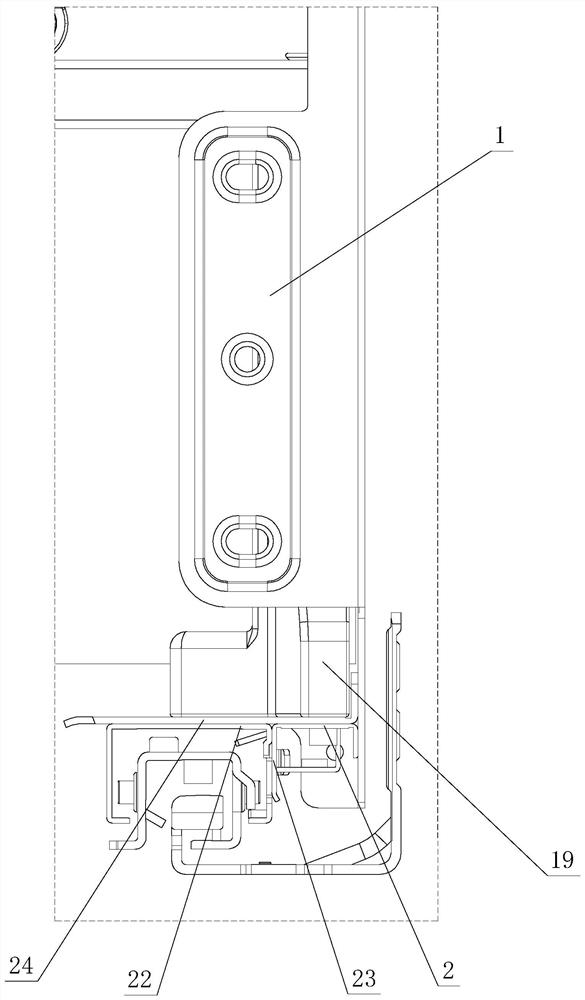

Adjustable rear-view mirror for a vehicle

InactiveUS6174062B1Improve the stability of bearingAdd supportMirrorsPicture framesMobile vehiclePinion

In an adjustable rearview mirror, especially an outside mirror, for a motor vehicle, whereby a first element (1) is affixable to the vehicle and a second element (2), rotatably attached to the first element (1), has or forms a mount for a mirror (4), whereby the two elements (1, 2) are designed as dish-shaped elements (1, 2) that nest with one another at least partially and are guided or bear against one another via outside and inside areas of contact forming a segment of a spherical surface and whereby a drive (6) is provided between the first and the second element (1, 2) is proposed, characterized in that the outer element (2) is designed on part of its inner surface with a gear-tooth system extending along a circular section of the inner surface of the outer element (2), with which a pinion (8) of a drive (6) mounted in the inside of the inner element (1) meshes for adjustment of the outer element (2) relative to the inner element (1), by which means can be achieved with a simple construction a design that is largely insensitive to vibrations.

