Manufacturing process for fiber cement board

A technology of fiber cement board and manufacturing process, which is applied in the direction of building structure, construction, covering/lining, etc., which can solve the problems of unsatisfactory product qualification rate, reduced board strength, autoclaved cracks, etc., to reduce the probability of autoclaved cracks , increase the strength of the board, and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Example Manufacturing process of fiber cement board

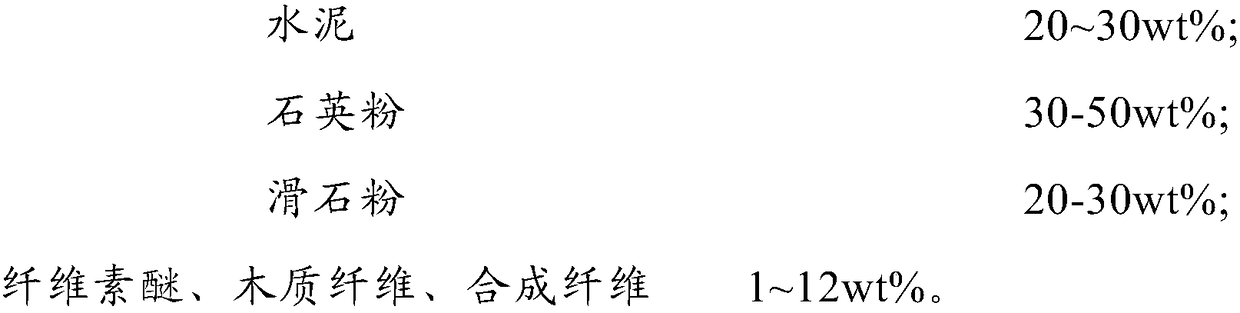

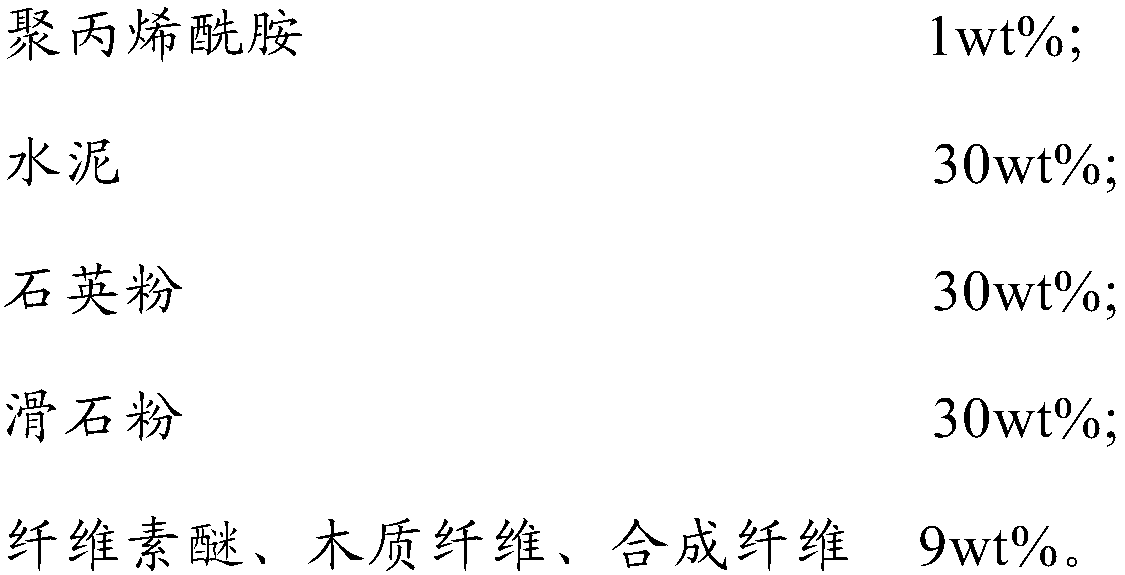

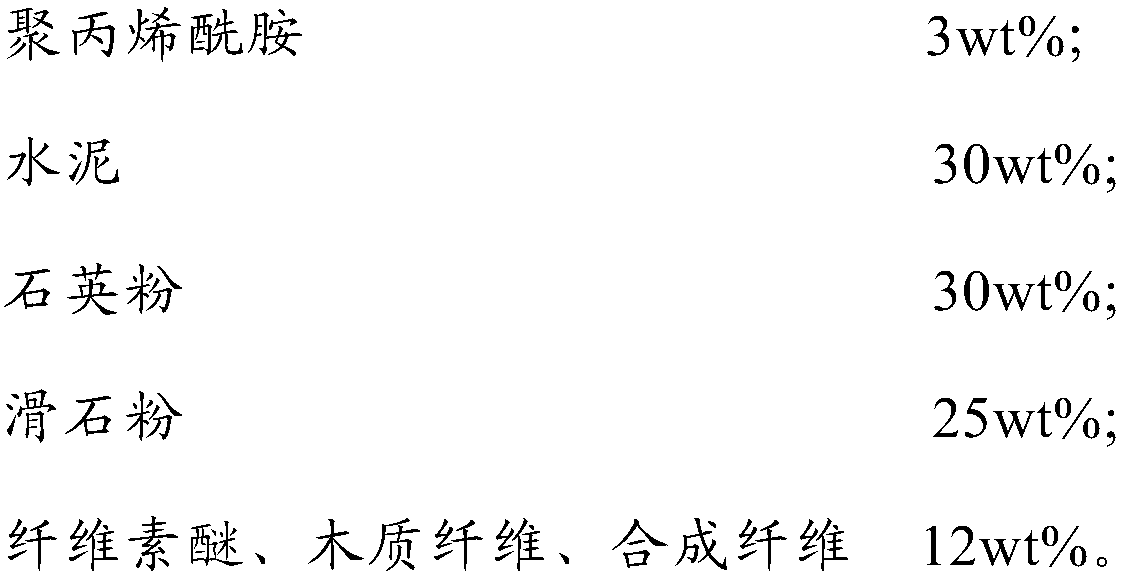

[0031] Craft one

[0032] First, dry-mix the wood fiber with a mixer, the dry mixing speed is 700rpm, and the dry mixing time is 10s, then add P·Ⅱ52.5 cement, 200 mesh quartz powder, polyacrylamide, 325 mesh talcum powder, cellulose ether, Synthetic fiber is continued to be dry-stirred, and the dry-stirring speed is 700rpm, and the dry-stirring time is 20s, and then wet stirring is added, and the stirring time is 95 seconds, and the stirring speed is 600rpm, and the raw materials of the fiber cement board are obtained, wherein polyacrylamide, The content of P·Ⅱ52.5 cement, 200 mesh quartz powder, polyacrylamide, 325 mesh talcum powder, cellulose ether, synthetic fiber and wood fiber is:

[0033]

[0034] Secondly, use a kneader to knead the raw materials of the fiber cement board, the kneading time is 180s, and the kneading speed is greater than or equal to 65rpm.

[0035] Thirdly, the fiber cement board protot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com