Coal pillar-free mining gob-side entry retaining roadway supporting system and method for three-soft-stratum coal seam

A technology with three soft coal seams and no coal pillars, which is applied in mining equipment, earthwork drilling, mine roof support, etc., can solve the problems of difficult maintenance of roadway sections, difficult gob-side entry retaining support technology, etc., and achieves a maintenance-free period. The effect of long, large working resistance and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] This embodiment takes the test mine located in the Weibei mining area as an example:

[0055] The test mine is located in the Weibei mining area, which belongs to the third soft coal seam. The existing gob-side entry retention technology for non-coal pillar mining has no obvious effect, the section of the roadway is difficult to maintain, and the floor drum is large. 1. The damage rate of the U-shaped steel gangue pillar is high, the support effect is difficult to guarantee, and the construction difficulty is relatively high.

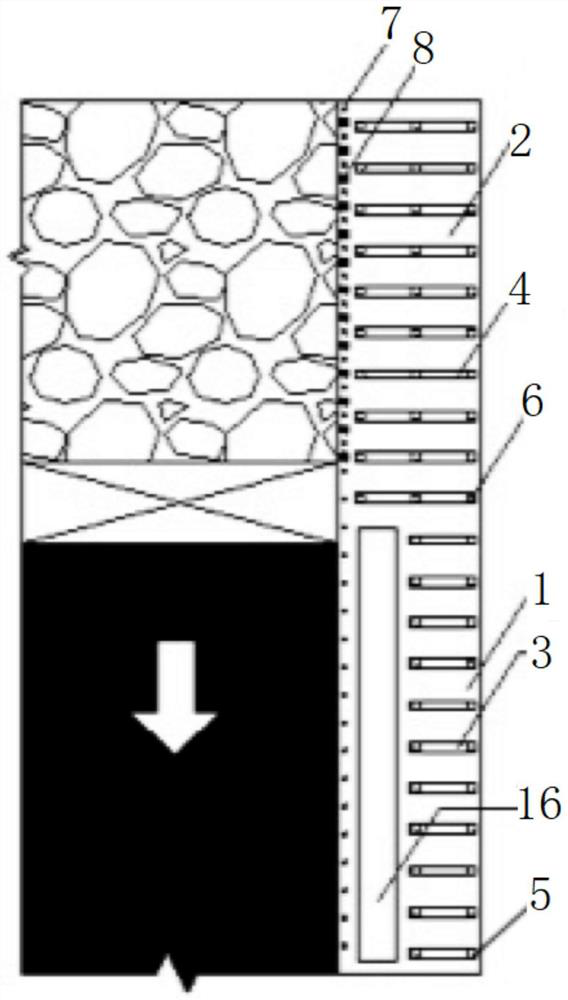

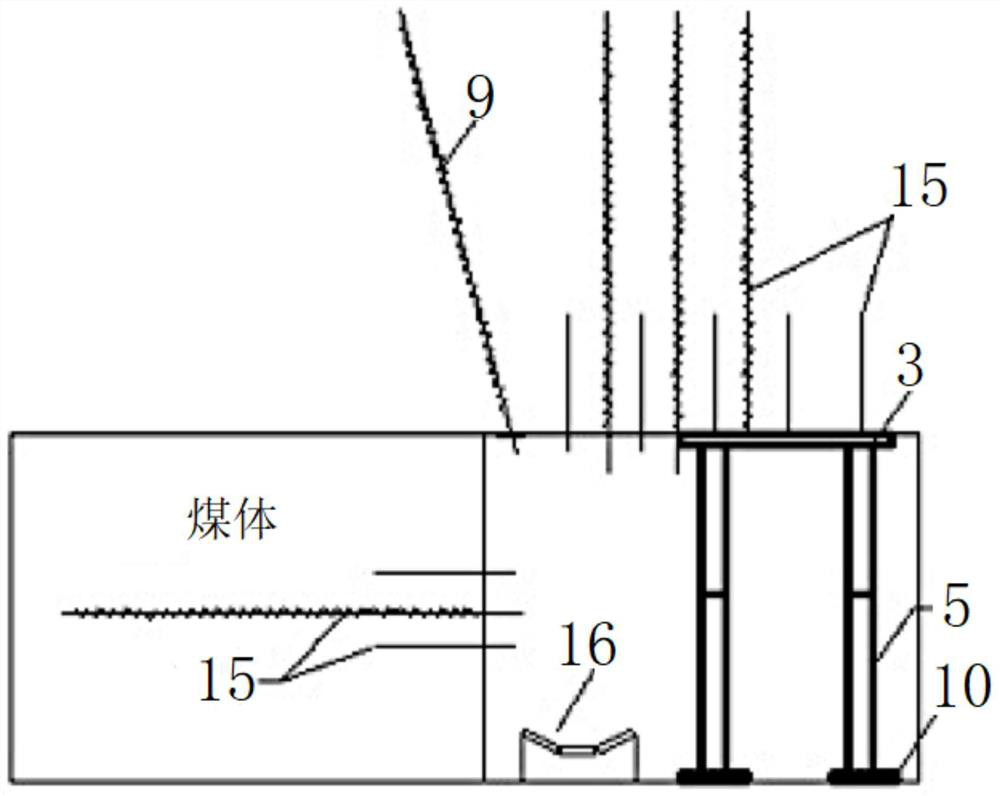

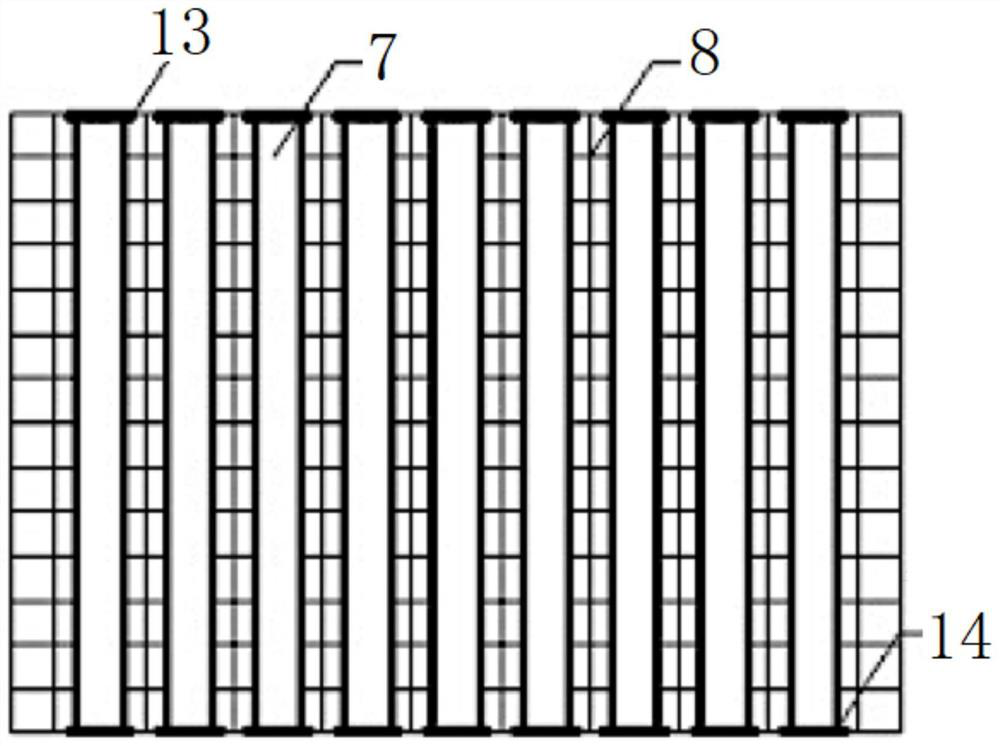

[0056] Aiming at the current situation of support in gob-side entry retaining in three soft coal seams without coal pillars, this embodiment provides a support system and method for gob-side entry entry retaining in three-soft coal seams without coal pillars, and proposes a solution for leading and lagging roadways Based on the original anchor net cable support 15, a special strengthening support measure has been proposed, and it has the effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com