Owner:MAGNA AUTECA ZWEIGNIEDERLASSUNG DER MAGNA HLDG

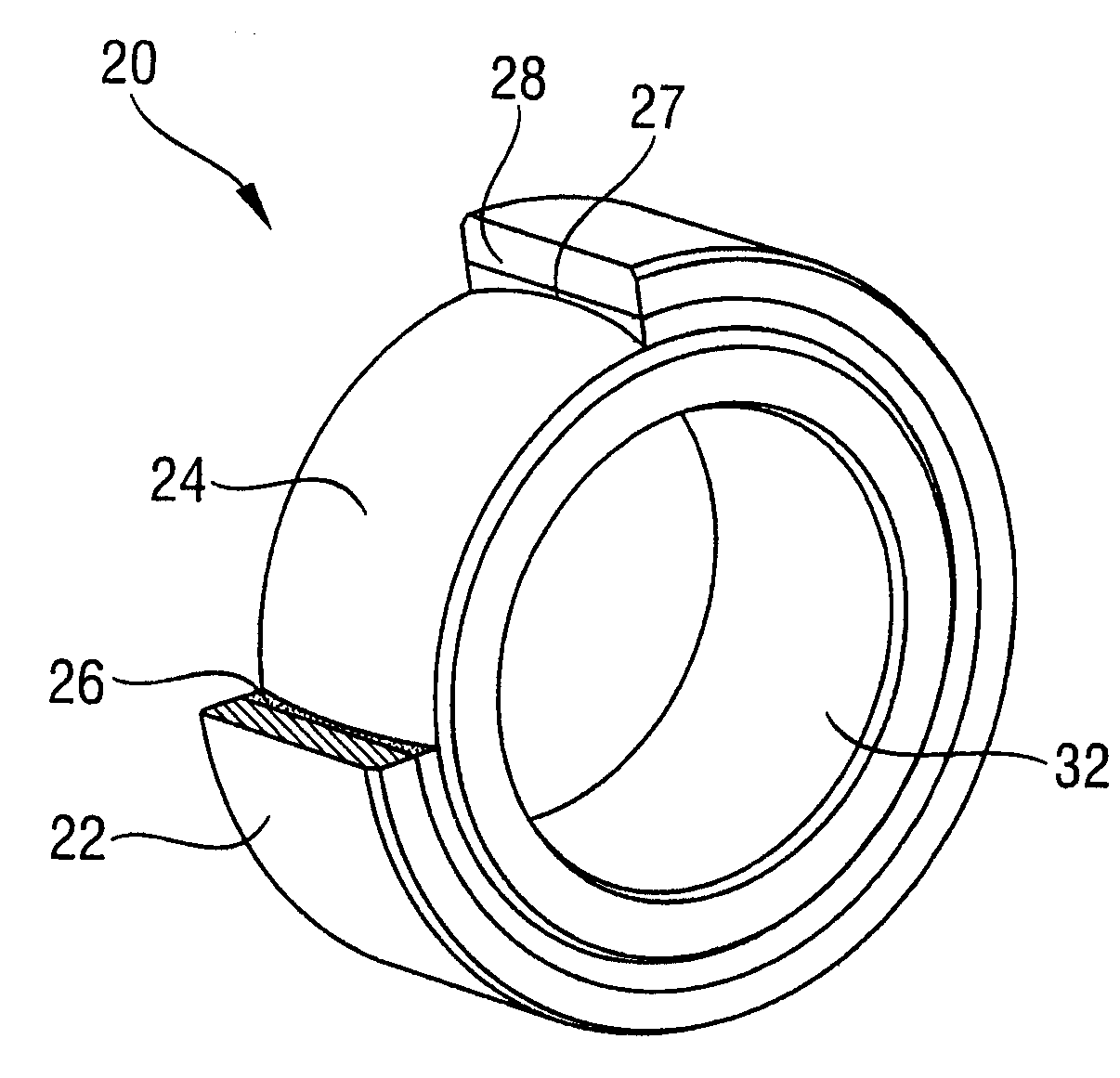

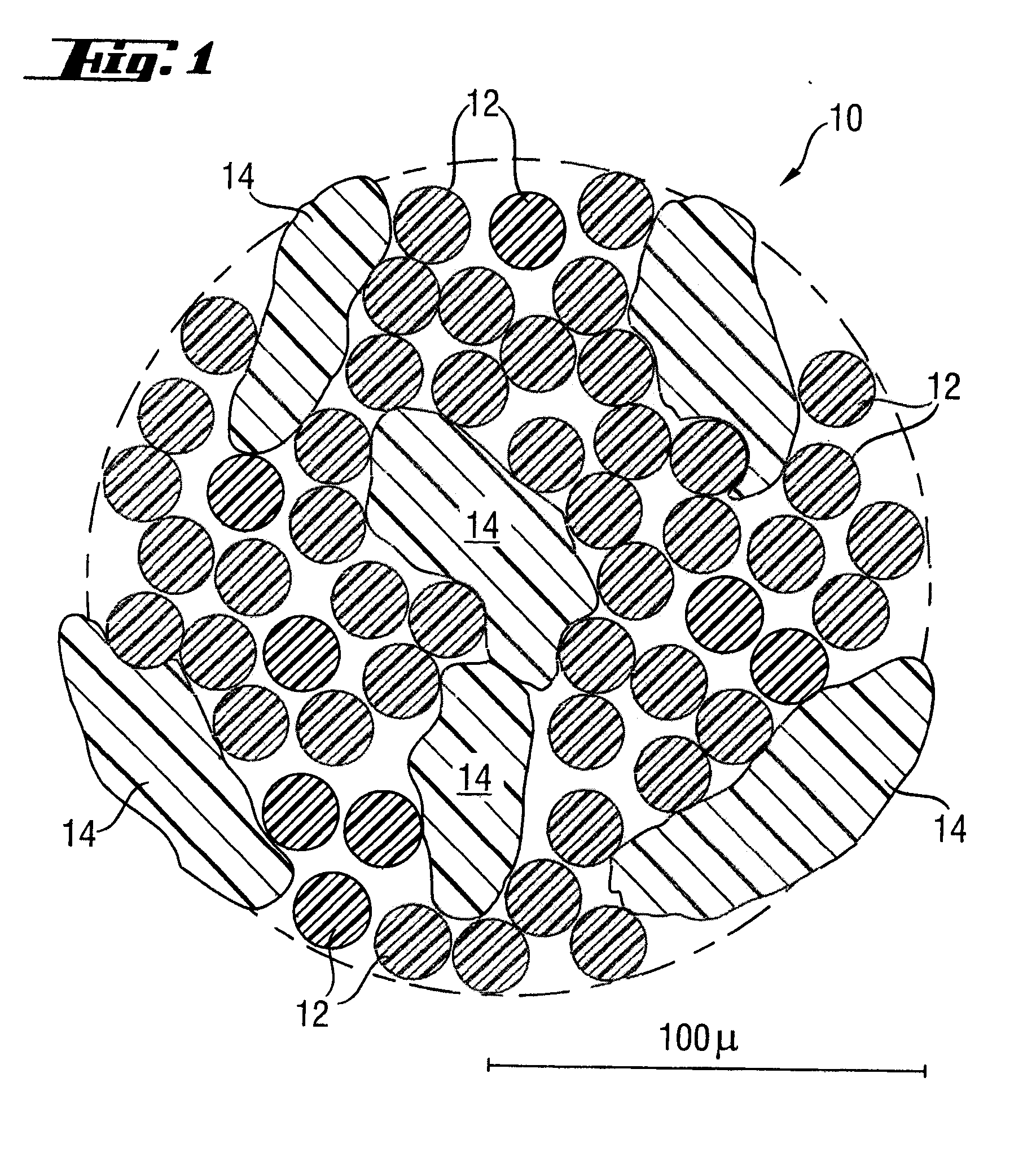

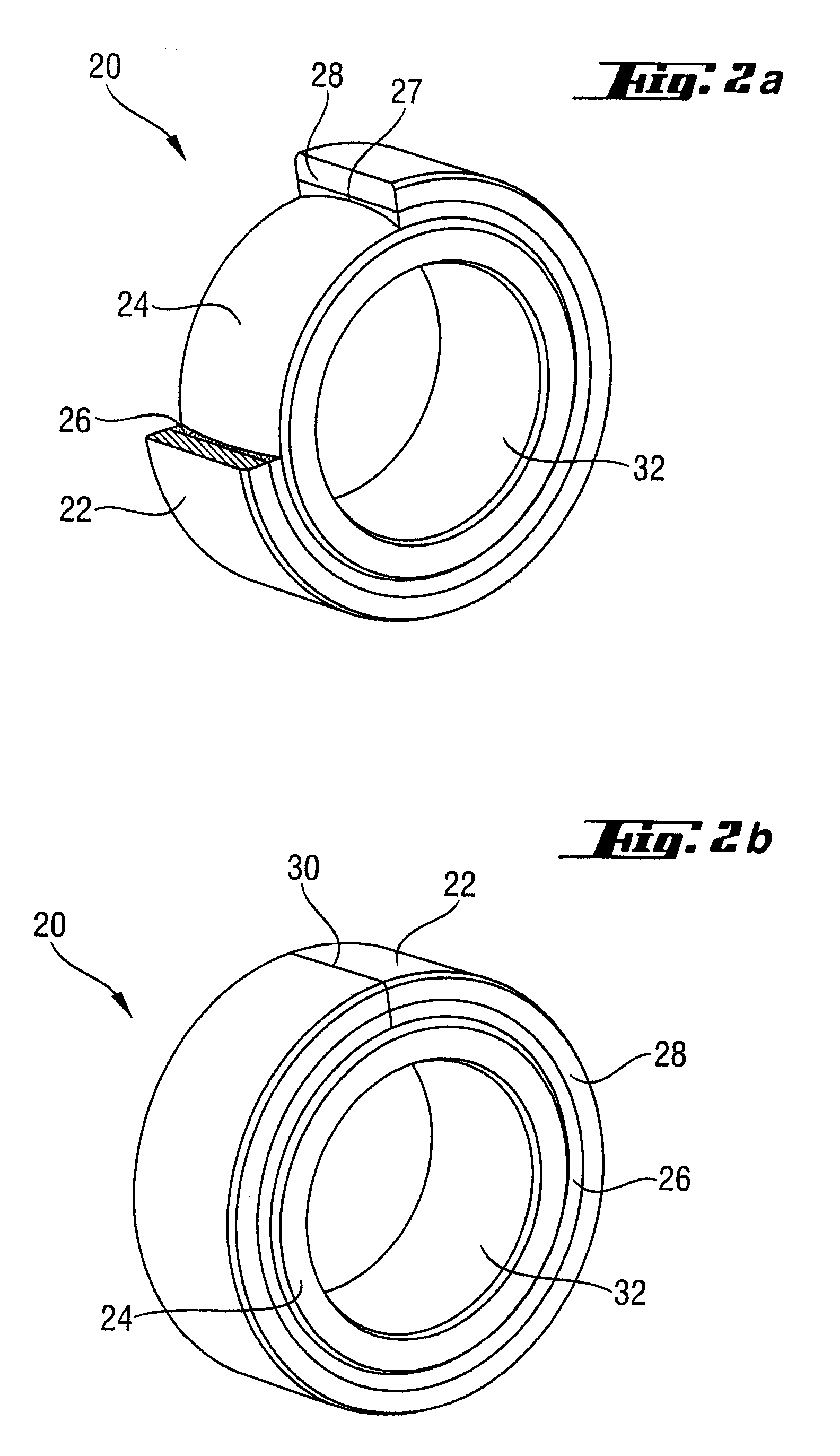

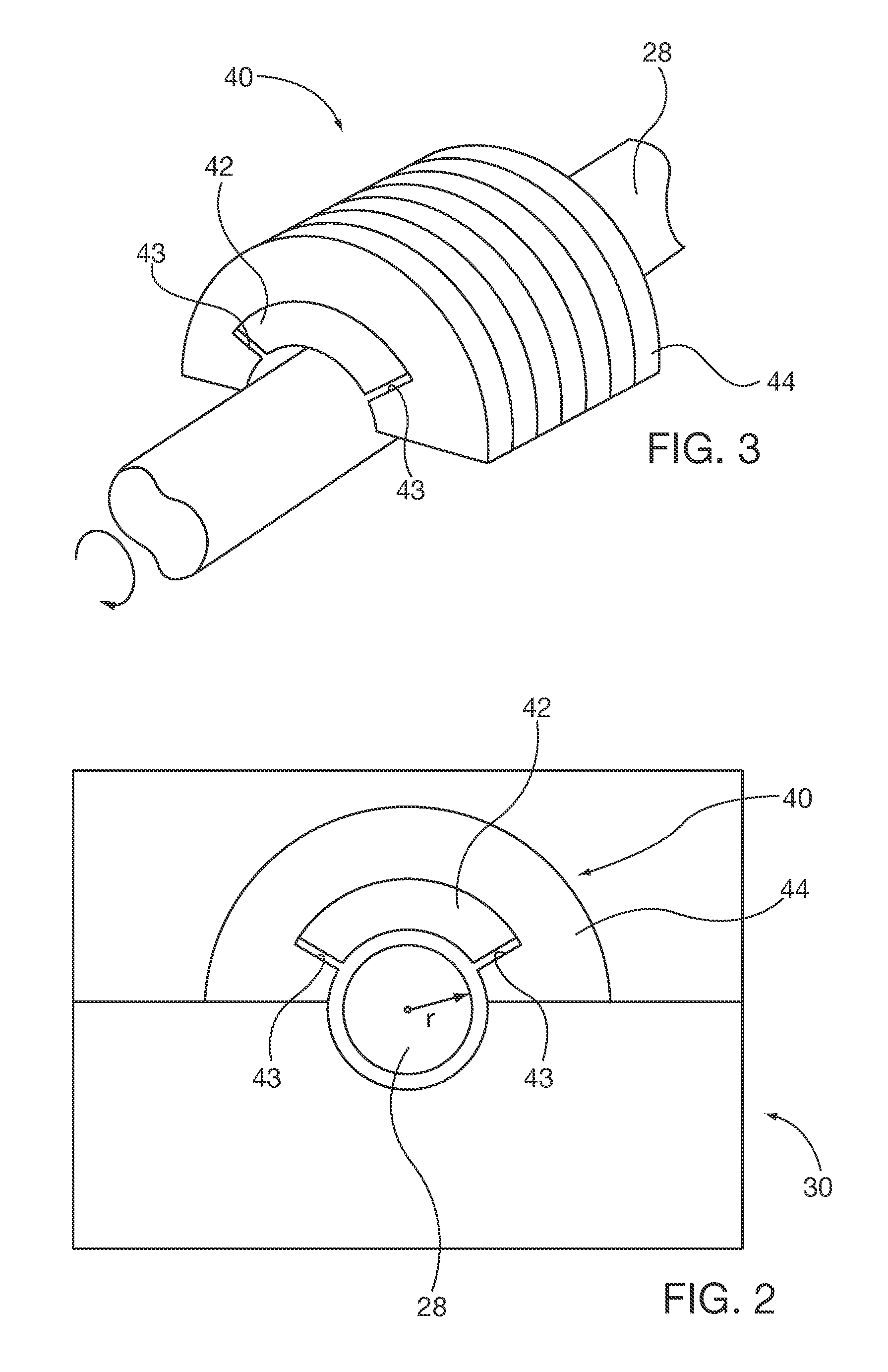

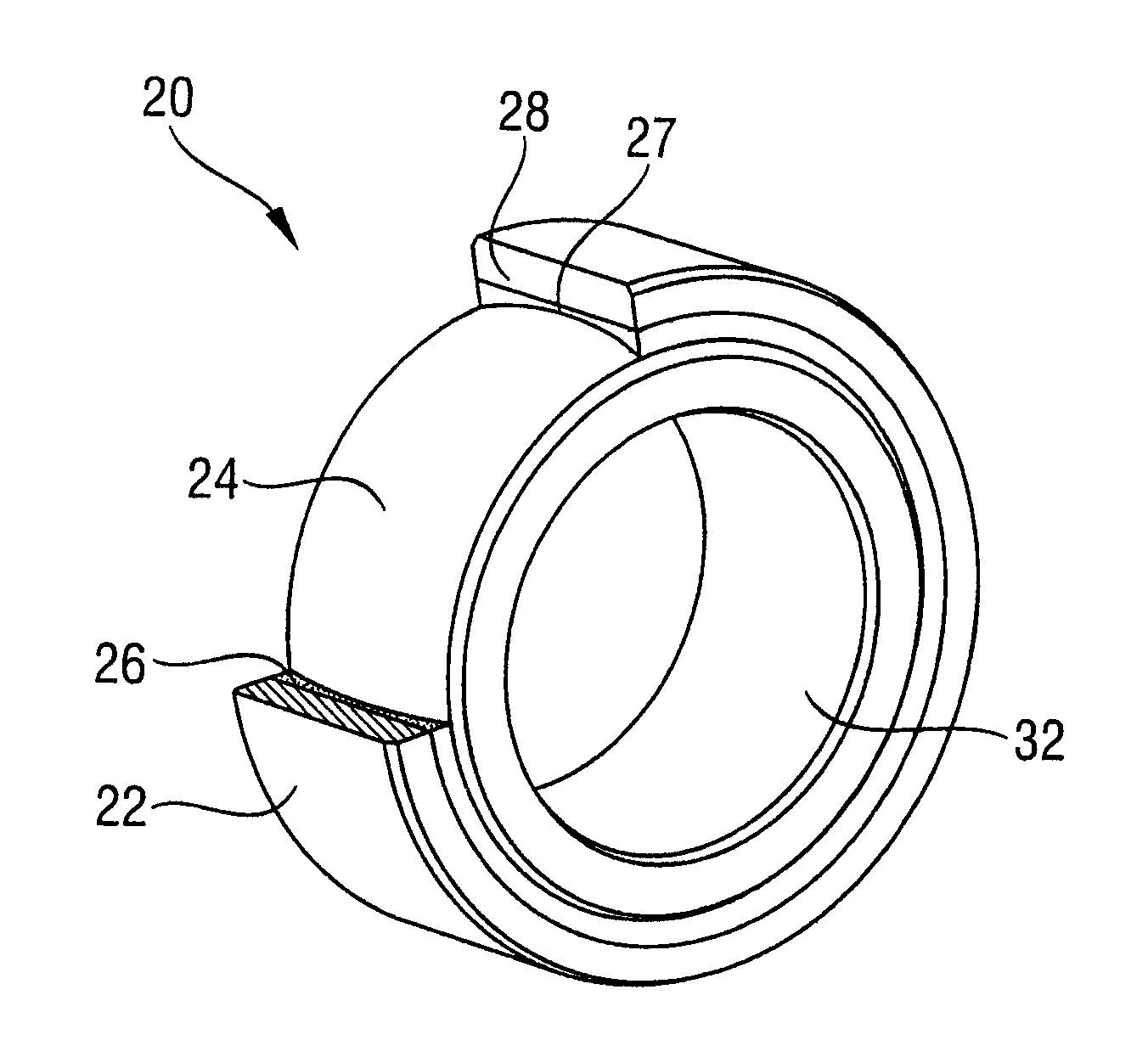

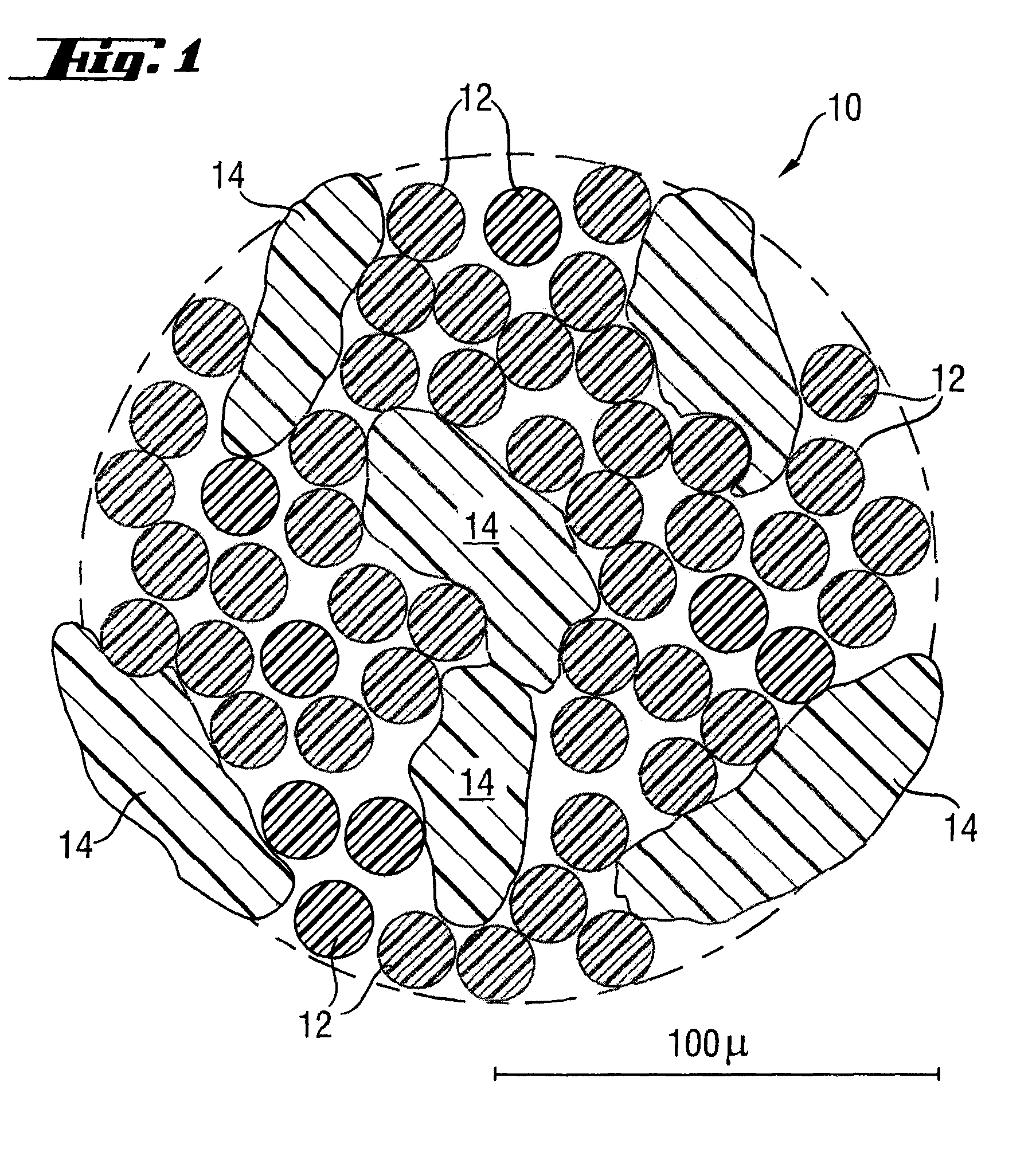

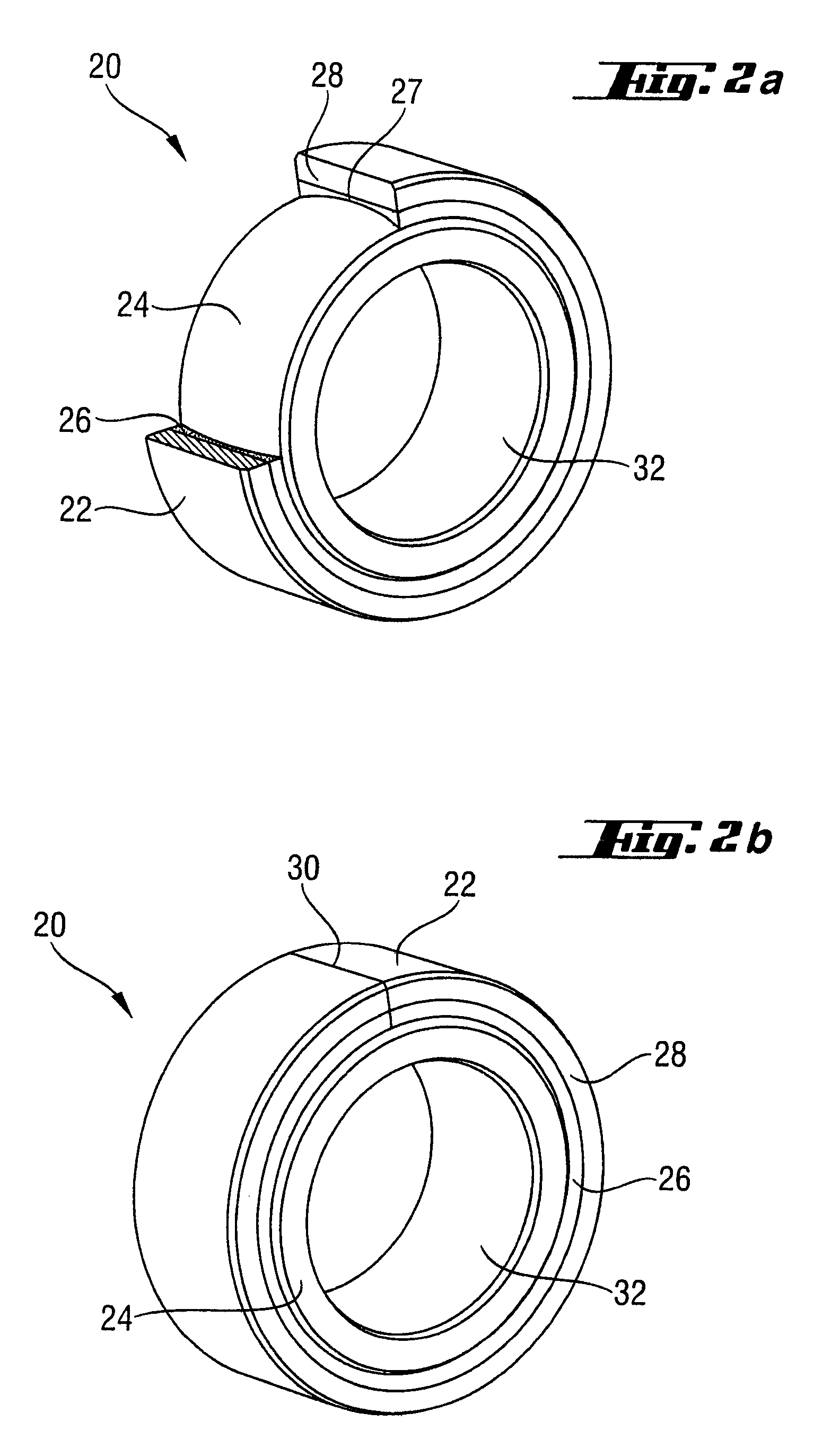

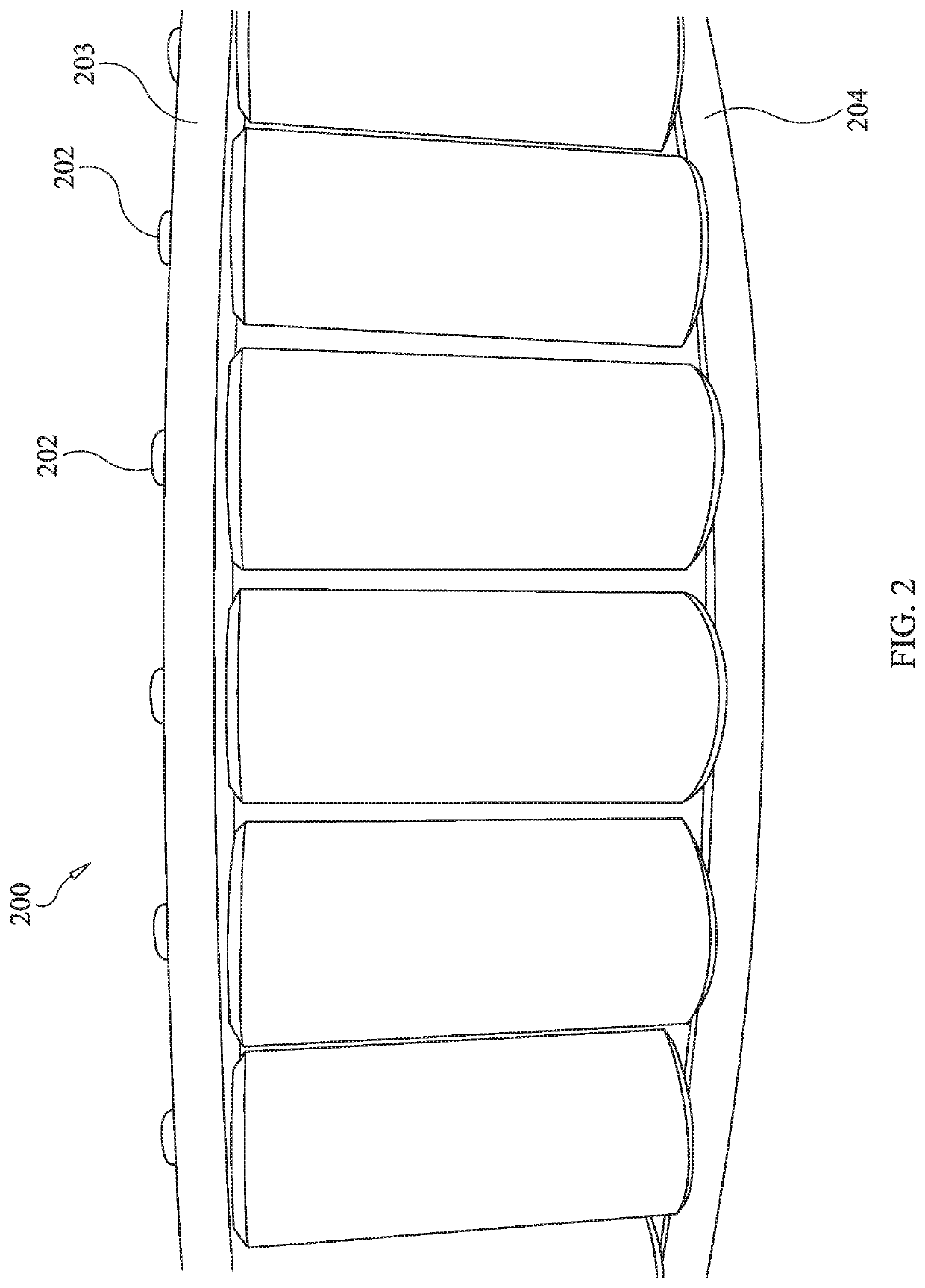

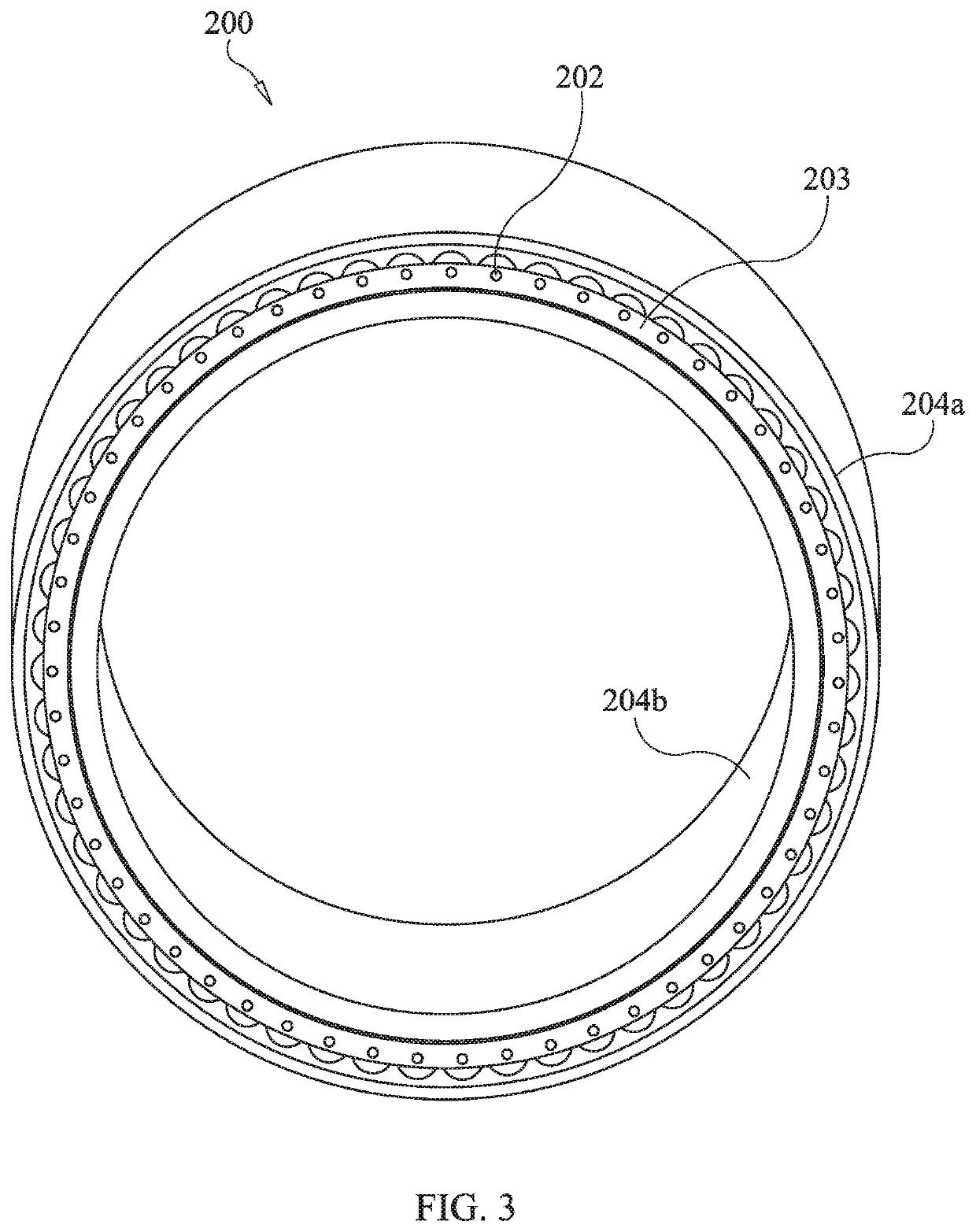

Universal joint bearing with plastic outer ring and procedure for its porduction

ActiveUS20080161117A1Excellent Adhesive PropertiesImprove mechanical propertiesYielding couplingRolling contact bearingsFiberUniversal joint

An outer race for a rocker bearing includes an internal sliding layer and an external support layer, wherein the sliding layer and the bearing layer are formed from a wound composite fiber material. The outer race is identified by exactly one parting line. A rocker bearing with such an outer race and a method for its production is also provided, in which a sliding layer and a support layer of synthetic resin impregnated fibers are wound in succession onto a winding mandrel, and outer races are formed after setting on the winding body thus produced. The sliding layer and the support layer are wound onto a cylindrical winding mandrel, and the outer race is provided with exactly one parting line opening it, and sliding layer material on its inside is removed to such an extent that a partially spherical contour is obtained for receiving a complementary inner race.

Owner:FEDERAL MOGUL DEVA

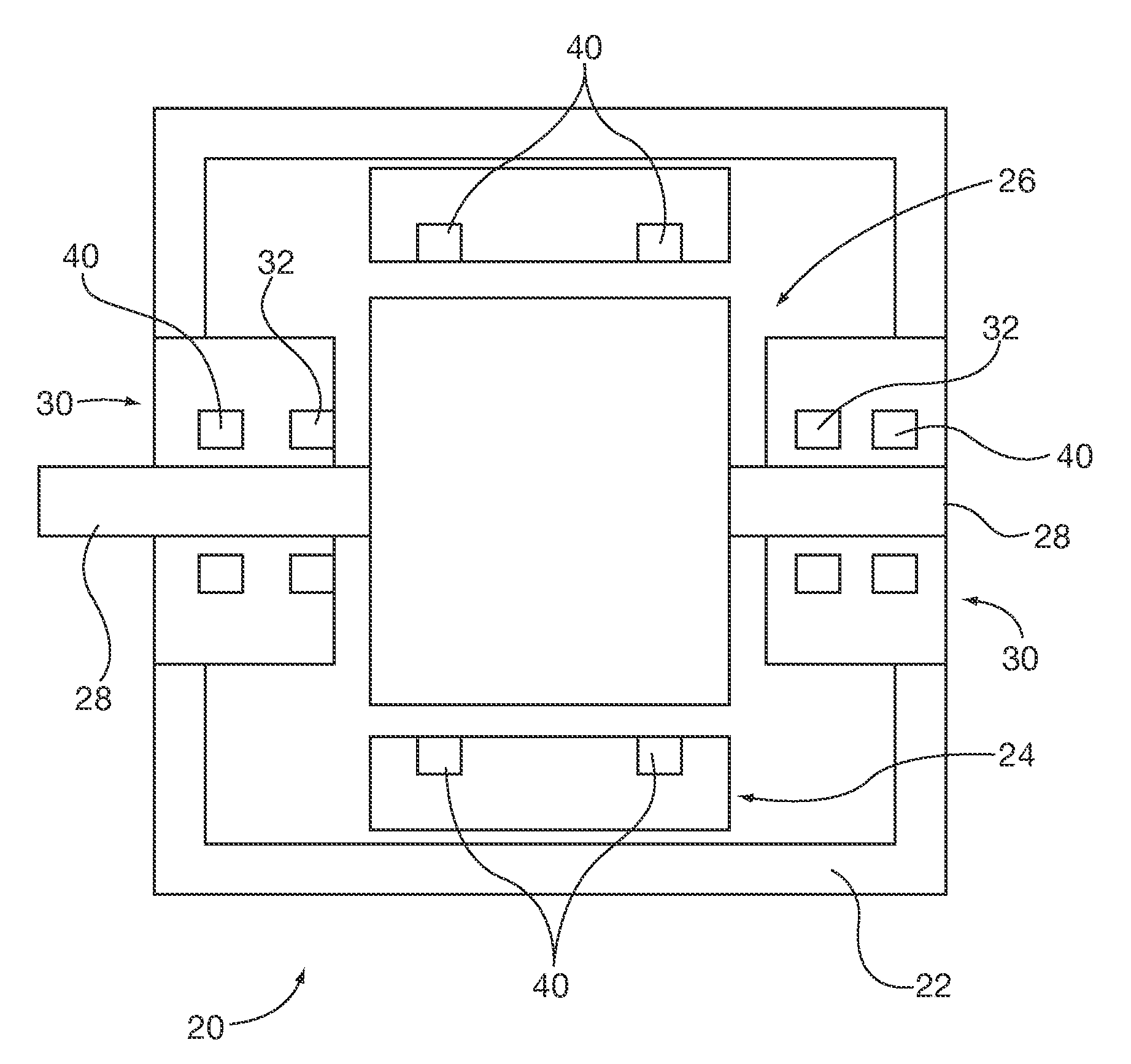

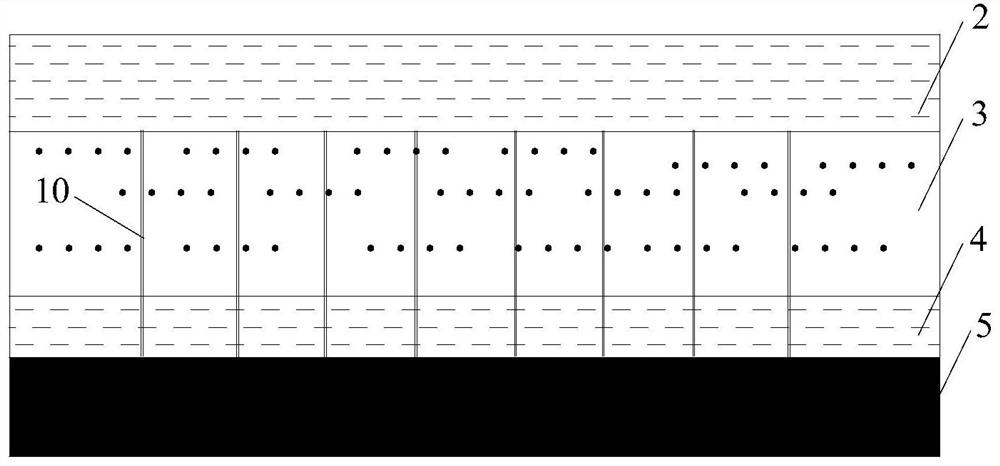

Passive magnetic bearings for rotating equipment including induction machines

InactiveUS20130049507A1Reduce wearEnhance stabilityRotary bearingsShaftsElectric machineryMagnetic orientation

Permanent magnet bearings are incorporated into rotating equipment, such as induction machines, in addition to active magnetic or lubricated primary shaft support bearings. The passive magnetic bearings incorporate permanent magnets that generate directionally oriented magnetic fields of selective intensity. The magnetic field directions are aligned with a desired shaft support bearing preload direction and intensity, for example to exert axial thrust or radial preloads on the support bearings. A plurality of magnetic bearings may be oriented in opposed relationship with neutral or offsetting resultant forces. The passive magnetic force preload may be utilized to offset rotor vertical weight during induction startup or stopping cycles. Passive magnetic force preload may be applied to lubricated bearings to assure their operational stability. The passive magnetic bearings can also absorb radial or axial thrust forces imparted on the rotor shaft during induction machine operation, that may reduce machine operational noise, and energy consumption.

Owner:SIEMENS IND INC

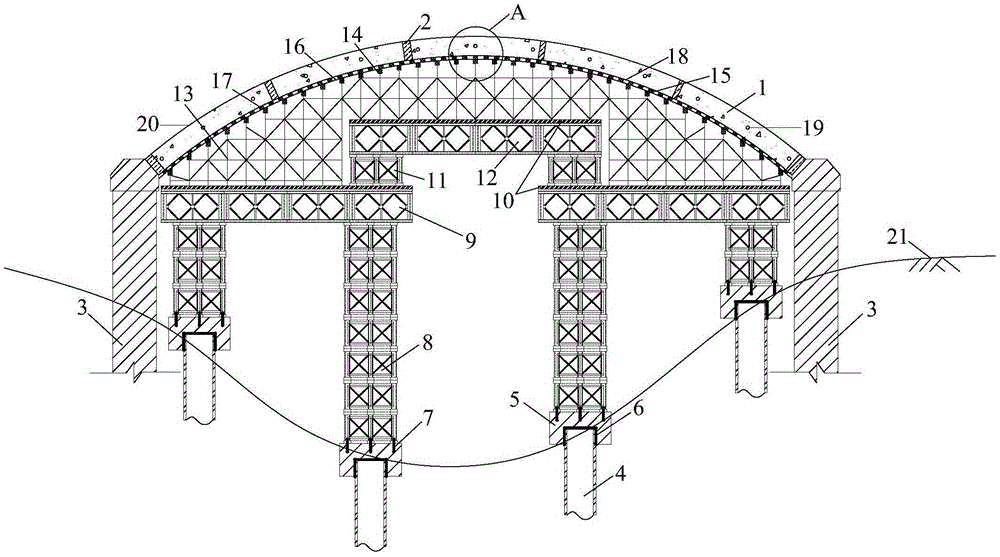

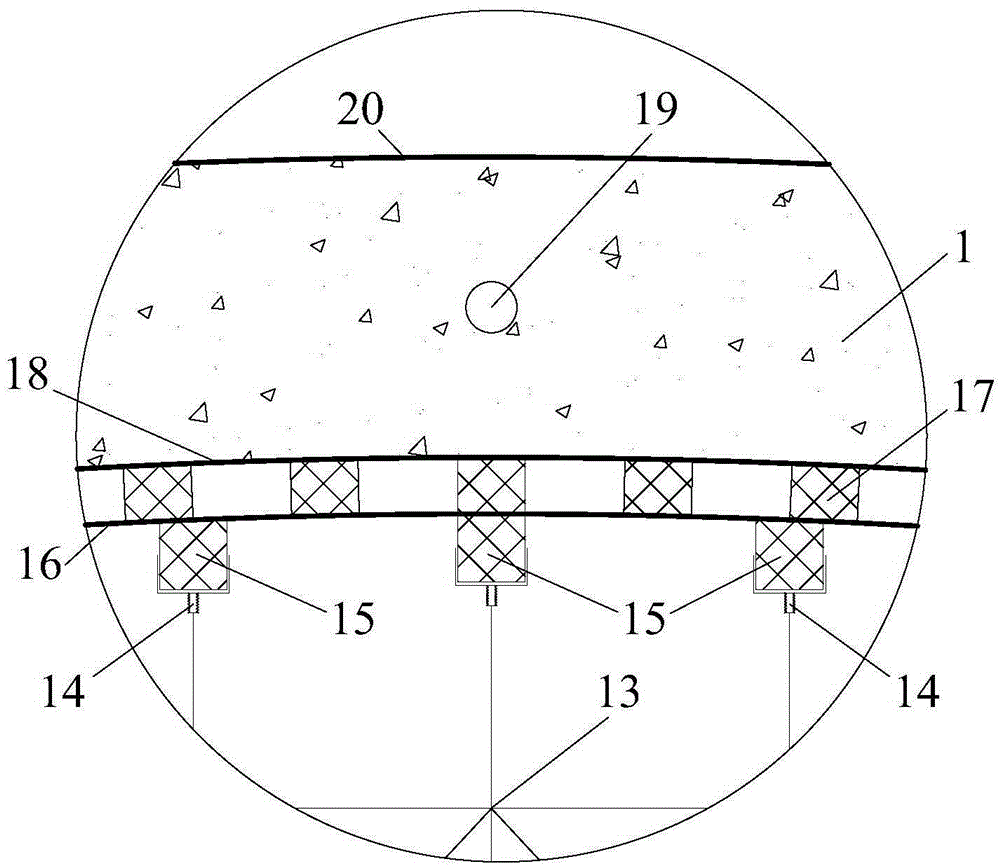

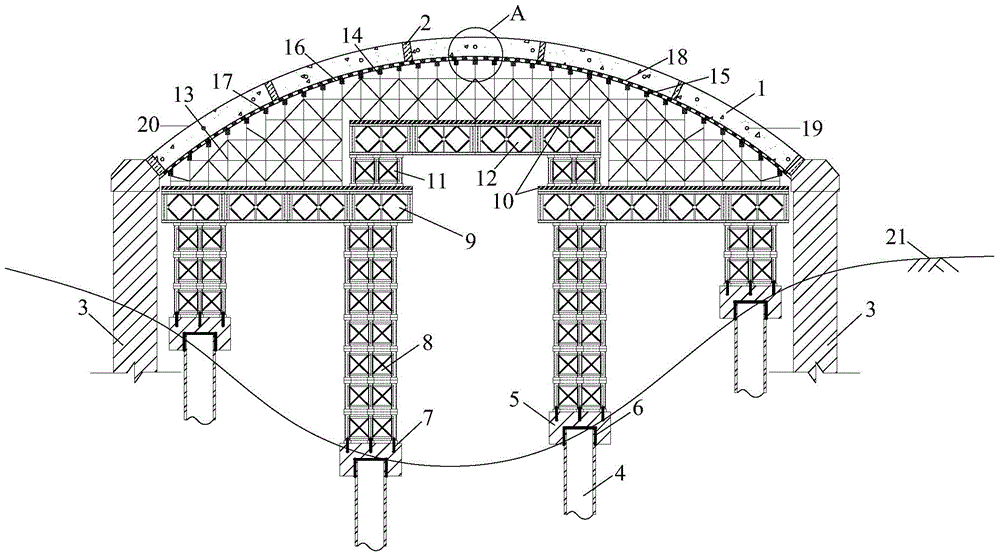

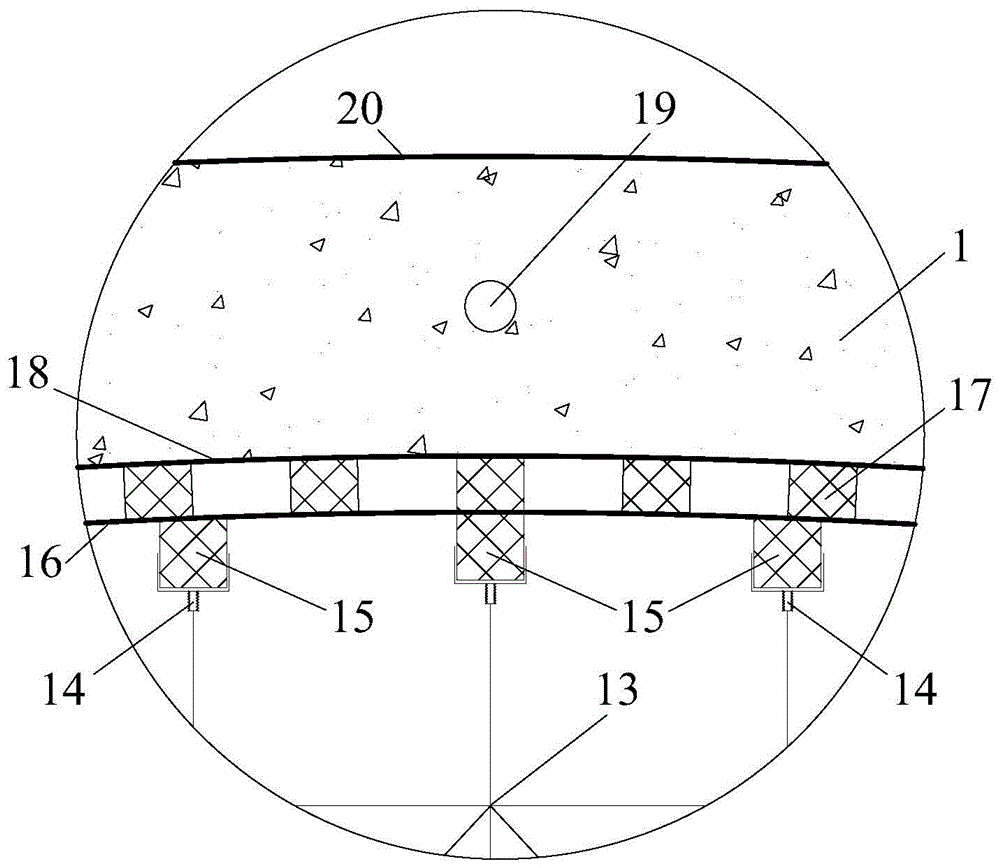

Construction method of ultra-wide main arch ring of large span open-spandrel type arch bridge in extremely-cold regions

ActiveCN105200925AEasy to pull out for recyclingImprove the stability of bearingBridge erection/assemblySupporting systemEconomic benefits

The invention relates to a construction method of an ultra-wide main arch ring of a large span open-spandrel type arch bridge in extremely-cold regions. The construction method mainly comprises the following steps: leveling the construction field, inserting and piling recyclable short steel pipe piles, pouring concrete foundation beams, splicing beret slices to form beret posts and columns, erecting a cuplock steel pipe shelf, laying the bottom template of the main arch ring, binding the steel reinforcement framework of the main arch ring, mounting a temperature adjusting pipe network system, pouring concrete to the main arch ring by segment, heating, and curing, pouring concrete to the interval grooves and post-cast strips, grouting the temperature adjusting pipe network system and removing the template supporting system. The template supporting system of the ultra-wide main arch ring of the large span open-spandrel type arch bridge and the concrete pouring and curing method in extremely-cold regions can ensure the concrete pouring quality of the main arch ring, accelerate the construction speed, reduce the project cost, and achieve better technical and economic benefits.

Owner:西安市市政建设(集团)有限公司

Passive magnetic bearings for rotating equipment including induction machines

InactiveUS9048701B2Reduce wearImprove the stability of bearingRotary bearingsShaftsMagnetic bearingElectric machine

Permanent magnet bearings are incorporated into rotating equipment, such as induction machines, in addition to active magnetic or lubricated primary shaft support bearings. The passive magnetic bearings incorporate permanent magnets that generate directionally oriented magnetic fields of selective intensity. The magnetic field directions are aligned with a desired shaft support bearing preload direction and intensity, for example to exert axial thrust or radial preloads on the support bearings. A plurality of magnetic bearings may be oriented in opposed relationship with neutral or offsetting resultant forces. The passive magnetic force preload may be utilized to offset rotor vertical weight during induction startup or stopping cycles. Passive magnetic force preload may be applied to lubricated bearings to assure their operational stability. The passive magnetic bearings can also absorb radial or axial thrust forces imparted on the rotor shaft during induction machine operation, that may reduce machine operational noise, and energy consumption.

Owner:SIEMENS IND INC

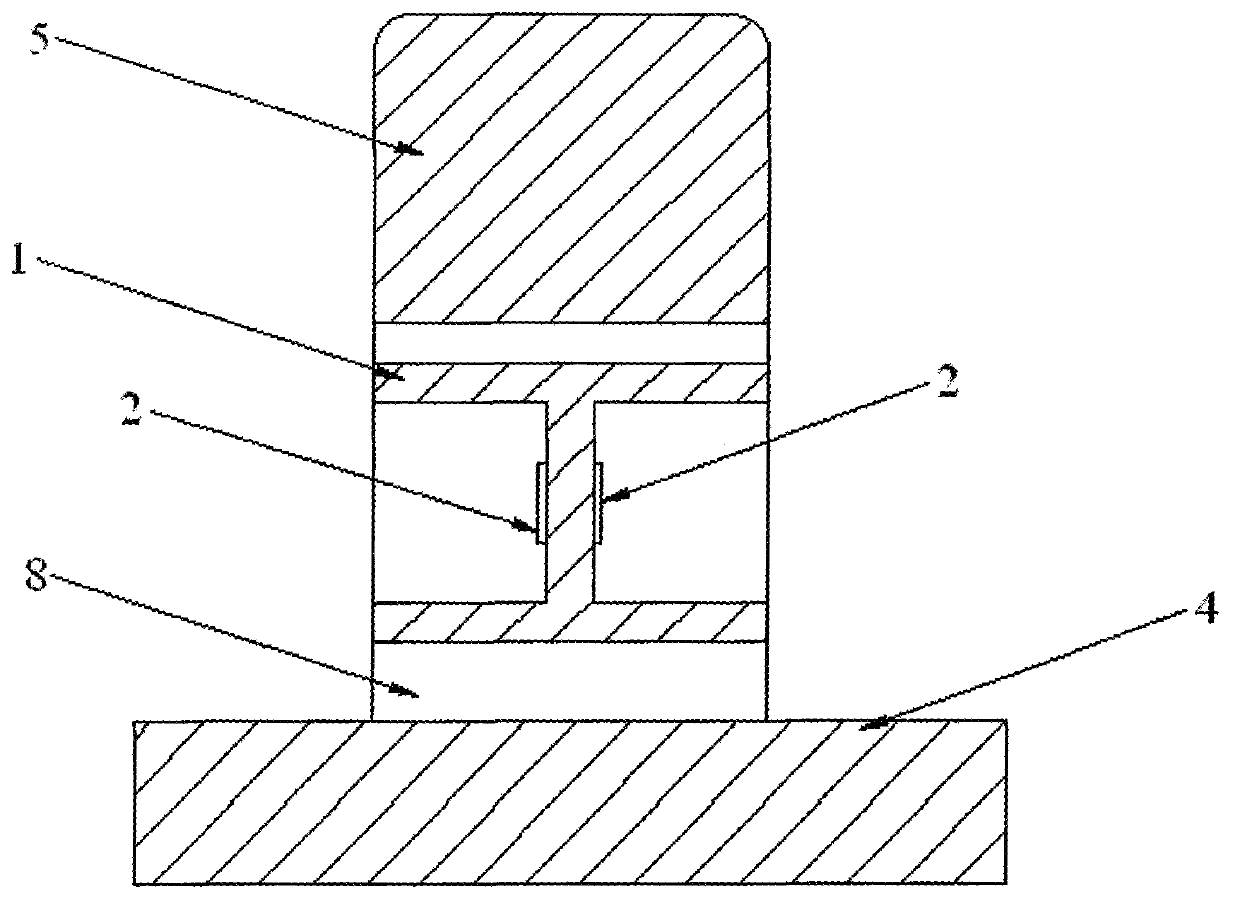

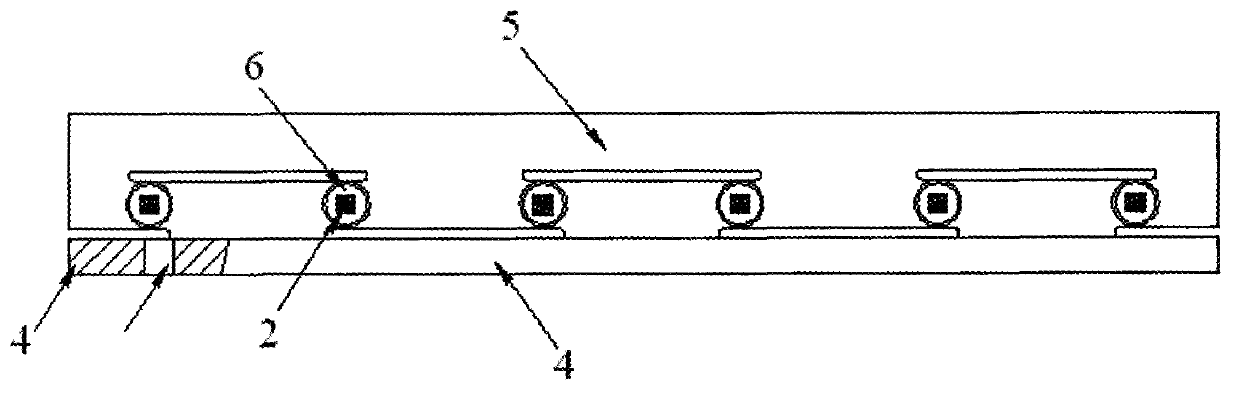

Railroad track scale sensor and producing method thereof

InactiveCN102879069AMeet the needs of weighingSimple structureSpecial purpose weighing apparatusElastomerElectrical resistance and conductance

The invention discloses a railroad track scale sensor which comprises an elastic body, at least one group of strain resistors and leads which are sequentially connected. The longitudinal section of the elastic body is 'H'-shaped, each group of strain resistors is divided into two portions and adhered to symmetrical positions of two sides of the waist of the elastic body, each portion is composed of at least four strain resistors which are connected by the leads to form a bridge circuit, and the strain resistors in each portion are parallelly connected. The invention further discloses a producing method of the railroad track scale sensor. The method includes the steps: providing the elastic body with the 'H'-shaped longitudinal section; providing at least one group of strain resistors, wherein each group of strain resistors is divided into two portions and adhered to symmetrical positions of two sides of the waist of the elastic body, and each portion includes at least four strain resistors; and providing the leads and connecting the strain resistors through the leads to from the bridge circuit. The railroad track scale sensor is simple in structure, easy to mount and high in measuring precision, and the method is low in cost and easy to produce.

