Novel thin coal seam overlapped side-unloading structure

A thin coal seam, side unloading technology, applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems of high labor intensity, excessive lag of the end support, and easy danger, so as to improve safety and coal mining Efficiency, avoiding excessive lag, and reducing the effect of support difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

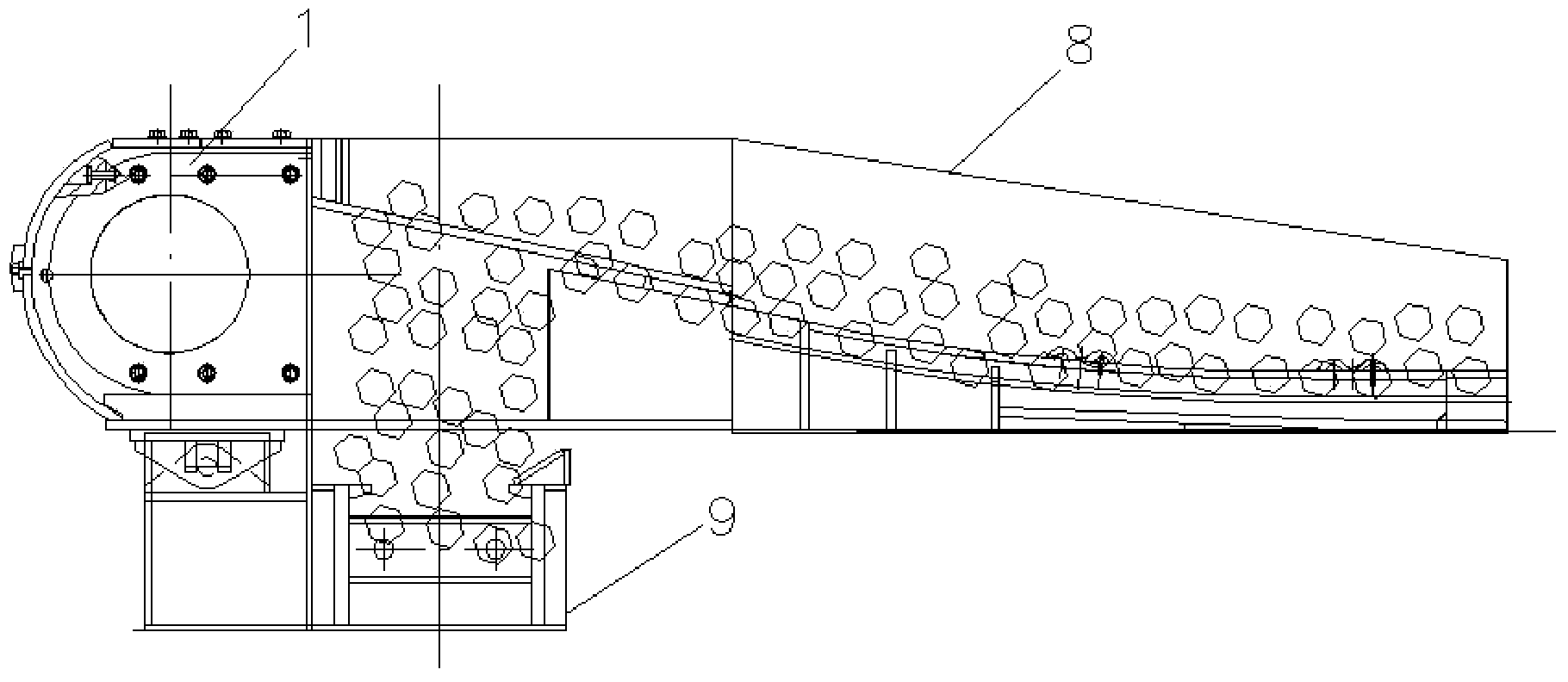

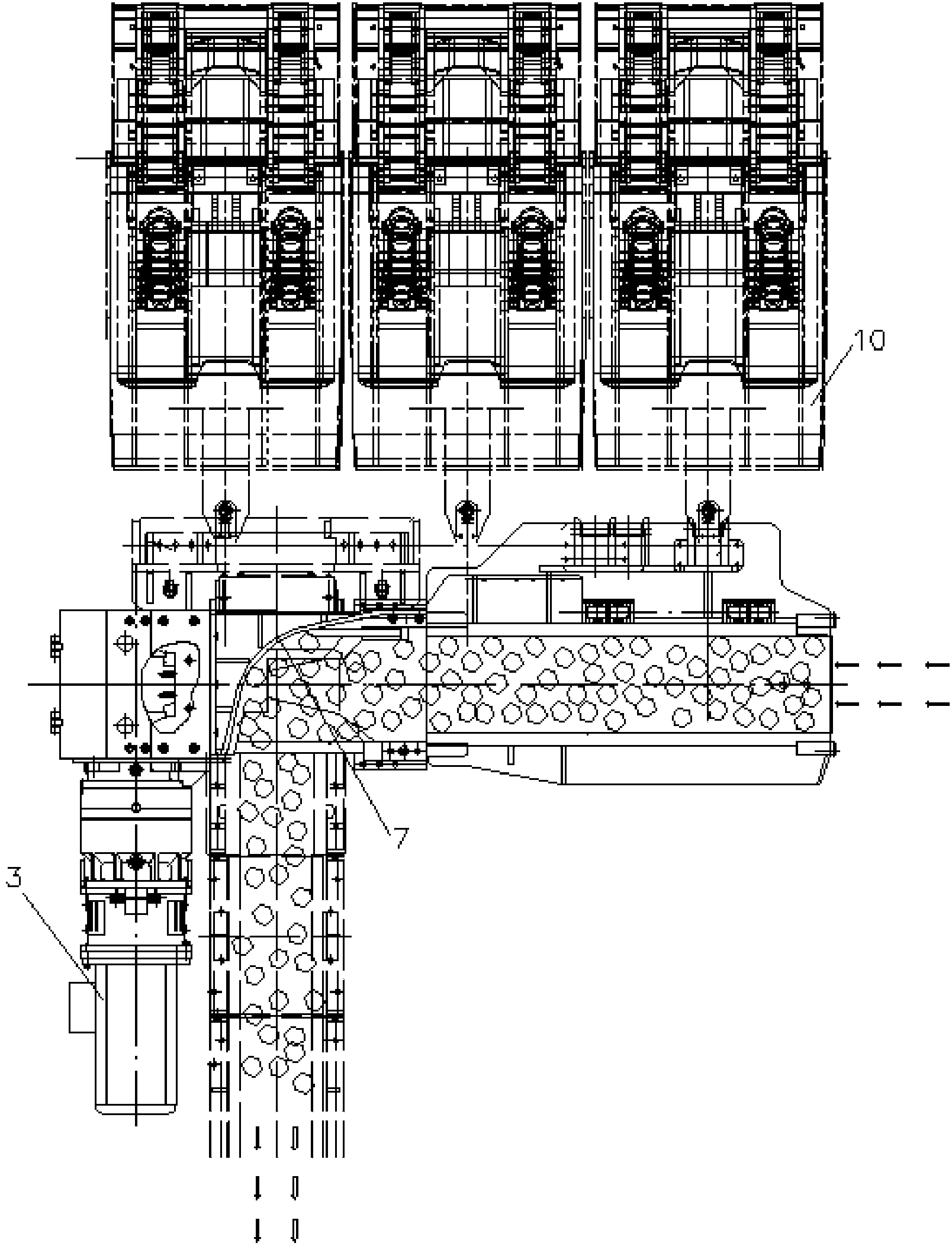

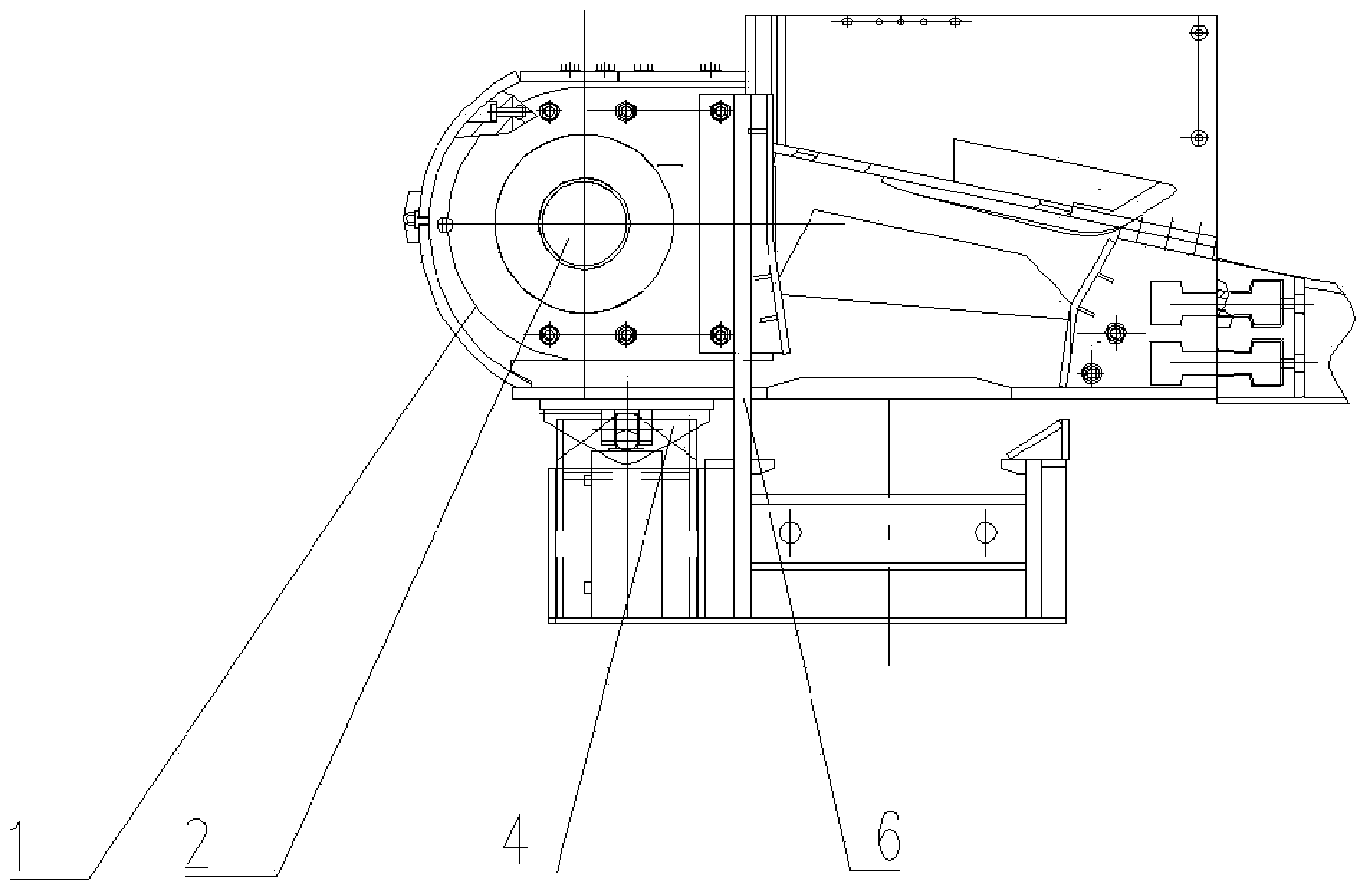

[0017] Such as figure 1 , 2 , 3, and 4, the present invention is a novel thin coal seam overlapping side unloading structure, comprising a conveyor 8 and a loader 9, an unloading connection groove 5 is installed at the tail of the loader 9, and the conveyor 8 The head of the machine is fixedly lapped on the unloading connection groove 5 of the 9 machine tails of the reloading machine. An arc-shaped coal plow plate 7 is installed next to the head of the conveyor 8 above the unloading connection groove 5, so that the coal close to the head of the conveyor 8 can be diverted and then fall into the tail of the transfer machine 9 below, and then be transferred by the transfer machine 9 Continue to deliver.

[0018] The machine head of the conveyor 8 includes a head frame 1, on which a sprocket shaft group 2 is installed, and also includes a power part 3 connected to the sprocket shaft group 2, and the power part 3 is arranged in the direction of the coal wall The outer side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com