Ultraviolet light curing transfer film and its preparation method and application

A technology of ultraviolet light and transfer film, which is applied in the field of decorative materials, can solve the problems of exhaust gas pollution, plate falling and separation, etc., and achieve the effect of full paint film, good environmental protection and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162] Example 1: Imitation of large white or black and white marble colorful transfer film

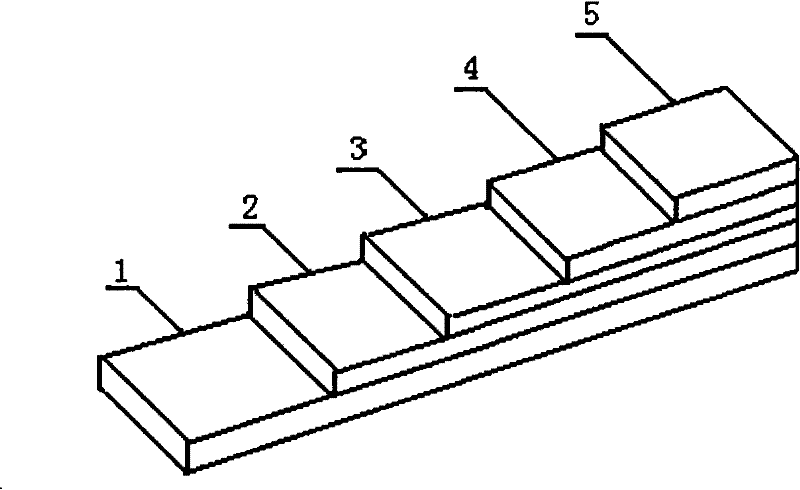

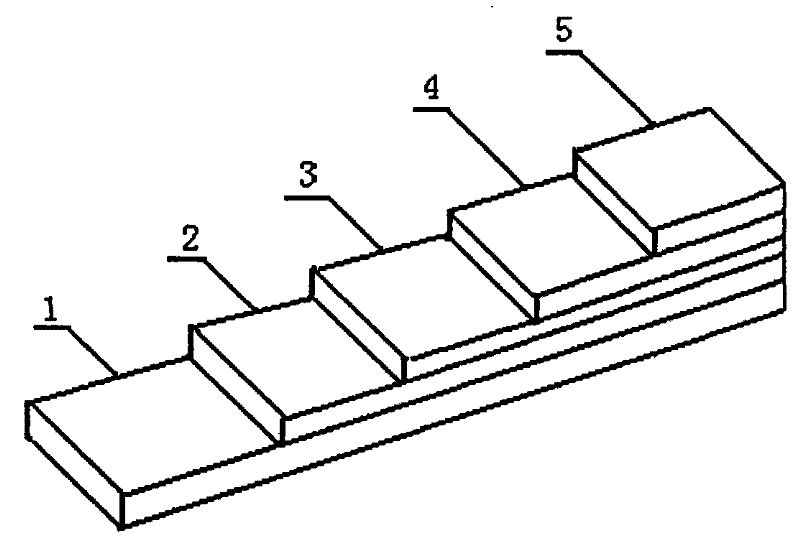

[0163] The structure of imitation large white or black and white marble colorful transfer film can be found in figure 1 . It consists of a base carrier film 1, a release agent layer 2, a UV-curable protective layer 3, a UV-curable ink decorative pattern layer 4, and a UV-curable paint base color layer 5. Concrete preparation method comprises the following steps:

[0164] 1) Pre-shrink the polypropylene film (base carrier film) at 120°C to remove static electricity.

[0165] 2) Infrared curing is carried out after uniform coating or printing of the release agent on the surface of the polypropylene film obtained in step 1); infrared curing is to adjust the infrared heating temperature to 60°C, and the leveling time is 1 minute, so that the release agent is fully cured Obtain a release agent layer with a thickness of 1 micron;

[0166] In terms of weight percentage, the release agent...

Embodiment 2

[0178] Example 2: Beige or light yellow multi-colored transfer film imitating Shaanna

[0179] The structure of the imitation Shaanna beige or light yellow multicolored transfer film is the same as that in Example 1. Concrete preparation method comprises the following steps:

[0180] 1) Bake and pre-shrink the polyethylene film (base carrier film) at 160°C to remove static electricity.

[0181] 2) Infrared curing is carried out after the polyethylene film surface obtained in step 1) is evenly coated or printed with a release agent. Infrared curing is to adjust the infrared heating temperature to 150 ° C, the leveling time is 0.01 minutes, and the solvent in the coating is fully Volatilize; after the release agent is fully cured, a release agent layer with a thickness of 5 microns is obtained;

[0182] In terms of weight percentage, the release agent is: 30% of hydroxymethyl cellulose, 25% of carnauba wax, 15% of methyl ethyl ketone, 5% of ethyl acetate, 11% of fluorine-conta...

Embodiment 3

[0196] Embodiment 3: Imitation wood grain colorful transfer film

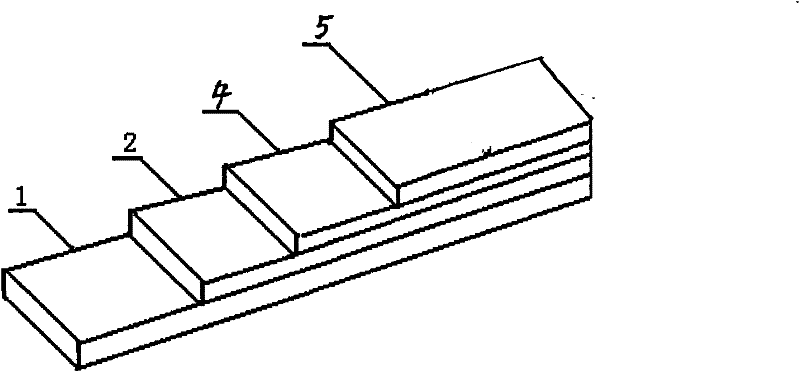

[0197] The structure of imitation wood grain colorful transfer film can be found in figure 2 . It is composed of a base carrier film 1, a release agent layer 2, a UV-curable ink decorative pattern layer 4, and a UV-curable paint base color layer 5. Concrete preparation method comprises the following steps:

[0198] 1) Bake and pre-shrink the polyvinyl chloride film (base carrier film) at 180°C to remove static electricity.

[0199] 2) Infrared curing is carried out after the surface of the polyvinyl chloride film obtained in step 1) is evenly coated or printed with a release agent. Infrared curing is to adjust the infrared heating temperature to 80 ° C, the leveling time is 2 minutes, and the solvent in the coating Fully volatilize; after the release agent is fully cured, a release agent layer with a thickness of 100 microns is obtained;

[0200] In terms of weight percentage, the release agent is: 30% hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com