Owner:福建省莆田市衡力传感器有限公司

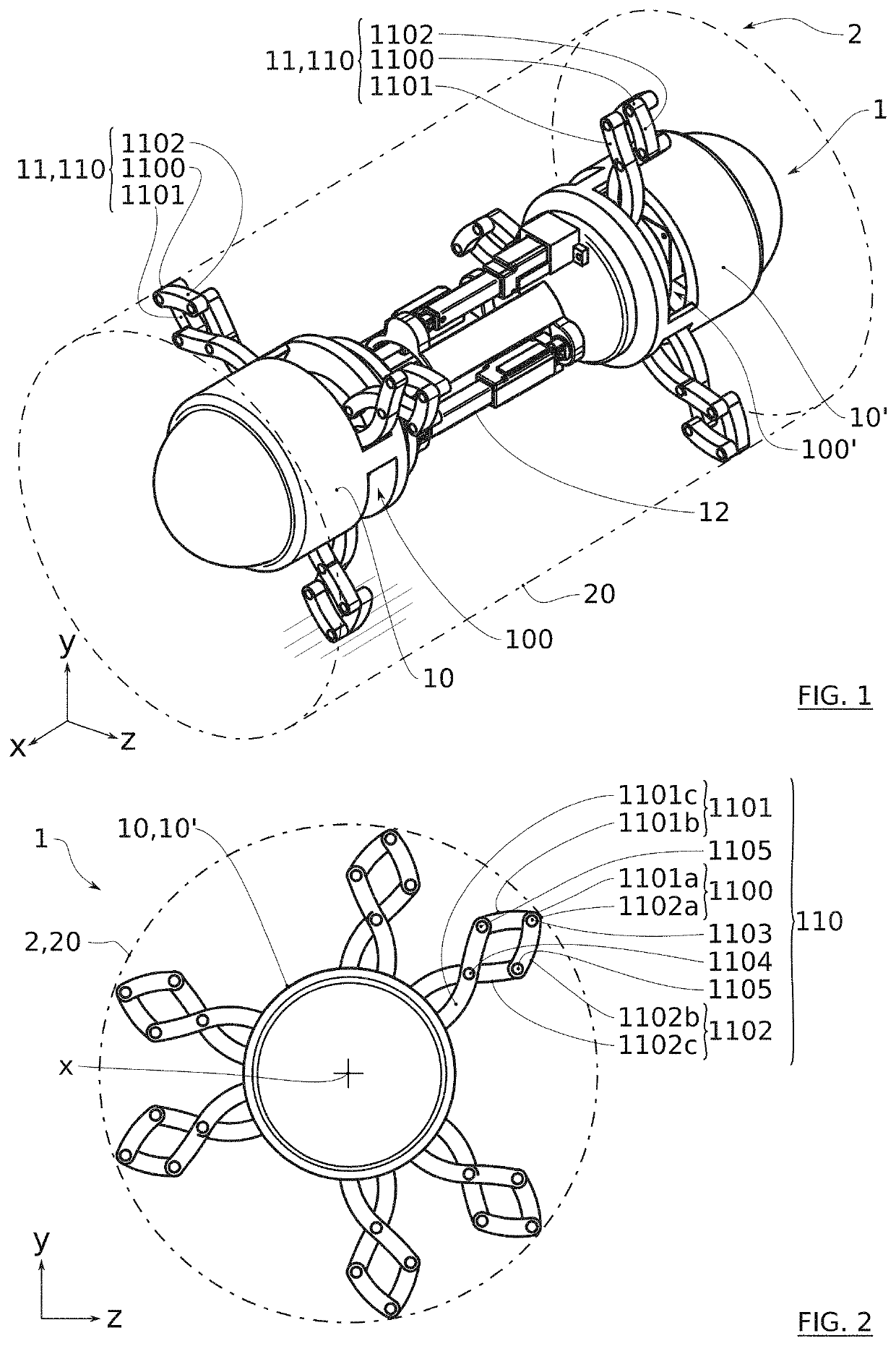

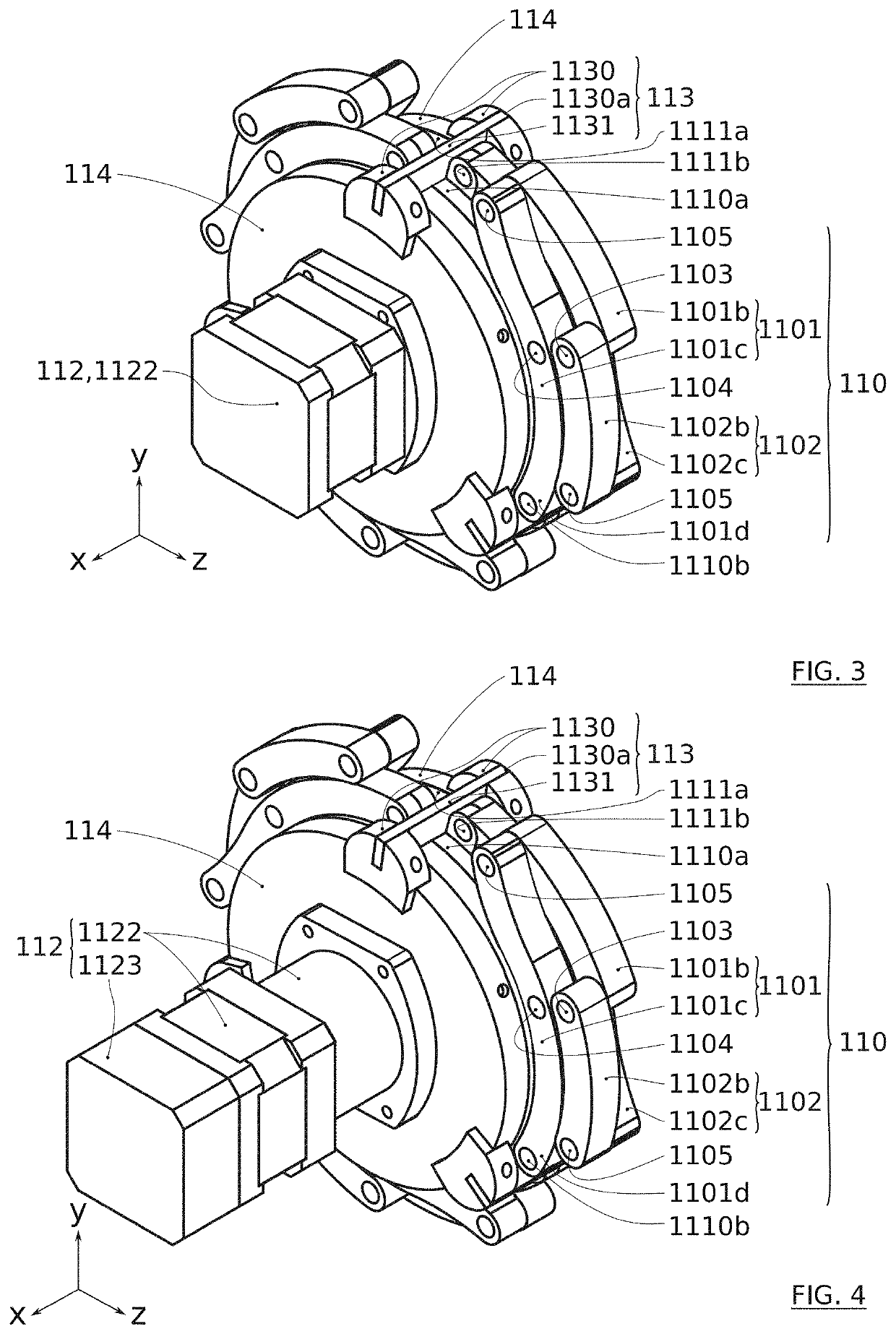

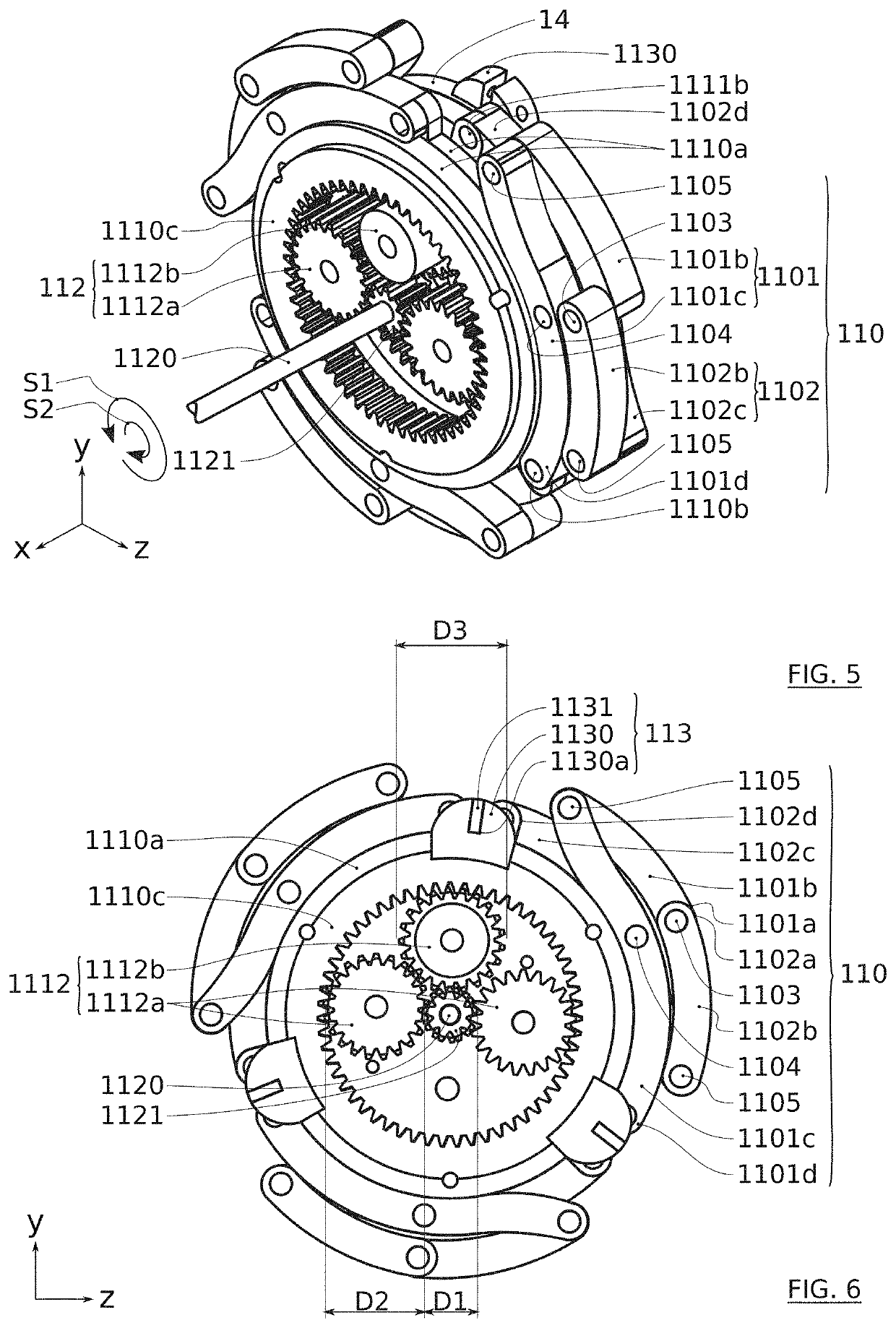

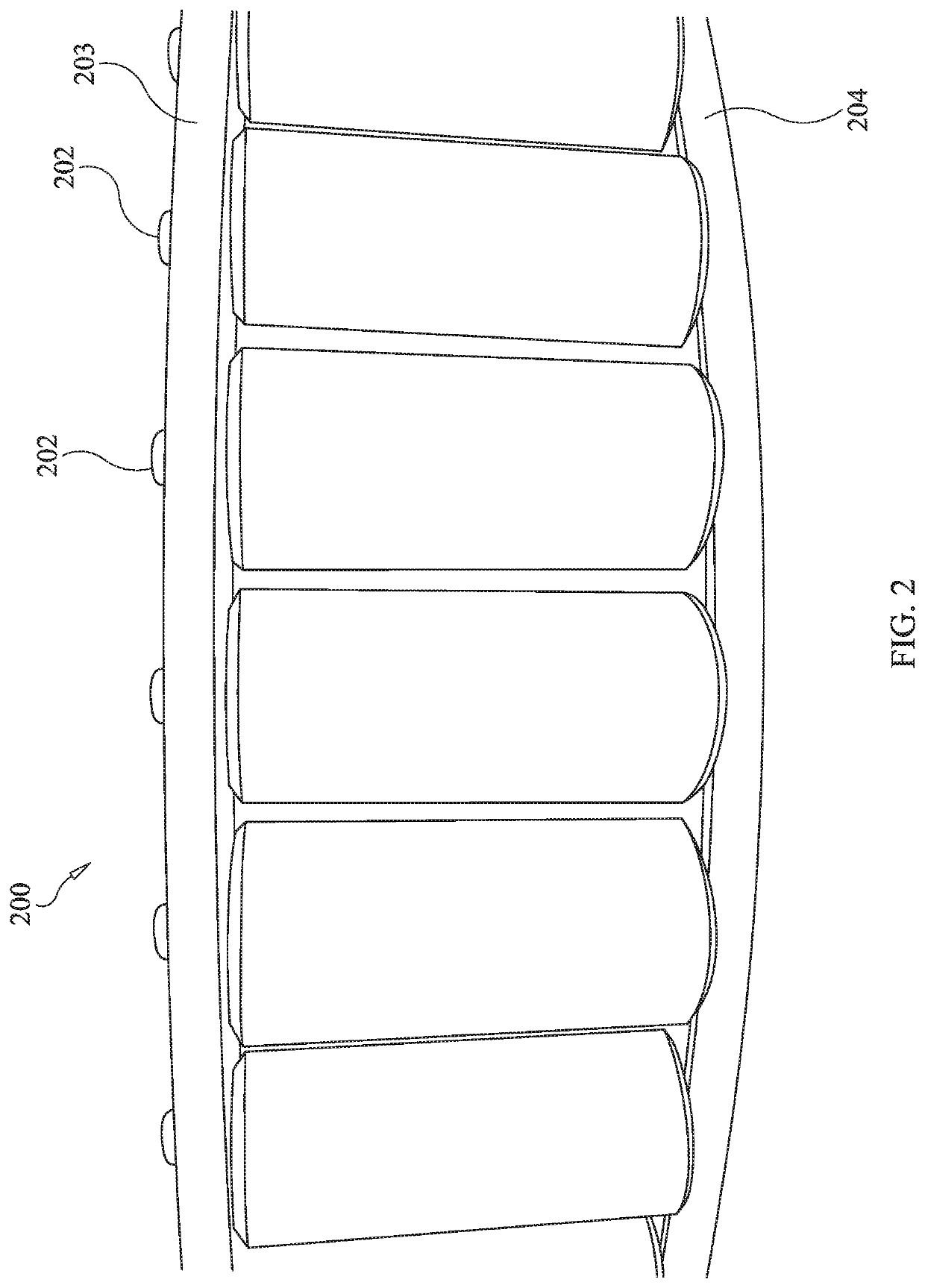

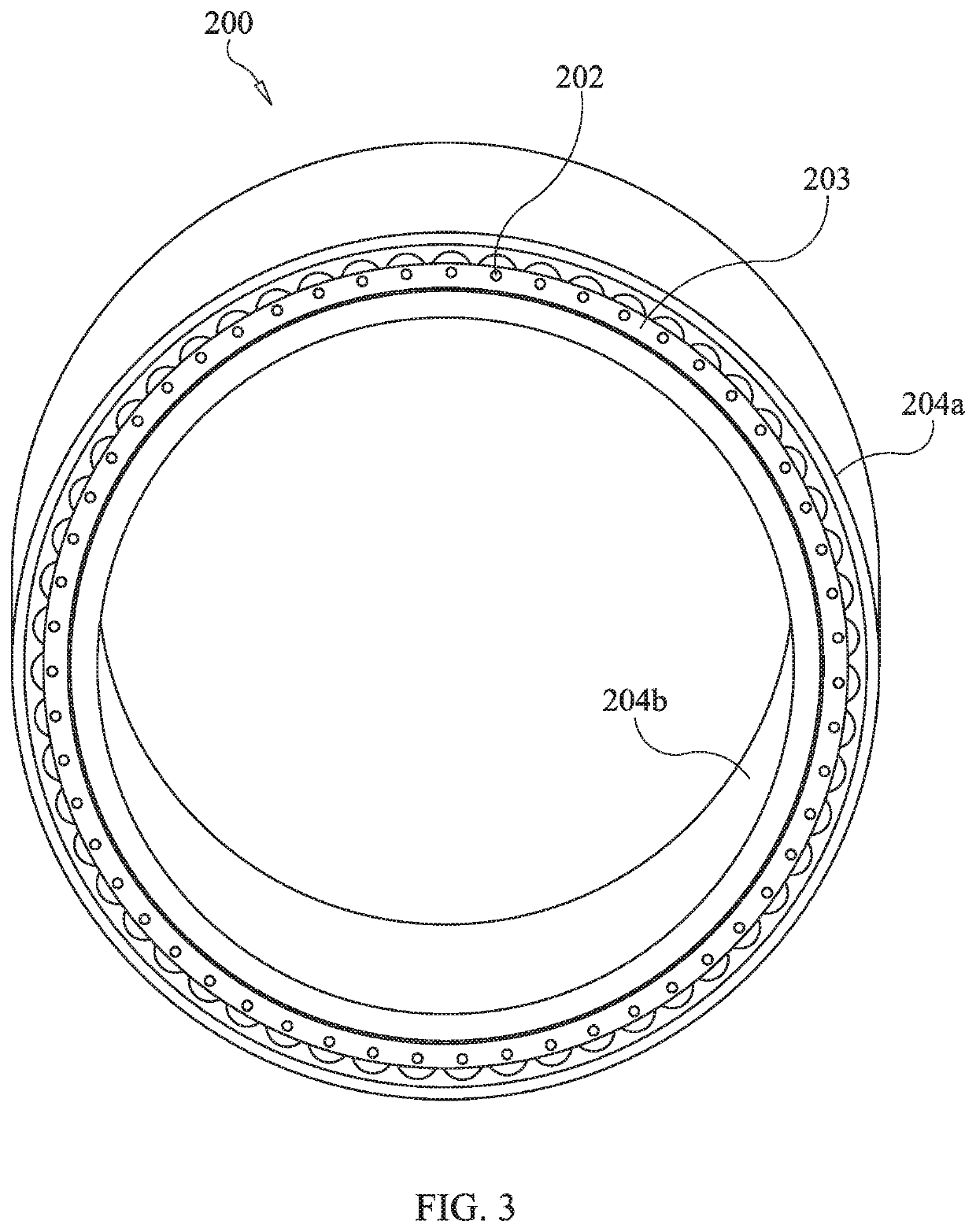

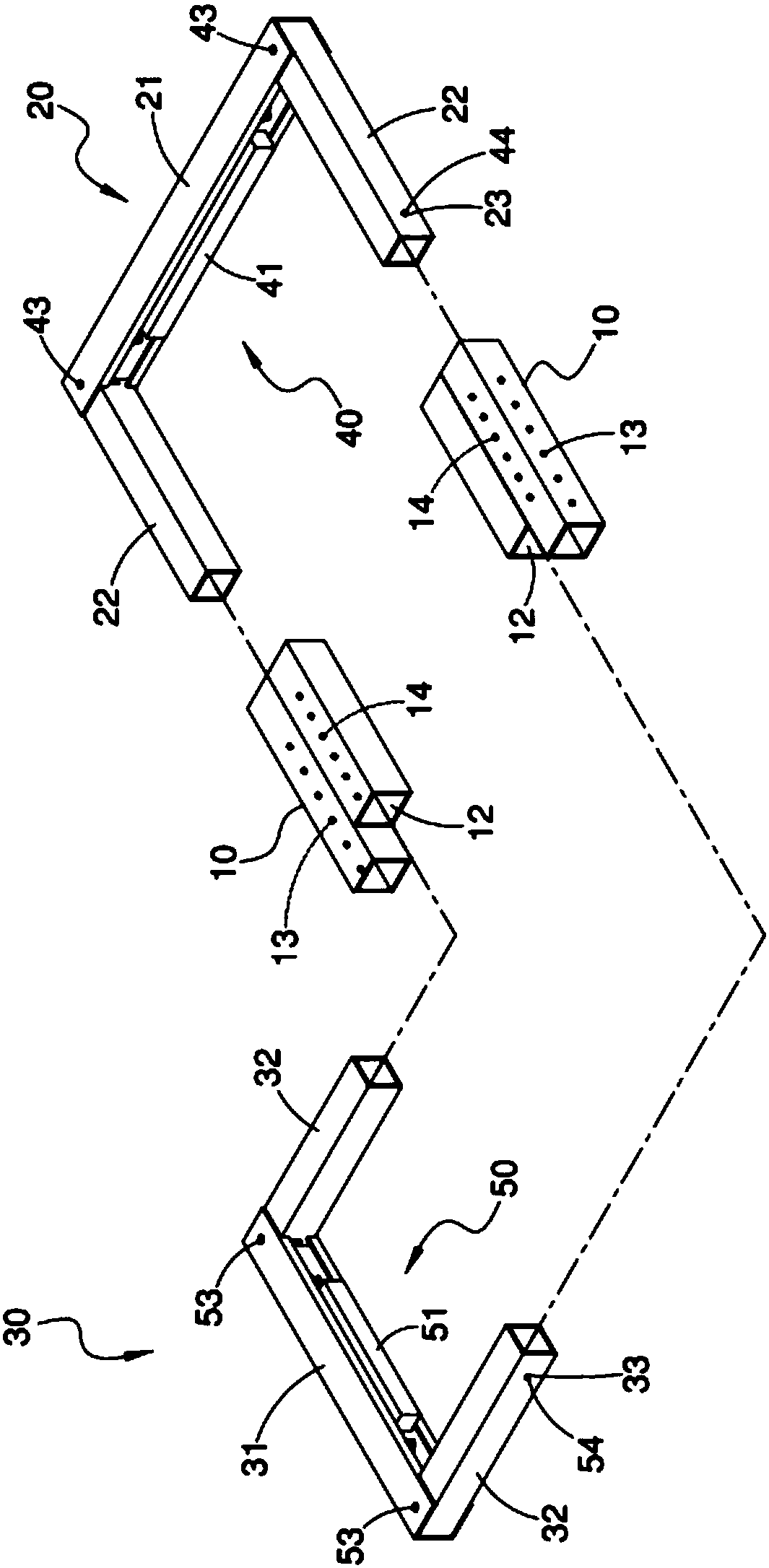

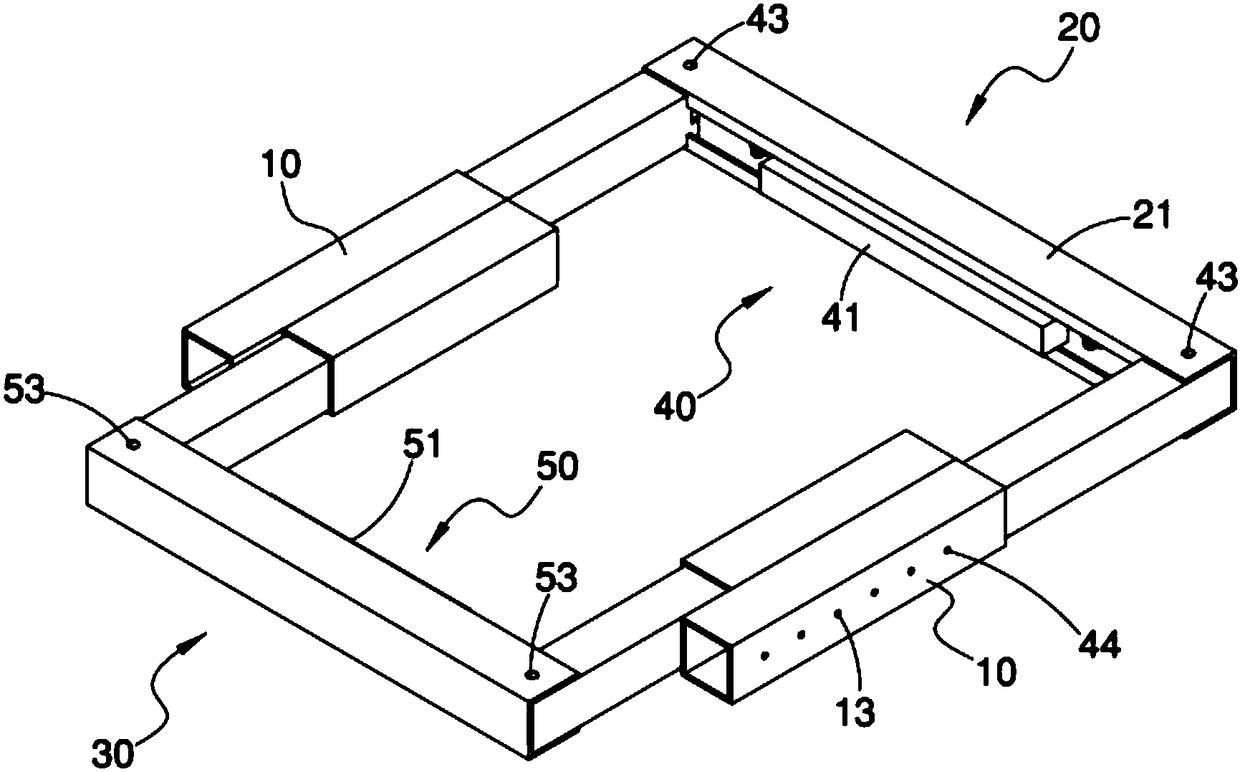

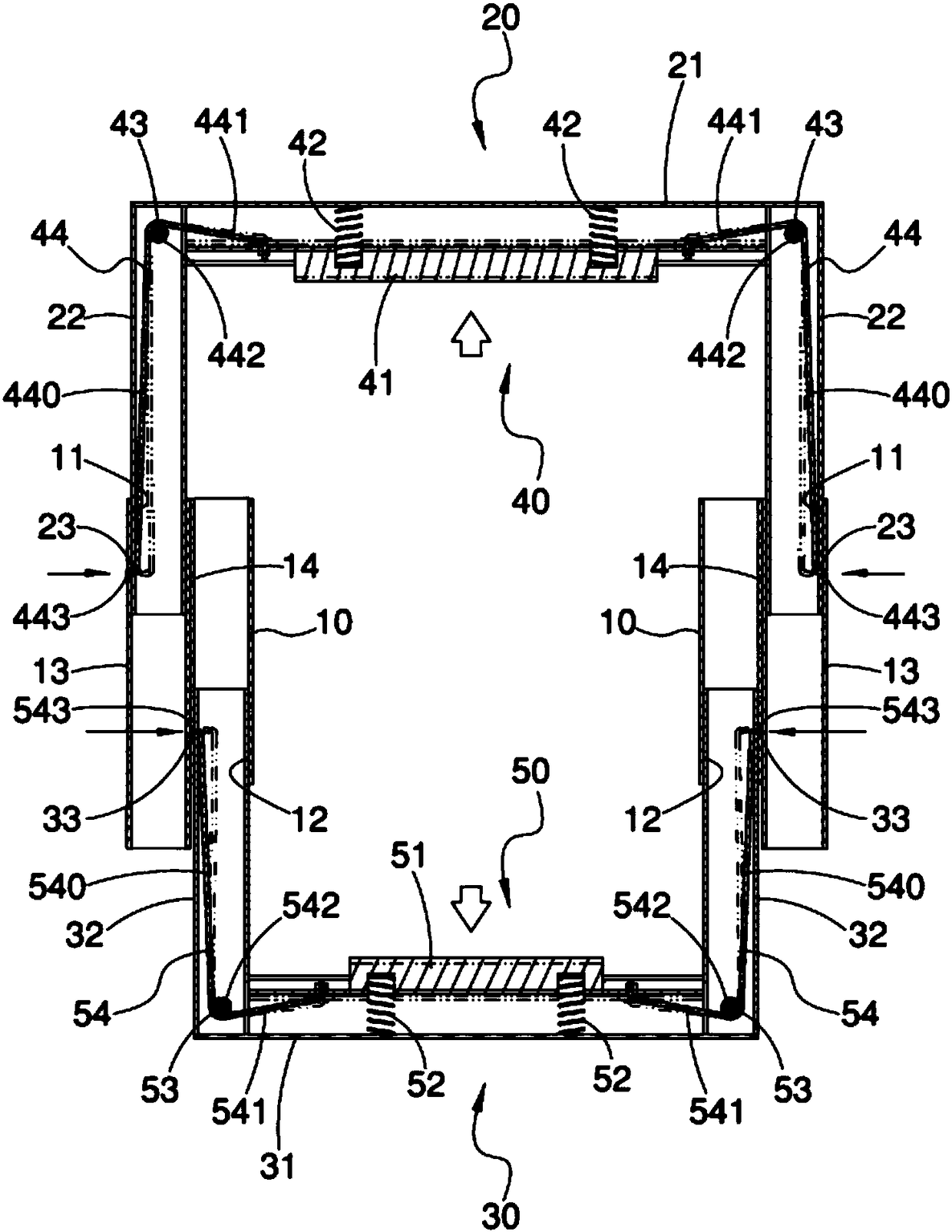

Conduit-exploring robot comprising a bearing module

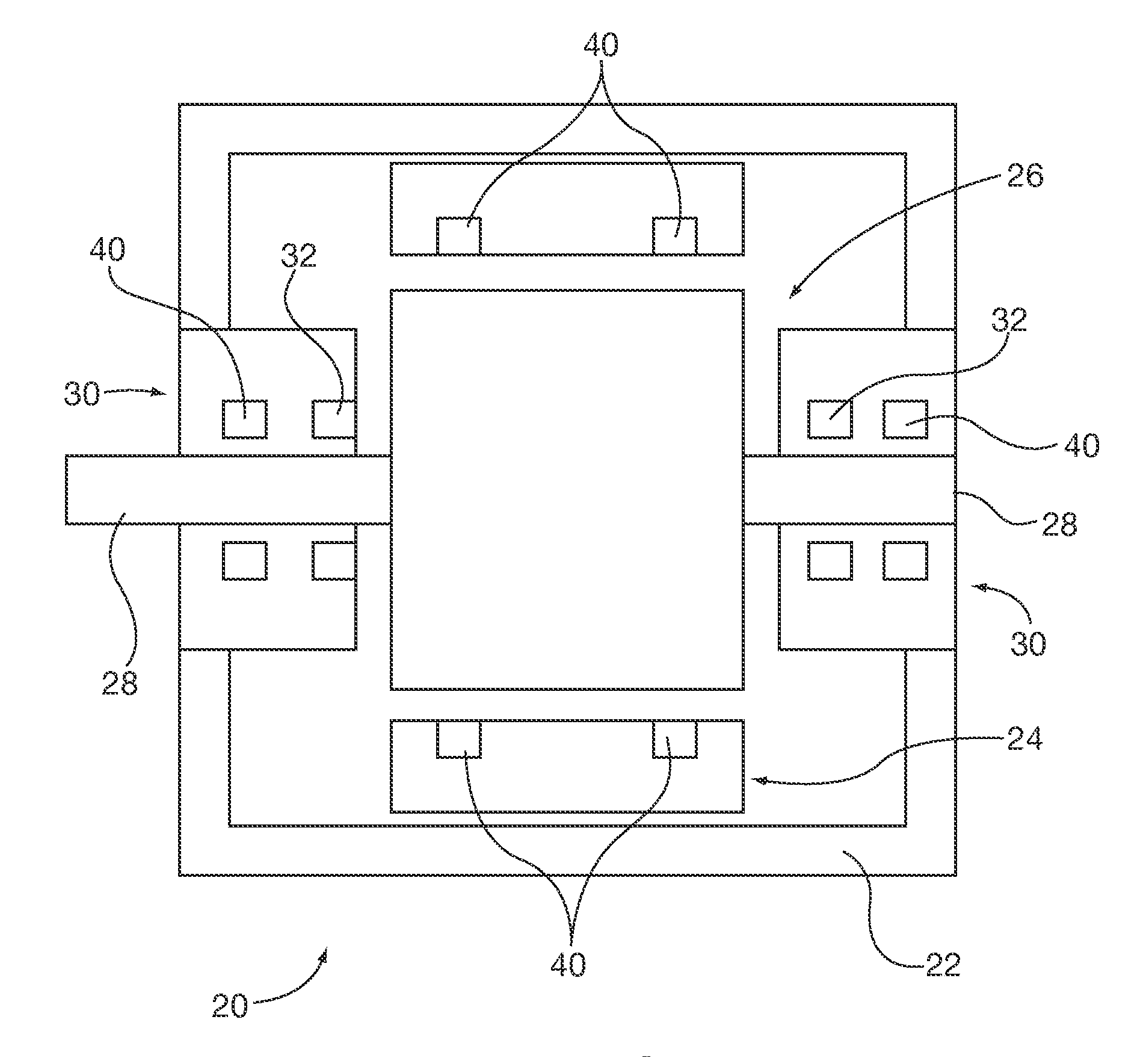

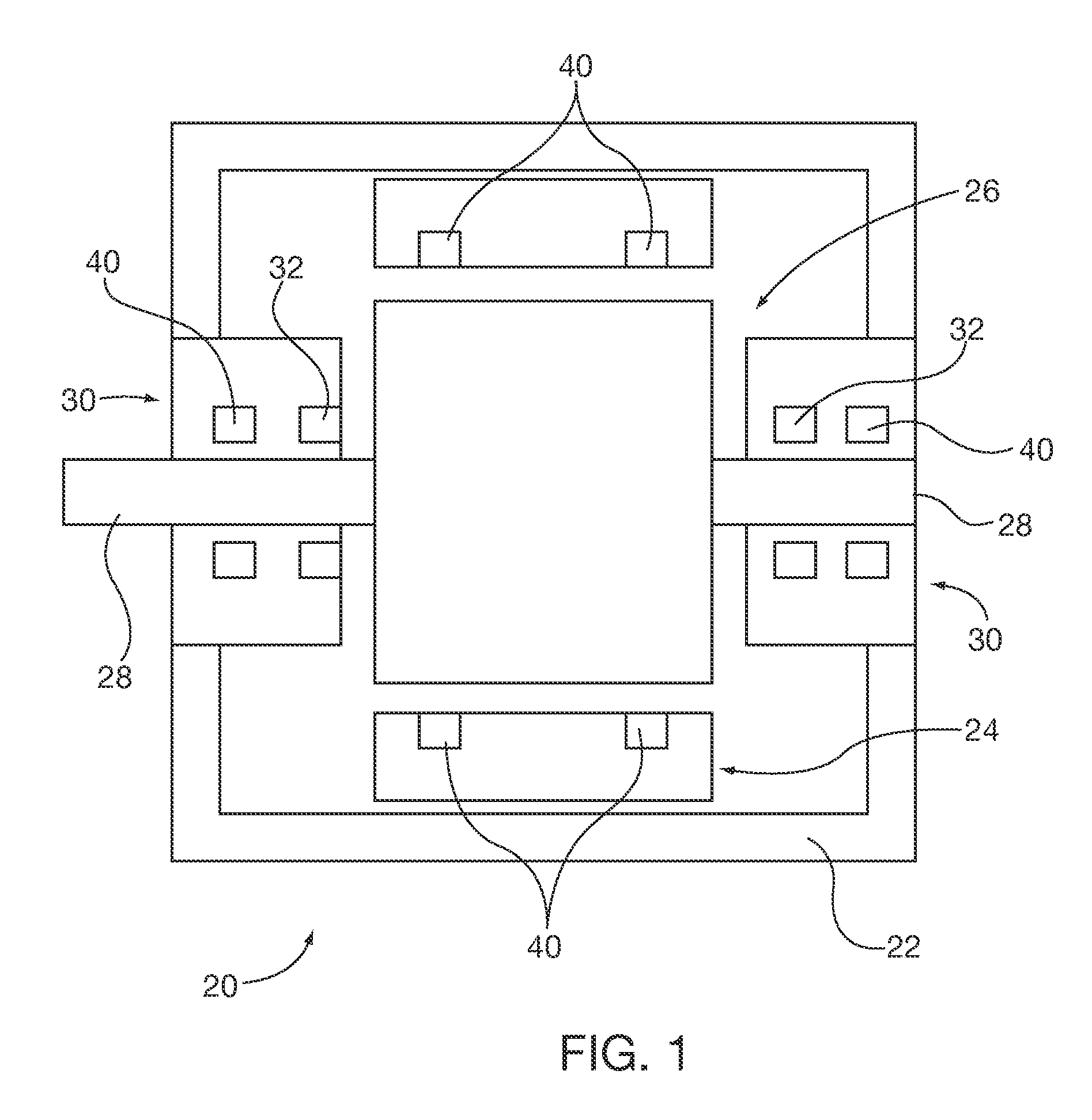

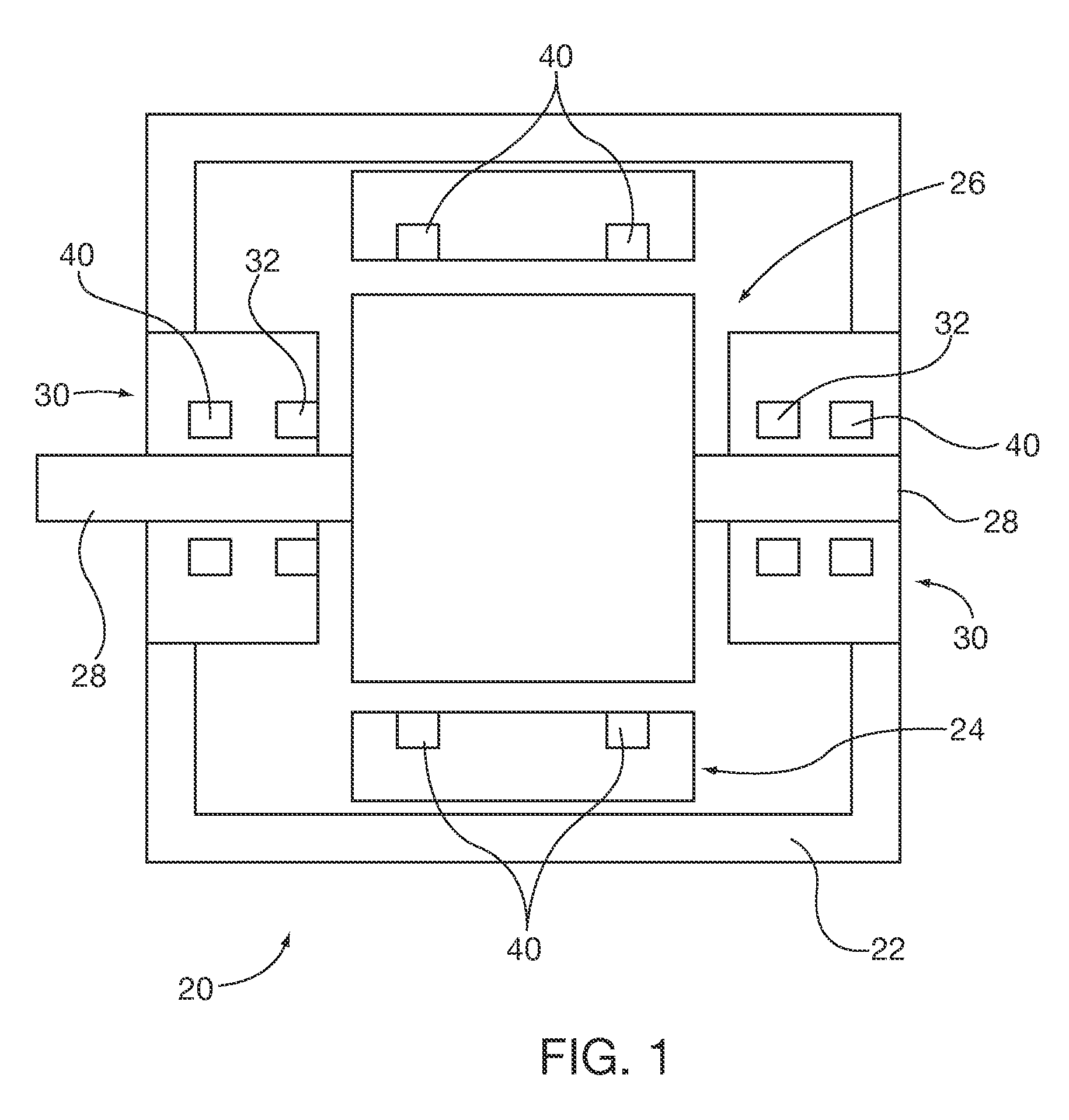

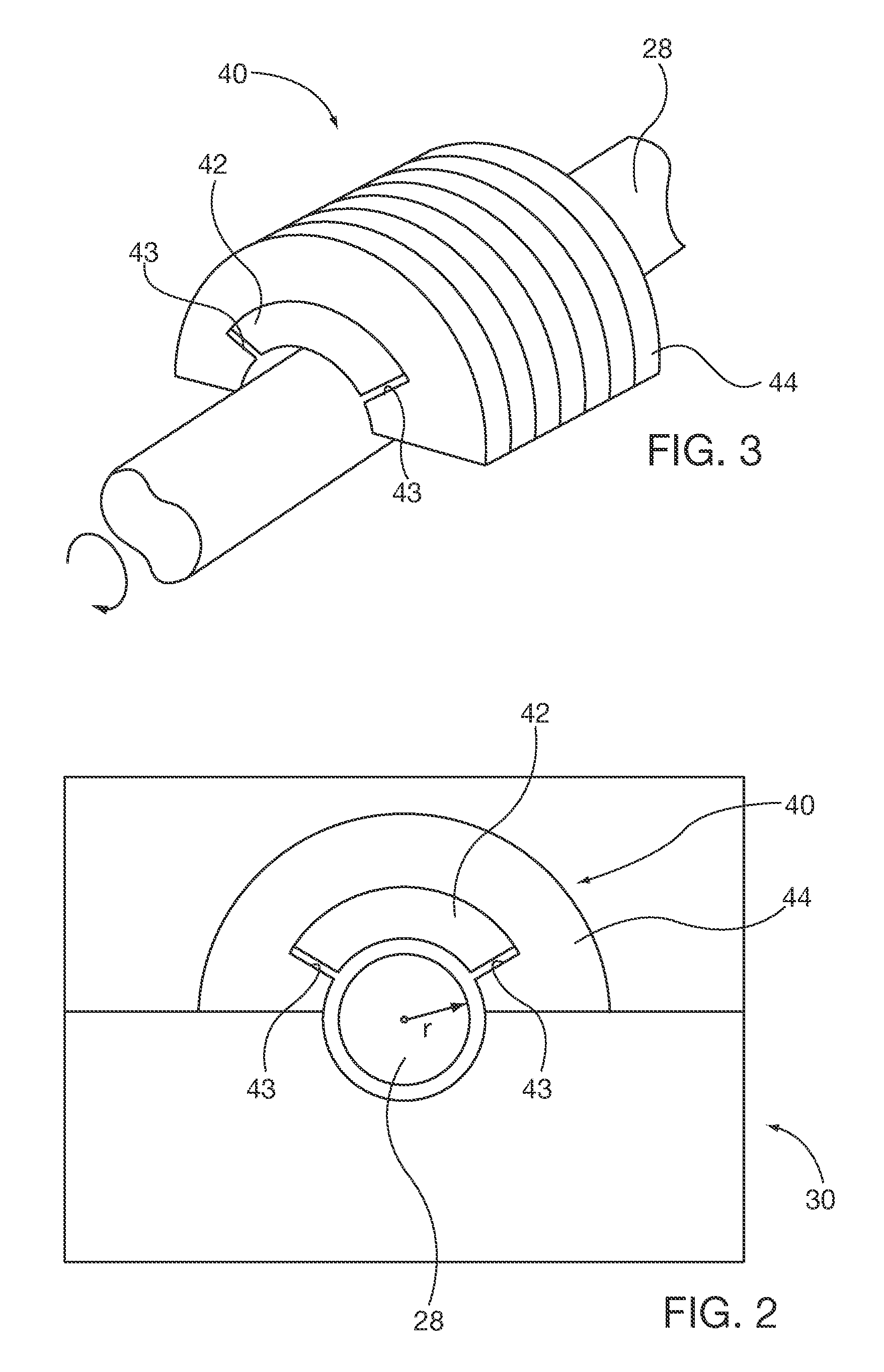

PendingUS20220341533A1Improve the stability of bearingLess sensitiveProgramme-controlled manipulatorPigs/molesClassical mechanicsControl theory

A robot for exploring a conduit including a first frame and a second frame. The first frame and the second frame each including a bearing module provided with a plurality of articulated arms. Each articulated arm including a bearing portion that can be applied against a wall of the conduit. Each bearing module is further configured to alternately switch from a bearing portion engaged configuration into a bearing portion disengaged configuration. The articulated arms are disposed in a plane perpendicular to the longitudinal axis x of the robot, and the articulated arms are capable of at least partially moving between said engaged configuration and said disengaged configuration, via a rotational motion about an axis parallel to the longitudinal axis x.

Owner:AUTONOMOUS CLEAN WATER APPLIANCE ACWA ROBOTICS

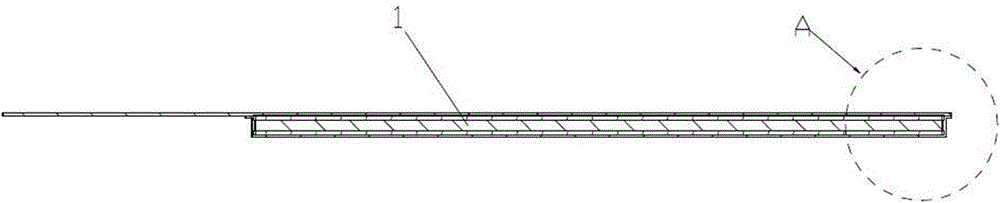

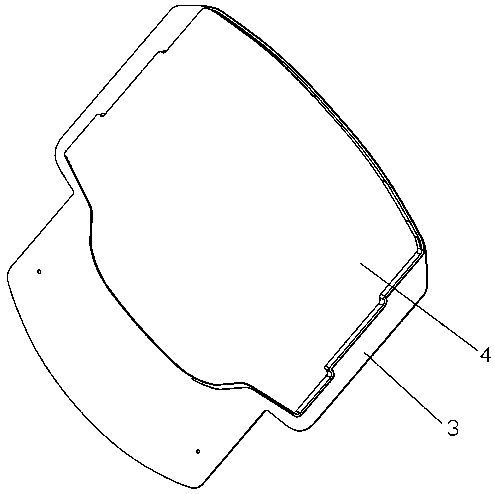

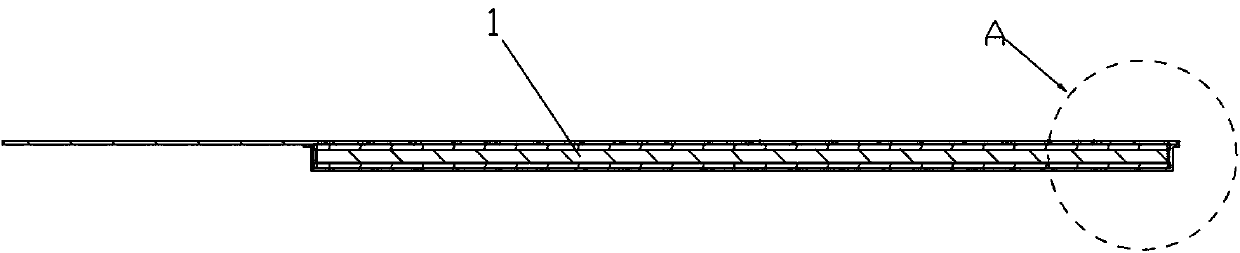

