Patents

Literature

102 results about "Lines tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tension lines. lines that can be extrapolated by connecting linear openings made when a round pin is driven into the skin of a cadaver, resulting from the principal axis of orientation of the subcutaneous connective tissue (collagen) fibers of the dermis; they vary in direction with the region of the body surface.

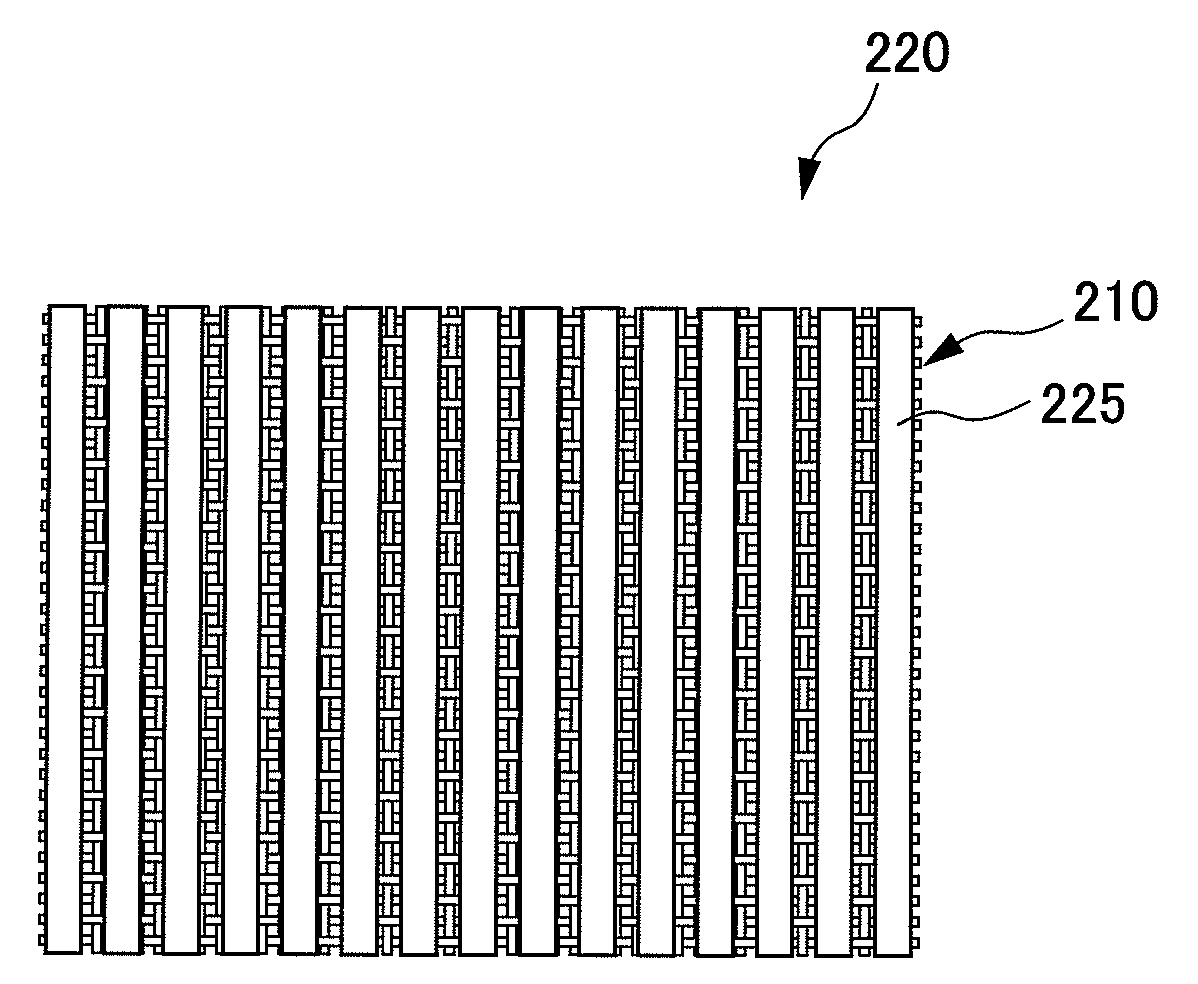

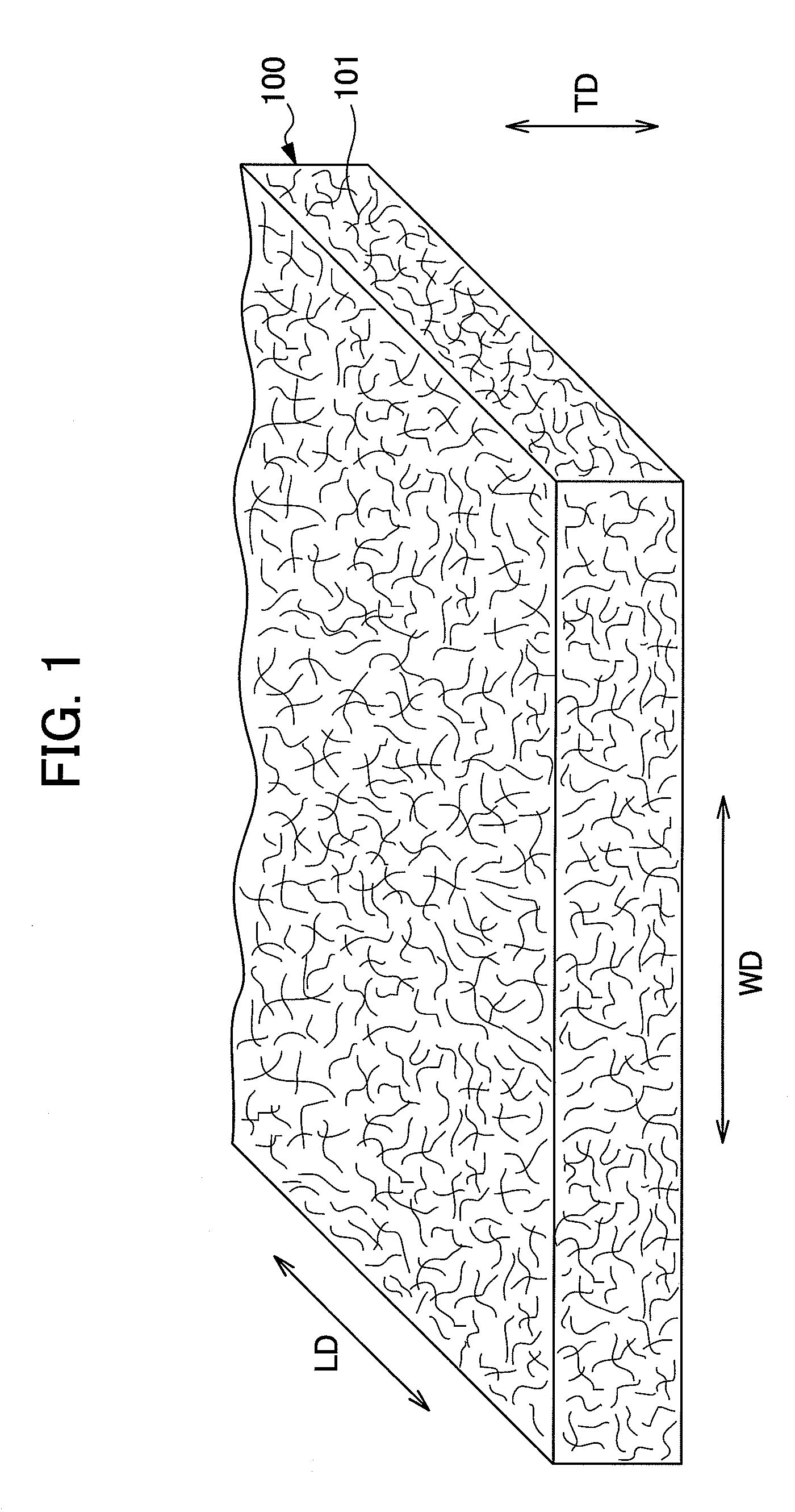

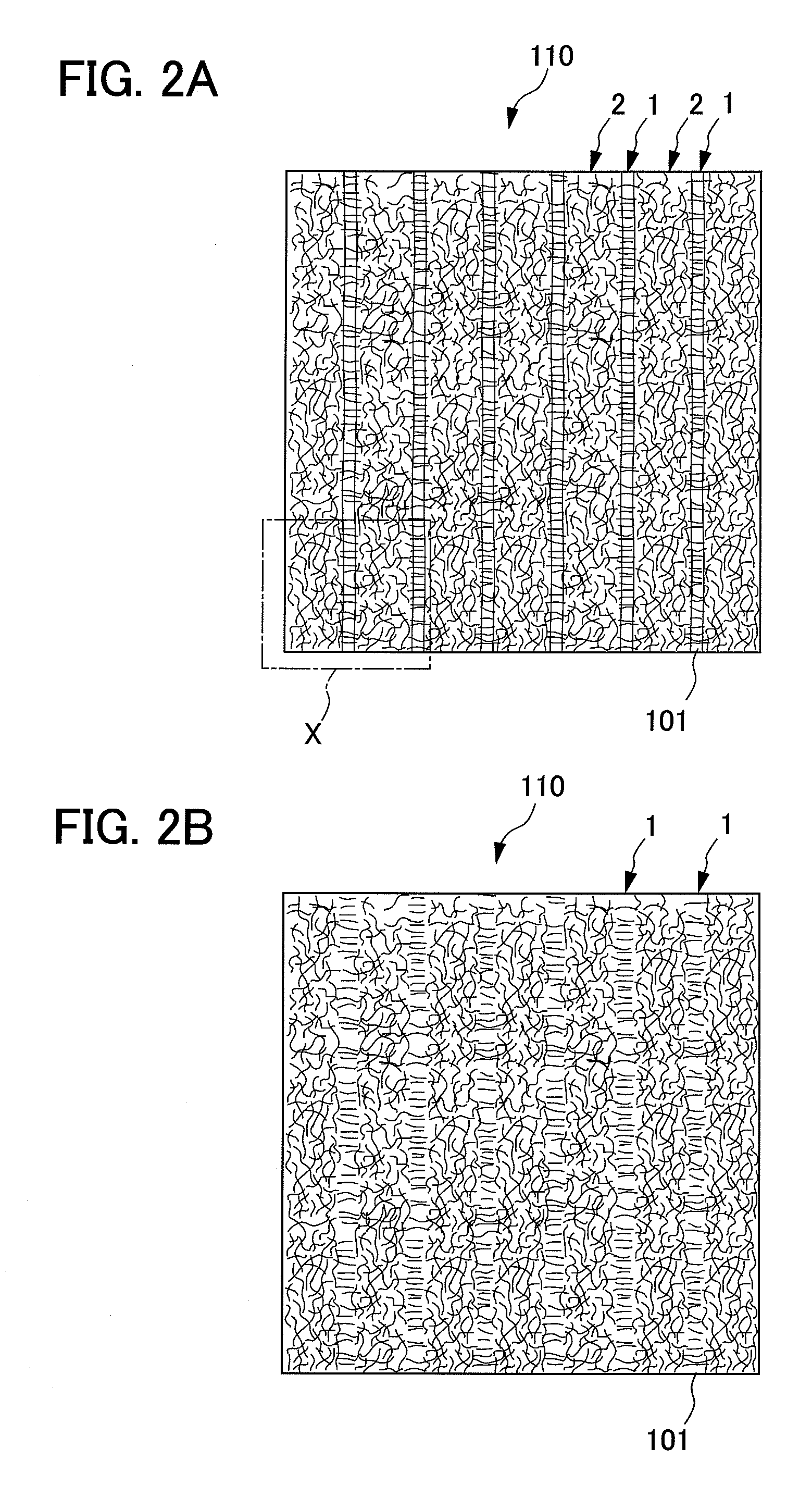

Nonwoven fabric

A nonwoven fabric having a predetermined strength against line tension is provided. A nonwoven fabric includes first regions, second regions, and third regions, in plural, wherein the second regions are arranged on both sides of the first regions, and the third regions are arranged on sides opposite to the first regions side of the second regions. The first regions have the highest content ratio of laterally orientated fibers, and the second regions have the highest content ratio of longitudinally orientated fibers.

