Gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method

A technology of combined support and support body, which is applied in the direction of pillars/brackets, roof beams supporting mine roofs, earthwork drilling and mining, etc., can solve problems such as difficulty in roadway support, and reduce manual lifting and installation. The effect of reducing the difficulty of support and improving the recovery rate of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

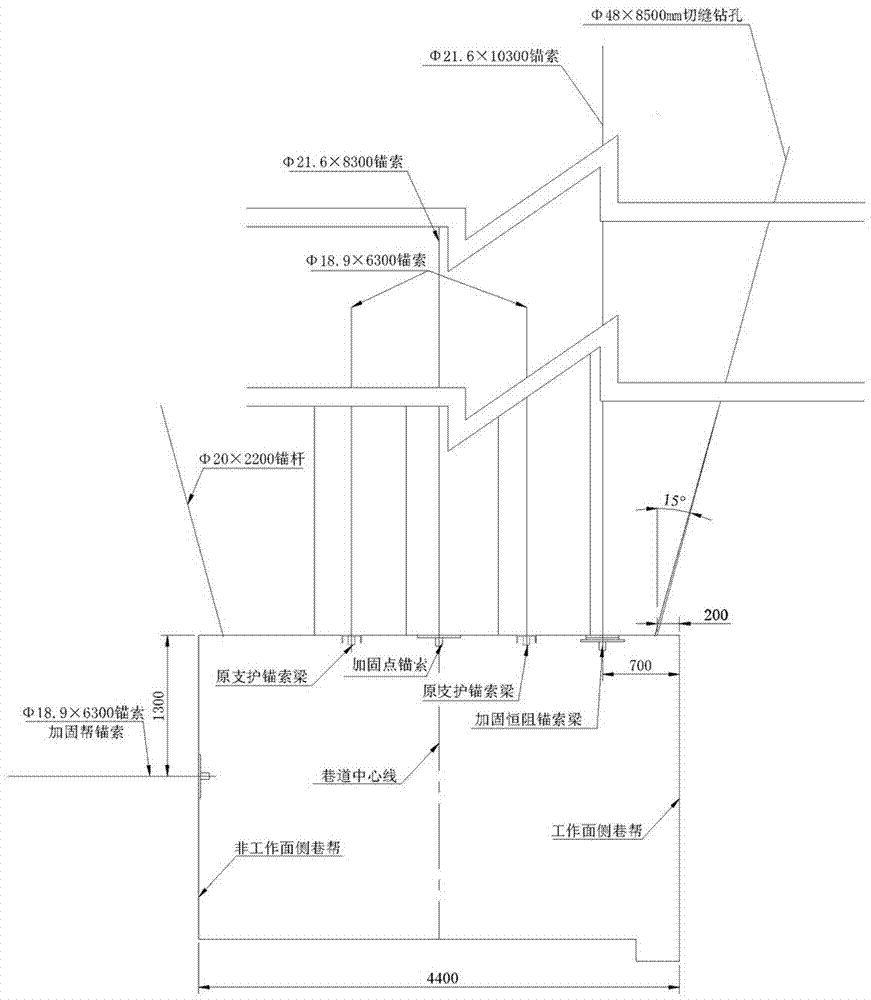

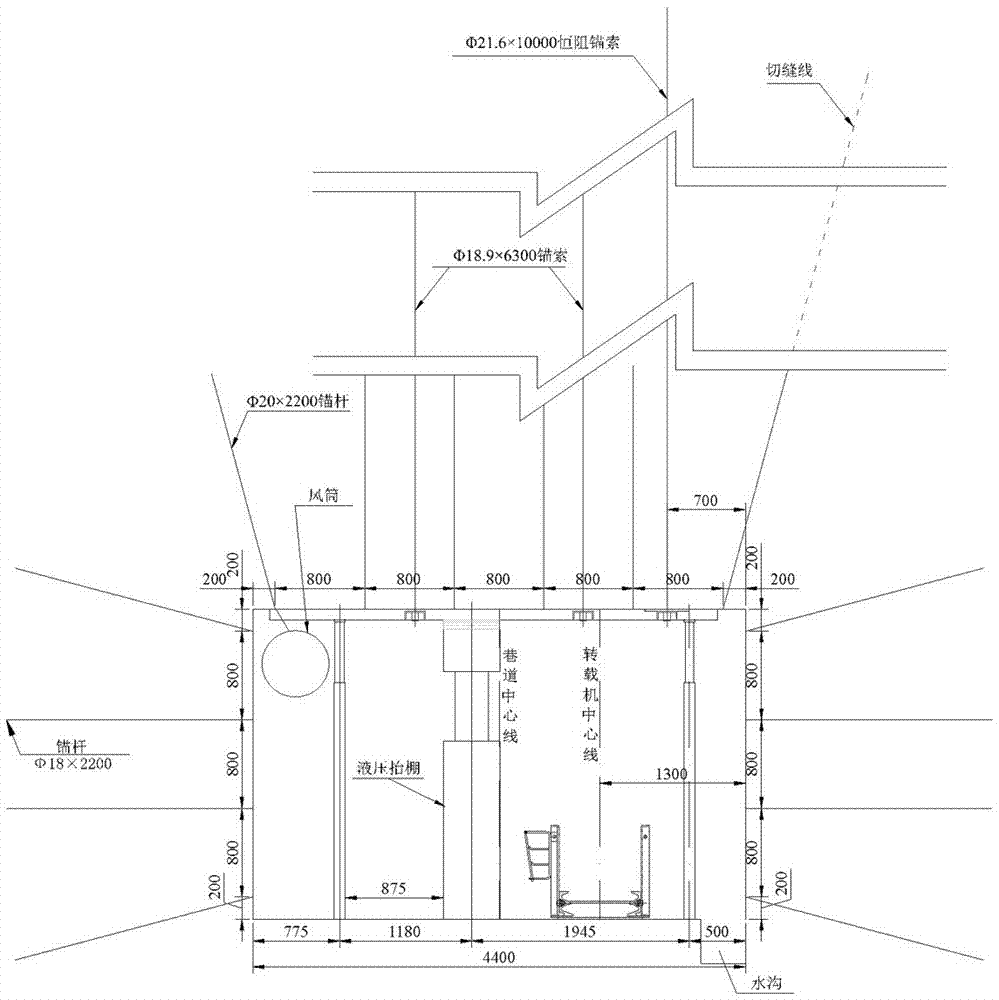

[0025] The joint support method of the flexible support body beside the roadway retaining goaf and the rigid support body in the roadway according to the present invention, arranges a row of point anchor cables in the roadway to reinforce the roadway roof during excavation, and arranges a row of point anchor cables in the roadway side of the non-working face Anchor cables are used to strengthen the side of the roadway. A row of constant resistance anchor cable beams are arranged at a certain distance from the side roadway of the working face to reinforce the roof of the roadway. The lane support area in the lane is divided into "advance support area", "lag support area", "stabilized area for lane formation", and "stable lane formation"; among them, the