High-load spare tire cover plate for car trunk and production method of high-load spare tire cover plate

ActiveCN106183133AHigh plate strengthGood toughnessLamination ancillary operationsLaminationWoven fabricSpare tire

The invention discloses a laminated plate for cars and particularly relates to a high-load spare tire cover plate for a car trunk. The high-load spare tire cover plate comprises a PU layer. Metal sheets are composited to the surfaces of the single side or double sides of the PU layer. A car decoration fabric layer is composited to the metal sheet on one optional side. A non-woven fabric layer wraps the surfaces of the areas, other than the area covered with the car decoration fabric layer, of the PU laminated plate. The periphery of the non-woven fabric layer is adhered to the car decoration fabric layer under pressure. The invention further provides a production method of the high-load spare tire cover plate. The high-load spare tire cover plate has the advantages that the structural strength and toughness of the PU laminated plates for the cars are increased, and the high-load spare tire cover plate is high in plate strength, good in toughness, good in bearing stability, little in limitation as car plates, and the like.

Owner:NINGBO SUNLIGHT MOTOR PARTS

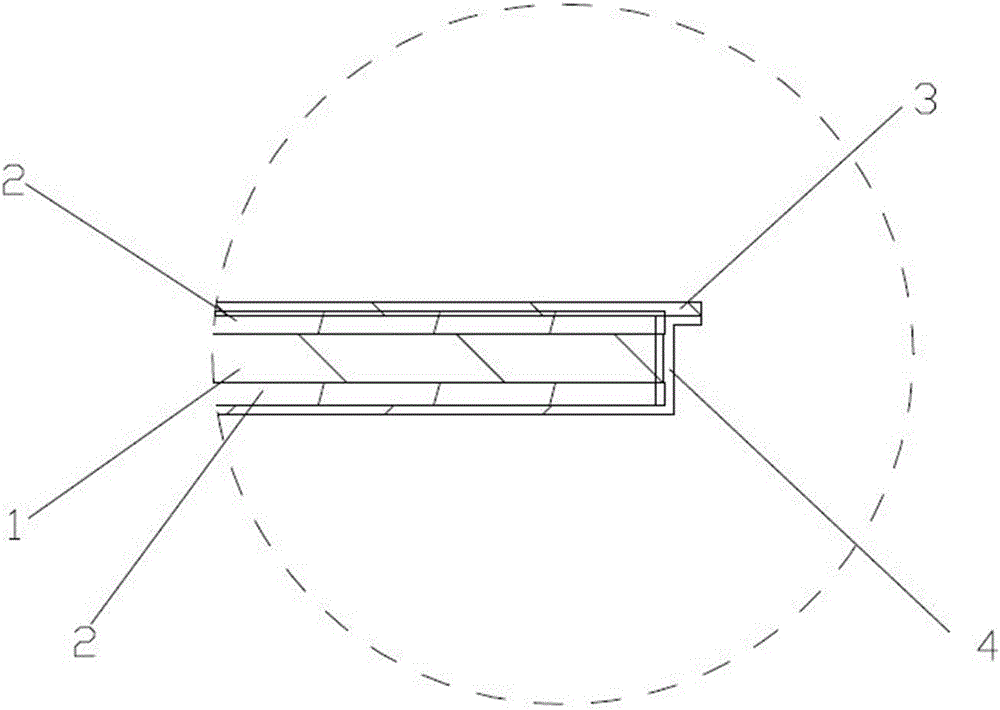

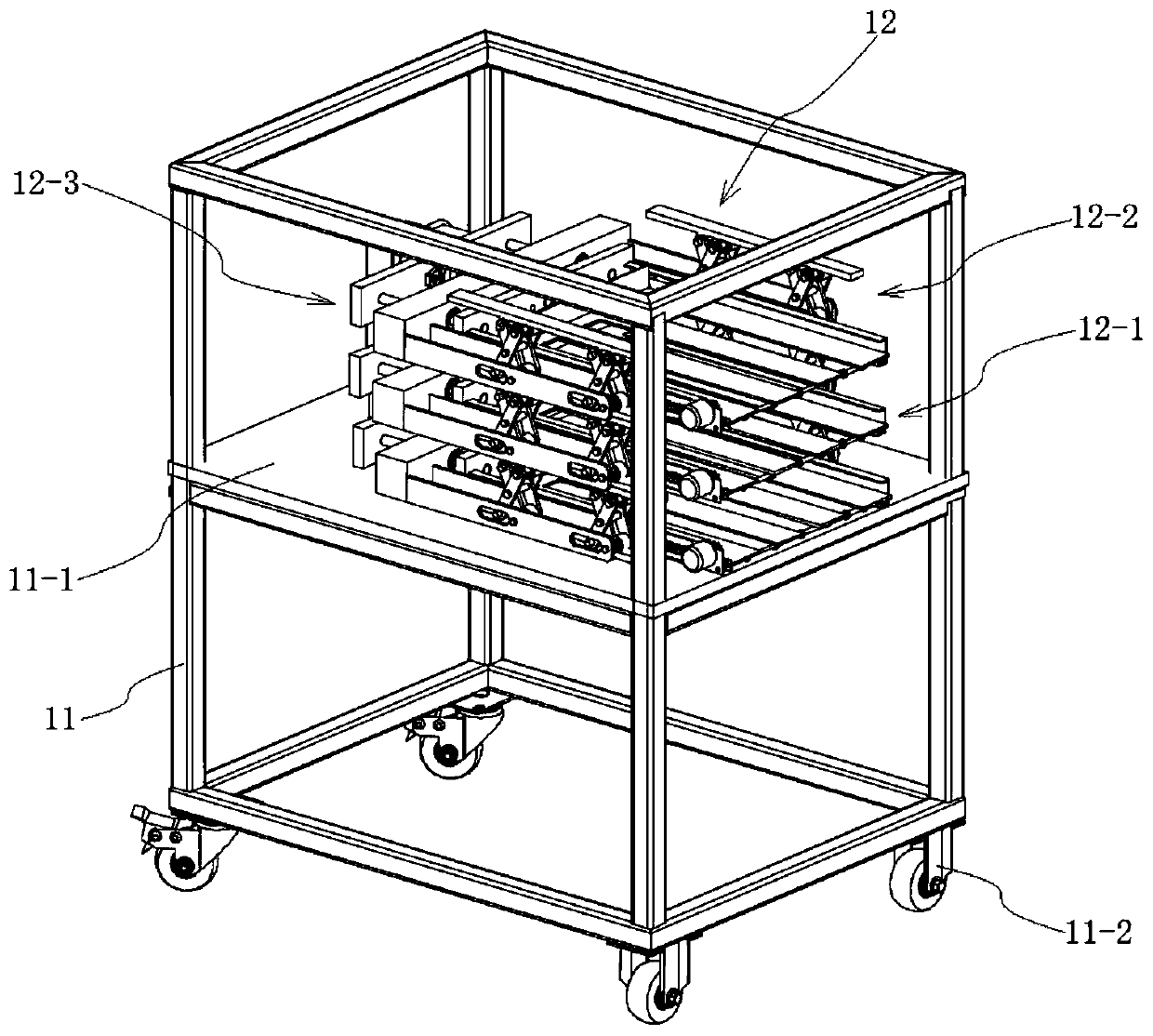

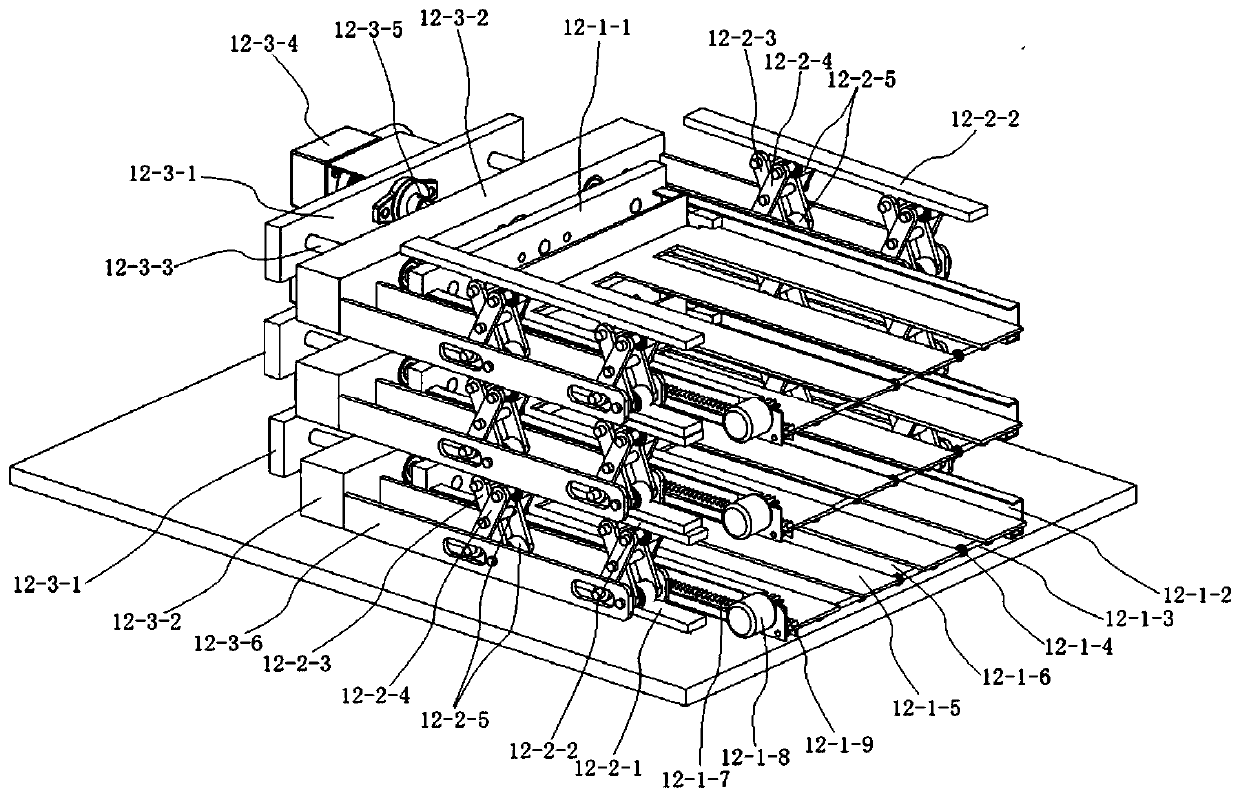

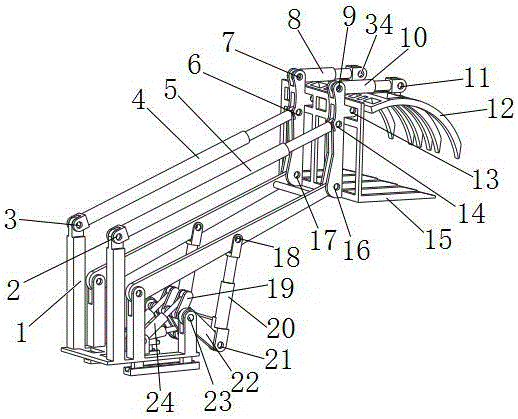

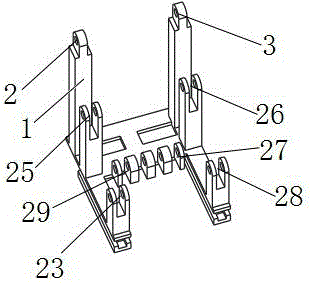

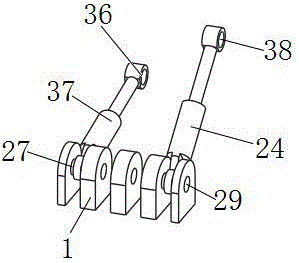

Intelligent storage and fetching bookshelf device with adjustable book storage thickness and control method thereof

