Support lattice shell of concrete spherical shell structure and construction method

A spherical shell structure and concrete technology, applied in the direction of arch structure, dome roof structure, building components, etc., can solve the problems that the quality of concrete molding is difficult to meet the requirements of structural design, the difficulty of laying out lines, etc., and reduce the amount of wood used. , Improve the construction quality and ensure the effect of structural accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

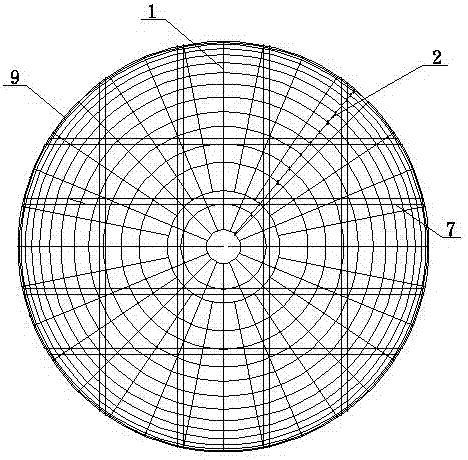

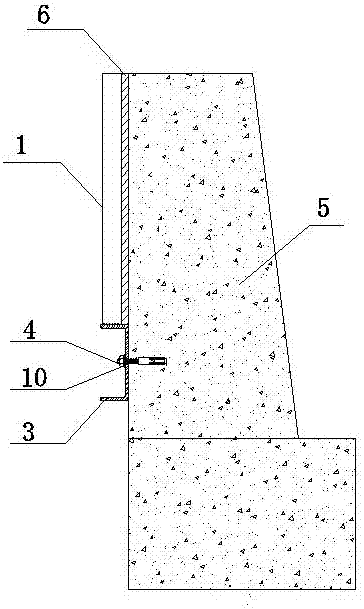

[0038] Step 1: Deepen the design of the radial steel pipe 1, the circumferential steel pipe 2, the expansion bolt annular member 3, and the expansion bolt 4, determine the number and spacing of the radial steel pipe 1, the circumferential steel pipe 2, and the expansion bolt 4 according to the structural construction load, and determine The section size of the expansion bolt ring member 3 is determined according to the structure of the radial steel pipe 1, the circumferential steel pipe 2, and the arc of the expansion bolt ring member 3;

[0039] Step 2, select the installation method of the expansion bolt 4 according to the construction needs, and then fix the expansion bolt annular member 3 in the concrete spherical shell 5 through the expansion bolt 4;

[0040] Step 3: First assemble the radial steel pipe 1 and the circumferential steel pipe 2 on the ground, so that the radial steel pipe 1 and the circumferential steel pipe 2 form a separate segmented reticulated shell 901, ...

Embodiment 2

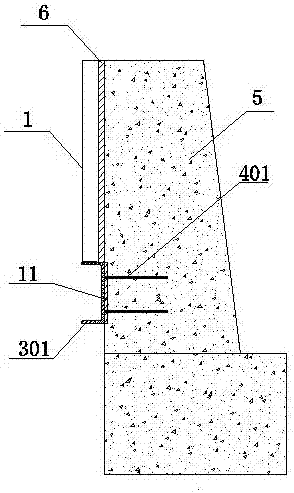

[0044] Step 1: Carry out in-depth design on the radial steel pipe 1, the circumferential steel pipe 2, the embedded part annular member 301, and the embedded part 401, and determine the quantity and The spacing is to determine the cross-sectional size of the embedded part ring member 301, and determine the arc of the radial steel pipe 1, the circumferential steel pipe 2, and the embedded part ring member 301 according to the structure;

[0045] Step 2: Select the installation method of the embedded part 401 according to the construction needs, and then fix the embedded part ring member 301 in the concrete spherical shell 5 through the embedded part 401;

[0046] Step 3: First assemble the radial steel pipe 1 and the circumferential steel pipe 2 on the ground, so that the radial steel pipe 1 and the circumferential steel pipe 2 form a separate segmented reticulated shell 901, and wait until the required number of fragmented reticulated shells is reached After 901, the assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com