advance support area is located within 20m outside the working face Inside, a single-row hydraulic shed lift with π-shaped beams and single columns is used for support; the lagging support area is located at 0 to 80m inside the w...

Embodiment 2

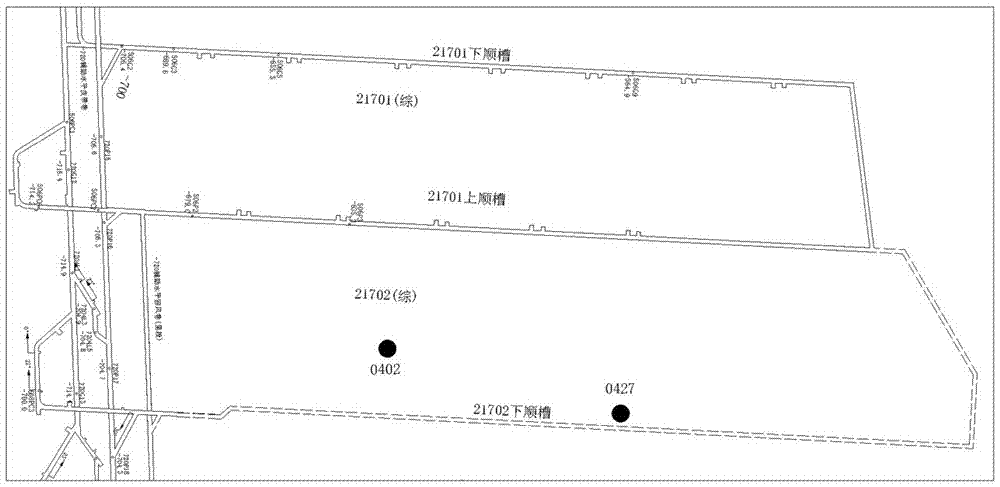

[0027] In this embodiment, taking the 21702 working face of the 17th mining area in the south wing of a coal mine as an example, the joint support and roof cutting, pressure relief and roadway retention technology are implemented.

[0028] General situation of the working face: the corresponding ground elevation of the 21702 working face is +33.96m, and the elevation range of the down channel is -666.7~-522.2m. The north of the working face is the 21701 goaf, the south is the solid coal and the 21703 down-slot that is being excavated, the west is the -720 auxiliary horizontal belt lane, the -720 auxiliary horizontal track lane and the return air lane of the seventeenth mining area, and the east is the 2502 goaf. Down the working face along the groove along the second 2 For coal seam excavation, the design cross section is rectangular, the roadway height of the excavation section is 2.8m, the roadway width is 4.4m, and the net section roadway height is 2.6m. The roadway layou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com