Owner:UNI CHARM CORP

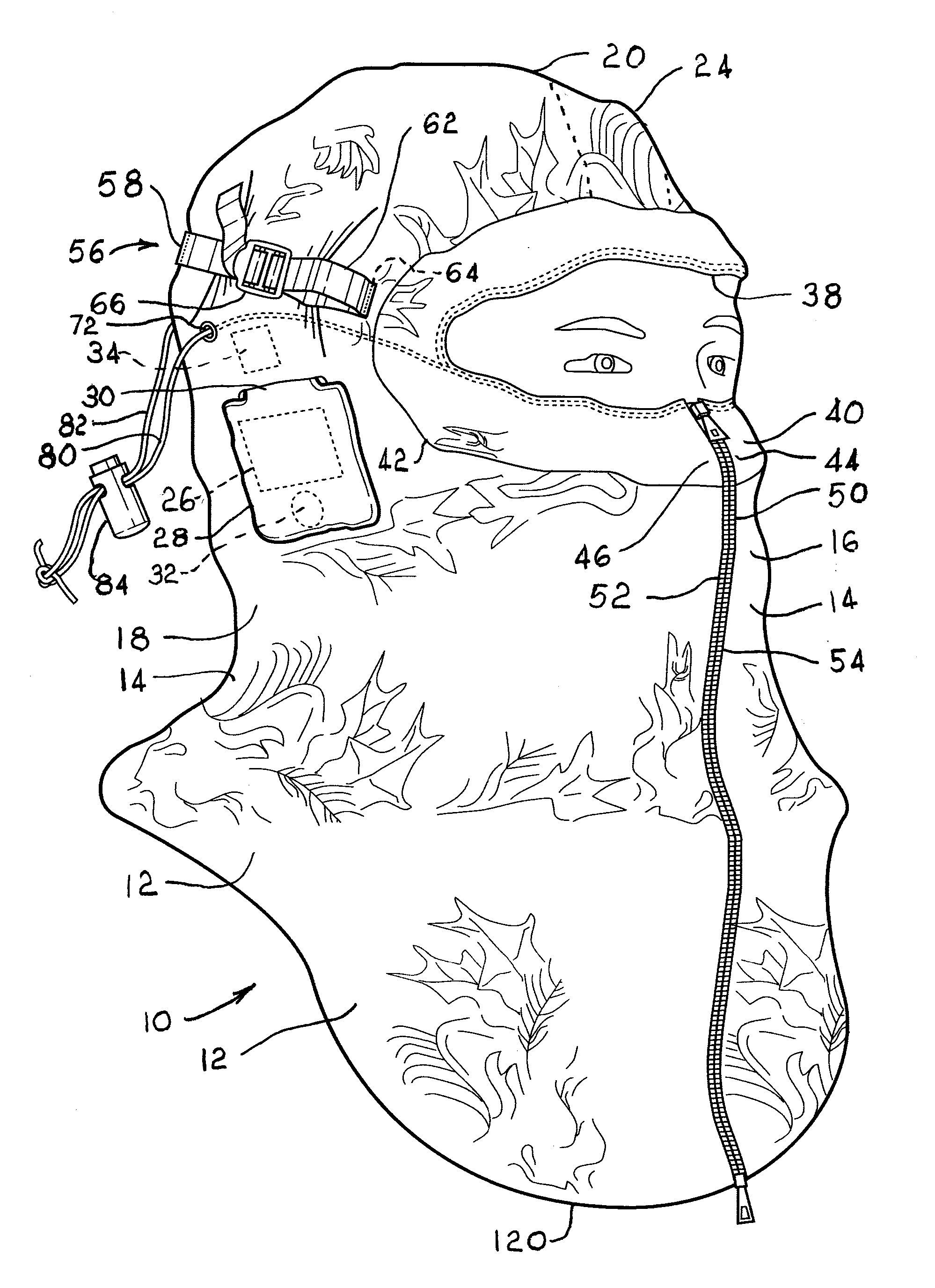

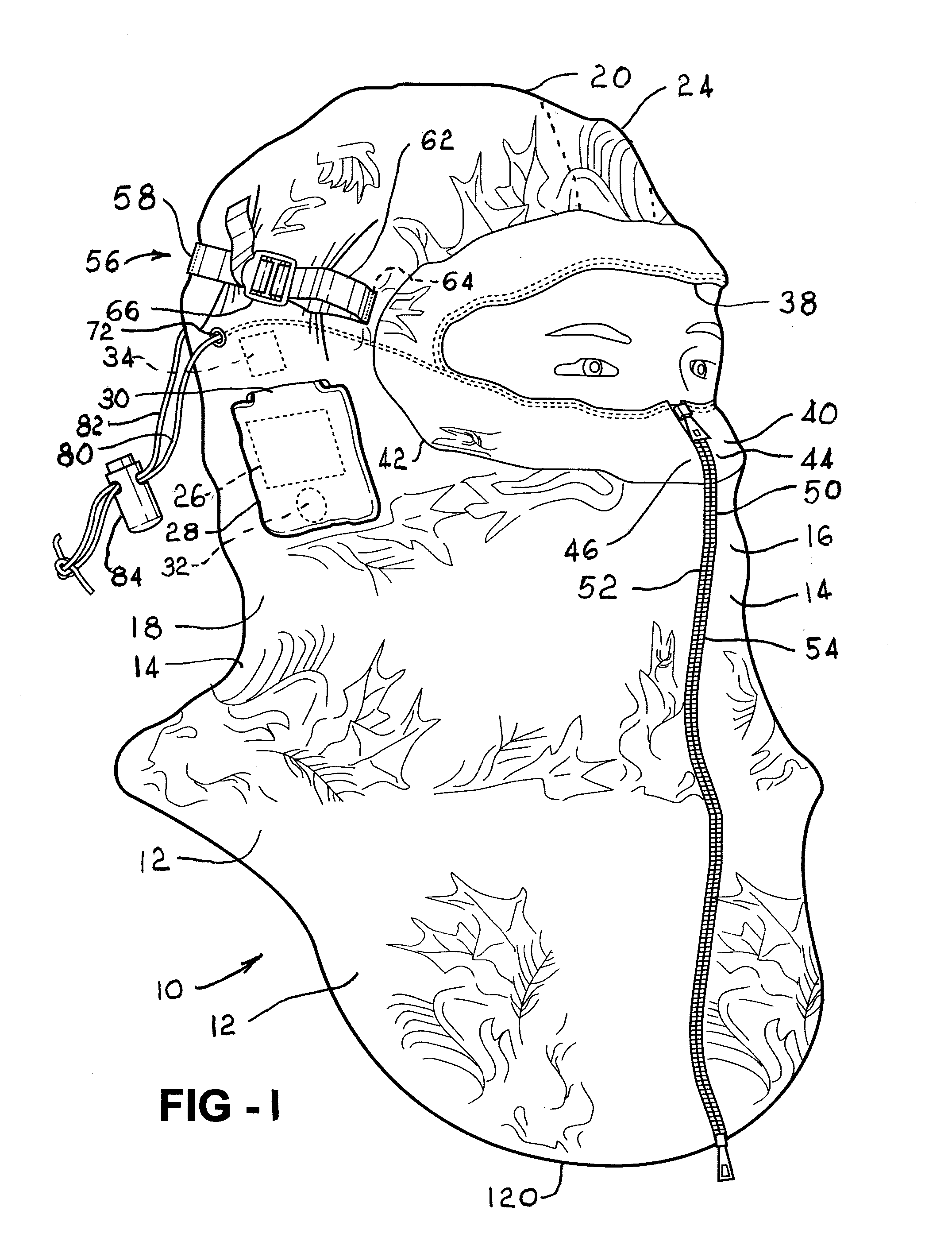

Hunters Hood with Adjustable Face Opening

Owner:ALTUS BRANDS

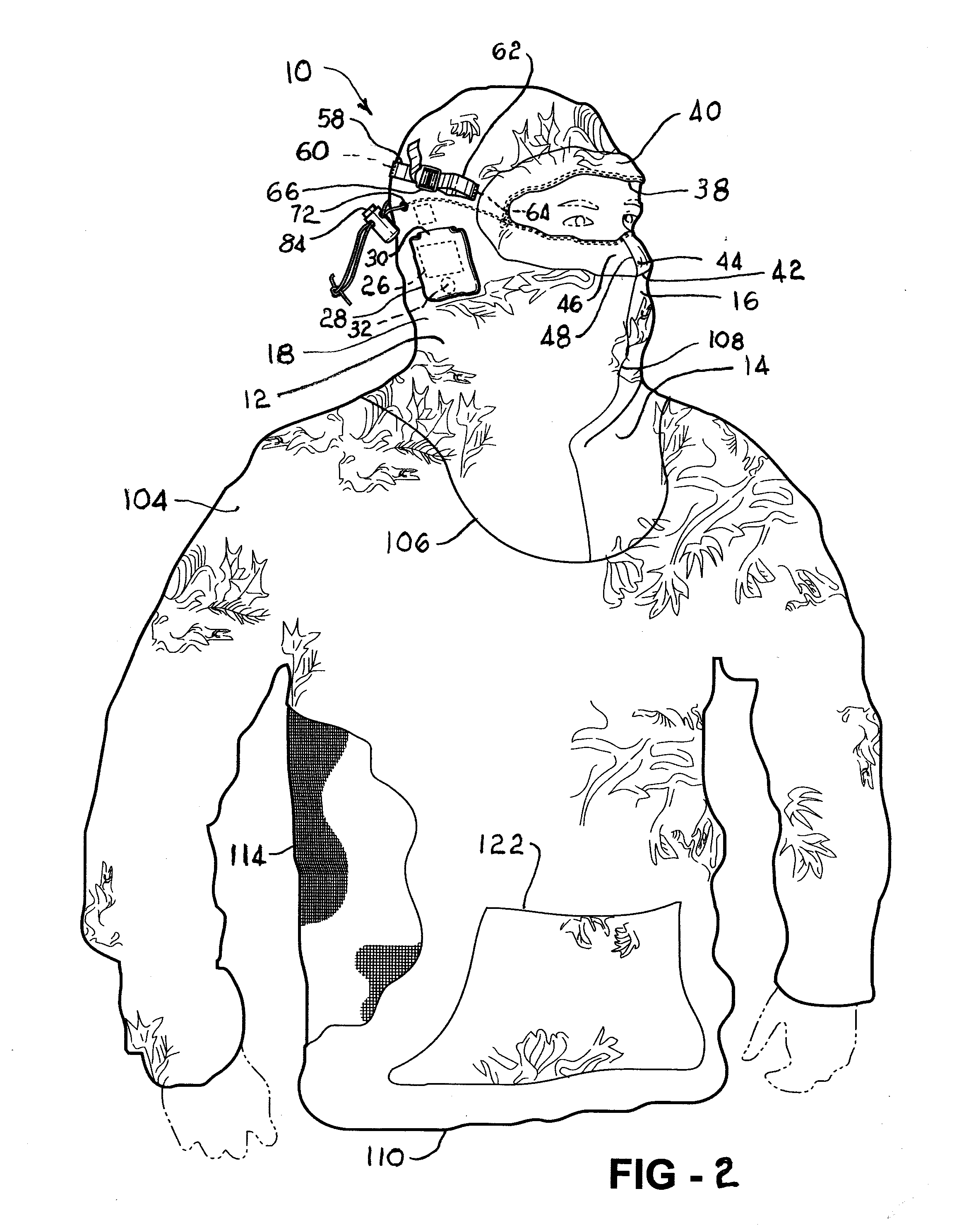

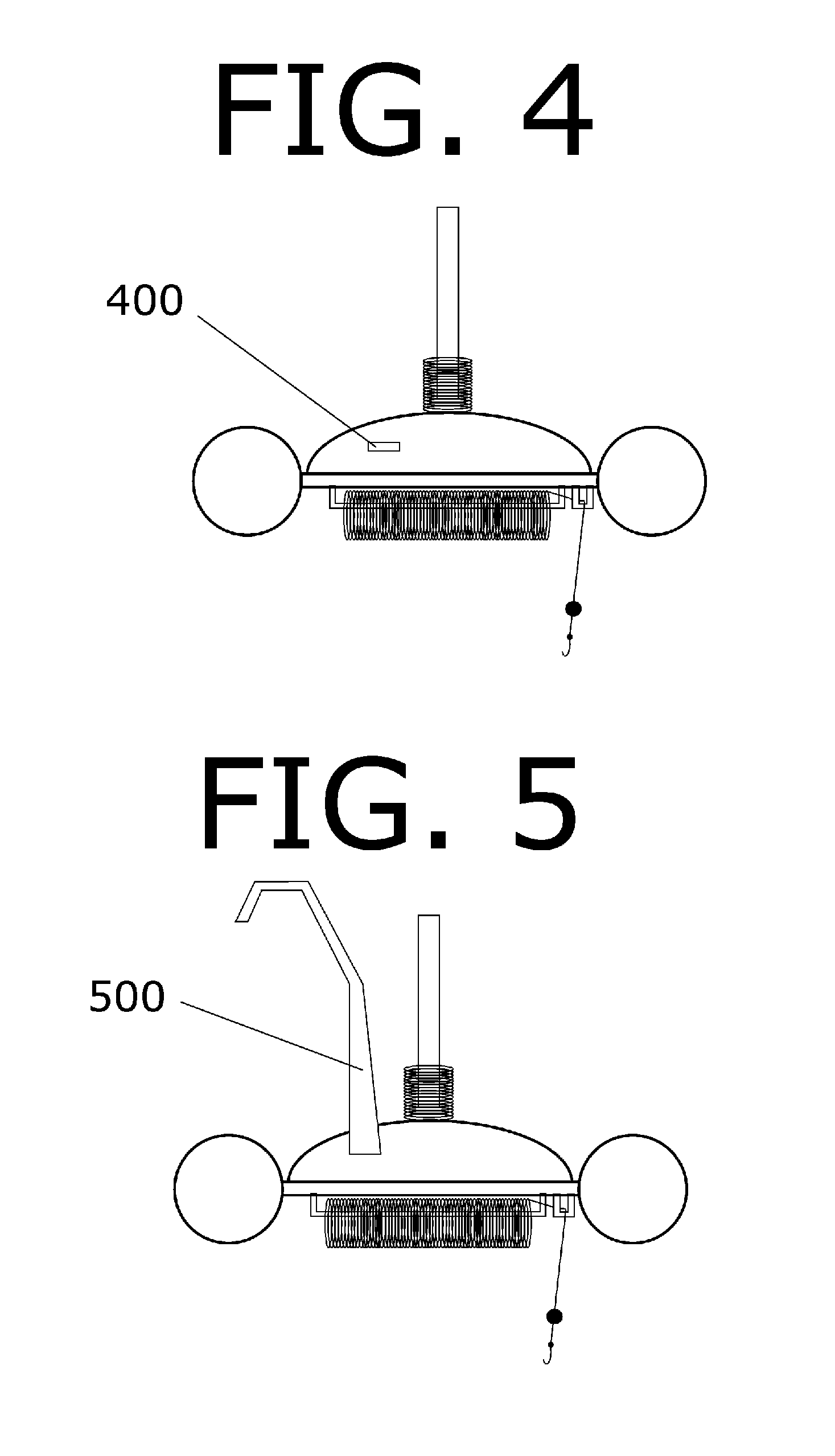

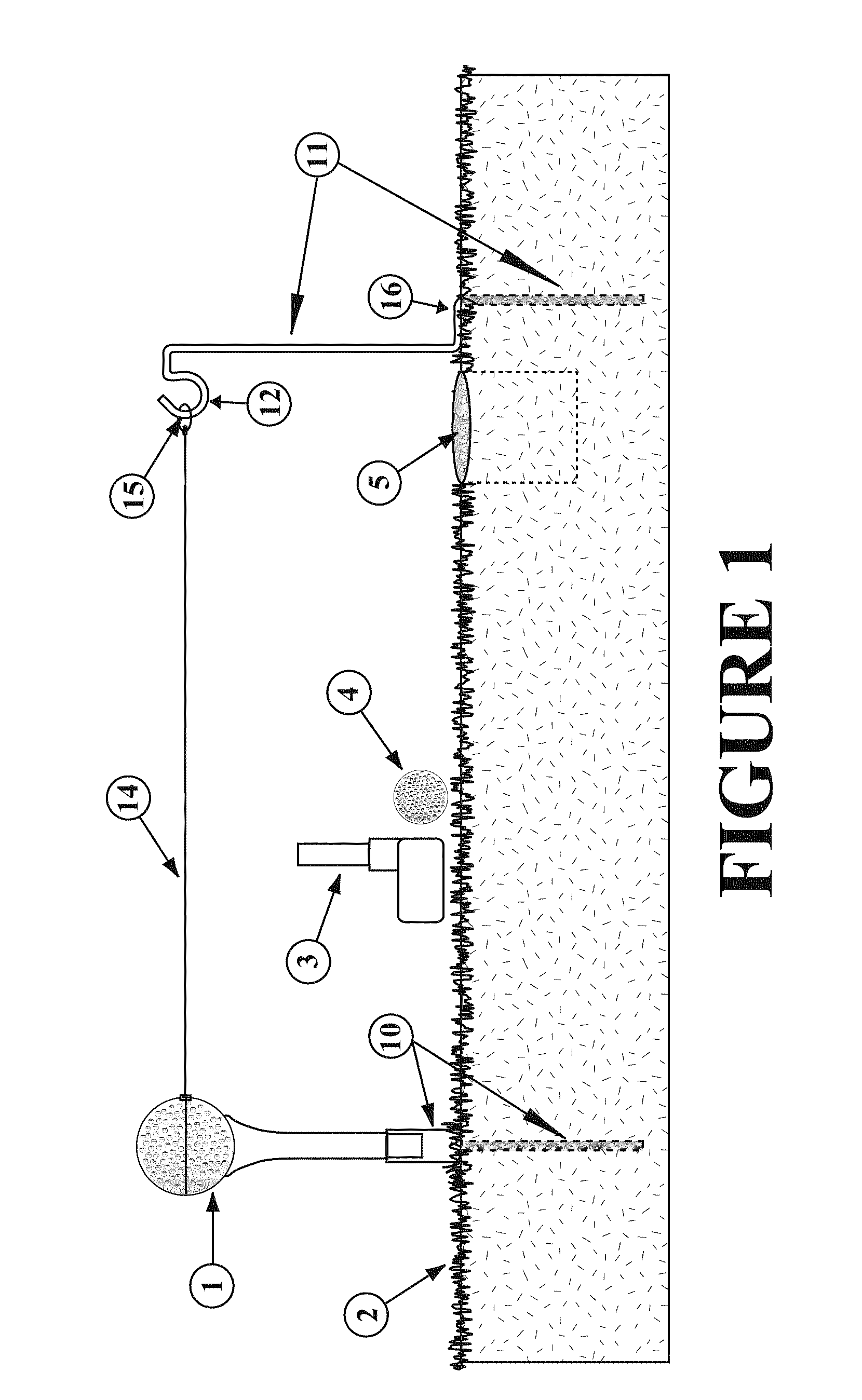

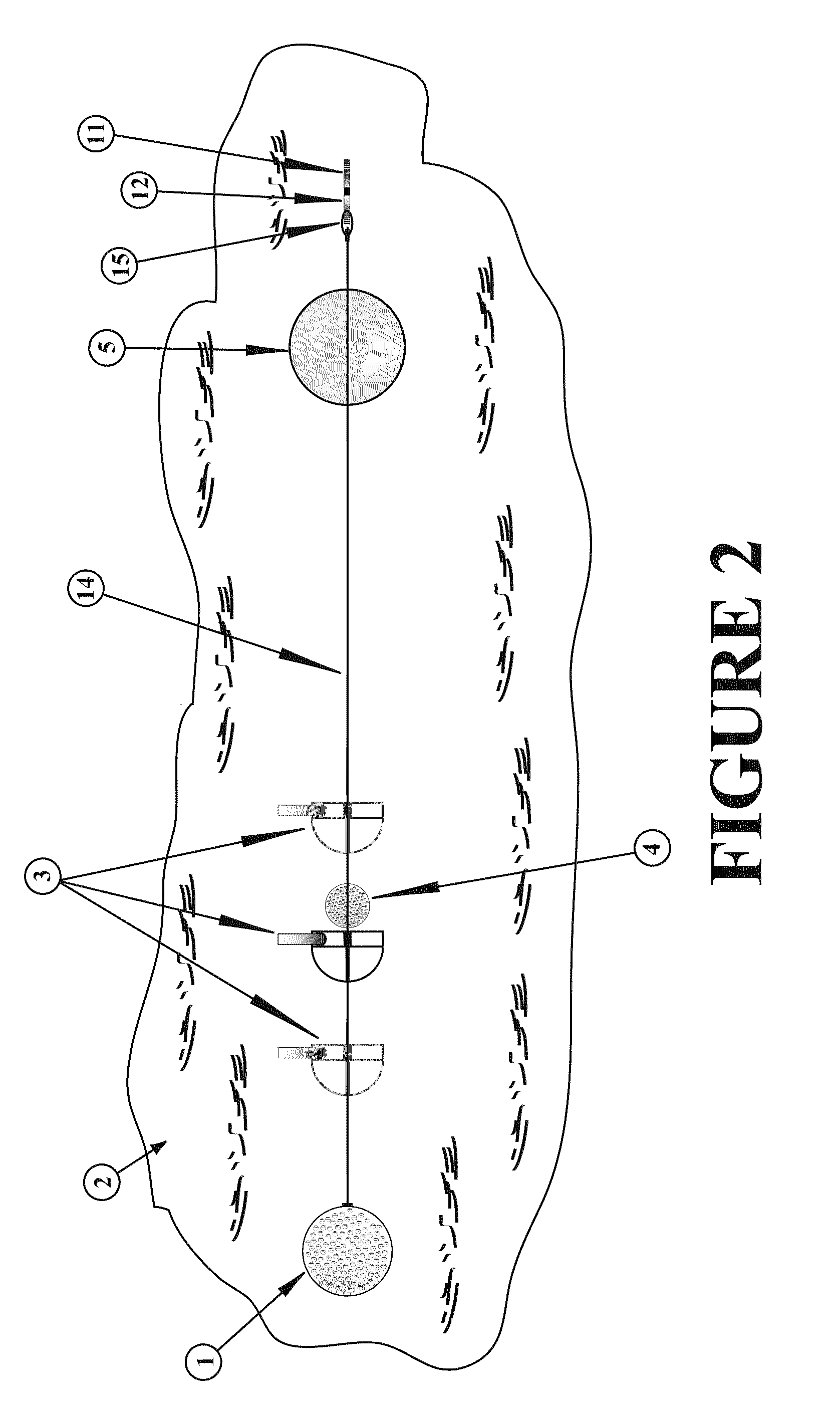

Remote Control Fishing Robot

A low-clearance remote control fishing robot is disclosed. A domed device casing is mounted between a pair of floats. The top of the device is fitted with a lightweight probe mounted on a spring. Each float has installed within its rear end a pivotal air jet. The air jets are powered by an onboard compressor. Beneath the device casing is a reel of fishing line. An electric motor drives the reel. Sensors are provided to gauge line length and depth and line tension. Onboard depth-finding and fish-finding sonar are provided, as well as other sensing systems, and an above-surface or below surface camera. Two way data communication occurs wirelessly with a remote control unit. A water-impervious carry case is provided to store the device and remote control. A positioning apparatus may be installed for fishing from a fixed position against a boat, pier, or ice hole.