InactiveCN111301915AOptimize book storage spaceSimple and efficient withdrawalStorage devicesMechanical engineeringSoftware engineering

The invention discloses an intelligent storage and fetching bookshelf device with adjustable book storage thickness and a control method thereof, and belongs to the field of intelligent bookshelves. The intelligent storage and fetching bookshelf device with adjustable book storage thickness comprises a book storage rack device, a book taking and returning device and a control system, wherein the book storage rack device is provided with horizontal push-pull book boxes which are stacked up and down, the adjacent horizontal push-pull book boxes are connected through a book box height lifting mechanism and a height lifting driving mechanism, the book storage thickness space of each layer of book box is flexibly adjusted through the height lifting driving mechanisms according to the thicknessof books, the problems that thin books occupy large space and thick books cannot be stored are solved, and the book storage space of the book storage rack device is effectively optimized; and moreover, a book box telescopic bracket of each horizontal push-pull book box can stretch back and forth under the action of a book telescopic driving mechanism, and book supporting rods of the book taking and returning device are matched to move up and down, so that books on each book box telescopic bracket are taken and put, and the taking and returning action of the books is simpler and more efficient.

Owner:CHANGZHOU INST OF TECH

Rotor for laboratory centrifuges with hold-down element for centrifugation containers

ActiveUS7806819B2Easily and economically manufactureExcellent characteristicsCentrifugesEngineeringLaboratory centrifuge

The invention relates to a rotor for laboratory centrifuges which is designed for accommodating at least one centrifugation container, and an adapter for accommodating a sample vessel and for use in a laboratory centrifuge rotor. The rotor has at least one hold-down element by which the at least one centrifugation container is held in the rotor and protected from axial displacement. In addition, a contact pressure may be produced on the at least one centrifugation container on the rotor.

Owner:THERMO ELECTRONICS LED GMBH

Deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief

ActiveCN112377193AEfficient productionSolve the problem of continuous tension in miningMining devicesUnderground miningMining engineeringCoal pillar

The invention provides a deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief, and relates to the technical field of coal mining. Ventilation and support in deep well gob-side entry retaining are improved. The deep well small coal pillar gob-side entry retaining method comprises the steps that roof geological conditions are determined, blasting parameters are determined according to the roof geological conditions, the roof-breaking pressure relief effects of lower key layers with different thicknesses are numerically simulated,and roof-breaking parameters of a roadway are determined; then excavating blast is conducted in the test roadway, and a displacement monitoring station, an anchor rod and an anchor cable stress monitoring station are arranged on surrounding rock in the roadway; and the supporting parameters are corrected, excavating blast is conducted in the gob-side entry retaining roadway, and supporting is conducted according to the corrected supporting parameters. According to the method, blasting is conducted on the side, deviating from solid coal, of a coal seam roof, stress transmission of the key layer is cut off at the lower key layer of the pre-split coal seam roof, thus high stress acting on small coal pillars and gob-side entry retaining is transferred, therefore the roadway environment is improved, and roadway maintenance is facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

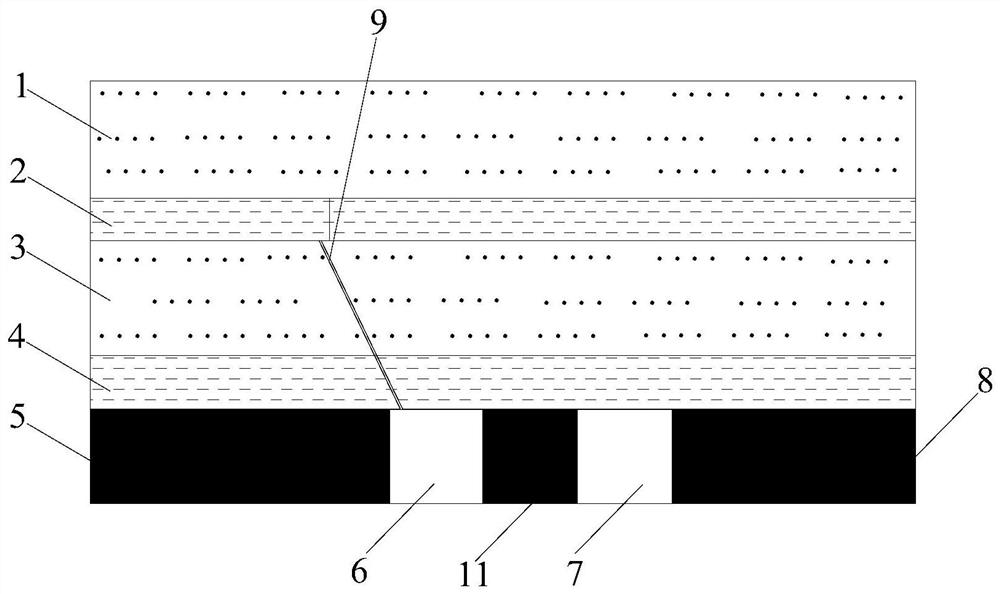

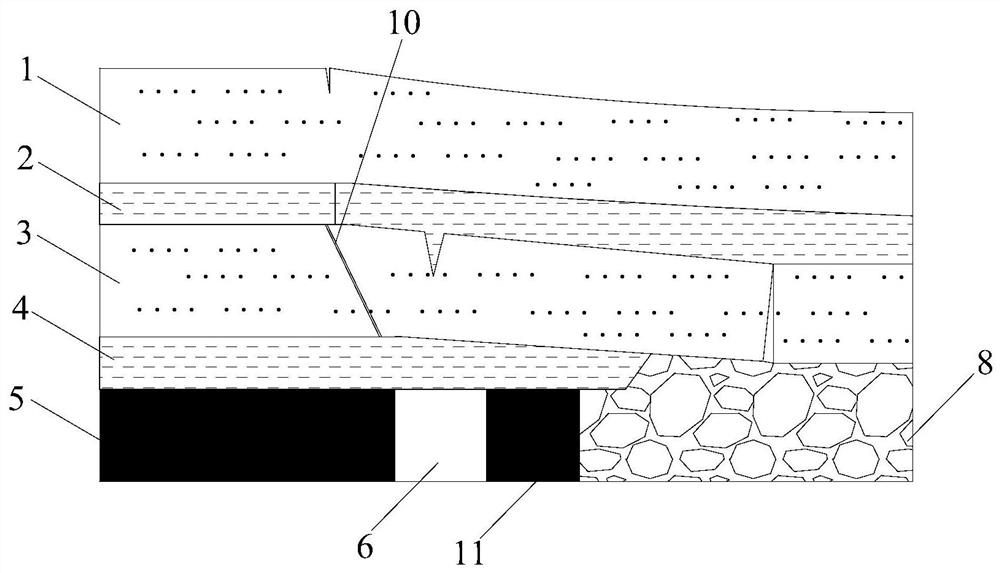

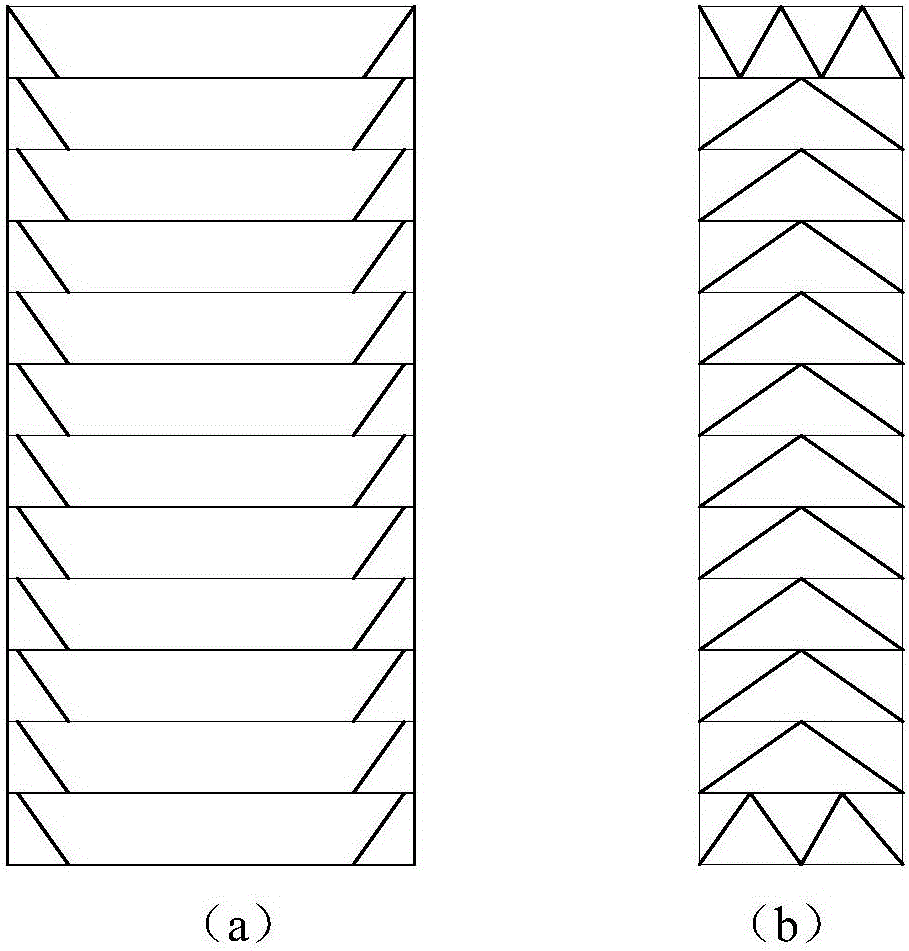

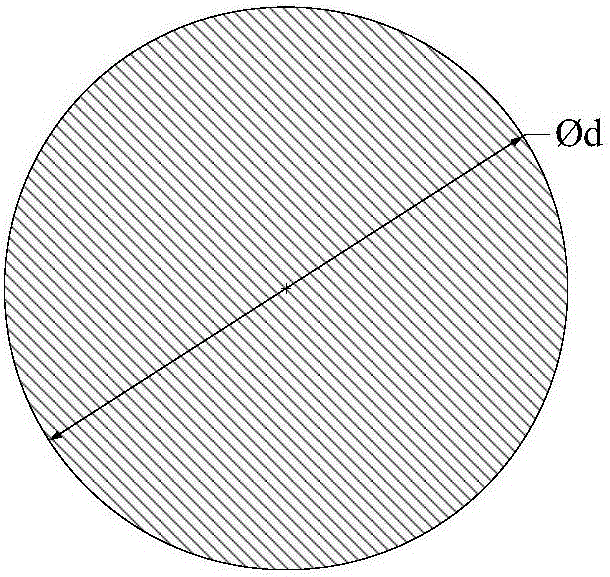

Universal joint bearing with plastic outer ring and procedure for its production

ActiveUS8226297B2Improve the stability of bearingImprove residual stressYielding couplingRolling contact bearingsFiberUniversal joint

An outer race for a rocker bearing includes an internal sliding layer and an external support layer, wherein the sliding layer and the bearing layer are formed from a wound composite fiber material. The outer race is identified by exactly one parting line. A rocker bearing with such an outer race and a method for its production is also provided, in which a sliding layer and a support layer of synthetic resin impregnated fibers are wound in succession onto a winding mandrel, and outer races are formed after setting on the winding body thus produced. The sliding layer and the support layer are wound onto a cylindrical winding mandrel, and the outer race is provided with exactly one parting line opening it, and sliding layer material on its inside is removed to such an extent that a partially spherical contour is obtained for receiving a complementary inner race.

