Elastic clamp applied to thin sheet parts of laser micromachining machine tool

A machine tool and laser technology, applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of unreliable positioning, time-consuming clamping, poor versatility, etc., and achieve the effect of low cost, simple structure, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

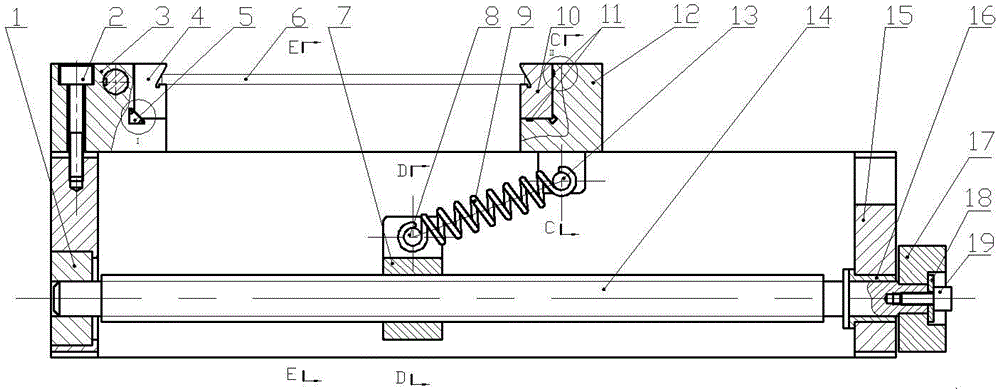

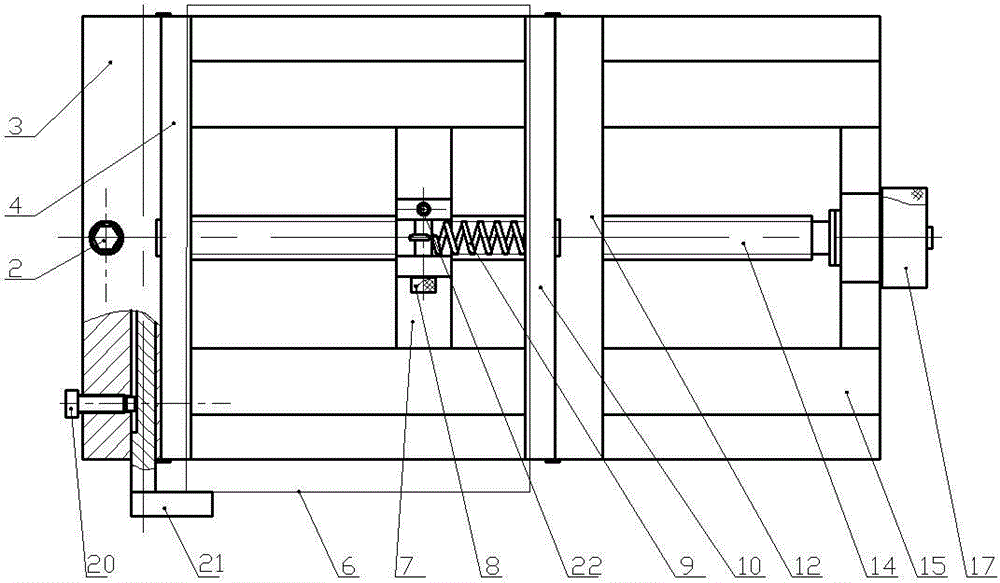

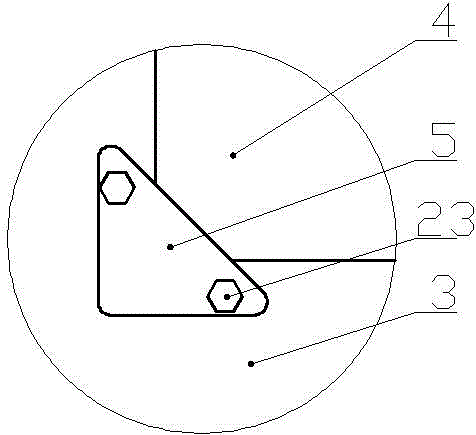

[0034] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be construed as a limitation on the technical solution.

[0035] Such as Figure 1-7 As shown, the fixture includes a clamp body 15, a fixed clamp base 3, a movable clamp base 12, No. 1 quick-change jaw 4, No. 2 quick-change jaw 10 and a screw rod 14. There is a dovetail above the clamp body 15, and the clamp body The middle of 15 is a through groove, the nut 7 is threadedly connected in the middle of the screw mandrel 14, the screw mandrel 14 passes through the through groove of the clamp body 15, the left end of the screw rod 14 is inserted into the left end hole of the clamp body 15 and is connected with the No. 1 shaft sleeve 1 To form a small clearance fit, the right end of the screw rod 14 is inserted into the right end hole of the clamp body 15 and forms a small interference fit with the No. 2 bushing 16, and the knob 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com