Under-pressure leaking stoppage device for oil and gas conveying pipeline

A technology for leak plugging of conveying pipelines and under pressure, which is applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc. Eccentric wear, prevent angle deflection, ensure the effect of coaxiality and verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

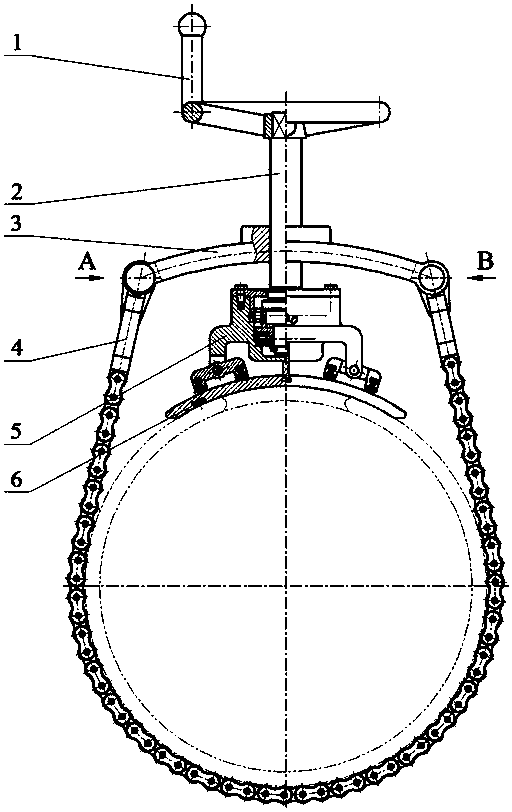

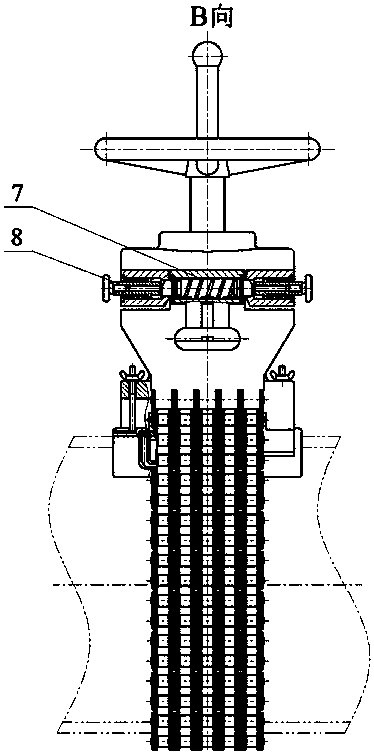

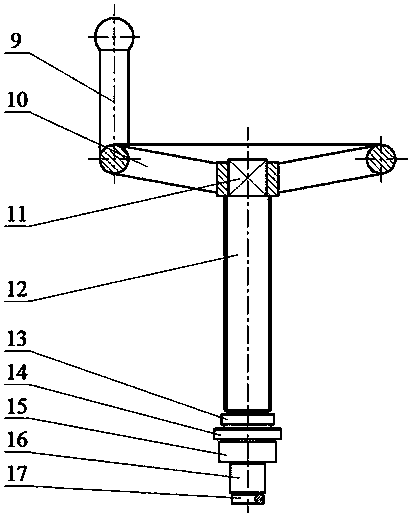

[0025] exist figure 1 and figure 2 Among them, the pressure plugging device for oil and gas transmission pipeline consists of rotating hand wheel 1, transmission shaft 2, upper slip 3, lower slip 4, pressure body 5, plugging patch 6, locking block 7 and unlocking block 8 composition. Among them, the upper part of the transmission shaft 2 is connected with the rotary hand wheel 1 through a square diameter joint, and its shaft body is connected with the upper slip 3 through the trapezoidal thread of the helical shaft, while the lower part is connected with the inner ring single rib cylindrical roller bearing and thrust roller bearing. Connected with the pressure applying body 5, the upper slip 3 and the lower slip 4 of the leakage plugging device are connected together through a pin shaft, and the leakage plugging patch 6 is connected with the pressure applying body 5 through a fastening body. In addition, the locking block 7 Put them into the locking bushing of the right cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com