Constructional column top concreting method

A technology of structural columns and concrete, which is applied in the field of engineering, can solve the problems of waste of concrete, complex formwork at the inclined opening of structural columns, fluidity and self-weight can not ensure that the concrete on the top of the column is in close contact with the floor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Structural drawings further illustrate the present invention.

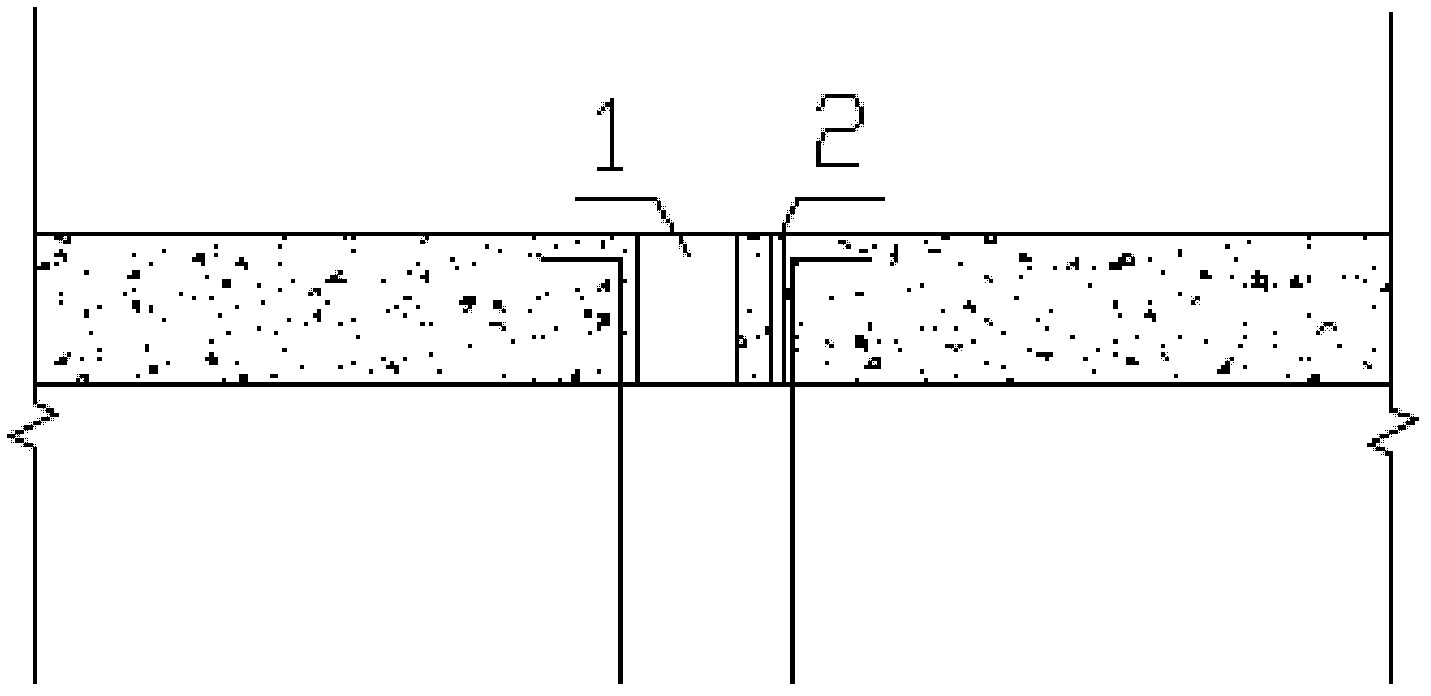

[0012] Such as figure 1 As shown, the present invention is carried out according to the following steps: during the construction of the structure, the casing 1 is pre-embedded at the upper floor of the structural column position, and the exhaust pipe 2 is pre-embedded beside the casing 1, and the column top concrete passes through the pre-embedded The casing of 1 pours the concrete at the top of the structural column, and the air is exhausted through the embedded exhaust 2. The height of the casing and the exhaust pipe is the height of the structural beam or the thickness of the structural plate, and the casing and the exhaust pipe can be steel pipes, iron pipes and plastic pipes.

