Three-shell collaborative supporting method for surrounding rock of deep well large-section roadway and chamber group

A large-section, deep-well technology, applied in wellbore lining, underground chambers, shaft equipment, etc., can solve the problems of large deformation of surrounding rock, restricting safe and efficient mining of deep mines, and easy instability of supporting structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

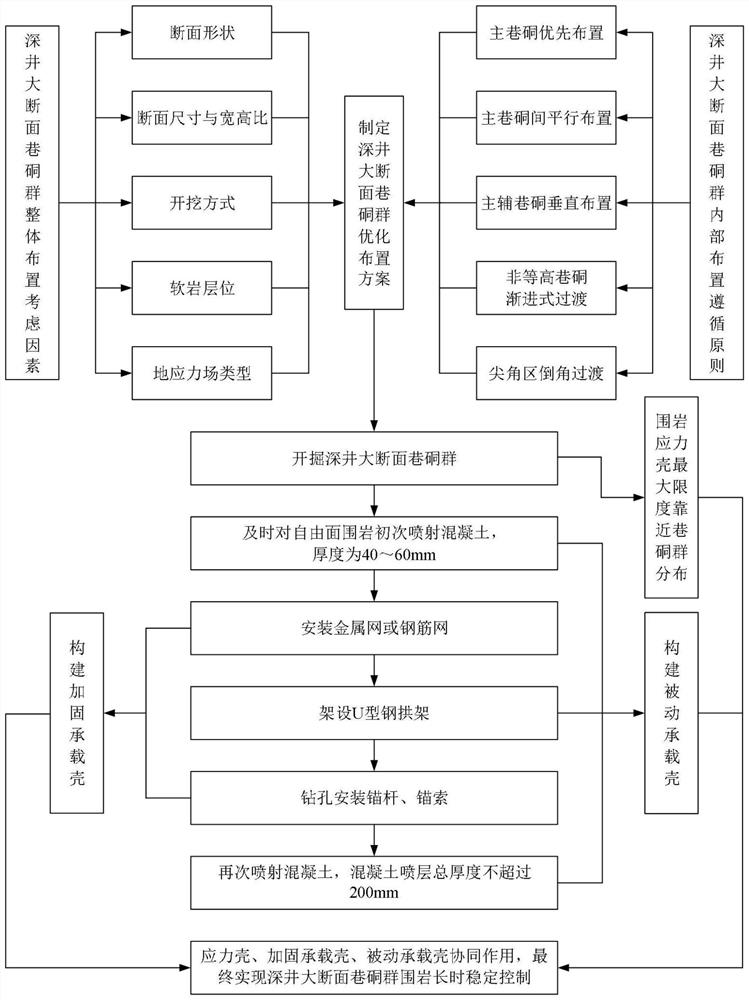

[0044] Such as figure 1 As shown, a "three-shell" coordinated support method for the surrounding rock of a large section roadway group in a deep well, including the following steps:

[0045] a. Geological conditions in the planned layout area of large-section roadway groups in deep wells measured, specifically including geological structure, trend of dominant joints and fissures, surrounding rock lithology, type of in-situ stress field, etc.;

[0046] b. Determine the reasonable cross-sectional shape, optimal layout axis, section size and width-to-height ratio, excavation method, and optimal layout method based on soft rock layers for deep well large-section roadway groups, and initially plan the overall layout of deep well large-section roadway groups plan;

[0047] c. The arrangement of all lanes and aisles in the deep well large-section lane group follows the priority layout of main lanes, parallel arrangement between main lanes, perpendicular arrangement of main lanes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com