High-load spare tire cover plate for car trunk and production method of high-load spare tire cover plate

A spare tire cover and trunk technology, which is applied in spare tire layout, chemical instruments and methods, vehicle parts, etc., can solve the problems of insufficient strength and toughness, and achieve small limitations, good bearing stability, and toughness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

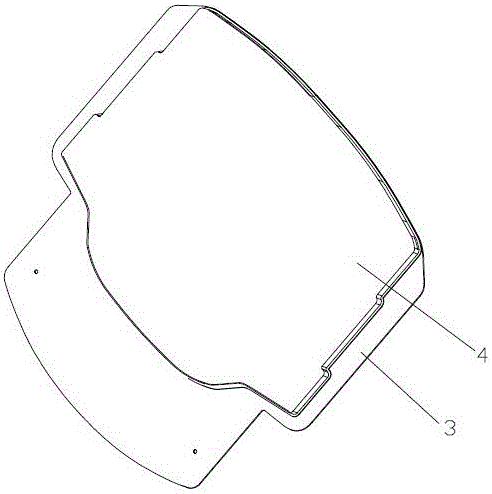

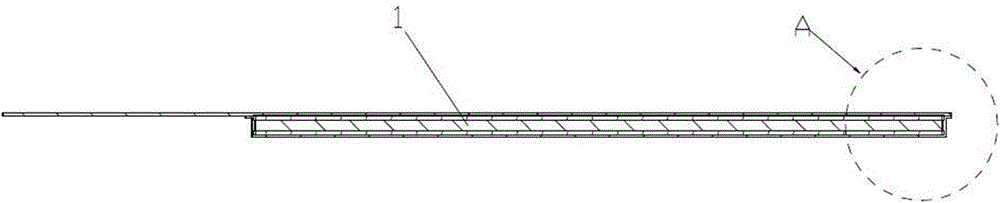

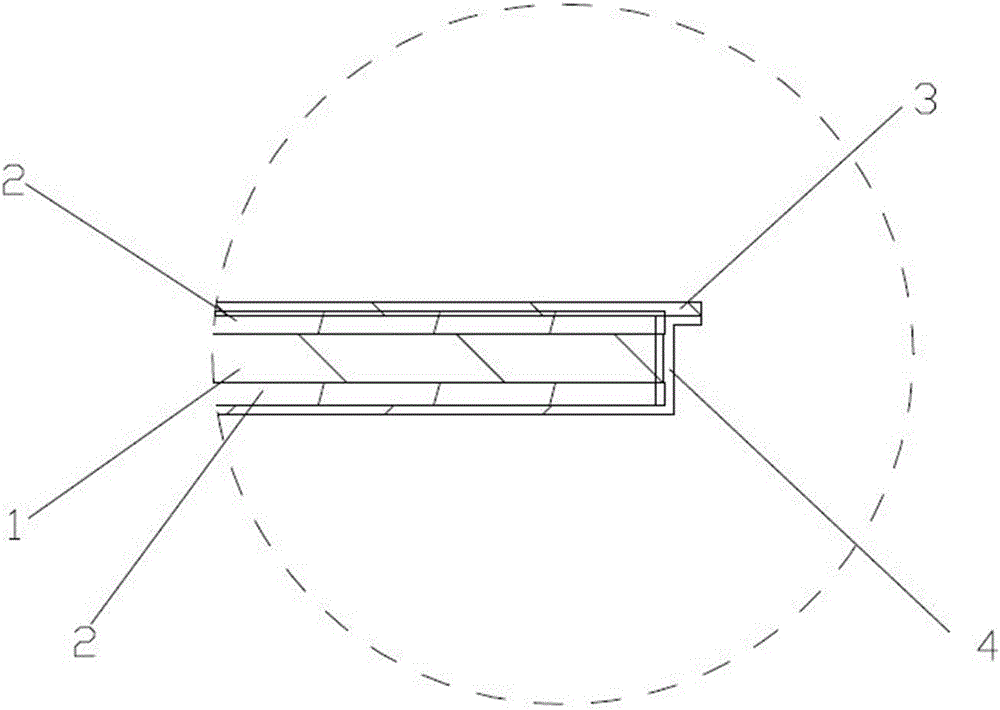

[0027] Such as Figure 1-3 As shown, a kind of high-load vehicle trunk spare tire cover provided in this embodiment includes a PU layer 1, and a metal sheet 2 is compounded on the surface of both sides of the PU layer 1. The metal sheet 2 on the side is compounded with a vehicle decorative fabric layer 3, and the surface of the PU laminated board is covered with a non-woven fabric layer 4 except for the vehicle decorative fabric layer 3. Both the peripheral edge of the layer 4 and the peripheral edge of the automotive decorative fabric layer 3 are pressure-bonded.

[0028] Simultaneously, the present invention also provides a method for preparing a spare tire cover for a high-load vehicle trunk as described above, which uses a metal blanking machine or a high-pressure water cutting machine, a foaming machine and a hydraulic press, and is characterized in that it includes the following steps:

[0029] Step 1, punching; the metal sheet 2 is punched and formed by a metal punchin...

Embodiment 2

[0034] The general structure of the spare tire cover for a high-load vehicle trunk provided in this embodiment is consistent with that of Embodiment 1, but in order to facilitate the PU lamination after the above-mentioned PU laminated board is used on the car body The overall lifting and flipping operation of the board, such as Figure 4 and Figure 5 As shown, the PU laminated board in this embodiment is also provided with a handle installation hole 5, and a handle 6 is connected to the handle installation hole 5.

[0035] The preparation method of the spare tire cover of a high-load vehicle trunk provided in this embodiment is also similar to the preparation method of the spare tire cover of a high-load vehicle trunk provided in the embodiment. Consistent, but in this embodiment, considering that the handle installation hole 5 has been opened on the PU laminated board, the PU foamed laminated body, automotive decorative fabric and non-woven fabric base are used in step 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com