Owner:FEDERAL MOGUL DEVA

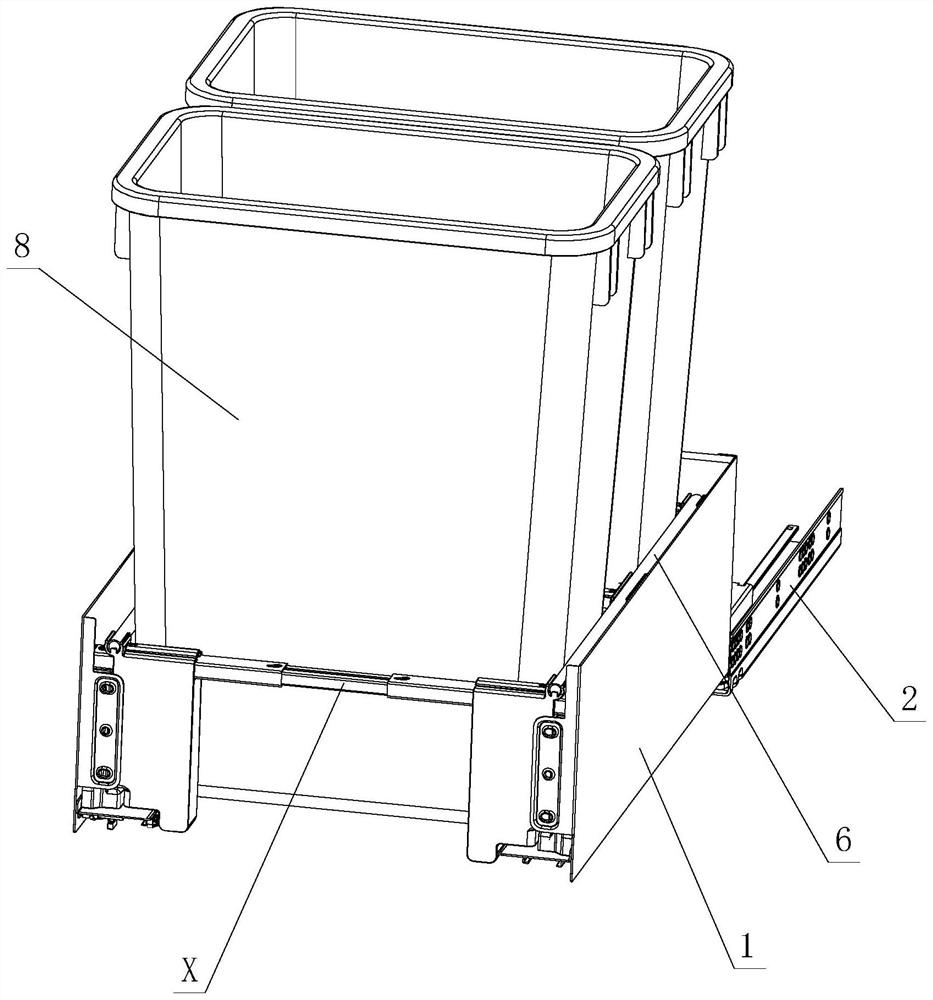

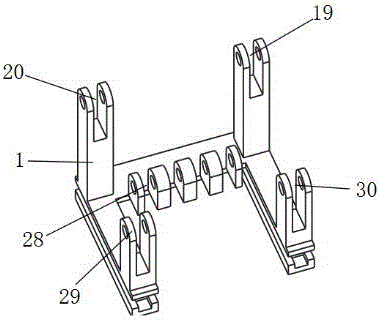

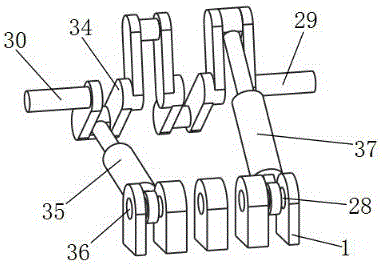

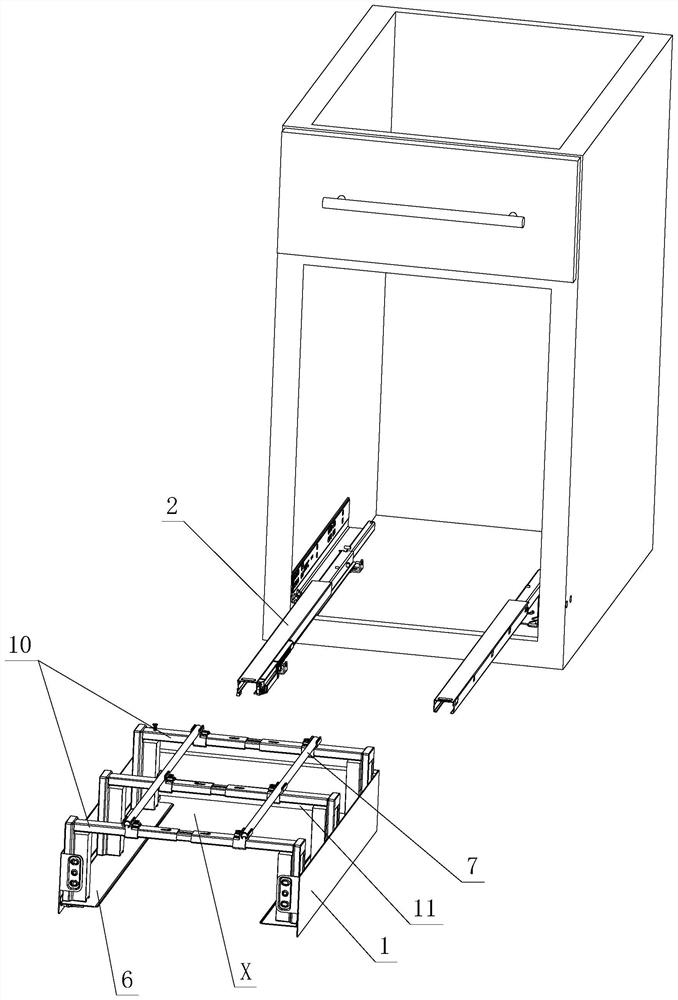

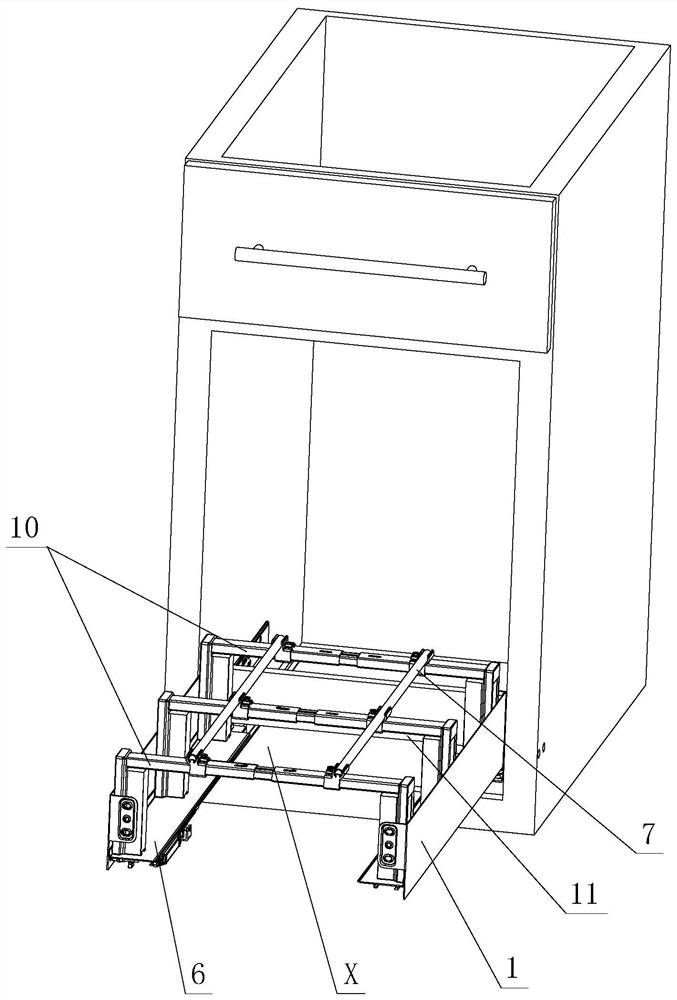

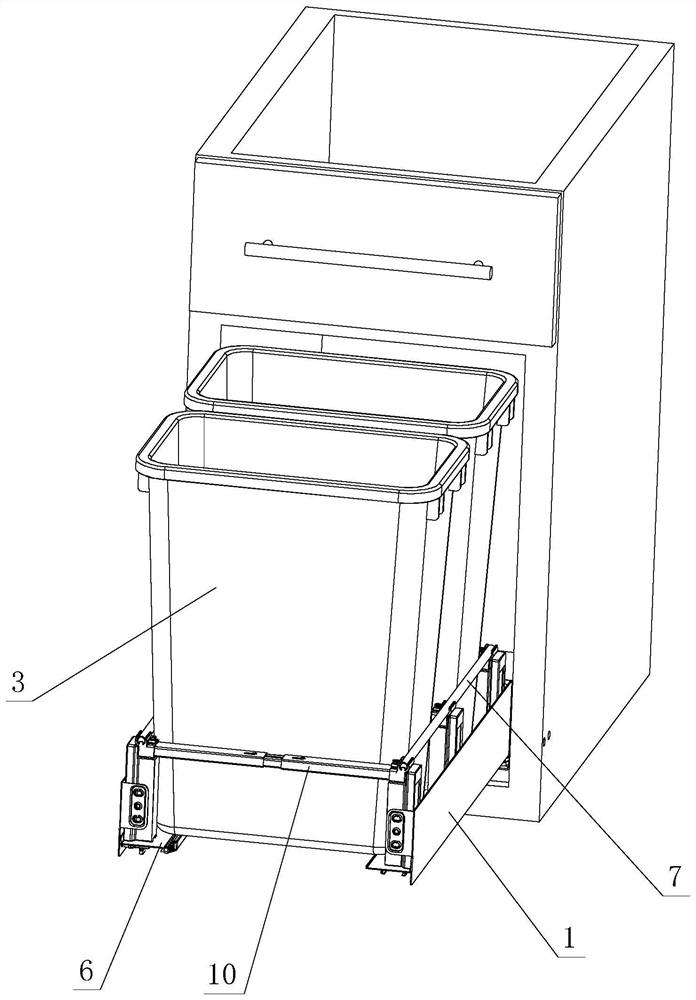

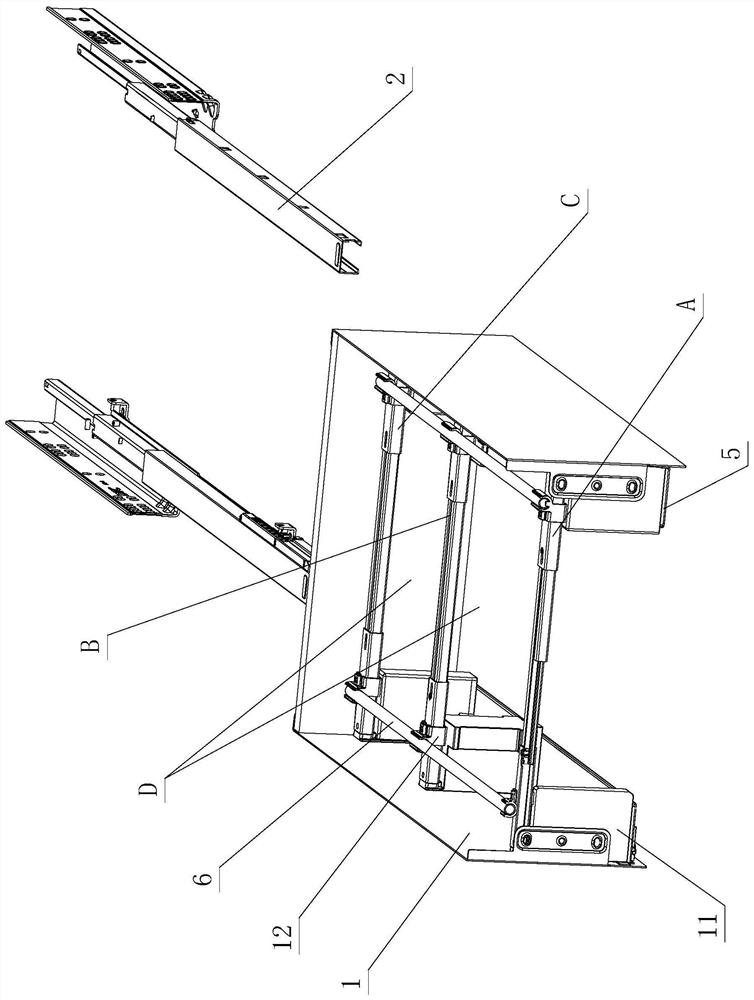

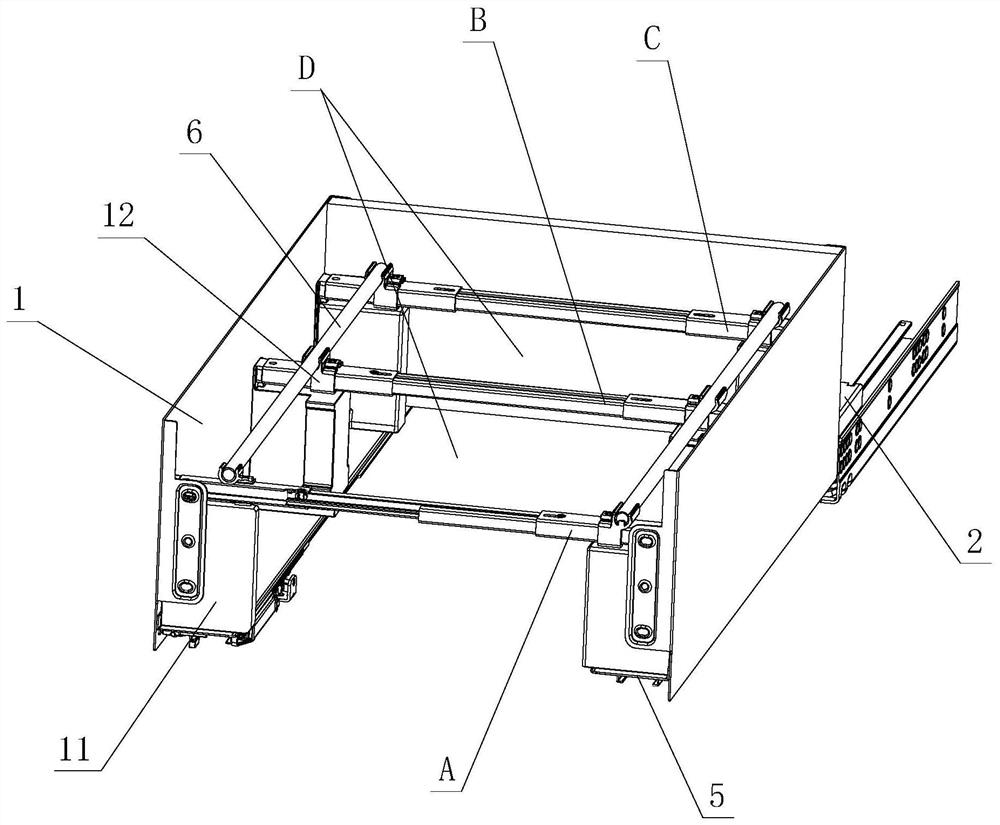

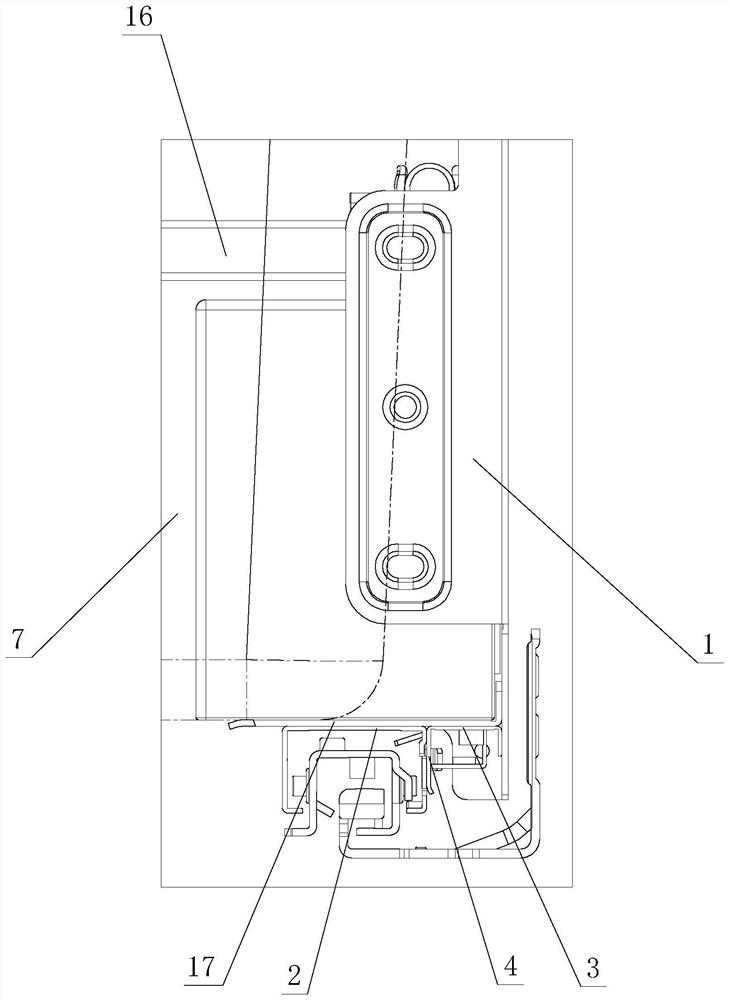

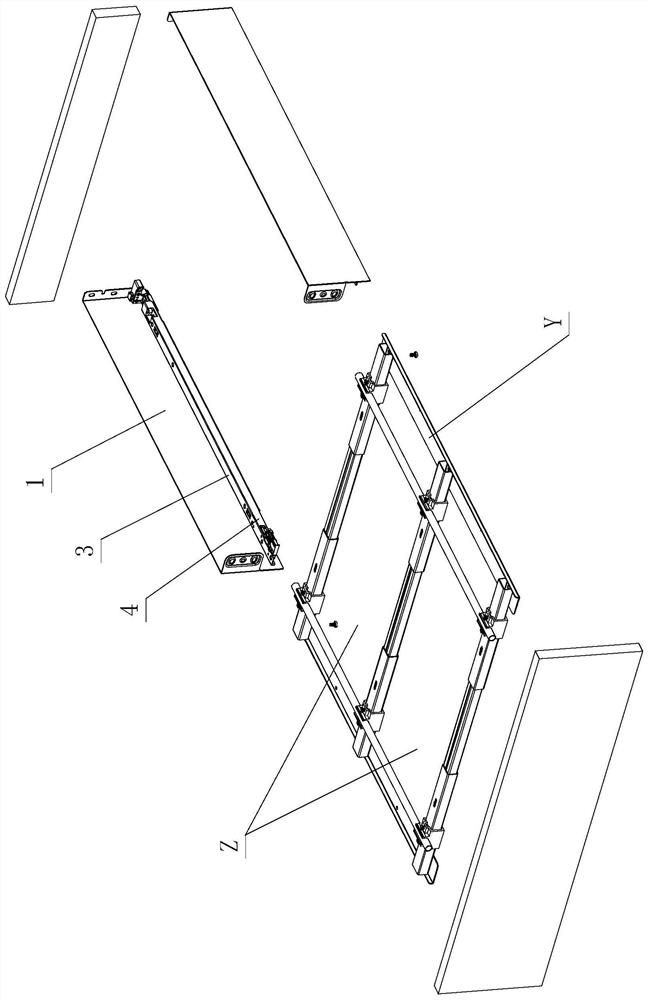

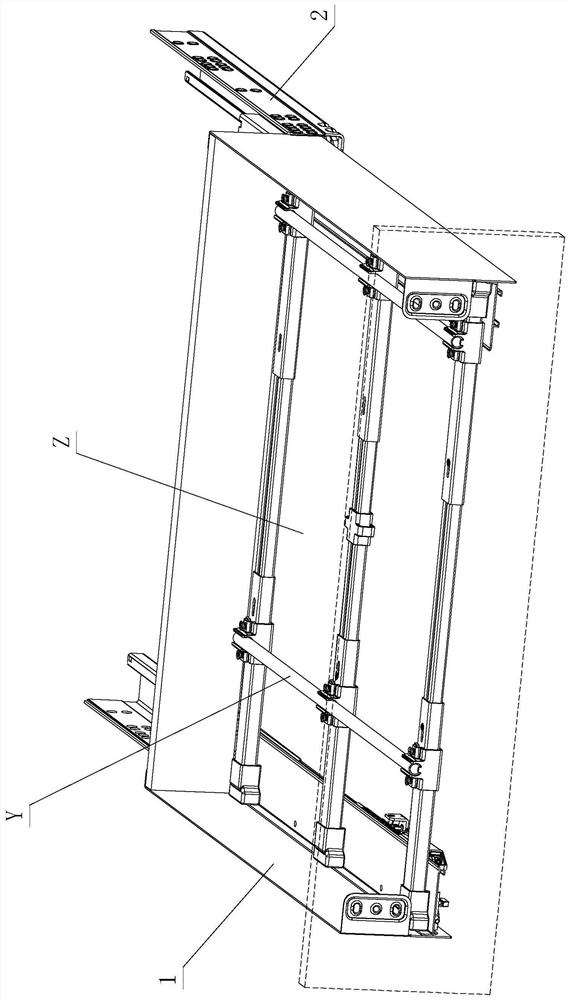

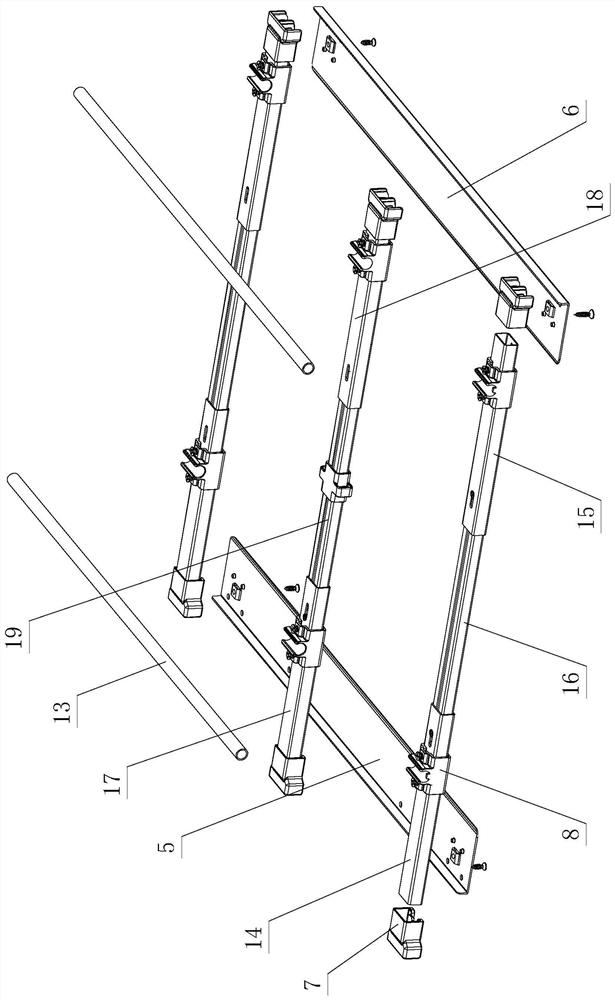

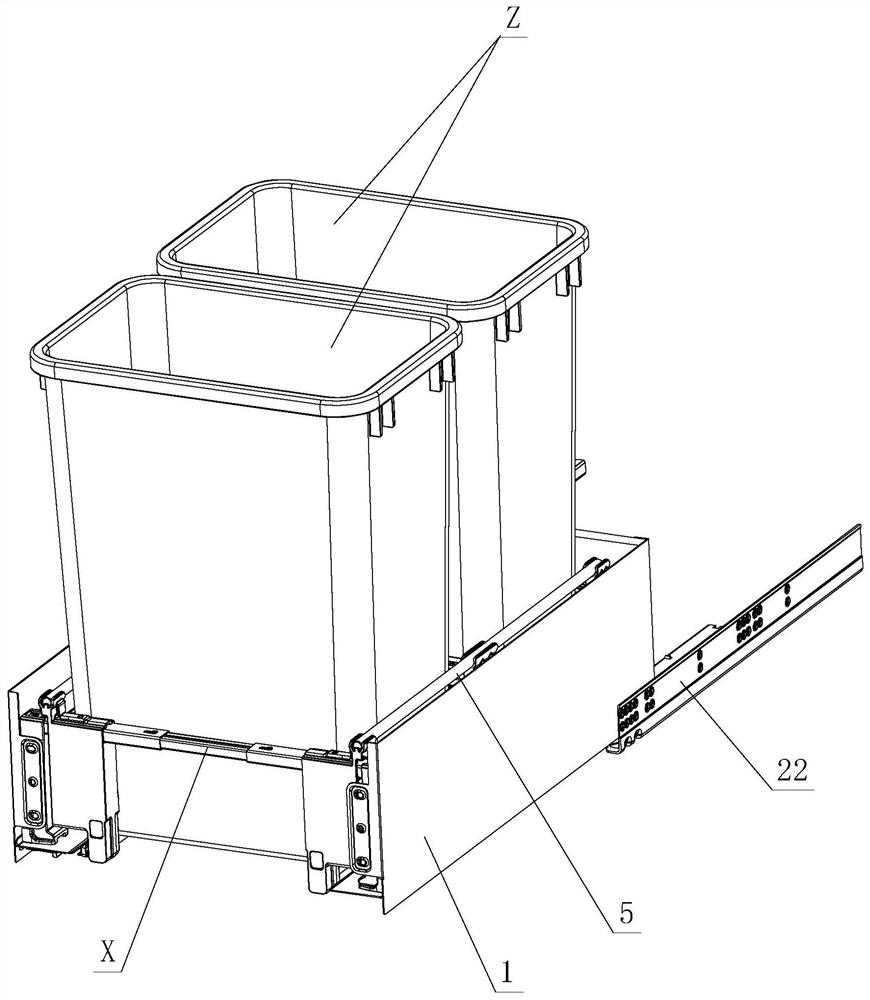

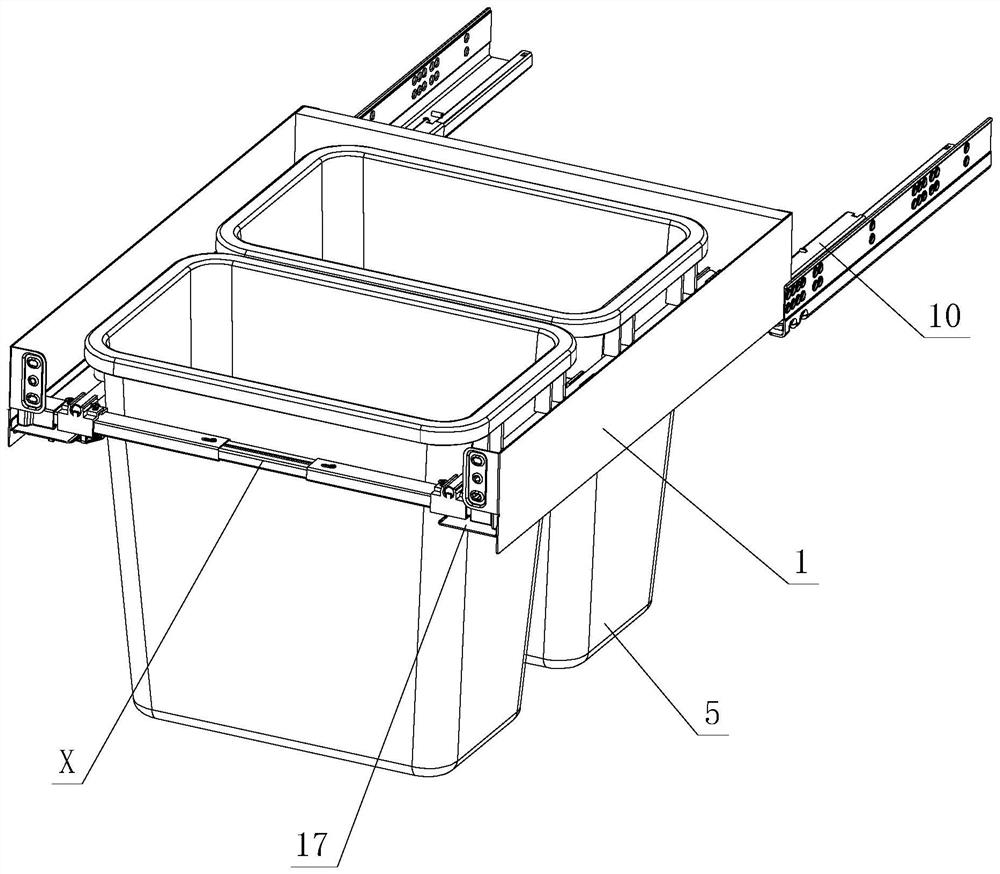

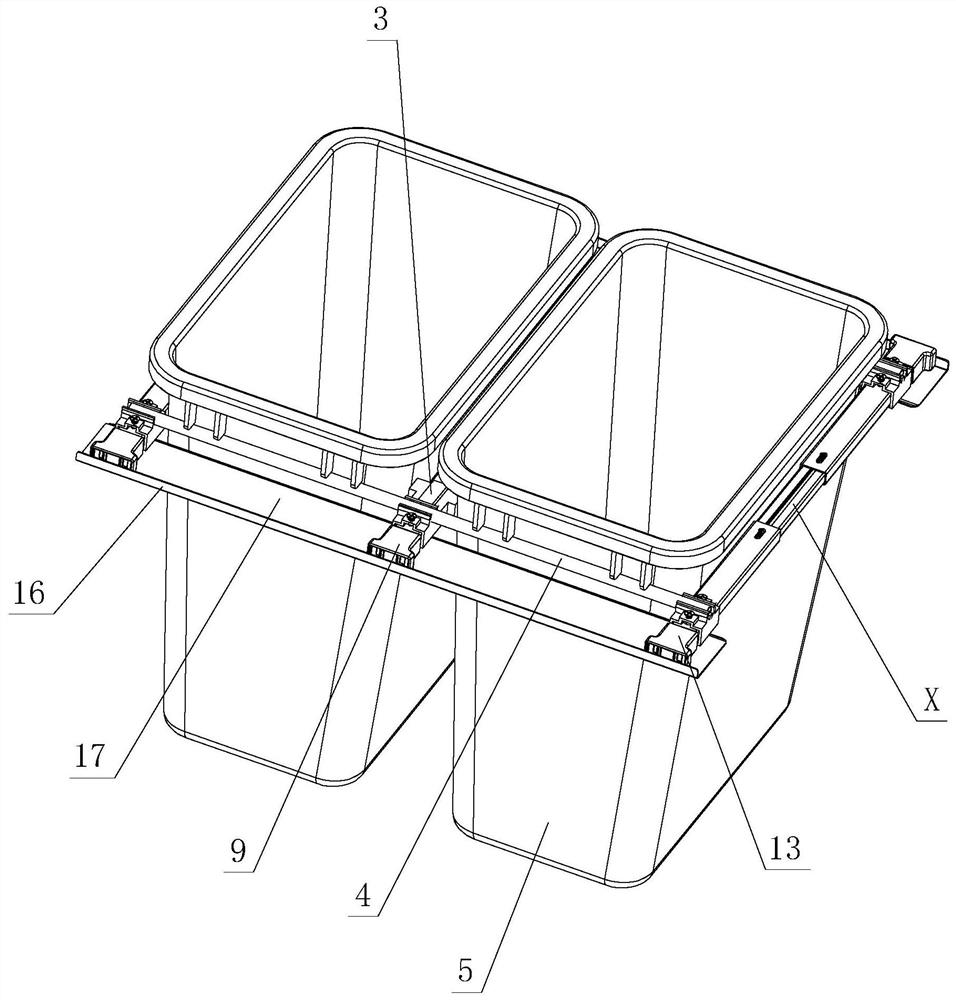

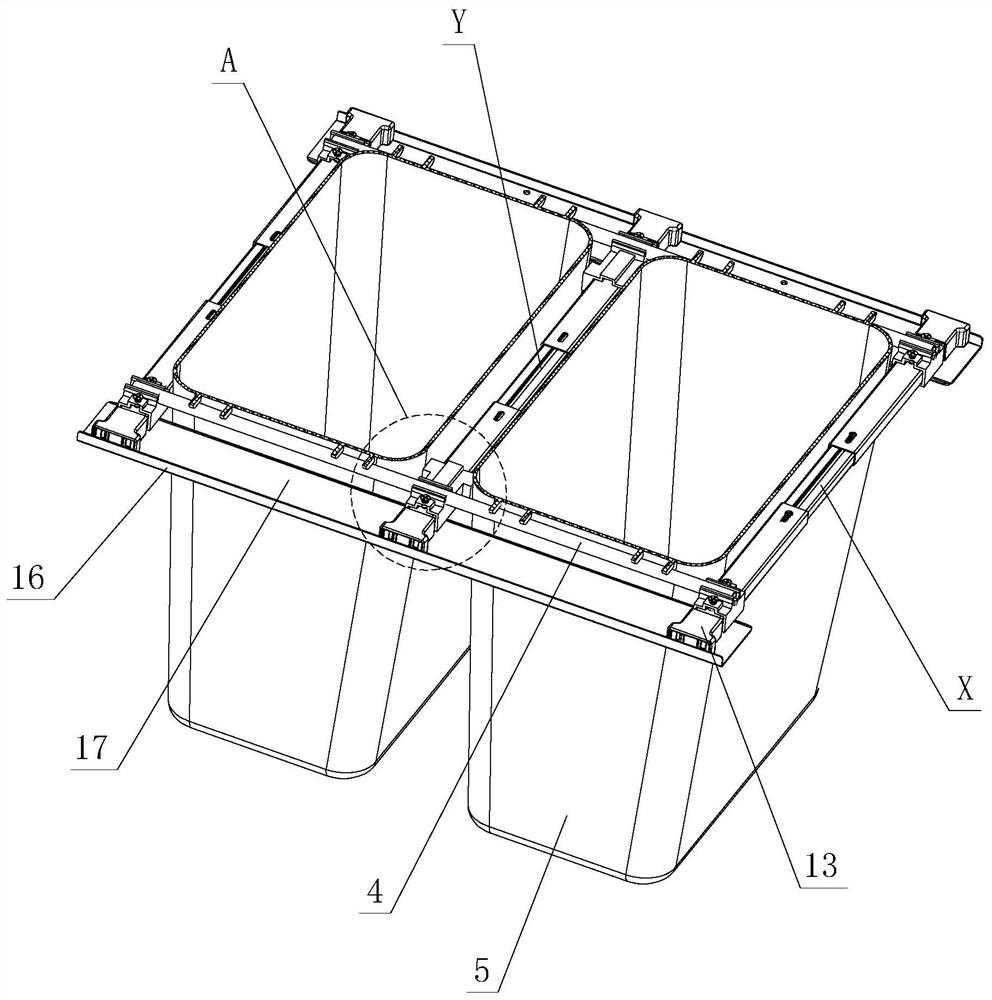

Bearing structure for device

PendingCN112336095AEasy to holdEfficient storageRefuse receptaclesDrawersStructural engineeringMoving parts

The invention discloses a bearing structure for a device. The structure comprises a left side plate, a right side plate and a sliding rail assembly, supporting parts are arranged on the lower portionsof the left side plate and the right side plate respectively, and leaning parts are arranged on the left supporting part and the right supporting part respectively; the side plate is detachably arranged on the sliding rail assembly, and the sliding rail assembly leans against the inner side of the leaning part during assembly; a bearing device is arranged between the left supporting part and theright supporting part, the bearing devc comprises at least two front-back transverse rod telescopic assemblies which are arranged front and back and can transversely move in a positioning mode, front-back movable pieces transversely move on the front-back transverse rod telescopic assemblies respectively, an upper supporting and fixing part and a lower bearing part are arranged between the front-back movable pieces, the upper supporting and fixing part and / or the lower bearing part synchronously and transversely move along with the front-back moving part; at least one placeable device capableof being placed and a bearing area capable of adjusting the longitudinal and / or transverse size are formed between the front-back transverse rod telescopic assemblies and the movable pieces during movement; and the device is placed on the bearing area, the side part of the device is positioned and acted on the upper supporting part and / or the front-back transverse rod telescopic assembly, and thebottom of the device is positioned and supported on the lower bearing part.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

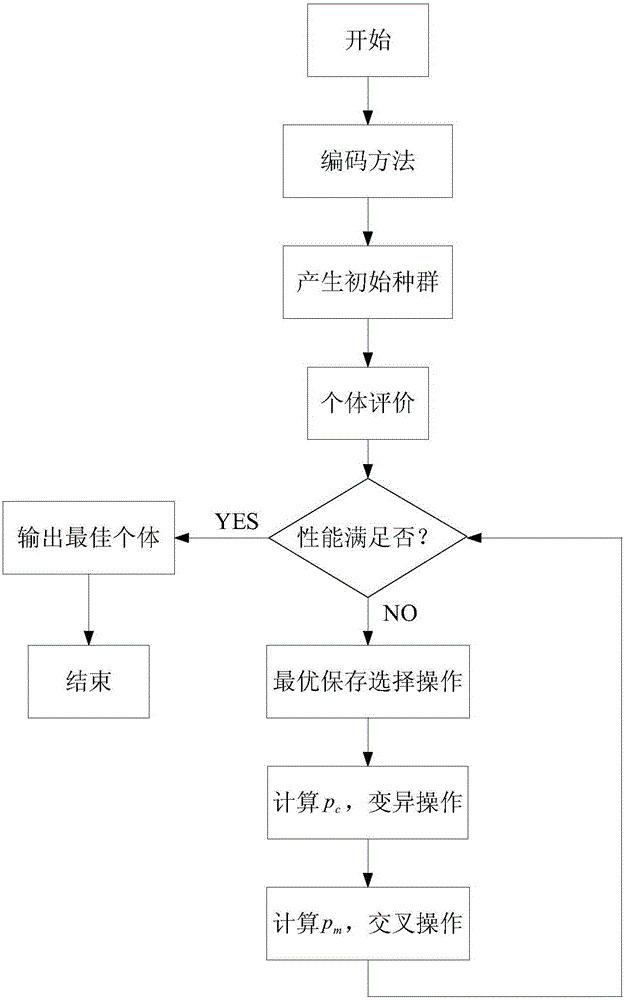

Stereoscopic garage optimization method based on self-adaption genetic algorithm

ActiveCN106682254AImprove the stability of bearingDesign optimisation/simulationSpecial data processing applicationsNODALElement model

A stereoscopic garage optimization method based on a self-adaption genetic algorithm comprises the steps that (1) a finite element model of stereoscopic garage bearing is established on the basis of original design parameters, and a maximum bending moment load borne by each rod part and a maximum bearing deformation value are computed; (2) a total weight target function of optimal design of a steel structure framework of the stereoscopic garage is established, and the needed design parameters are processed by equivalence; and (3) in order to ensure that the structure framework of the garage has enough strength, rigidity and stability, a condition that structural stress and node displacement do not exceed allowable values is taken as a constraint condition, and a stereoscopic garage optimization scheme is obtained by the self-adaption genetic algorithm. The invention provides the stereoscopic garage optimization method based on the self-adaption genetic algorithm, wherein bearing stability is high.

