Clamping equipment special for machining double holes in gasket

A technology for clamping equipment and gaskets, applied in metal processing equipment, clamping, clamping devices, etc., can solve the problems of pinch marks on the outer edge surface of gaskets, difficult to control clamping force, and slow processing speed. Achieve the effect of improving product quality, high consistency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

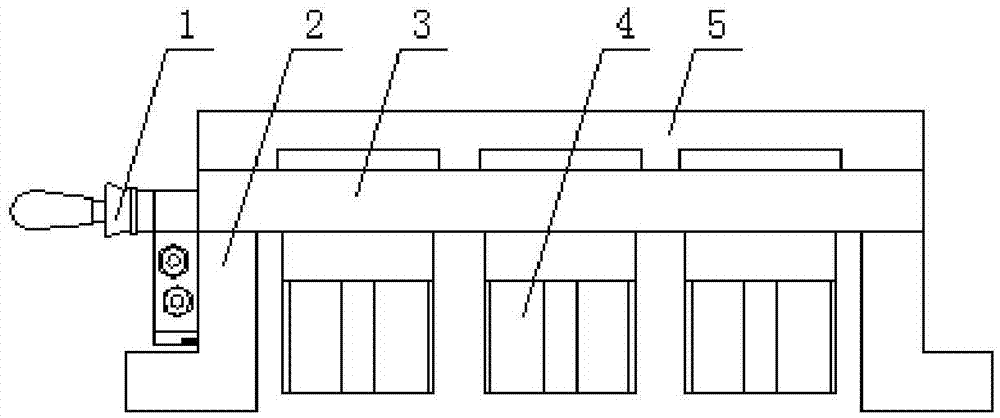

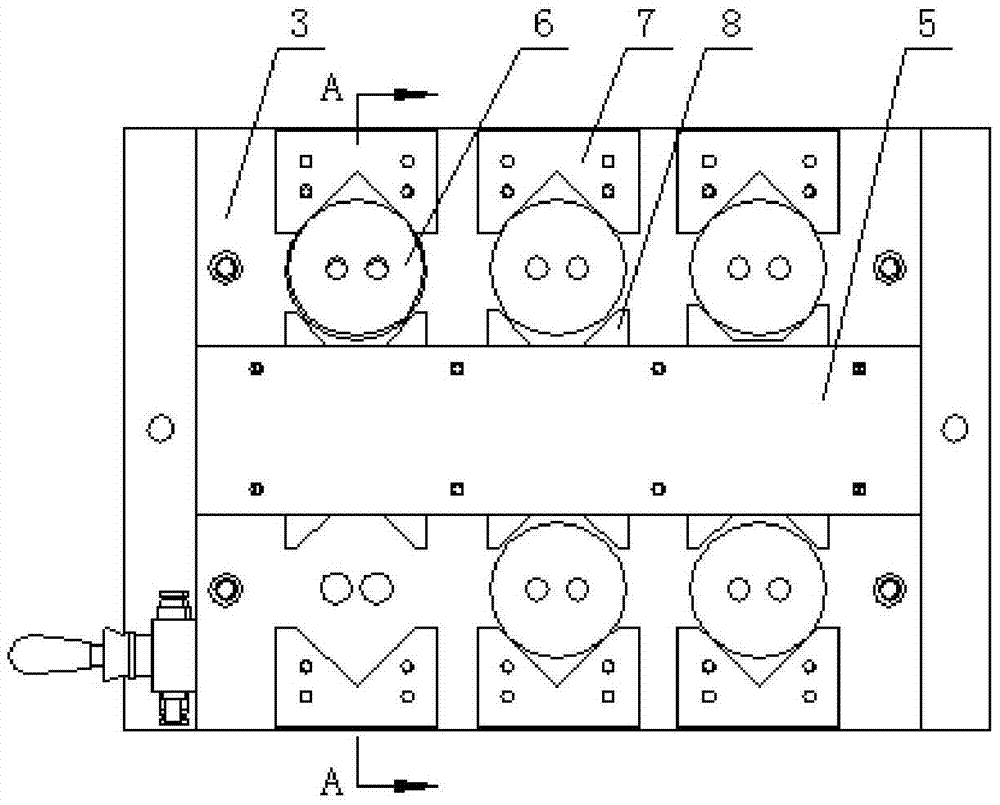

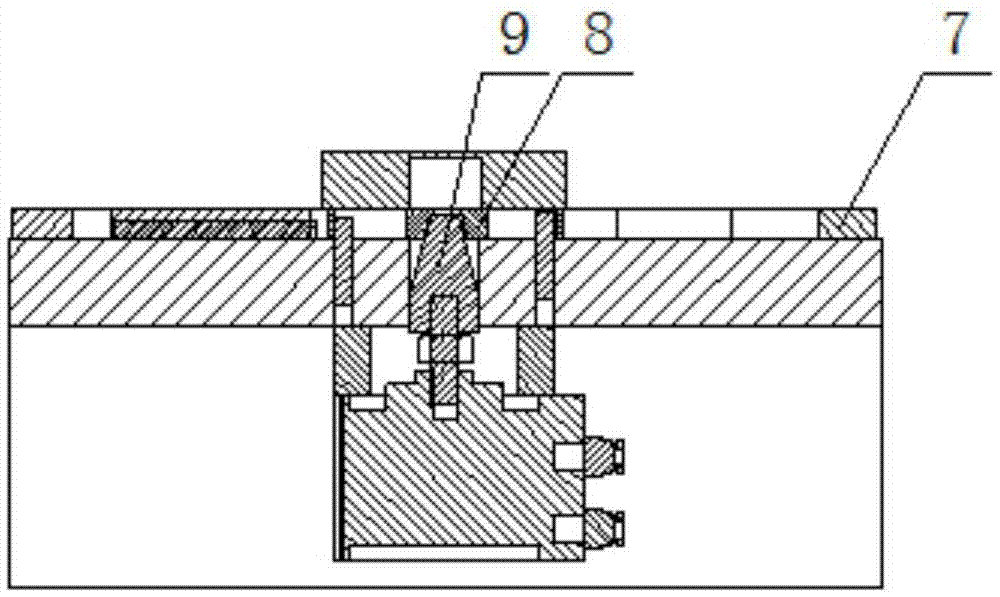

[0021] A special clamping device for double holes for gaskets, including a base, a fixed positioning block 7, a sliding compression block 8 and a compression cylinder 4. The base is composed of a main board 3 and a supporting board 2, and the left and right sides of the lower bottom of the main board are One support plate is installed respectively, and the two support plates are arranged symmetrically. A row of vertically upwardly arranged compression cylinders are evenly distributed on the bottom surface of the main board, and a controller 1 for controlling the cylinders is installed on the support plate. The piston rod of each compression cylinder is all connected with a wedge block 9, and the front and rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com