Large-piece processing clamping method

A large workpiece, turning technology, applied in the field of turning and clamping of super long workpieces, can solve the problem of particularly high strength requirements of double centers, achieve large expansion force, good coaxiality, ensure coaxiality and related The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

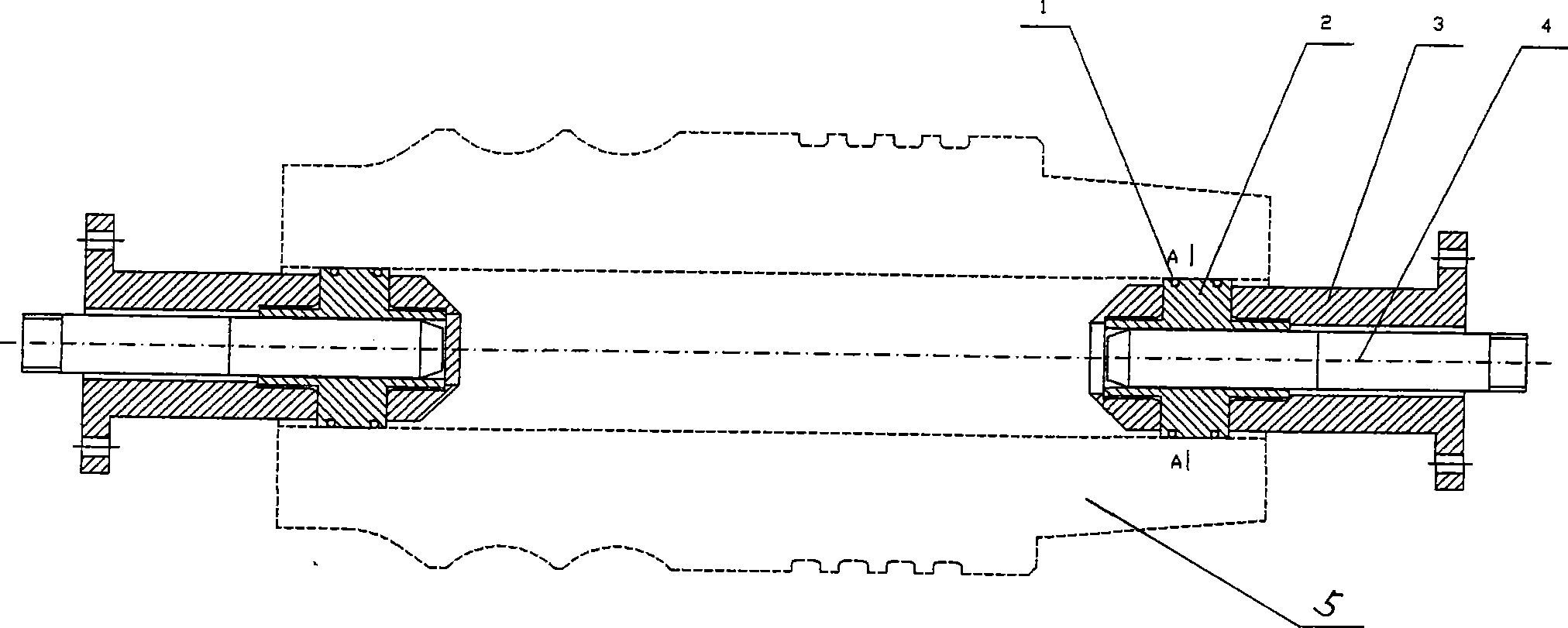

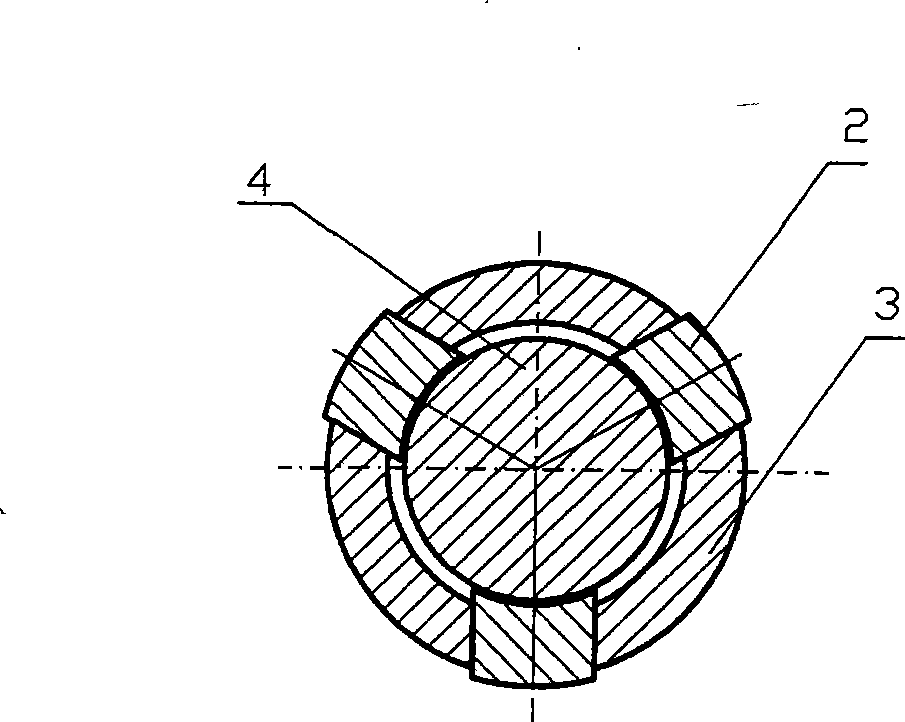

[0009] Embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

[0010] Connect one end of the clamp body 3 of a pair of expanding core fixtures to the two-way automatic hydraulic chuck respectively, and the other end extends into the processed inner hole of the workpiece 5 (petroleum drill pipe joint), start the two-way automatic hydraulic chuck, and pass the chuck The hydraulic piston in the disc drives the push rod 4 in the fixture to extend forward, relying on the front end of the push rod 7 0 ~9 0 The inclined conical surface pushes the radial slider 2 to move radially outward at the same time, and the two ends of the inner hole of the workpiece are tightened, and then the turning process can be carried out. There are three uniformly distributed and identical radial sliders 2 in each end of the expanding core fixture. Two rubber rings 1 are arranged in the arc-shaped grooves on the outer circle of the same group of rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com