Owner:ENJOYOR COMPANY LIMITED

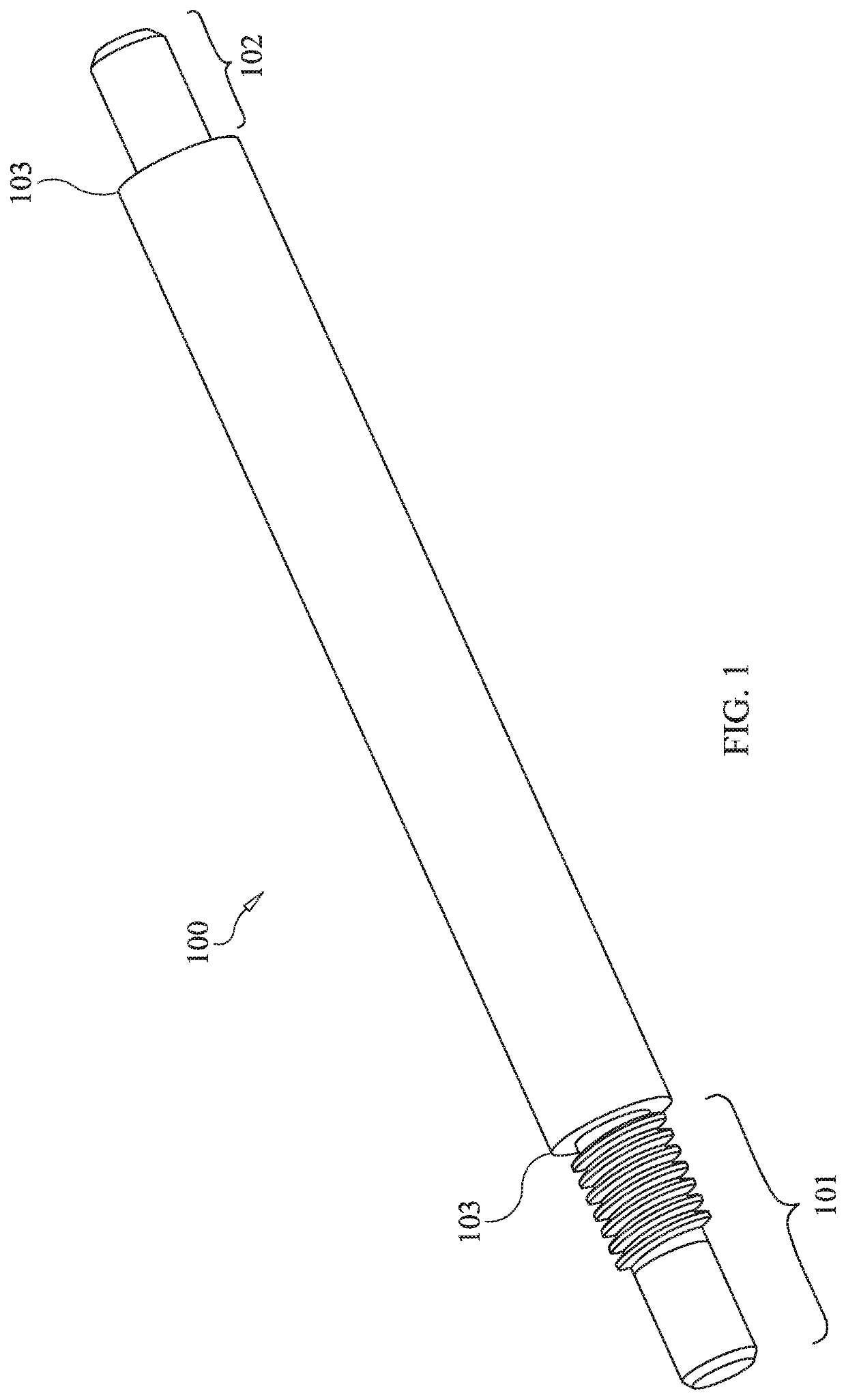

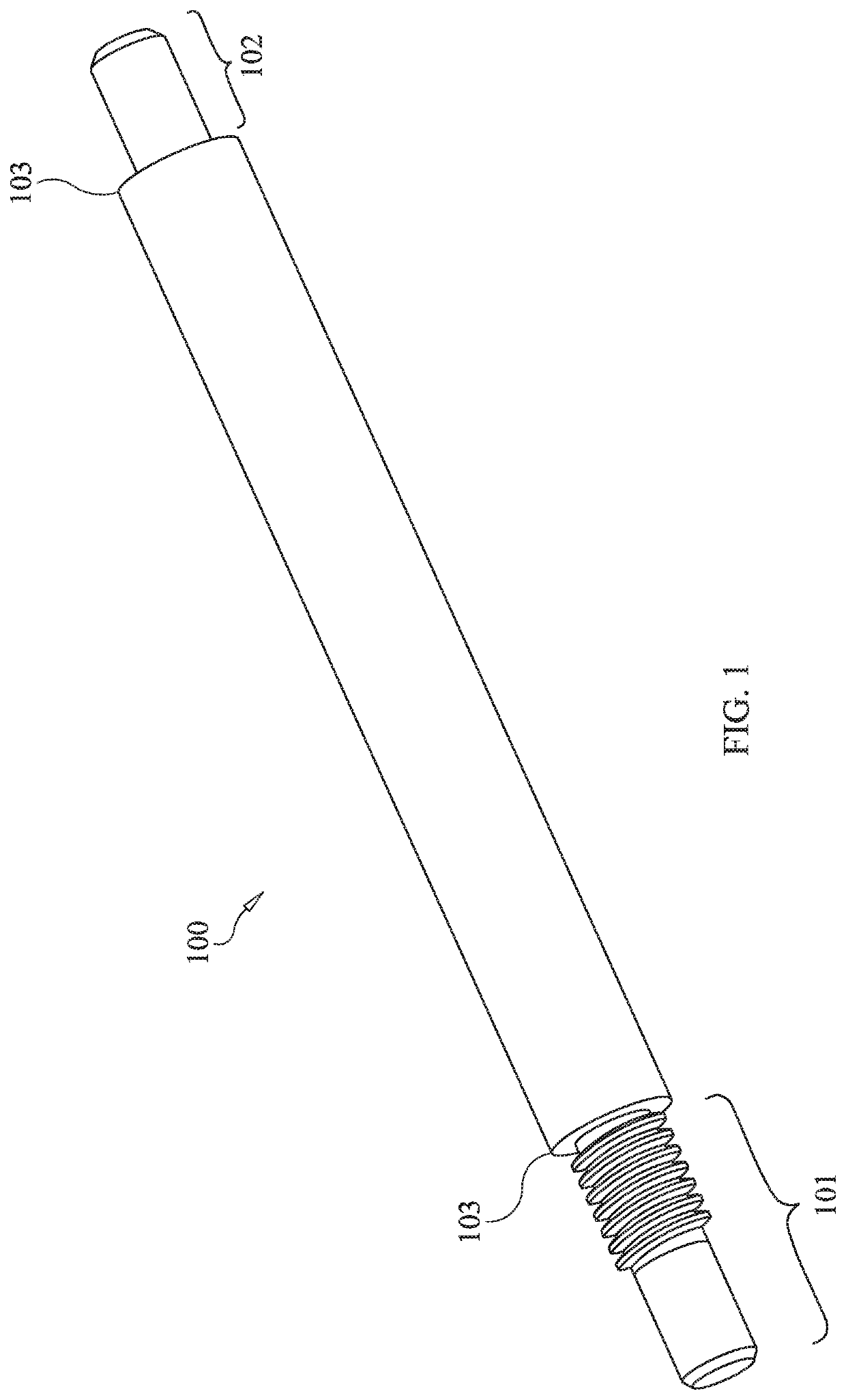

Bearing and bearing pin and method of manufacture

ActiveUS20200386265A1Improve the stability of bearingReduced skewing of the pinsRoller bearingsBearing componentsEngineeringScrew thread

A pinned roller bearing assembly and cage wherein the pin has two ends, a first end received in a first support ring, and a second end received in a second support ring, the pin comprising a threaded portion at one of the first or second ends, and the other end which is not threaded, or at least one shouldered end for engaging a countersunk support ring, or both a threaded end and one or both ends being shouldered.

Owner:ENGINEERED BEARING TECH INC

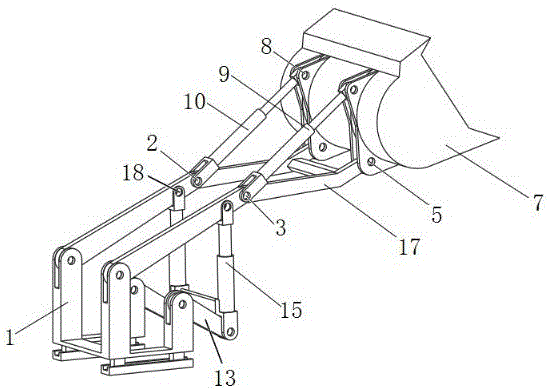

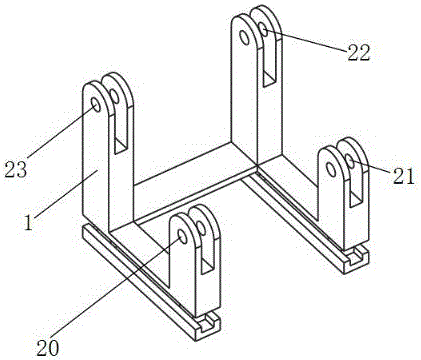

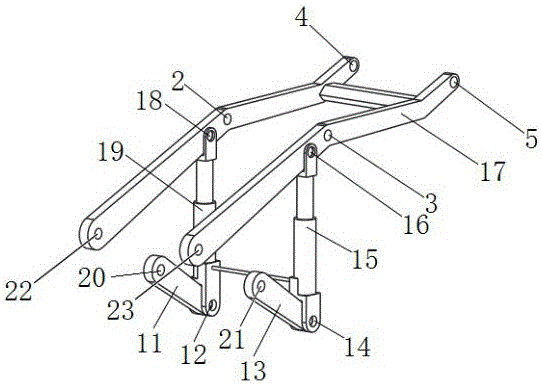

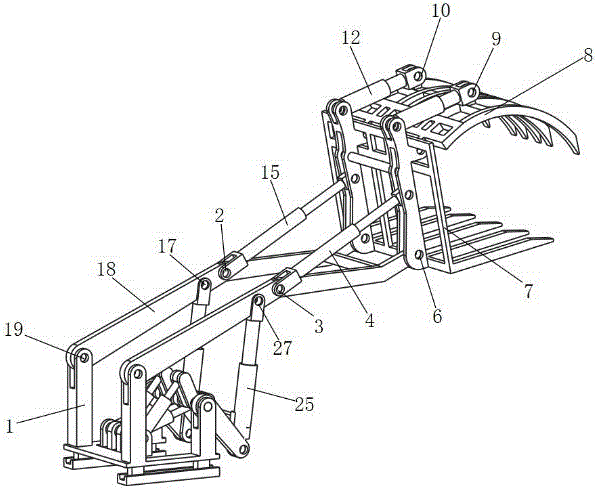

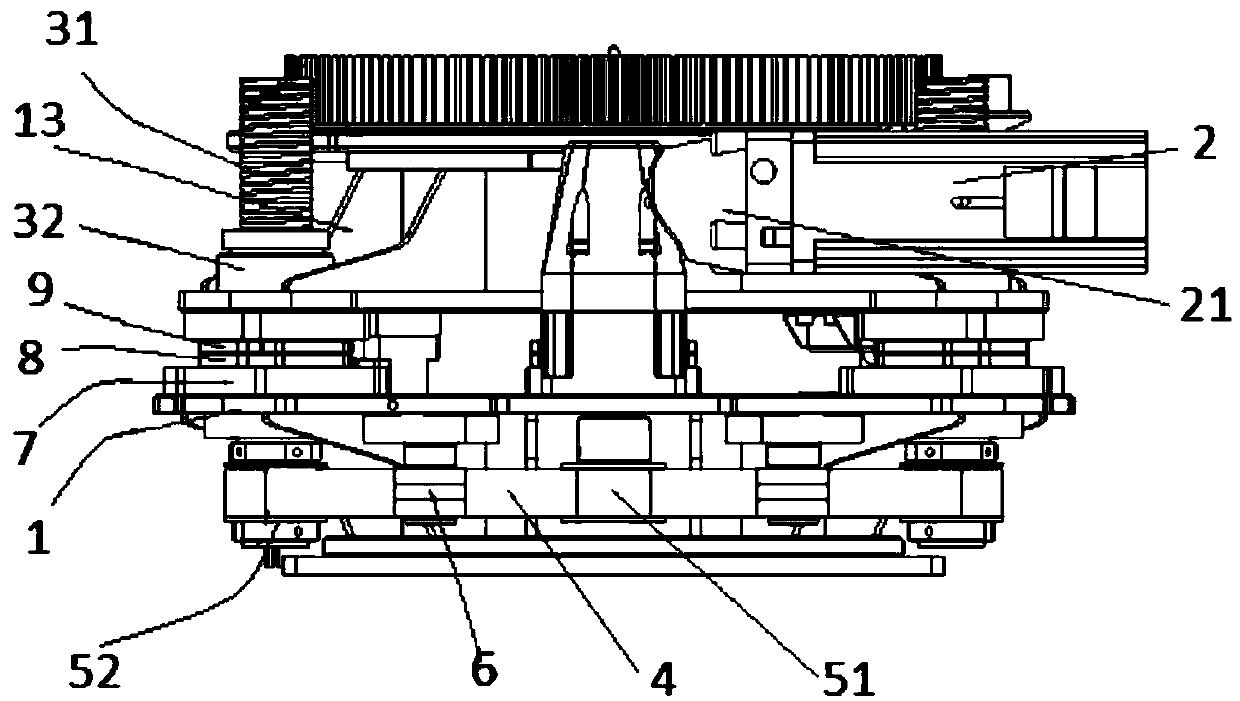

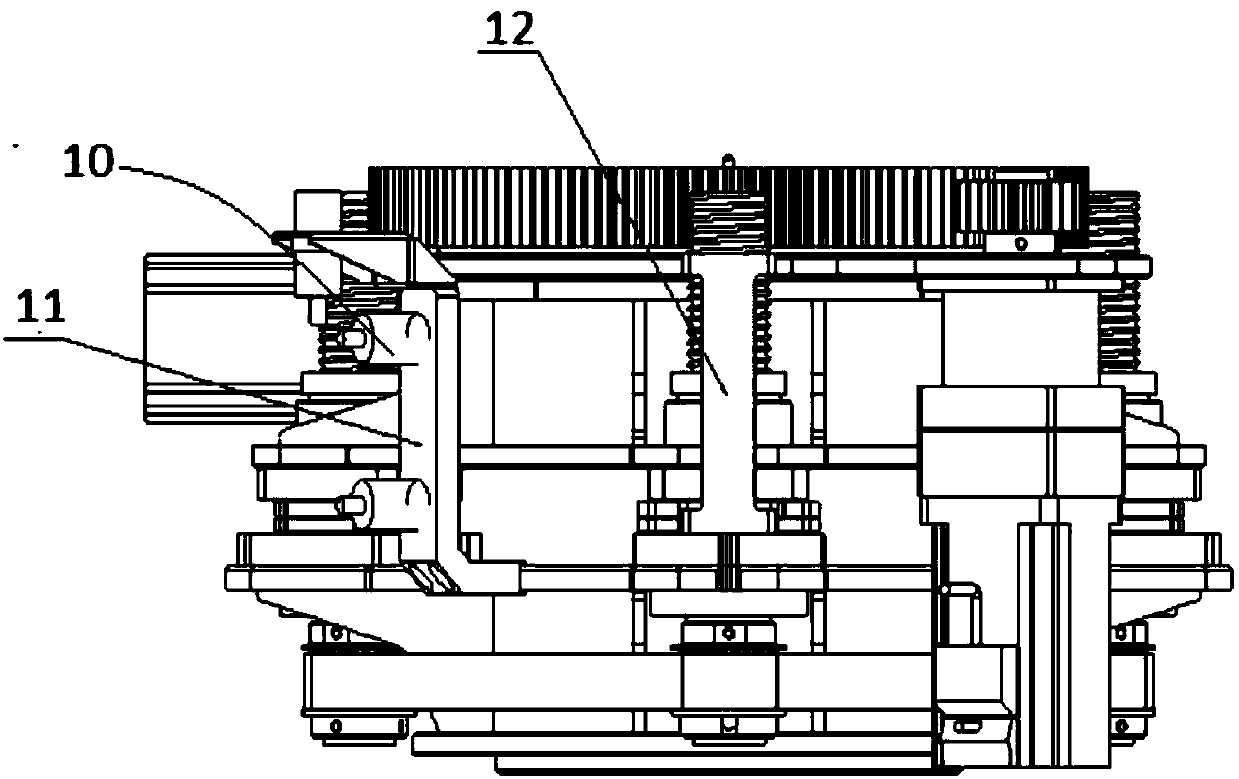

Plane three-degree-of-freedom electro-hydraulic mechanism type sliding loading robot

InactiveCN106049576ANo emissionsReduce noiseMechanical machines/dredgersThree degrees of freedomElectro hydraulic

The invention relates to a plane three-degree-of-freedom electro-hydraulic mechanism type sliding loading robot. The plane three-degree-of-freedom electro-hydraulic mechanism type sliding loading robot comprises a movable arm lifting mechanism, a bucket control mechanism and the like. According to the sliding loading robot, hydraulic elements are introduced into the movable arm lifting mechanism, so that the pressure of two cylinders is the same, the problem of unbalanced stress of two driving chains for lifting movable arms of an existing controllable sliding loading mechanism is solved, and the bearing stability of the movable arms is increased. The sliding loading robot has the characteristics of high mechanical efficiency, high response speed, high moving accuracy, good controllability and the like of the existing controllable sliding loading mechanism, has the advantages of low noise, no exhaust gas emission, low energy consumption and the like and is suitable for construction engineering such as garbage collection, road maintenance and the like in cities and other densely populated places; and the hydraulic elements are introduced, so that the sliding loading robot has high bearing and antivibration performance, an overload protection function is easy to realize, the reliability and practicability of the sliding loading robot are greatly increased, and the loading robot can be operated in a harsh construction environment.

Owner:SHANDONG JIAOTONG UNIV

Four-range-of-motion sliding type wood forklift with multi-unit linear driving function

InactiveCN106120892AImprove carrying capacityGuaranteed carrying capacityMechanical machines/dredgersHydraulic cylinderMulti unit

A four-range-of-motion sliding type wood forklift with a multi-unit linear driving function comprises a multi-unit linear driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like. The multi-unit linear driving mechanism is driven by multiple sets of linear drivers, high-power and high-torque power output is achieved through a crankshaft, and the power requirement for high-load operation of the sliding type wood forklift is met. A hydraulic cylinder is applied to the configuration design of the wood forklift as a connection rod, and a hydraulic element is introduced into the movable arm lifting mechanism, so that pressures in the cylinder are equal, the problem that in the prior art, stress on two driving chains for lifting a movable arm is unbalanced is effectively solved, and the bearing stability is improved. The sliding type wood forklift not only has the characteristics of being high in transmission efficiency, high in response speed, high in motion precision, good in controllability, capable of saving energy, environmentally friendly and the like as a controllable mechanism, but also has better bearing performance and vibration resistance through introduction of the multi-unit linear driving mechanism and the hydraulic element, can achieve the overload protection function easily and has great engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

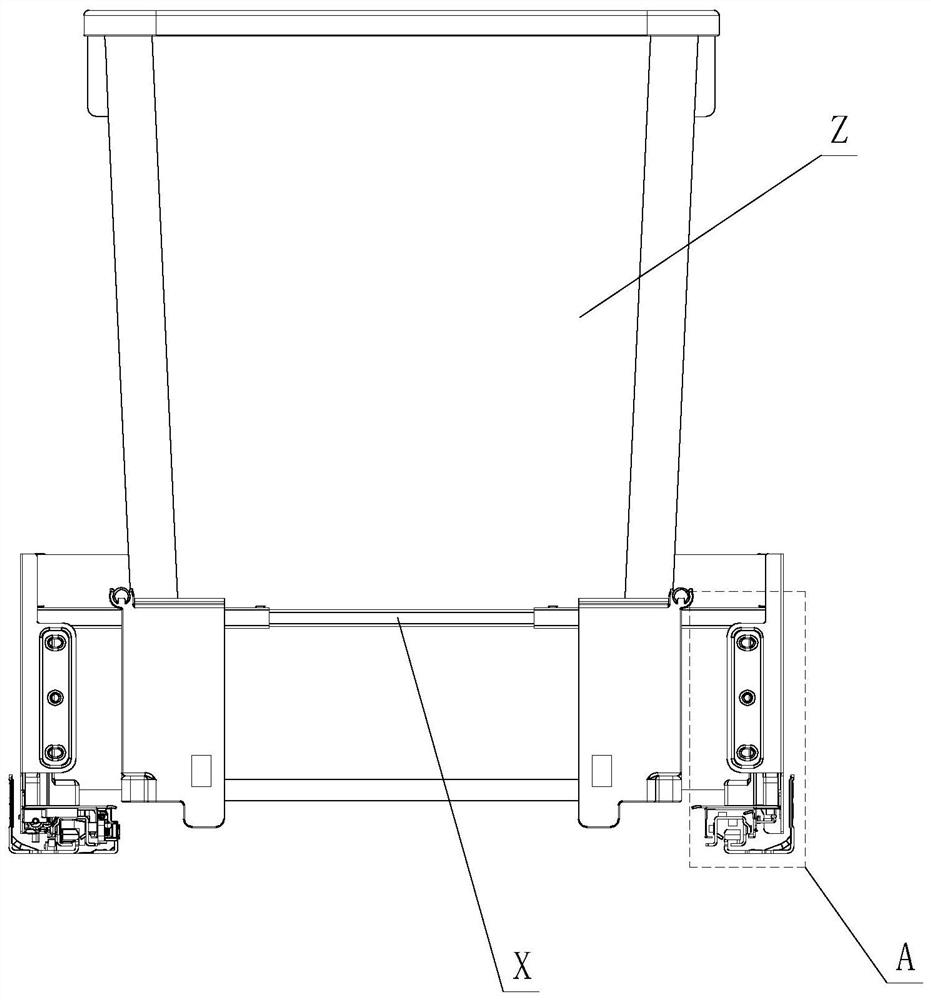

Concealed positioning and bearing structure of device

PendingCN112205788AEasy to holdEfficient storageRefuse receptaclesDrawersStructural engineeringMechanical engineering

A concealed positioning and bearing structure of a device comprises a left side plate, a right side plate, a left sliding rail assembly and a right sliding rail assembly, supporting parts are arrangedon the lower portions of the left side plate and the right side plate respectively, and leaning parts are arranged on the left supporting part and the right supporting part respectively; the side plates are detachably arranged on the sliding rail assemblies, and the sliding rail assemblies lean against the inner side of the leaning parts; a bearing device is arranged between the left supporting part and the right supporting part and comprises a transverse rod telescopic assembly and bases arranged on the left side and the right side, and the left base and the right base are supported on the left supporting part and the right supporting part and / or the left sliding rail assembly and the right sliding rail assembly respectively; the transverse rod telescopic assembly is fixed and / or longitudinally moves between the left base and the right base, a longitudinal rod transversely moves on the transverse rod telescopic assembly, and when the transverse rod telescopic assembly and the longitudinal rod move, at least one containing device and a bearing area with the adjustable longitudinal and / or transverse size are / is formed between the transverse rod telescopic assembly and the longitudinal rod; and devices are placed on the bearing area, the side portions of the devices are located on the transverse rod telescopic assembly and / or the longitudinal rods, and the two sides of the bottoms of the devices are located on the left base and the right base and / or the left sliding rail assembly and the right sliding rail assembly respectively.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Multiunit linear driving simple high-load electro-hydraulic controllable sliding wood forking machine

InactiveCN106049570AImprove carrying capacityGuaranteed carrying capacityMechanical machines/dredgersHydraulic cylinderElectro hydraulic

The invention relates to a multiunit linear driving simple high-load electro-hydraulic controllable sliding wood forking machine. The multiunit linear driving simple high-load electro-hydraulic controllable sliding wood forking machine comprises a multiunit linear driving mechanism, a movable arm lifting mechanism, a fork bucket control mechanism and the like, wherein the multiunit linear driving mechanism is driven by a plurality of groups of linear drivers, high-power and high-torque power output is realized by virtue of a crankshaft, and the power requirement of high-load operation of the sliding wood forking machine is satisfied. On the basis of the Pascal's principle, hydraulic cylinders are used as connecting rods so as to be introduced into the configuration of the wood forking machine, so that the problem of unbalanced stress of two driving chains for lifting movable arms in the existing design is effectively solved, and the bearing stability is increased. The sliding wood forking machine has the characteristics of high transmission efficiency, high response speed, high moving accuracy, good controllability, energy conservation, environmental friendliness and the like of a controllable mechanism, and the multiunit linear driving mechanism and hydraulic elements are introduced, so that the sliding wood forking machine has good bearing and antivibration performance, an overload protection function is easy to realize, and the sliding wood forking machine has good engineering application prospects and development potential.

Owner:SHANDONG JIAOTONG UNIV

Construction method of ultra-wide main arch ring of long-span hollow arch bridge in alpine region

ActiveCN105200925BEasy to pull out for recyclingImprove the stability of bearingBridge erection/assemblySupporting systemEconomic benefits

Owner:西安市市政建设(集团)有限公司

Adjusting structure for device bearing area

PendingCN112315236AImprove the stability of bearingImprove user experienceRefuse receptaclesDrawersEngineeringStructural engineering

An adjusting structure for a device bearing area comprises a left side plate, a right side plate and a sliding rail assembly, and a supporting part and a leaning part are arranged on the lower portions of the left side plate and the right side plate respectively. The side plate is detachably arranged on the slide rail assembly, and the slide rail assembly leans against the inner side of the leaning part during assembly; a bearing device is arranged between the left supporting part and the right supporting part and comprises a left base and a right base, the left base and the right base are supported on the left supporting part and the right supporting part and / or the left sliding rail assembly and the right sliding rail assembly respectively, at least three transverse rod telescopic assemblies arranged front, middle and back are arranged between the left base and the right base, and longitudinal rods are arranged among the front, middle and back transverse rod telescopic assemblies; the front, middle and rear transverse rod telescopic assemblies and the longitudinal rods form a bearing area capable of accommodating devices and adjusting the longitudinal and / or transverse size whenmoving; positioning adjusting piece assemblies are arranged on the front cross rod telescopic assembly, and / or the middle cross rod telescopic assembly, and / or the rear cross rod telescopic assembly,and / or the longitudinal rod; the device is placed on the bearing area, and the side portion of the device is positioned and acts on the positioning adjusting piece assembly when the device is placed.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Compact hidden bearing structure for drawer

PendingCN112220249AEasy to holdEfficient storageRefuse receptaclesDrawersStructural engineeringMechanical engineering

The invention discloses a compact hidden bearing structure for a drawer. The structure comprises left and right side plates and left and right sliding rail assemblies, a left supporting part and a right supporting part are arranged on the lower portions of the left and right side plates respectively, and leaning parts are arranged on the left and right supporting parts respectively; the side plates are detachably arranged on the sliding rail assemblies, and when the side plates are assembled, the sliding rail assemblies lean against the inner sides of the leaning parts; a bearing device is arranged between the left supporting part and the right supporting part and comprises a left base, a right base and a telescopic rod assembly; and the left base is at least supported on the left supporting part, the right base is at least supported on the right supporting part, positioning pieces are arranged at the two ends of the telescopic rod assembly respectively, the telescopic rod assembly isfixed or longitudinally slides on the left base and the right base through the positioning pieces respectively, and the two ends of the telescopic rod assembly are spaced from the left base, the rightbase and / or the sliding rail assemblies through the positioning pieces correspondingly. Through the improvement of the structure, the practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Extension seat body with space expansion function

InactiveCN108945013AReduce occupancyReduce volumeLuggageHand carts with one axisCarrying capacityEngineering

The invention discloses an extension seat body with a space expansion function. The extension seat body comprises two pipe seats, an outer telescopic seat, an inner telescopic seat, an outer locatingdevice and an inner locating device. The two pipe seats are symmetrically arranged. Each pipe seat is provided with an outer sliding hole and an inner sliding hole. The outer telescopic seat comprisesan outer transverse pipe and two outer telescopic pipes connected to the two ends of the outer transverse pipe, the outer telescopic seat is in an n shape overall, and the two outer telescopic pipesare telescopically arranged in the two outer sliding holes. The inner telescopic seat comprises an inner transverse pipe and two inner telescopic pipes connected to the two ends of the inner transverse pipe, the inner telescopic seat is in an n shape overall, and the two inner telescopic pipes are telescopically arranged in the two inner sliding holes. The outer locating device is arranged in theouter telescopic seat and can be driven by the outer transverse pipe to control the stretching length of the two outer telescopic pipes. The inner locating device is arranged in the inner telescopic seat and can be driven by the inner transverse pipe to control the stretching length of the two inner telescopic pipes. By the adoption of the above structure, the carrying capacity of carrying tools such as a luggage case and a cart can be greatly improved.

Owner:刘 文桂 +2

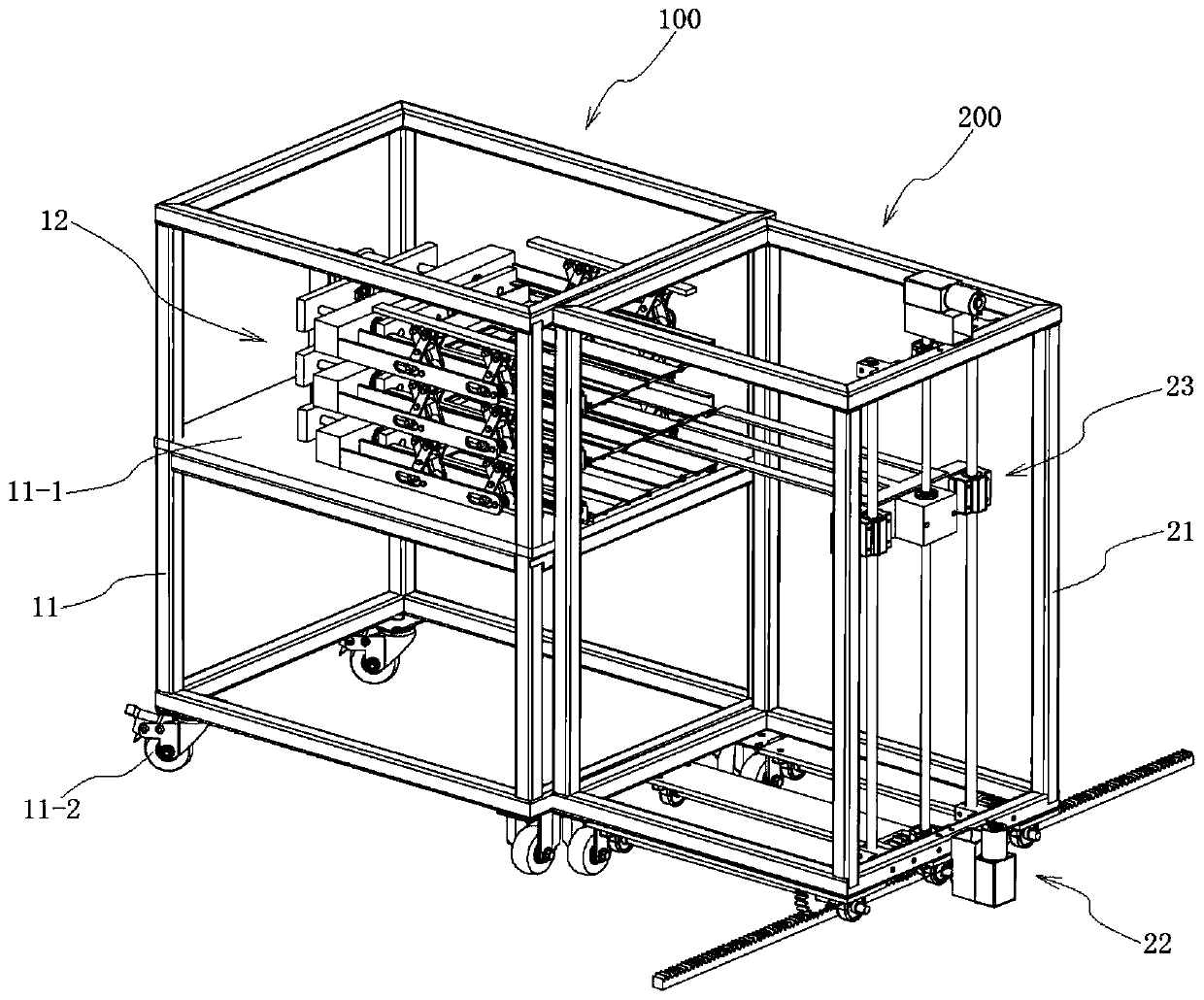

Automatic guiding transport vehicle

PendingCN110723234AImprove lifting stabilityImprove the stability of bearingLifting framesVehiclesControl engineeringMechanical engineering

The embodiment of the invention discloses an automatic guiding transport vehicle, and relates to the technical field of mobile robots. The automatic guiding transport vehicle is good in lifting bearing stability. The automatic guiding transport vehicle comprises a vehicle body and a lifting system arranged on the vehicle body. The lifting system comprises a base. A driving device and at least three sets of lifting mechanisms are arranged on the base. Each set of lifting mechanism comprises a lifting part and a transmission part connected with the lifting part. The driving device is connected with the transmission part of each lifting mechanism, and drives the transmission parts of all sets of lifting mechanisms to rotate synchronously, and the transmission parts drive the lifting parts torise or fall synchronously. The automatic guiding transport vehicle is applicable to various occasions or equipment with the need of lifting objects.

