Freely station-switchable welding fixture for multiple vehicle types

A welding fixture and station technology, applied in the direction of manufacturing tools, auxiliary devices, welding equipment, etc., can solve the problems that the structure cannot be adjusted, affect the welding work efficiency, etc., and achieve the effect of improving practicability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

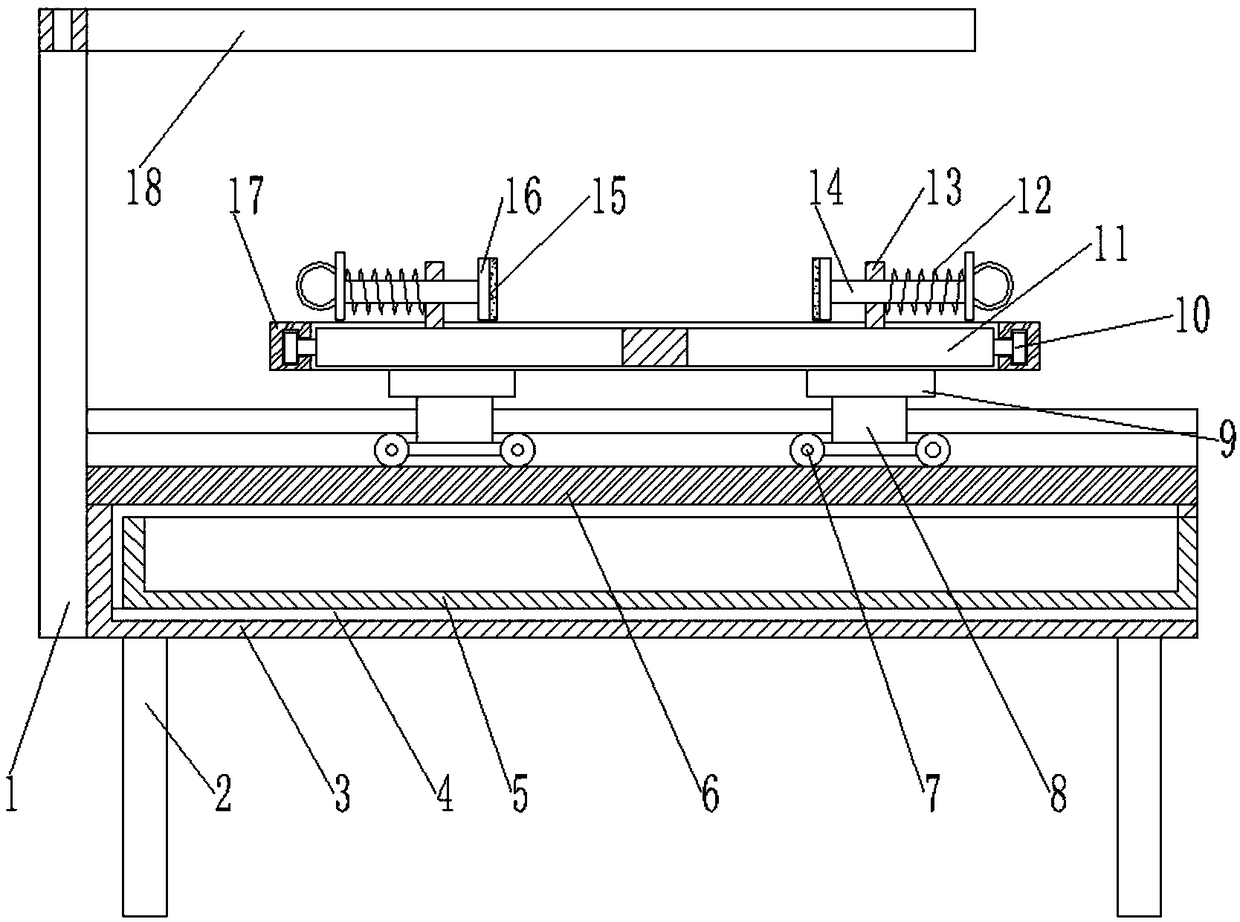

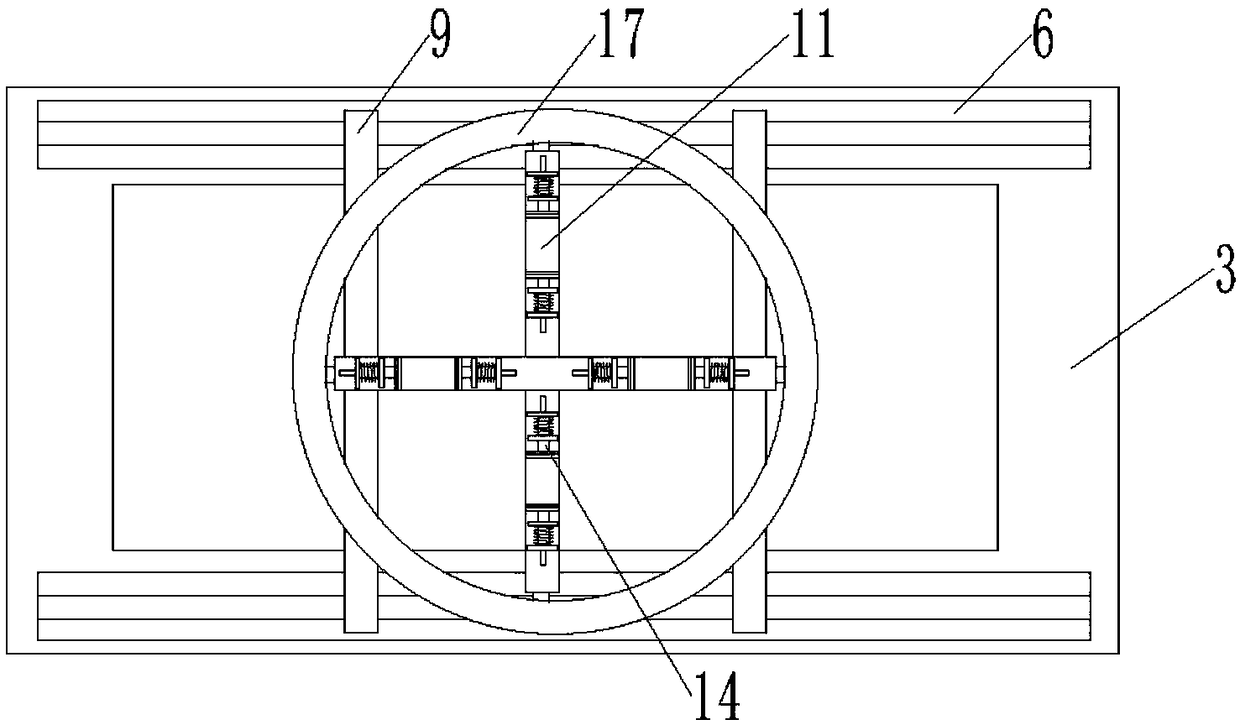

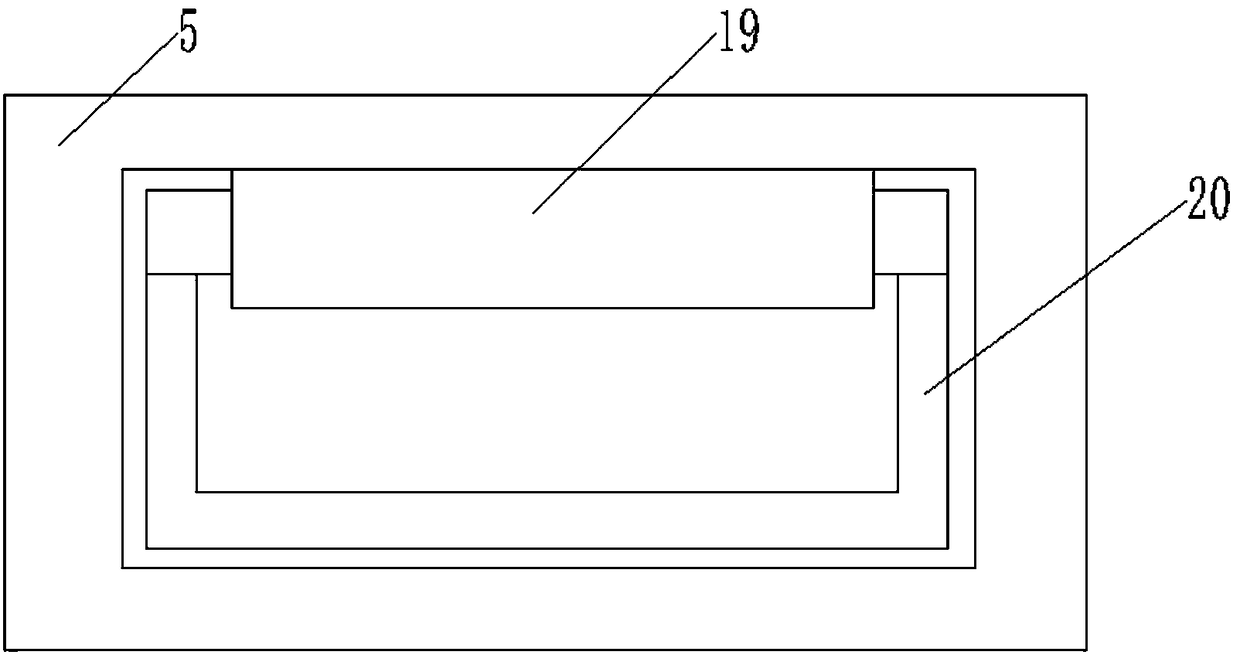

[0020] refer to Figure 1-3 , a welding fixture for various car models with freely switchable stations, including a bottom box 3, the four corners of the bottom outer wall of the bottom box 3 are connected with support columns 2 by bolts, and the outer wall of one side of the bottom box 3 is connected with a mounting rod 1 by bolts , the top outer wall of the installation rod 1 is connected with a rotating bearing through a bolt, and the installation rod 1 is connected with a beam 18 through a rotation bearing, and the inner wall at the bottom of the bottom box 3 is connected with a first slide rail 4 through a bolt, and inside the chute of the first slide rail 4 A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com