Long shaft double-head turning and clamping drive device and method

A driving device and a slender shaft technology, applied in the direction of the chuck, etc., can solve the problems of low machining accuracy, high price, low production efficiency, etc., and achieve the effects of improving production efficiency and productivity, increasing clamping rigidity, and facilitating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

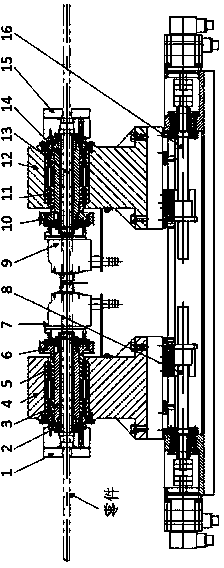

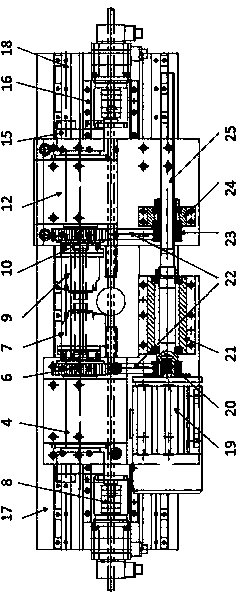

[0027] like figure 1 and 2 As shown, the clamping drive device for double-head turning of a slender shaft includes a left clamping unit, a right clamping unit and a power drive unit;

[0028] The left clamping unit includes a left hydraulic power chuck 1, a left pull rod 2, a left main shaft 3, a left main shaft case 4, a left main shaft bearing group 5, a left large synchronous pulley 6, and a left rotary oil cylinder 7; it is installed at the front end of the left main shaft 3 There is a left hydraulic power chuck 1, and a left rotary oil cylinder 7 is installed at the rear end, which is supported on the left main shaft case 4 through the left main shaft bearing group 5; a left pull rod 2 mechanism is arranged in the center of the main shaft, and the front end of the left pull rod 2 is connected with the left hydraulic power Chuck 1, the rear end is connected with the left rotary oil cylinder 7, through the control of the oil circuit connected to the left rotary oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com