Owner:HANGZHOU HIKROBOT TECH CO LTD

Integrated and optimized device containing structure

The invention discloses an integrated and optimized device containing structure. The integrated and optimized device containing structure comprises left and right side plates, left and right supporting parts are arranged on the left and right side plates, a containing device is arranged between the left and right supporting parts and comprises front, middle and rear cross rod telescopic assemblies, front, middle and rear moving parts are transversely and movably arranged on the front, middle and rear cross rod telescopic assemblies correspondingly, upper connecting rods are detachably arranged on the upper portions of the front, middle and rear moving parts, notch parts are formed in the lower portions of the front, middle and rear moving parts correspondingly, in addition, lower connecting rods are detachably arranged on the lower portions of the front, middle and rear moving parts through the notch parts in a penetrating mode correspondingly, the middle cross rod telescopic assembly and the middle moving part synchronously and longitudinally slides between the front and rear cross rod telescopic assemblies through the cooperation of the upper and lower connecting rods, at least one containing area capable of containing devices and capable of adjusting the longitudinal and / or transverse size is formed between the front, middle and rear cross rod telescopic assemblies and the front, middle and rear moving parts in the moving process, the devices are placed on the containing areas, the bottoms of the devices are positioned and supported on the lower connecting rods in a bearing mode, and the side portions of the devices act on the upper connecting rods and / or the front and rear cross rod telescopic assemblies and / or the middle cross rod telescopic assembly in a front-back and / or left-right positioning mode.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

Pinned cylindrical roller bearing

ActiveUS11015644B2Improve the stability of bearingReduced skewing of the pinsRoller bearingsBearing componentsClassical mechanicsScrew thread

A pinned roller bearing assembly having a plurality of pinned rollers, wherein each of the pins has a first threaded end received in a threaded aperture of a first support ring, and a second unthreaded and shouldered end received in a countersunk and unthreaded aperture of a second support ring. Each end of each pin extends through its respective support ring and is rivetingly domed outside the support ring to secure its position and configuration. The pinned roller bearings and support rings are disposed within an outer and inner race.

Owner:ENGINEERED BEARING TECH INC

Positioning bearing structure for device

PendingCN112450627AEasy to holdEfficient storageRefuse receptaclesKitchen cabinetsEngineeringStructural engineering

The invention discloses a positioning bearing structure for a device. The structure comprises a left supporting part and a right supporting part which are arranged on the lower portion of a left sideplate and the lower portion of a right side plate respectively, a bearing device is arranged between the left supporting part and the right supporting part and comprises a front transverse rod telescopic assembly, a middle transverse rod telescopic assembly and a rear transverse rod telescopic assembly, front and back movable pieces transversely move on the front transverse rod telescopic assemblyand the middle transverse rod telescopic assembly respectively, and a middle movable piece transversely moves on the middle transverse rod telescopic assembly; connecting rods are arranged among thefront, middle and rear movable pieces; the middle transverse rod telescopic assembly and the middle movable piece synchronously and longitudinally slide between the front and rear transverse rod telescopic assemblies through the connecting rods; at least two containing devices and a bearing area with the adjustable longitudinal and / or transverse size are formed between the front, middle and rear transverse rod telescopic assemblies and the front, middle and rear movable pieces when the assemblies and movable pieces move. Limiting parts are arranged on the front side and the rear side of the middle movable piece. And the at least two devices are positioned and placed on the bearing area in a suspended mode, and the at least two devices are mutually limited through the limiting parts of themiddle movable piece when being placed. Through the improvement of the structure, the practicability is high.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

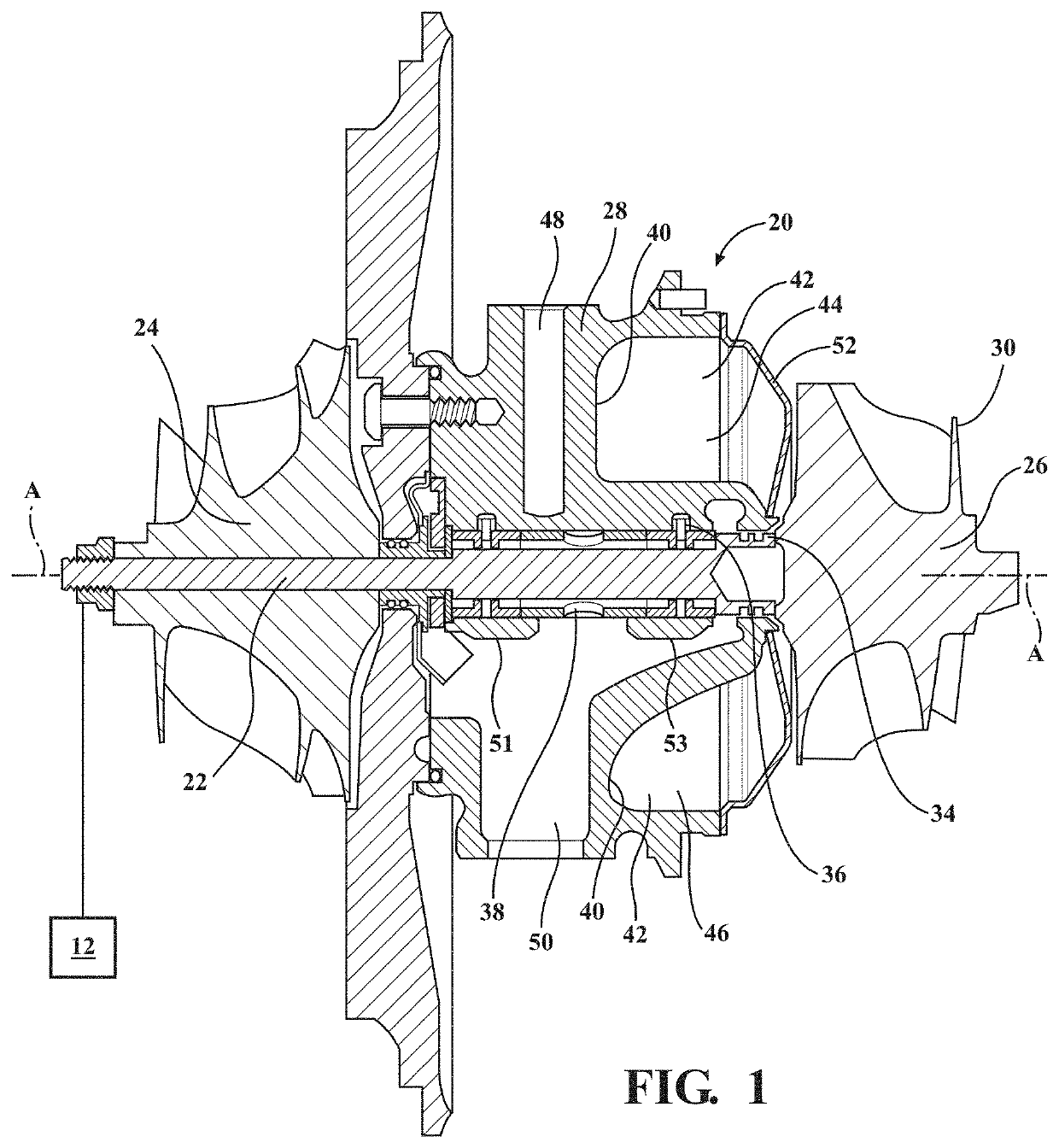

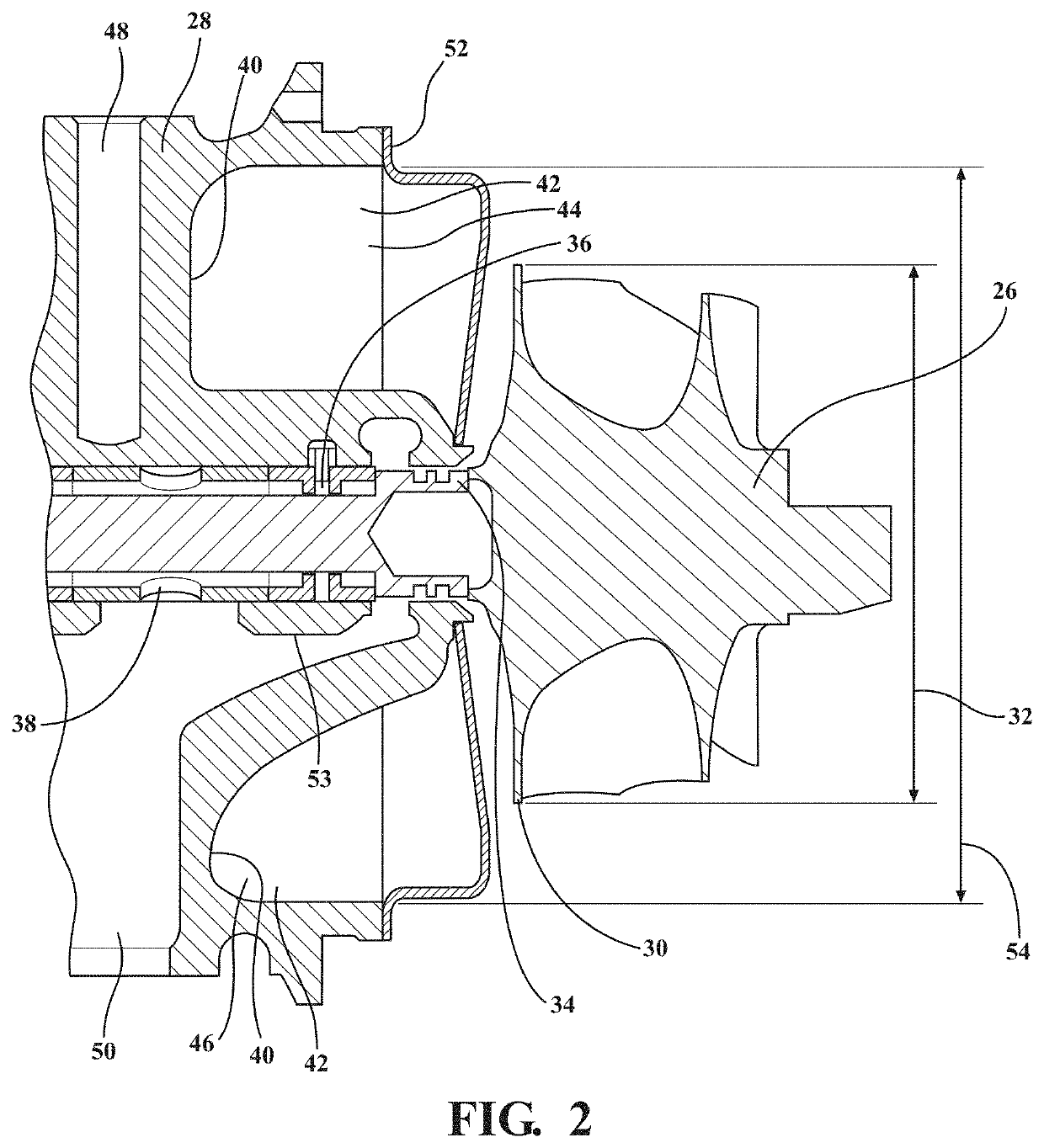

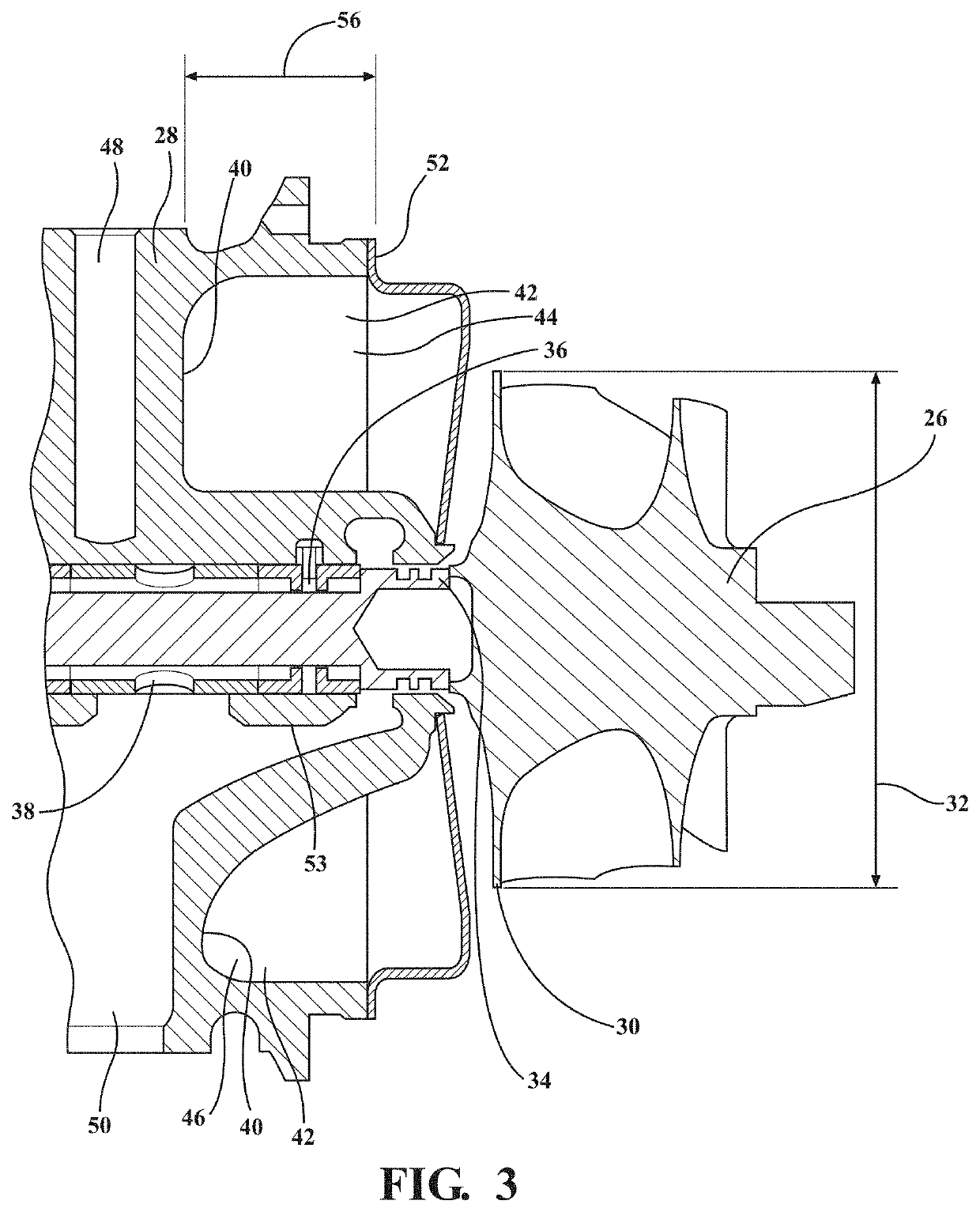

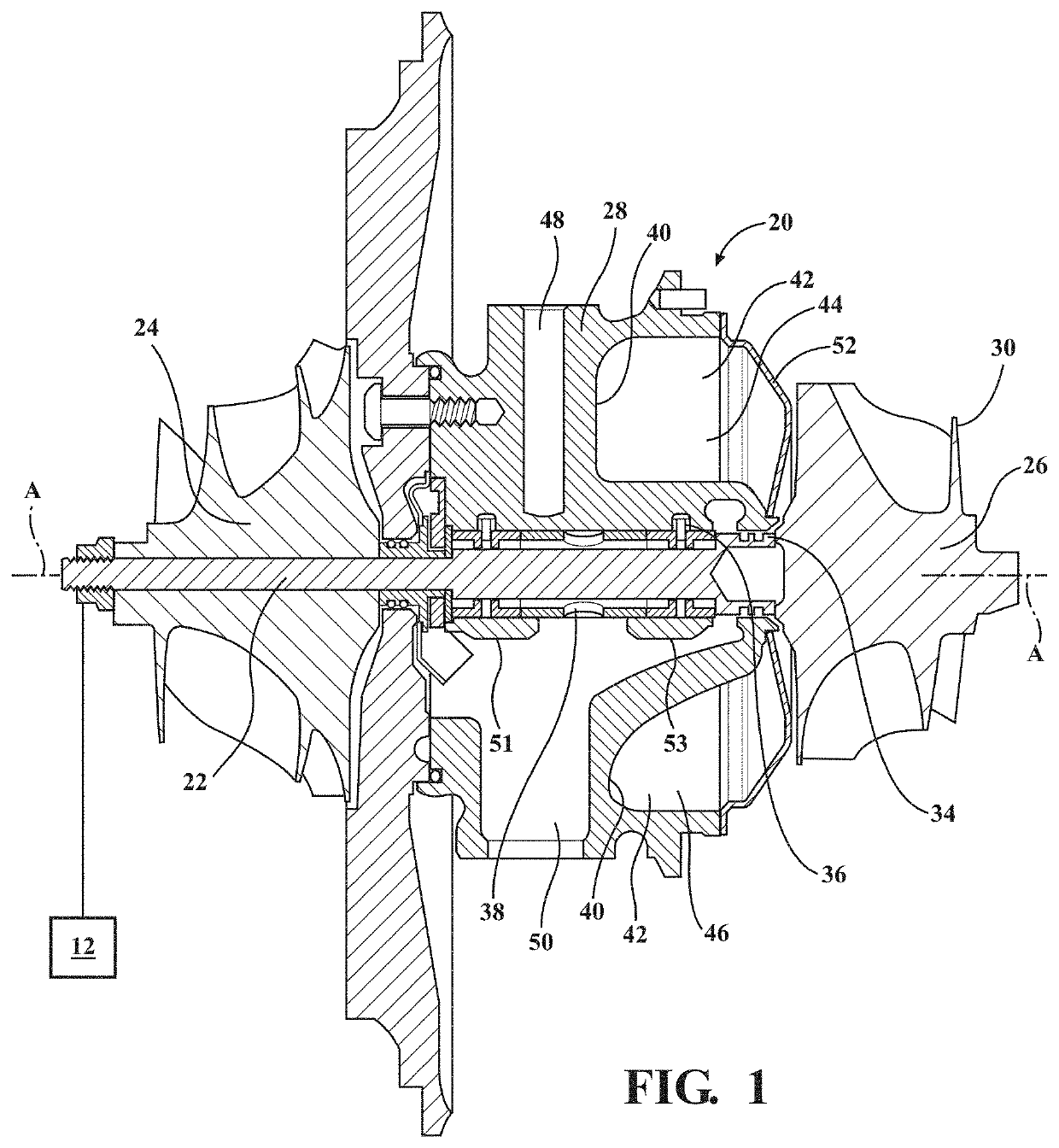

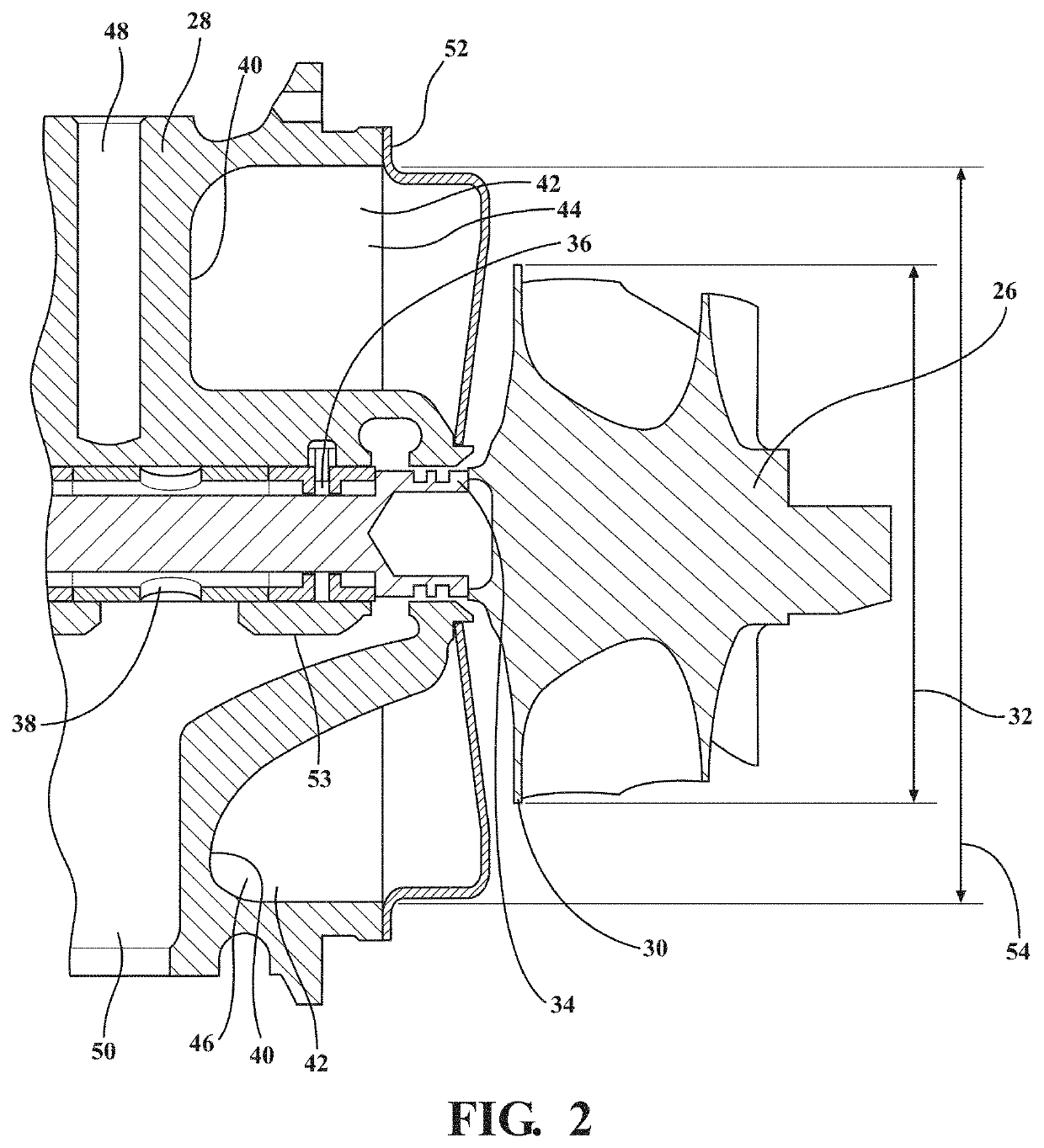

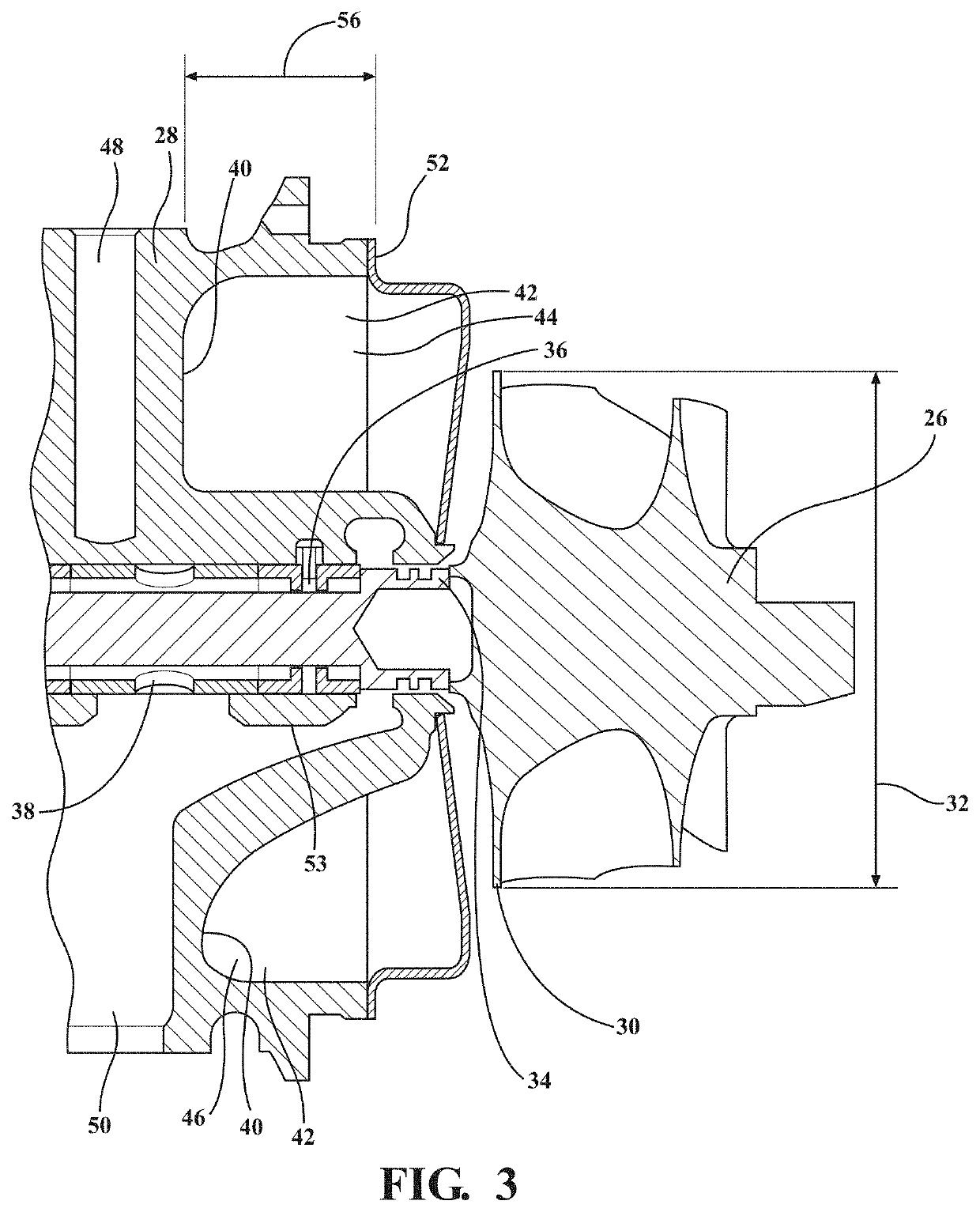

Turbocharger having a thermal dam

ActiveUS20210324788A1Reduce heat transferImprove compressor performanceShaftsCombustion enginesImpellerTurbine wheel

A turbocharger includes a shaft extending along an axis, a compressor wheel coupled to a first end of the shaft, a turbine wheel coupled to a second end of the shaft and having a first diameter; and a bearing housing extending about the shaft. The bearing housing is disposed between the compressor wheel and the turbine wheel. The bearing housing having a thermal dam having a volume extending circumferentially about the shaft and disposed proximate to the second end of the shaft between the compressor wheel and the turbine wheel. The thermal dam has a second diameter extending radially from the shaft. Moreover, the second diameter of the thermal dam is between 1.1 and 1.2 times greater than the first diameter of the turbine wheel.

Owner:BORGWARNER INC

A kind of high-load vehicle trunk spare tire cover plate and preparation method thereof

ActiveCN106183133BHigh strengthImprove toughnessLamination ancillary operationsLaminationEngineeringMetal sheet

The invention discloses a laminated plate for cars and particularly relates to a high-load spare tire cover plate for a car trunk. The high-load spare tire cover plate comprises a PU layer. Metal sheets are composited to the surfaces of the single side or double sides of the PU layer. A car decoration fabric layer is composited to the metal sheet on one optional side. A non-woven fabric layer wraps the surfaces of the areas, other than the area covered with the car decoration fabric layer, of the PU laminated plate. The periphery of the non-woven fabric layer is adhered to the car decoration fabric layer under pressure. The invention further provides a production method of the high-load spare tire cover plate. The high-load spare tire cover plate has the advantages that the structural strength and toughness of the PU laminated plates for the cars are increased, and the high-load spare tire cover plate is high in plate strength, good in toughness, good in bearing stability, little in limitation as car plates, and the like.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Turbocharger having a thermal dam

ActiveUS11215111B2Reduce heat transferImprove compressor performanceShaftsCombustion enginesImpellerThermodynamics

A turbocharger includes a shaft extending along an axis, a compressor wheel coupled to a first end of the shaft, a turbine wheel coupled to a second end of the shaft and having a first diameter; and a bearing housing extending about the shaft. The bearing housing is disposed between the compressor wheel and the turbine wheel. The bearing housing having a thermal dam having a volume extending circumferentially about the shaft and disposed proximate to the second end of the shaft between the compressor wheel and the turbine wheel. The thermal dam has a second diameter extending radially from the shaft. Moreover, the second diameter of the thermal dam is between 1.1 and 1.2 times greater than the first diameter of the turbine wheel.

Owner:BORGWARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com