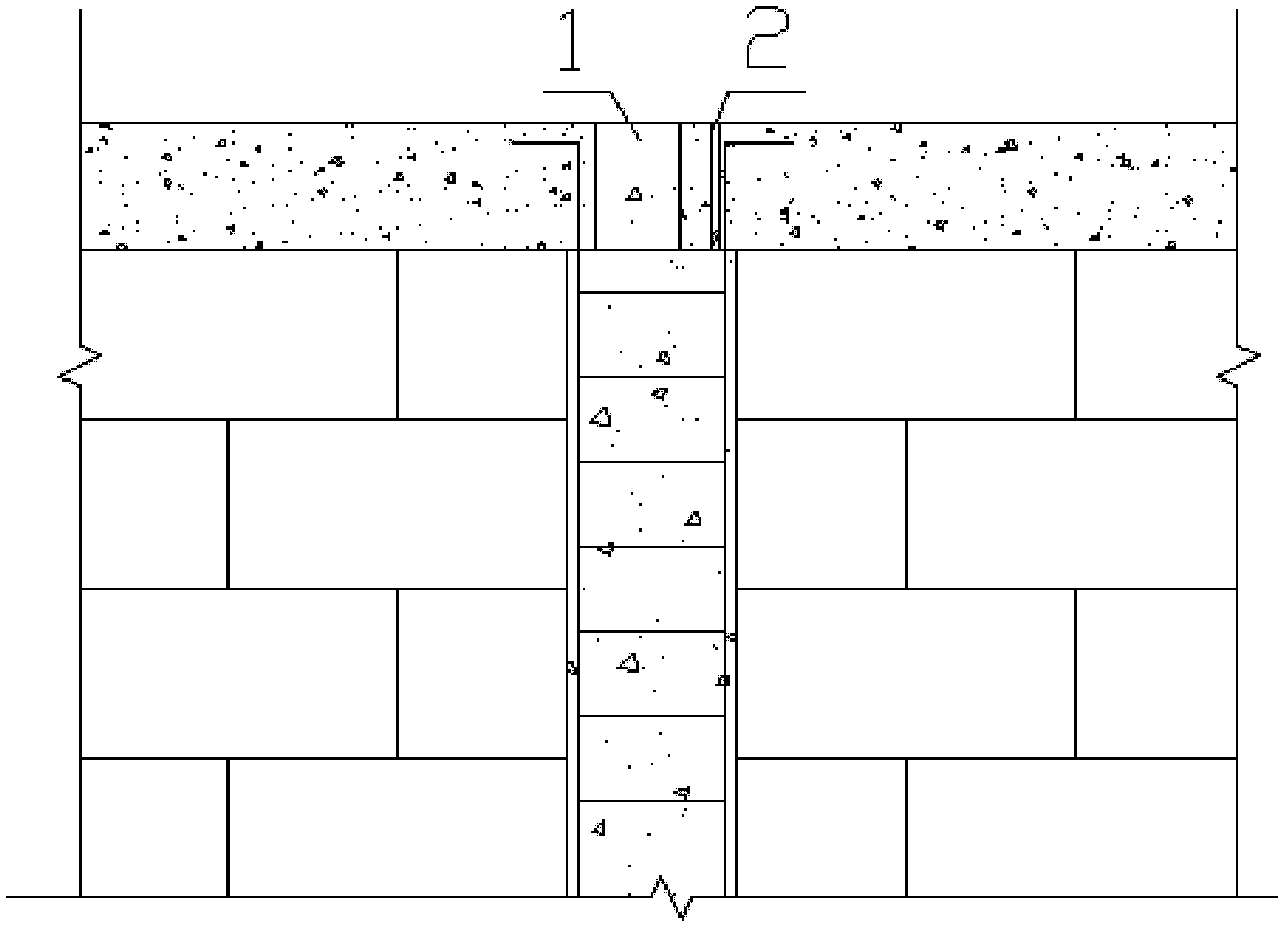

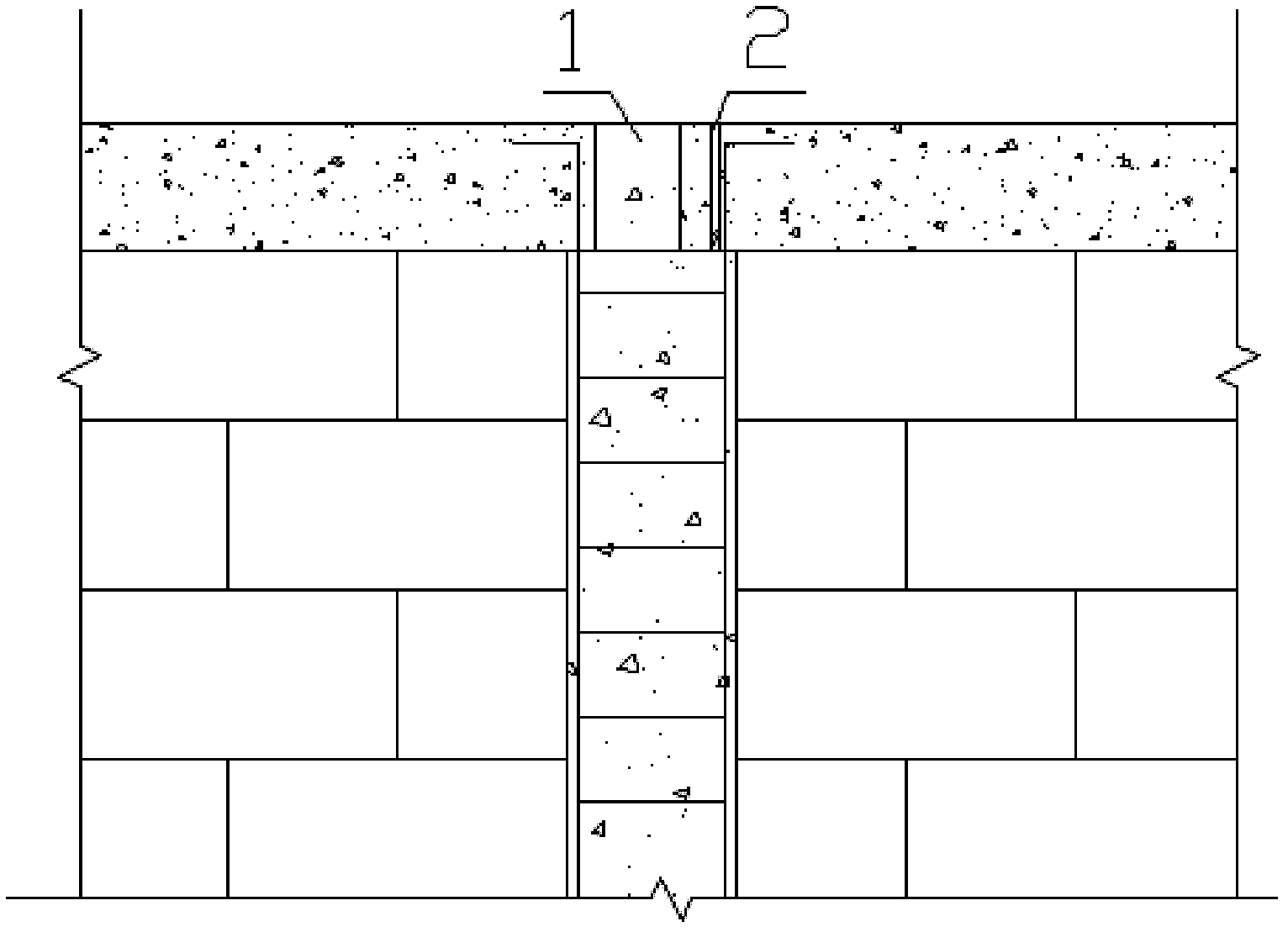

[0013] Such as figure 2 As shown, the formwork of the structural column is supported, the concrete on the top of the structural column is poured through the pre-embedded casing 1, and the air in the formwork of the structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com