Preparation method of 6-series aluminum alloy precision casting quenching plate

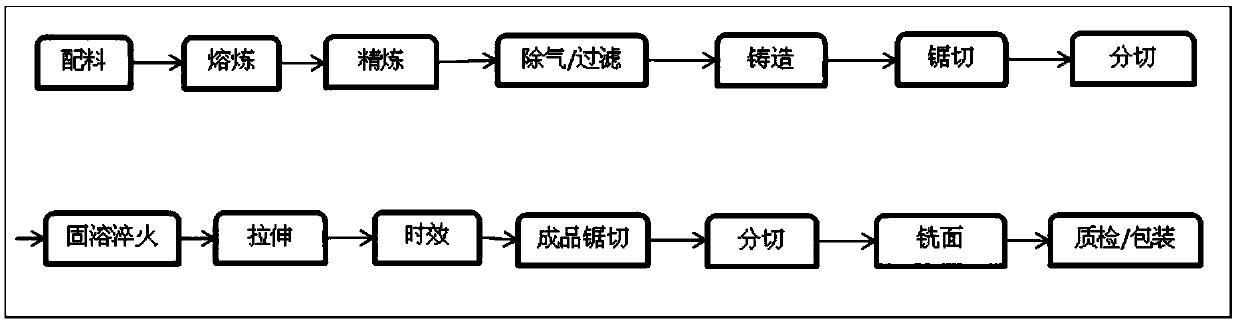

A precision casting and aluminum alloy ingot casting technology, which is applied in the field of aluminum alloy, can solve the problems of limiting the development space of aluminum alloy precision casting plates, incomplete internal stress release, and failure to satisfy customers, etc., to achieve low internal stress and fine grain structure The effect of uniformity and streamlining of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

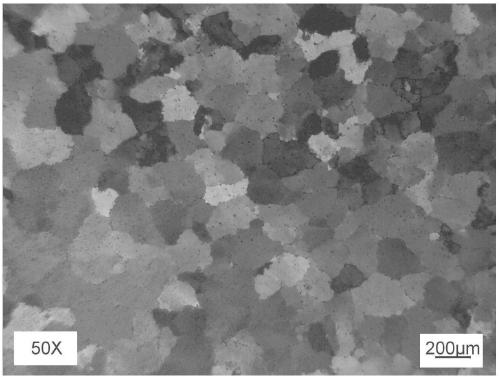

Embodiment 1

[0038] 1. Melting 6061 aluminum alloy, the composition is as A1 in Table 1. After degassing and filtering, the hydrogen content is 0.18ml / 100gAl, and semi-continuous casting is carried out to cast a flat ingot with a size of 450*1550*6000mm.

[0039] 2. Turn the four sides and one side of the cast ingot to 5mm, remove the casting segregation layer, cut and rough mill the surface into a 50*1530*6000mm plate.

[0040] 3. The plate obtained by rough milling is subjected to solution quenching, the heating rate is 10°C / min, the temperature is raised to 500°C, and the temperature is kept for 5 minutes.

[0041] 4. Stretch the above-mentioned quenched plate, the stretching rate is 15 mm / min, and the stretching rate is 1.5%.

[0042] 5. Aging, aging temperature 185 ℃, heat preservation 10h.

[0043] 6. Sawing and cutting into 50*1420*5000mm, cutting into 19*1420*5000mm, sawing speed 2100m / min, sawing speed 30dm 2 / mn, 260mm / min; feeding speed 70%, 45mm / min; table speed: 60mm / mmin. ...

Embodiment 2

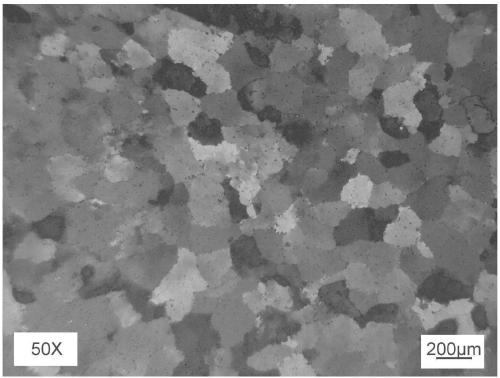

[0047] 1. Melting 6082 aluminum alloy, the composition is as B1 in Table 1, after degassing and filtering, the hydrogen content is 0.15ml / 100gAl, and semi-continuous casting is carried out to cast a flat ingot with a thickness of 650*2250*4500mm.

[0048] 2. Turn the four sides and one side of the cast ingot to 15mm, remove the casting segregation layer, cut and mill the surface into 100*2220*4500mm.

[0049] 3. Perform solution quenching on the slit plates at a heating rate of 50°C / min, raise the temperature to 550°C, and keep it warm for 150 minutes. After the heat preservation is completed, perform rapid high-pressure water quenching at a cooling rate of 32°C / s, and cool to room temperature.

[0050] 4. Stretch the above-mentioned quenched plate, the stretching rate is 6mm / min, and the stretching rate is 2.1%;

[0051] 5. Aging, aging temperature 172 ℃, heat preservation 15h;

[0052] 6. Sawing and cutting into 100*2100*3500mm, cutting into 23*2100*3500mm, sawing speed 250...

Embodiment 3

[0056] 1. Melting 6013 aluminum alloy, the composition is as C1 in Table 1, after degassing and filtering, the hydrogen content is 0.10ml / 100gAl, carry out semi-continuous casting, and cast a flat ingot with a thickness of 650*1850*4000mm.

[0057] 2. Turn the four sides and one side of the cast ingot to 20mm, remove the casting segregation layer, cut and mill the surface into 210*1830*4000mm.

[0058] 3. Perform solution quenching on the slit plates at a heating rate of 120°C / min, raise the temperature to 580°C, and keep warm for 300 minutes. After the heat preservation is completed, perform rapid high-pressure water quenching, cooling at a rate of 10°C / s, and cool to room temperature.

[0059] 4. Stretch the above-mentioned quenched plate, the stretching rate is 1.5mm / min, and the stretching rate is 3.0%;

[0060] 5. Aging, aging temperature 160 ℃, heat preservation 25h;

[0061] 6. Sawing and cutting into 210*1700*3000mm, cutting into 10*1700*3000mm, sawing speed 1600m / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com