Owner:FREEMAN CALEB

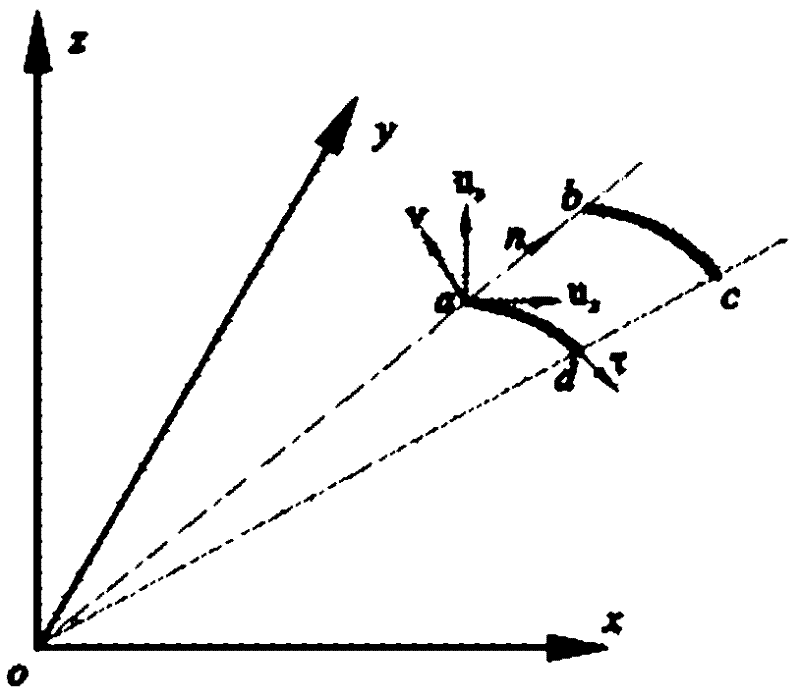

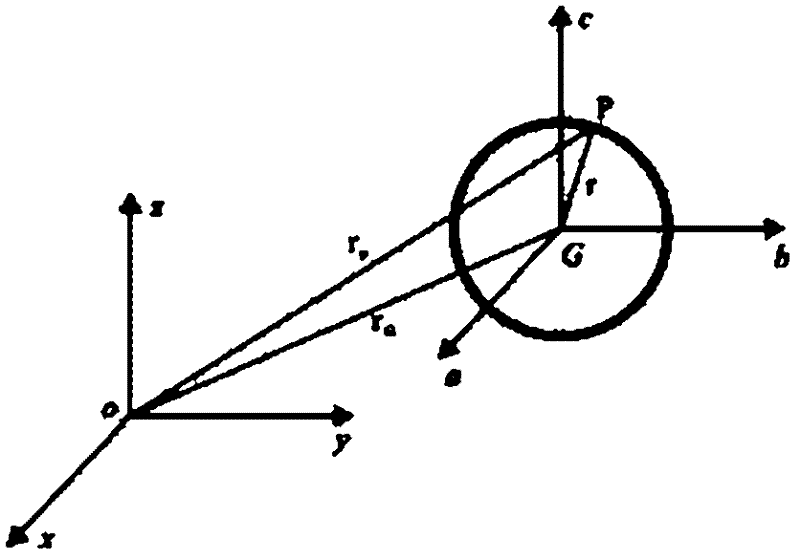

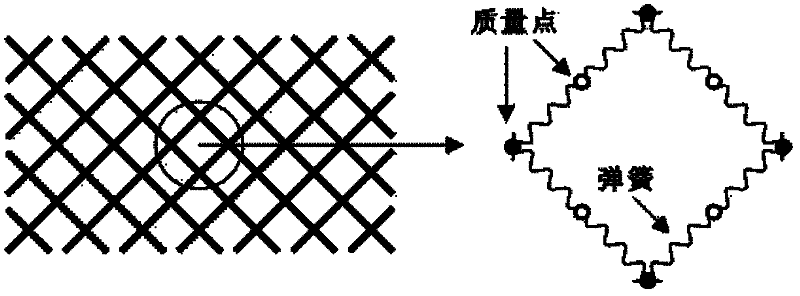

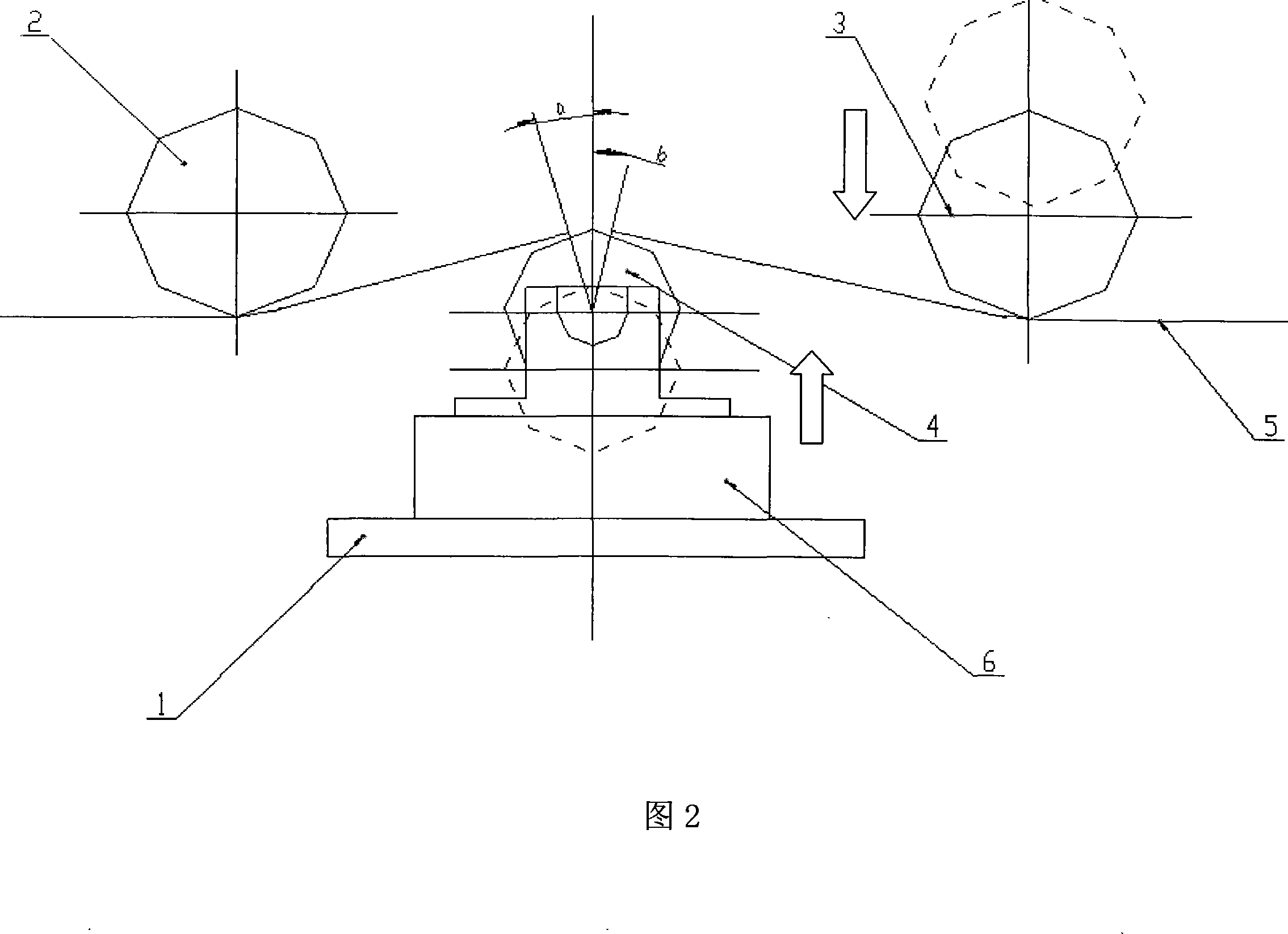

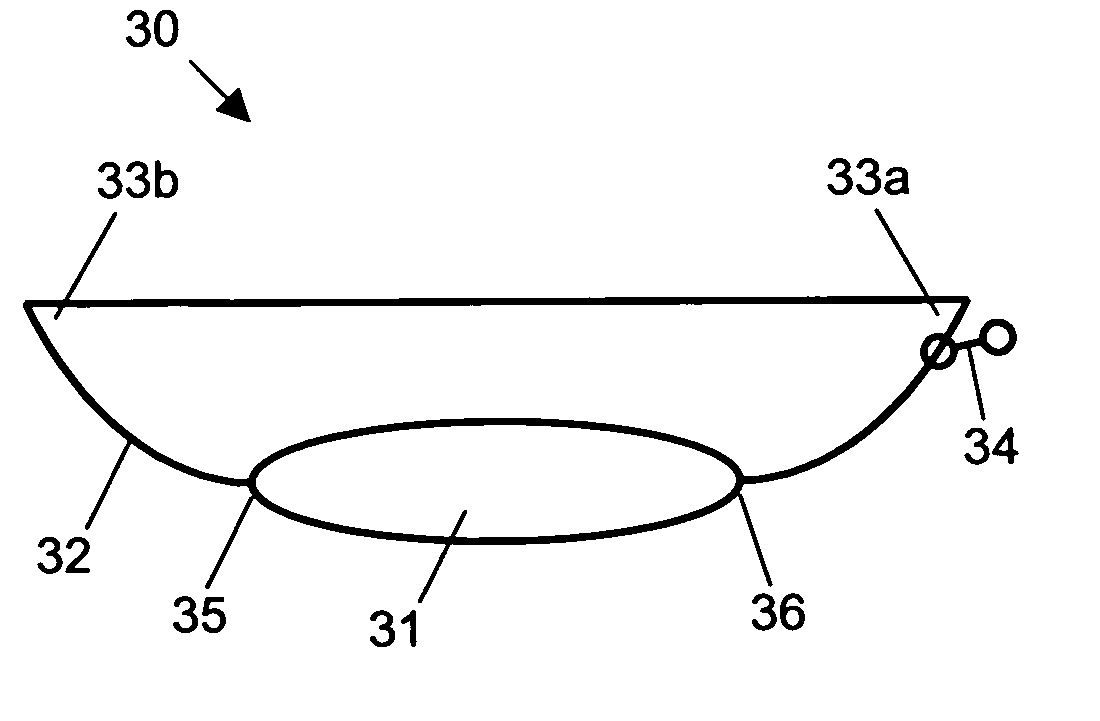

Numerical simulation method of hydrodynamic force response of deep-sea culture net cage group

