Control device for yarn trapper in sewing machine

A technology of a control device and a thread gripper, which is applied to the sewing machine control device, sewing equipment, sewing machine components, etc., can solve the problems of low accuracy, unsightly stitches, inconvenient use process, etc., and achieves high working stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

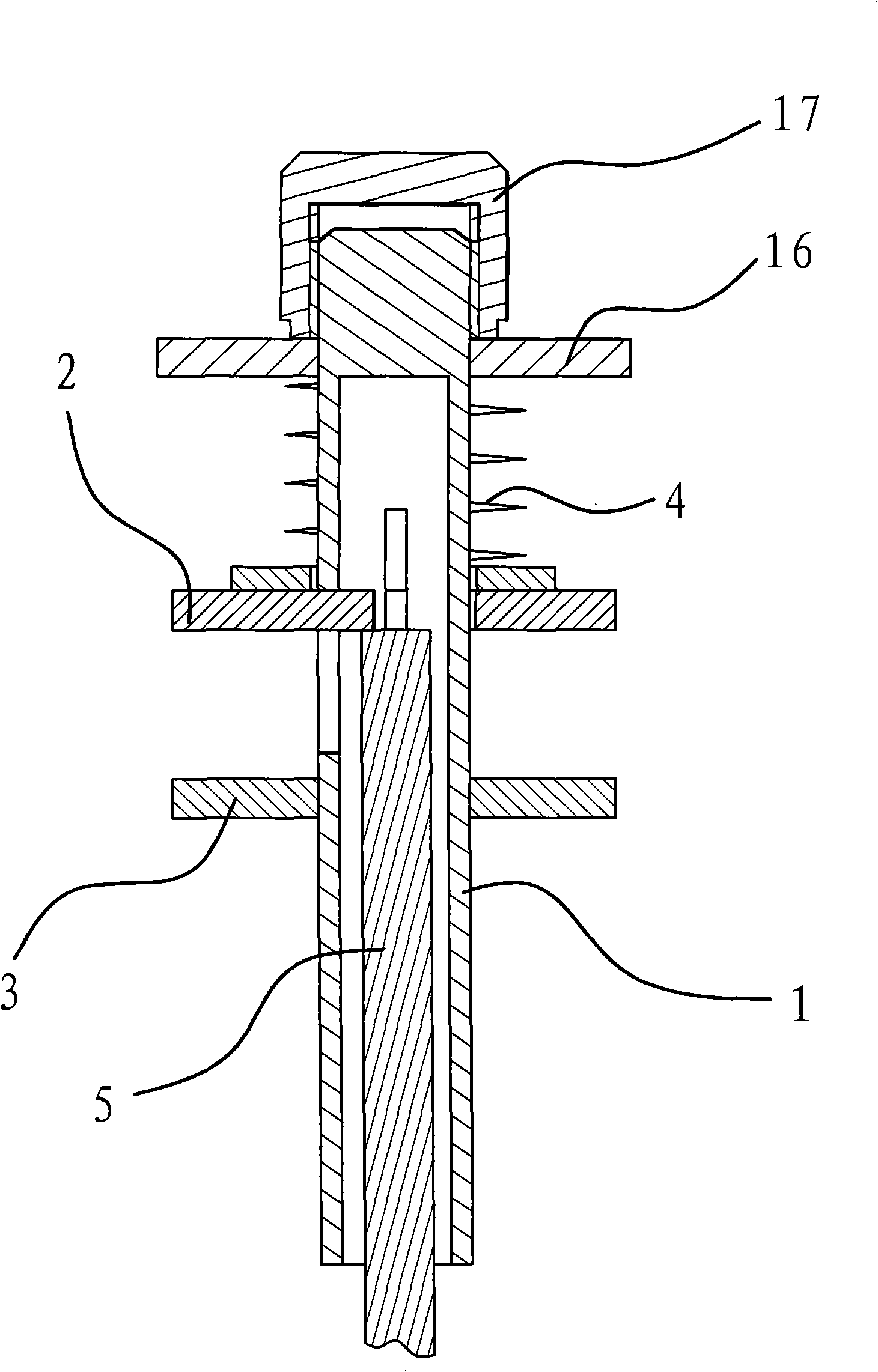

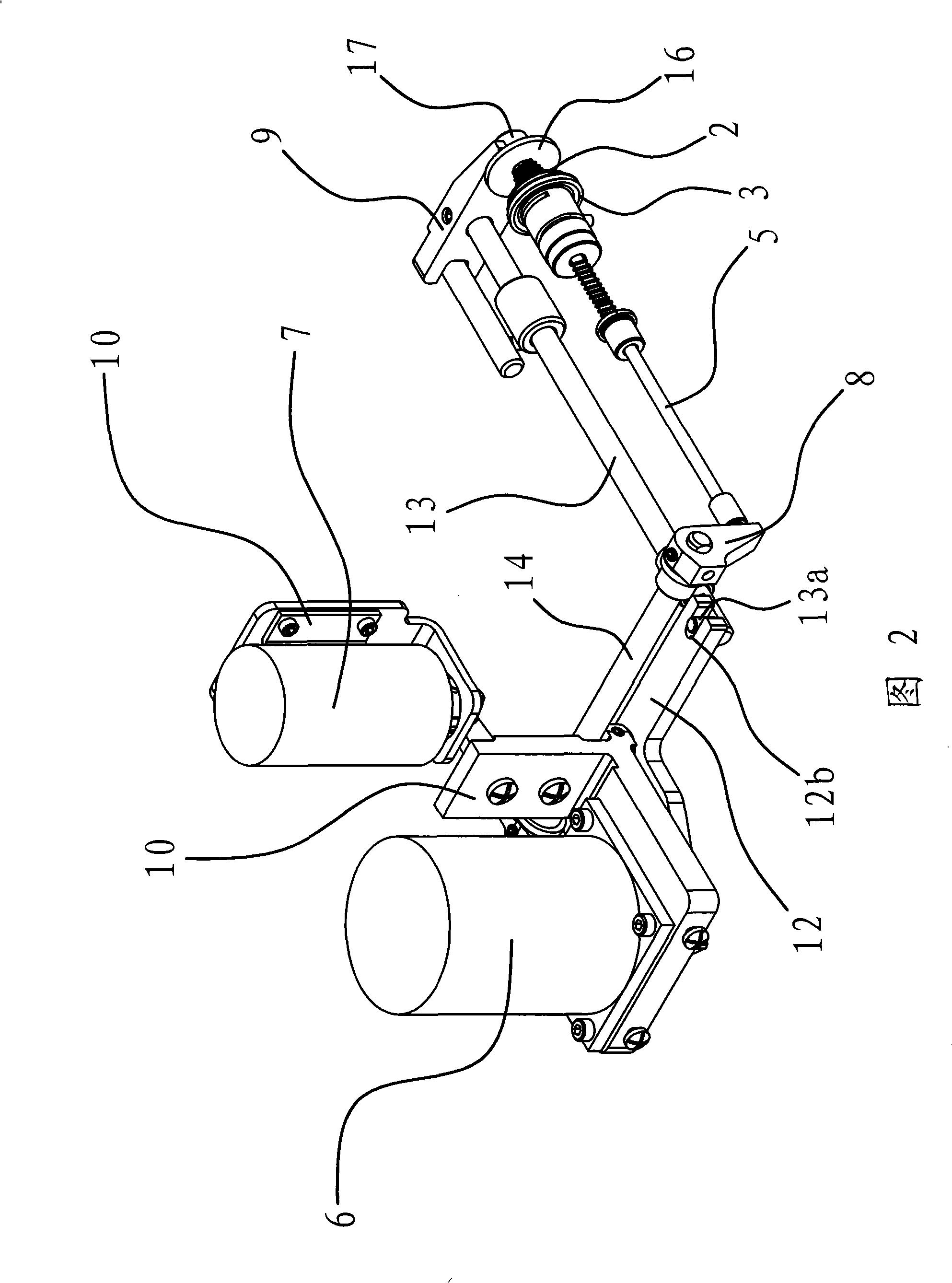

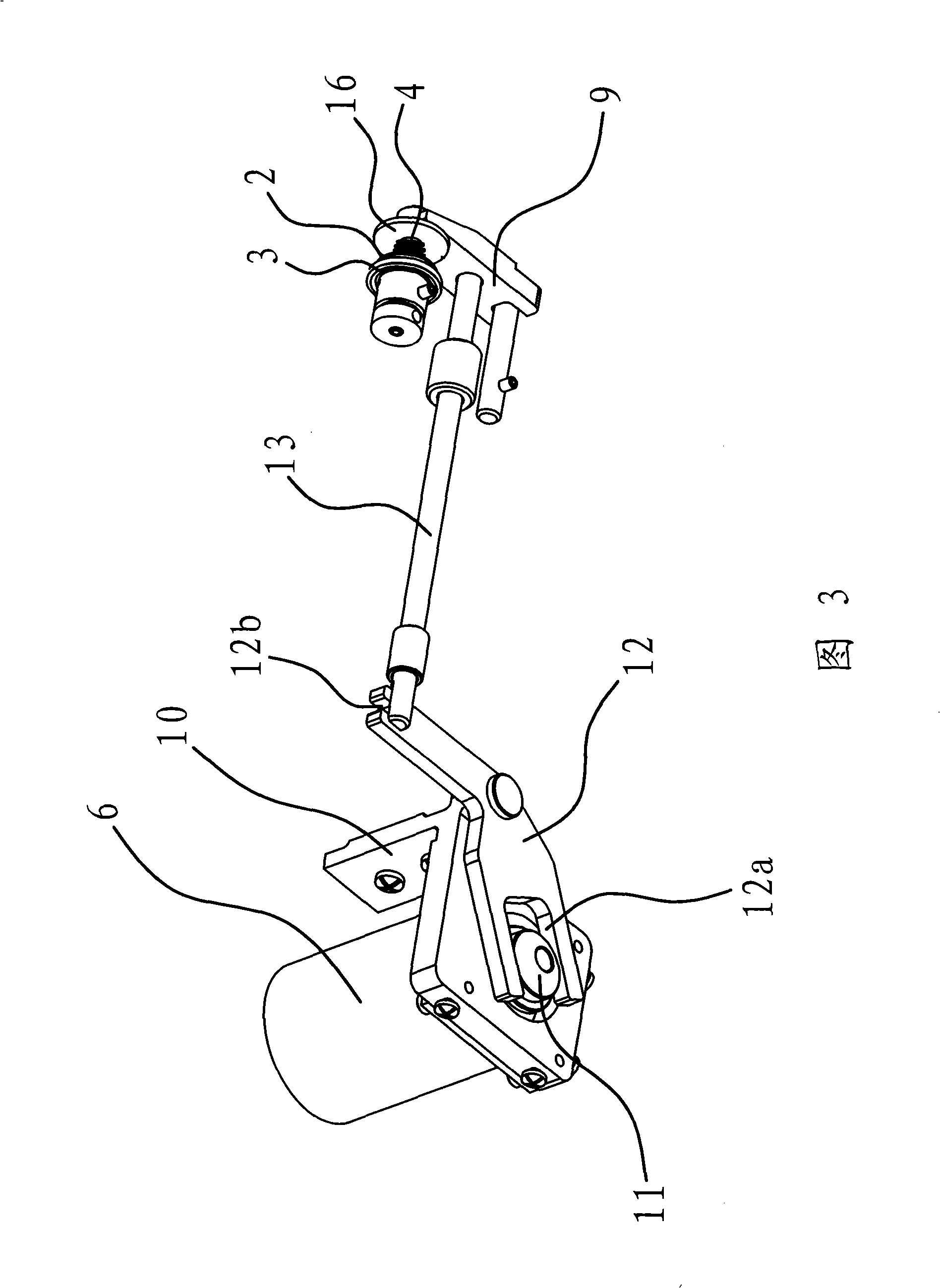

[0025] Such as figure 1 As shown, there is a thread clamp for clamping the suture in the sewing machine, and the tension of the sewing thread during the sewing process of the sewing machine can be adjusted by the thread clamp.

[0026] Thread tensioner is made up of parts such as bar body 1, upper chuck 2, lower chuck 3, spring 4 and thimble 5. The rod body 1 is cylindrical, and the lower chuck 2 is fixedly connected to the rod body 1 . The upper chuck 2 is sleeved on the rod body 1, and a spring 4 is also sleeved on the rod body 1. A clamping plate 16 is sleeved on the end of the rod body 1 and a nut 17 is threadedly connected. The above-mentioned spring 4 is in the upper clamp Between disc 2 and clamping plate 16. Under the elastic force of the spring 4 , the upper chuck 2 abuts against the lower chuck 3 , and the clamping plate 8 abuts against the nut 17 .

[0027] The thimble 5 is located in the rod body 1 , one end of the thimble 5 is connected with the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com