Multipurpose hydraulic vice and using method thereof

A vise and hydraulic technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of inability to process safety accidents, unstable clamped workpieces, high parallelism requirements, etc., achieve low operation and maintenance costs, and facilitate promotion Use, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

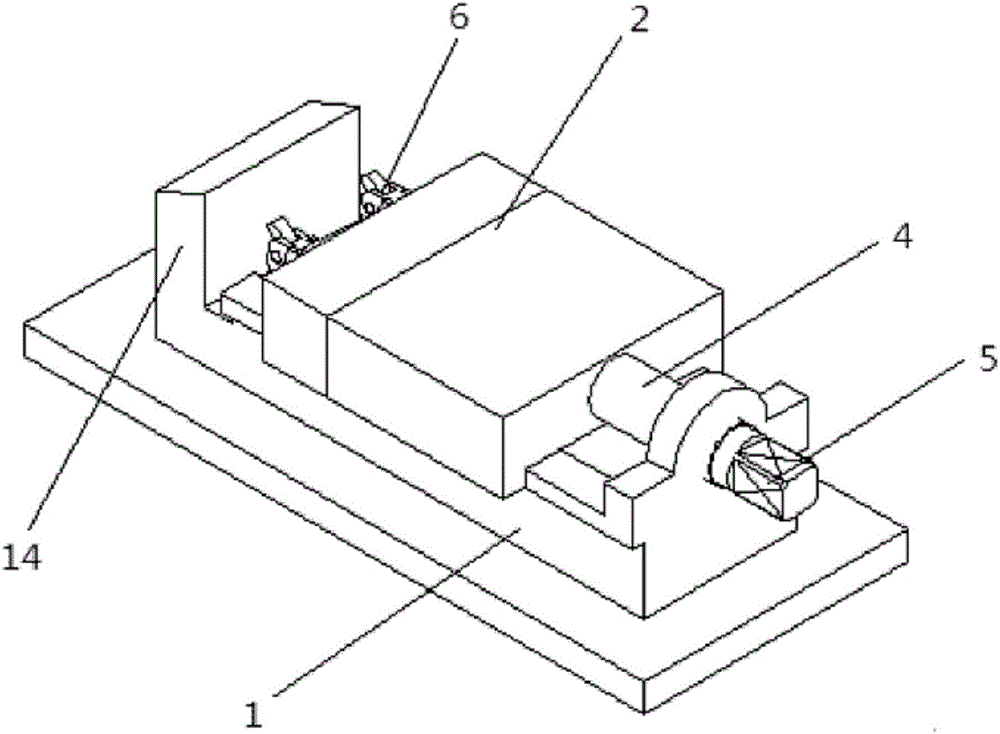

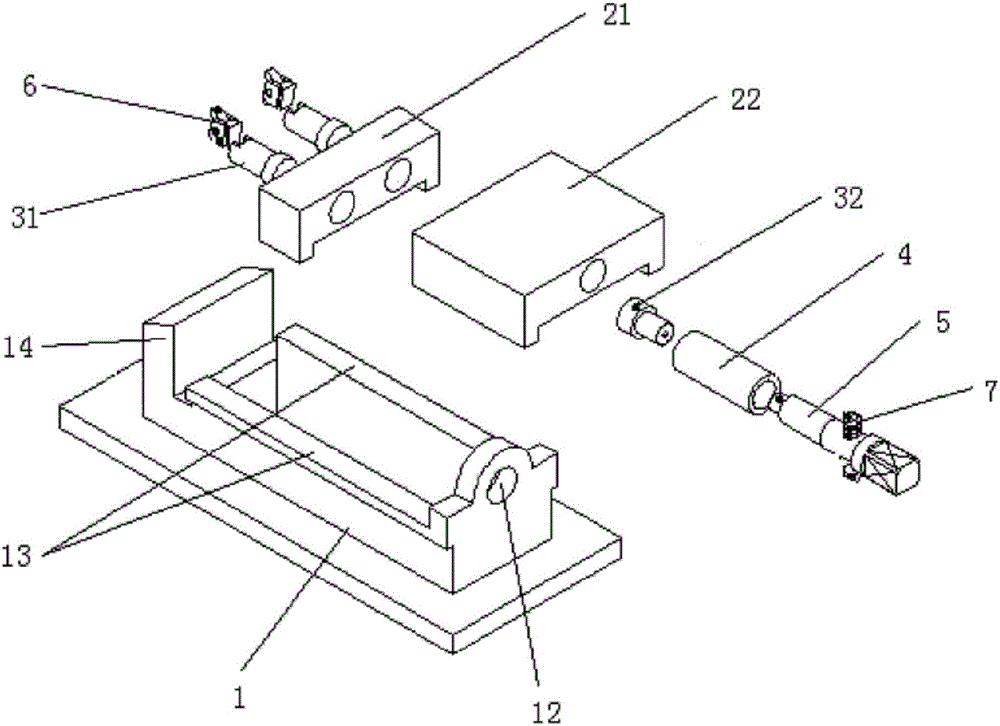

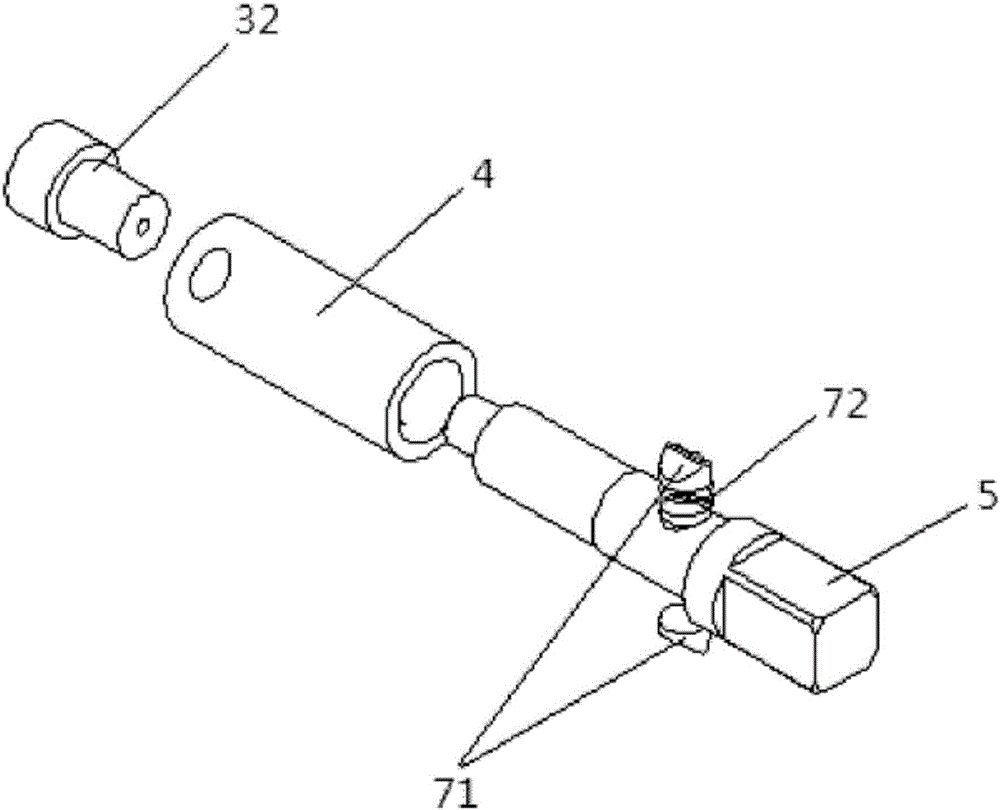

[0021] A kind of multipurpose hydraulic vise of the present invention, as Figure 1 to Figure 5 As shown, it includes a metal fixed clamp body 1, a movable clamp body assembly 2, a central plunger pump assembly 3, and a pre-clamping screw 4; the metal fixed clamp body 1 is provided with two rows of parallel guide rails 11; One end of the clamp body 1 is provided with a connecting ear plate, the ear plate is provided with a screw hole 12, and the other end is provided with a baffle plate 13 of a vertical base, wherein a leaky structure is formed between the two rows of guide rails; the movable clamp body assembly 2 can be moved along the The guide rail 13 moves on the metal fixed clamp body 1; the movable clamp body assembly 2 includes a movable clamp body 21 and a movable clamp body main body 22 fixedly connected together; the central plunger pump assembly 3 is located inside the movable clamp body assembly 2; The central plunger pump assembly 3 includes: two clamp piston rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com