Directional rock blasting crack propagation method and device

A technology of rock blasting and expansion method, which is applied in the field of directional fracture blasting and directional expansion of rock blasting cracks, which can solve problems such as unsatisfactory use effects, achieve significant technical and economic effects, reduce the number of blast holes, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

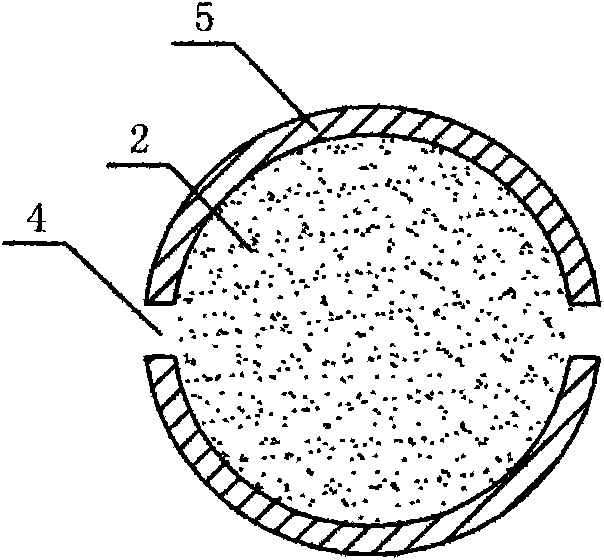

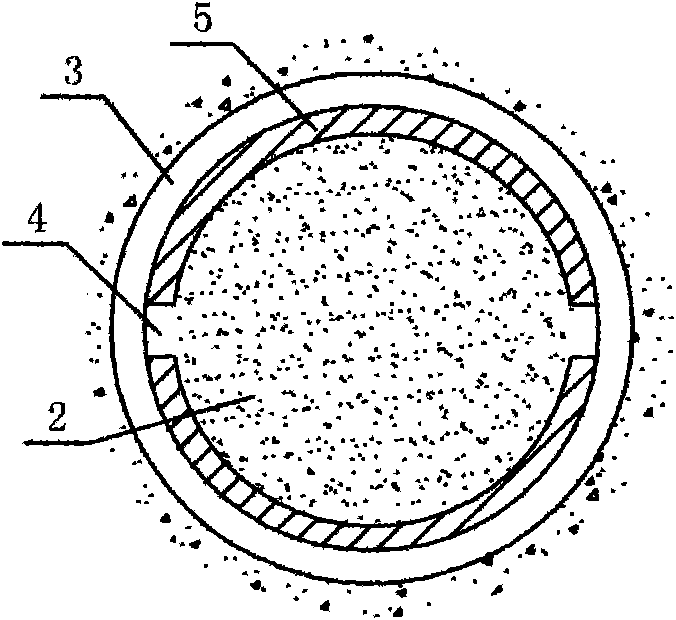

[0029] It can be seen from the above technical scheme that the method for directional expansion of cracks in rock blasting according to the present invention is to use the energy-shaping charge coil to release the energy of the explosive preferentially along the direction of the slit, and perform orientation on the roadway (tunnel) contour line and side slope. Fracture control blasting, so as to obtain a precisely controlled blasting fracture surface, limit the number of cracks and crack extension lengths in other directions such as surrounding rocks and slopes that need to be protected, so as to improve production efficiency, reduce production costs, and improve construction progress.

[0030] The present invention will be further described below in conjunction with accompanying drawing:

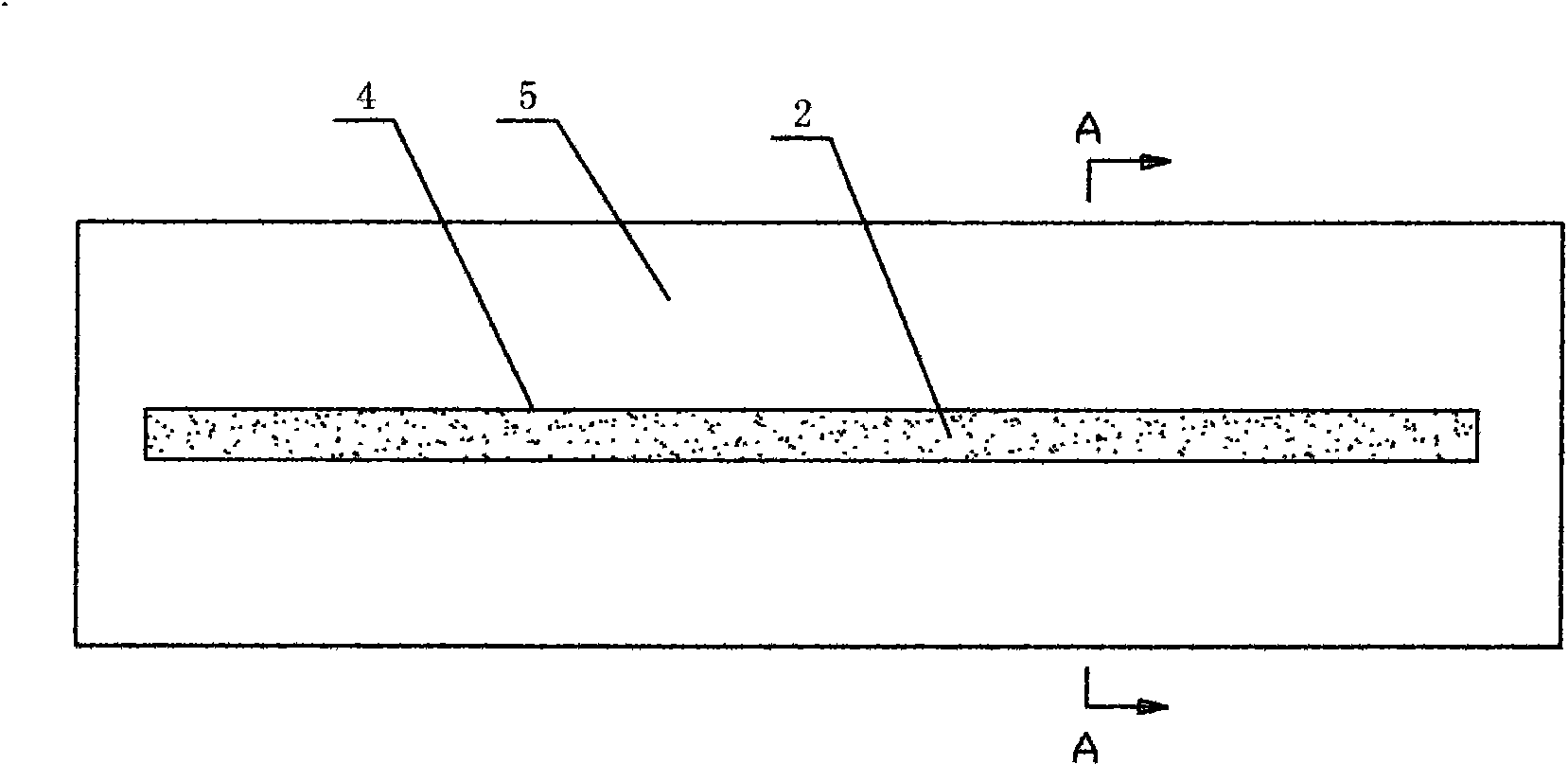

[0031] Such as figure 1 , figure 2 , image 3 As shown, a device for directional expansion of cracks in rock blasting, that is, a shaped charge roll, includes a slotted tube 5 and explos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com