Design of replaceable simple-joint robot flexible hand

A robot and single-joint technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of waste of robot hand materials and single structure design of robot hands, and achieve the effects of convenient replacement, improved production efficiency, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

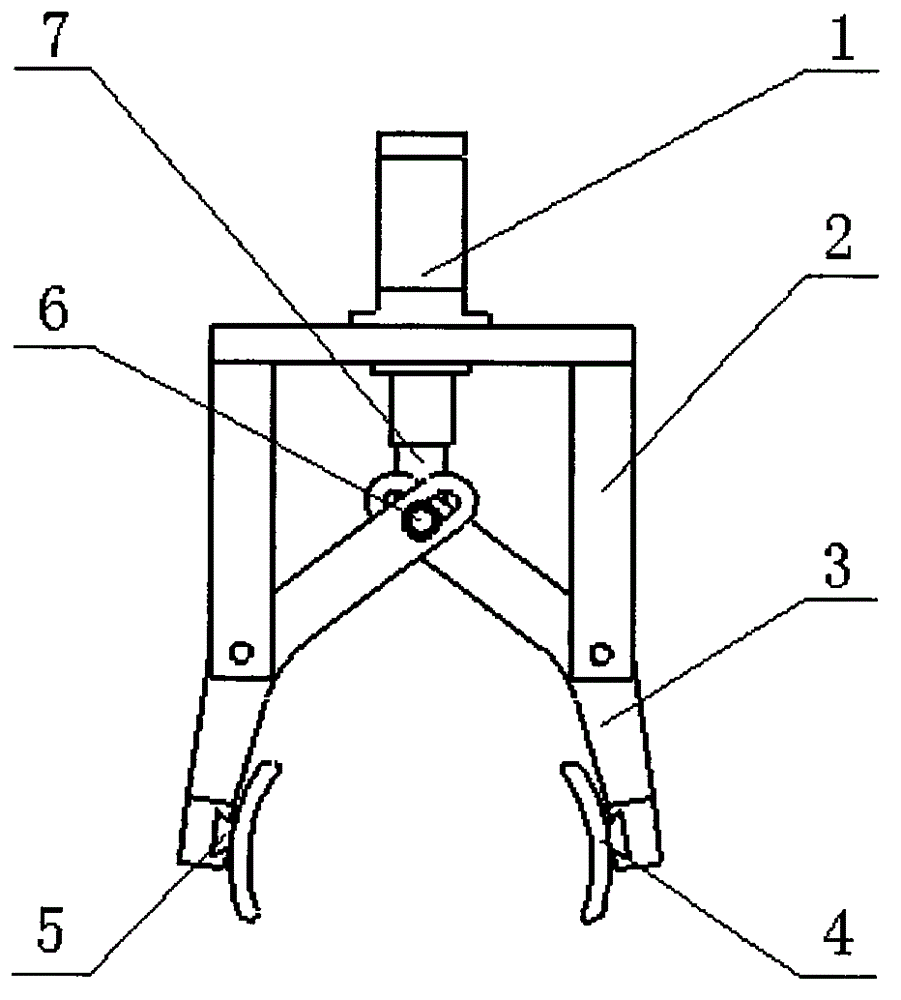

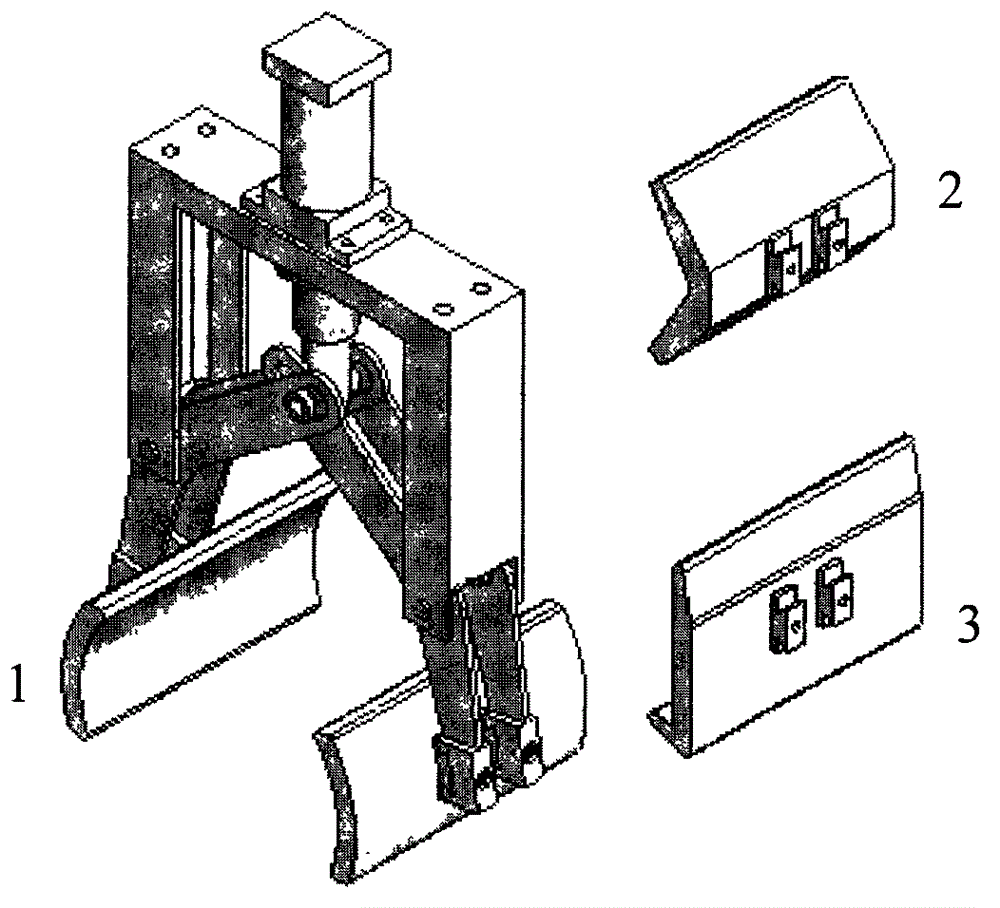

[0022] exist figure 1 In this design, a manipulator holding a cylindrical object is taken as an example. The design of the manipulator uses two fingers, which are parts that are in direct contact with the workpiece, and the finger loosens and clamps the workpiece through the opening and closing of the fingers. When the hydraulic cylinder 1 installed on the fixed bracket 2 drives the piston rod 7 to move upward, the piston rod pulls the cylindrical pin 6 and the connecting rod 3 to close the finger 4, thereby clamping the workpiece; when the hydraulic cylinder drives the piston rod to move downward , The piston rod pulls the cylindrical pin 6 and the connecting rod 3 to open the fingers 4, thereby loosening the workpiece. The replacement of robot fingers is mainly connected through the dovetail groove 5 at the joint, so when designing the fingers, it is only necessary to design the corresponding dovetail groove interface to facilitate the replacement of fingers, so as to meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com