The invention discloses a numerical simulation method of hydrodynamic force analysis of a deep-sea culture net cage group, comprising the following steps of: building a floating frame model; building a netting model; building an anchor line model; building a floating ball model; and solving by establishing a differential equation of motions. In the invention, a concentrated mass method and a rigid body kinematic theory are used for simulating the hydrodynamic force response of the deep-sea culture net cage group structure under the effects of waves; with the adoption of the method, anchor line tensions and floating frame motions of the deep-sea culture net cage group structure can be obtained; and according to the verification of physical experiments, the numerically simulated floating frame motions and anchor line tensions are matched with the actual floating frame motions and anchor line tensions. With the adoption of the method provided by the invention, the hydrodynamic force response of the net cage group composed of a plurality of the net cages can be analyzed and an anchor line system of a combined type net cage group can be optimized.

Owner:DALIAN UNIV OF TECH

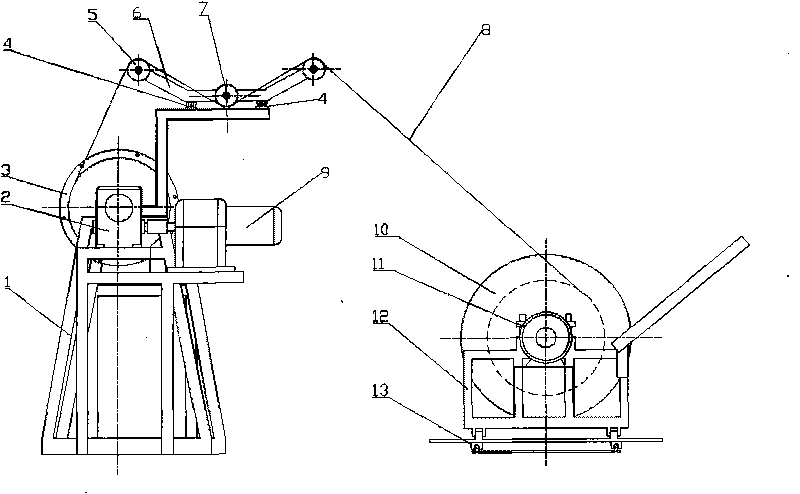

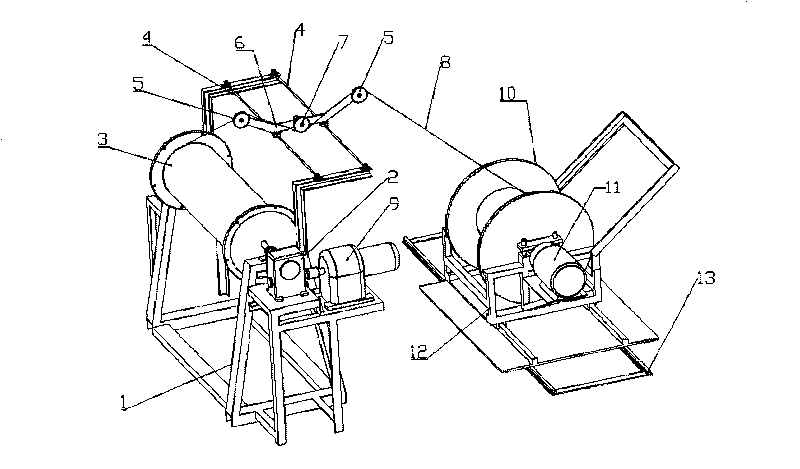

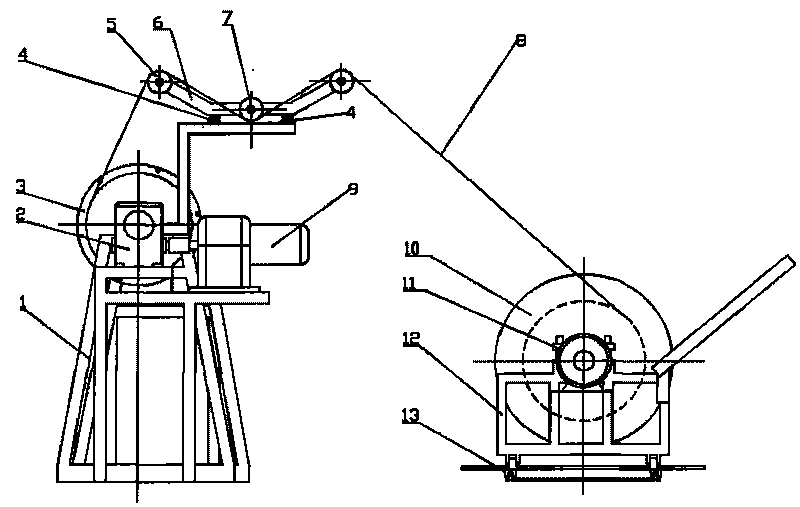

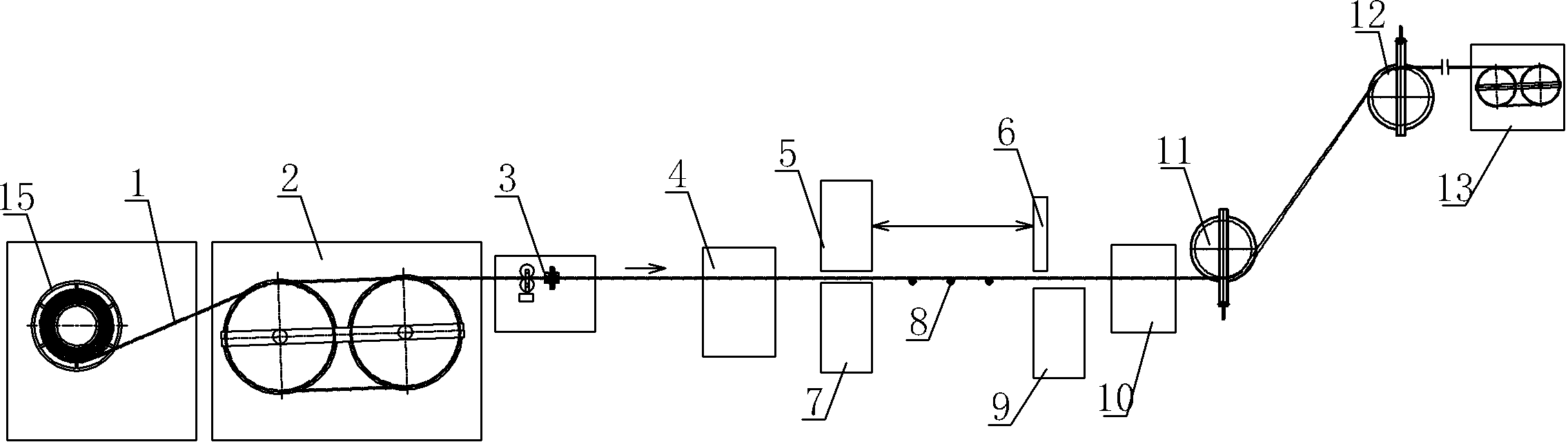

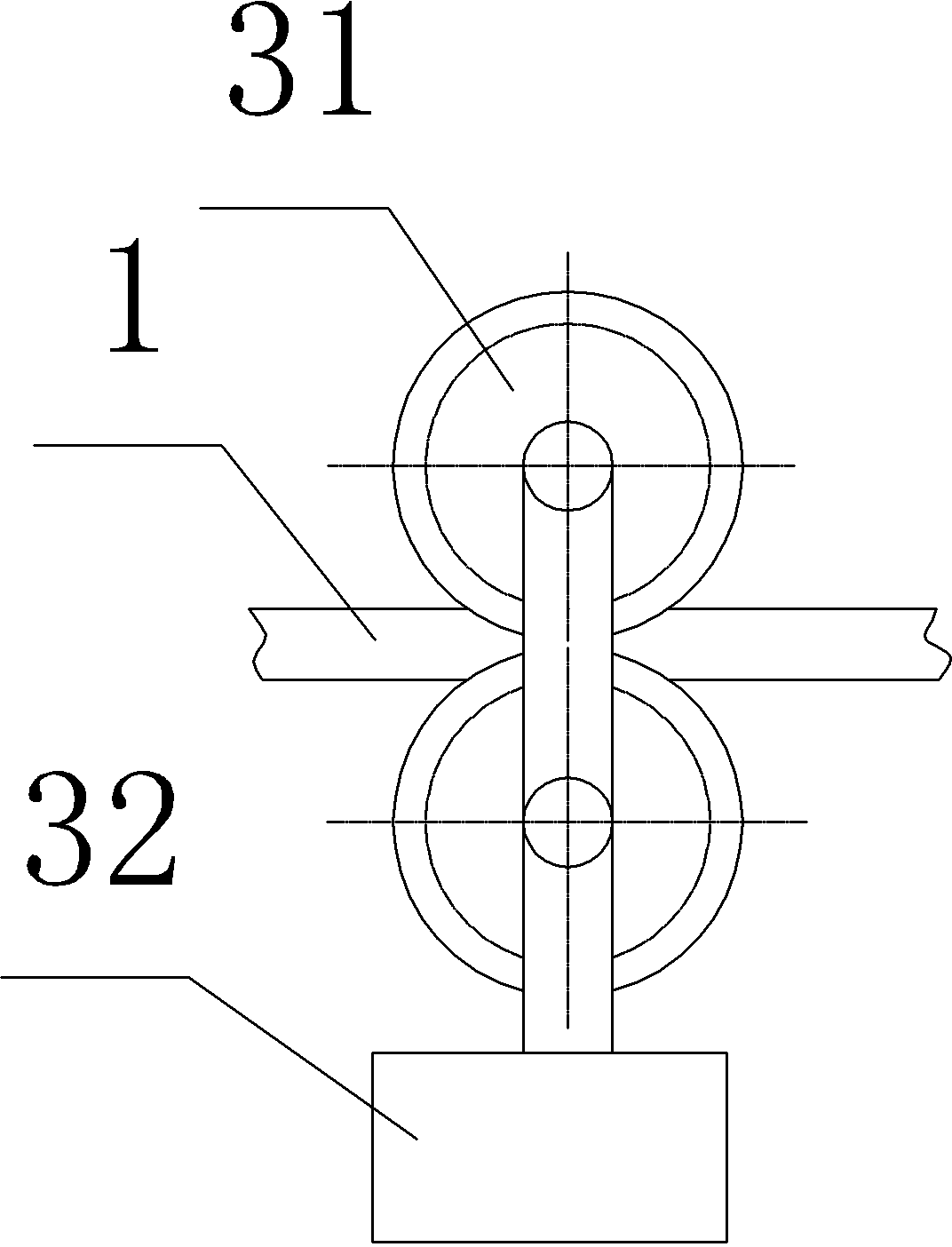

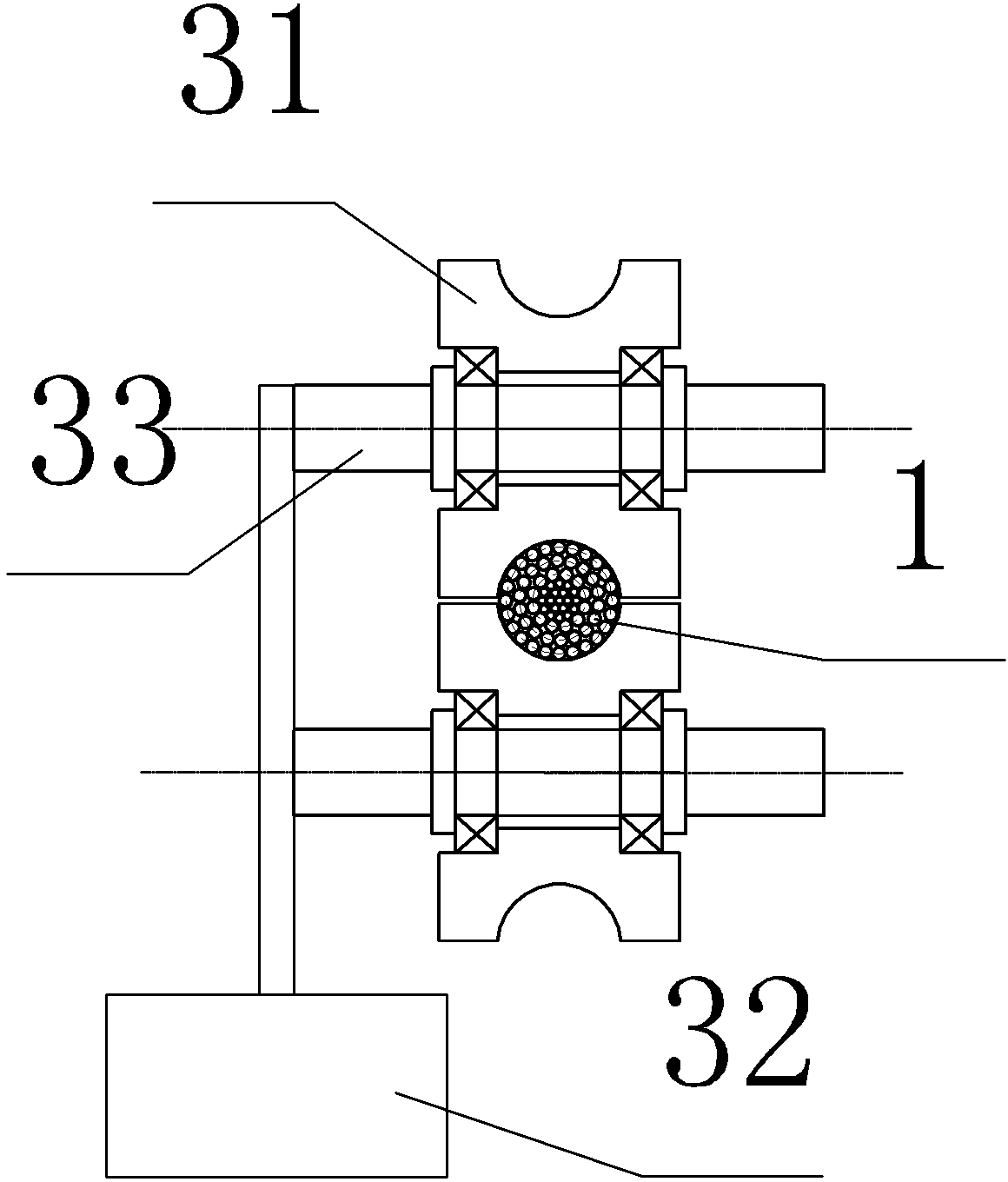

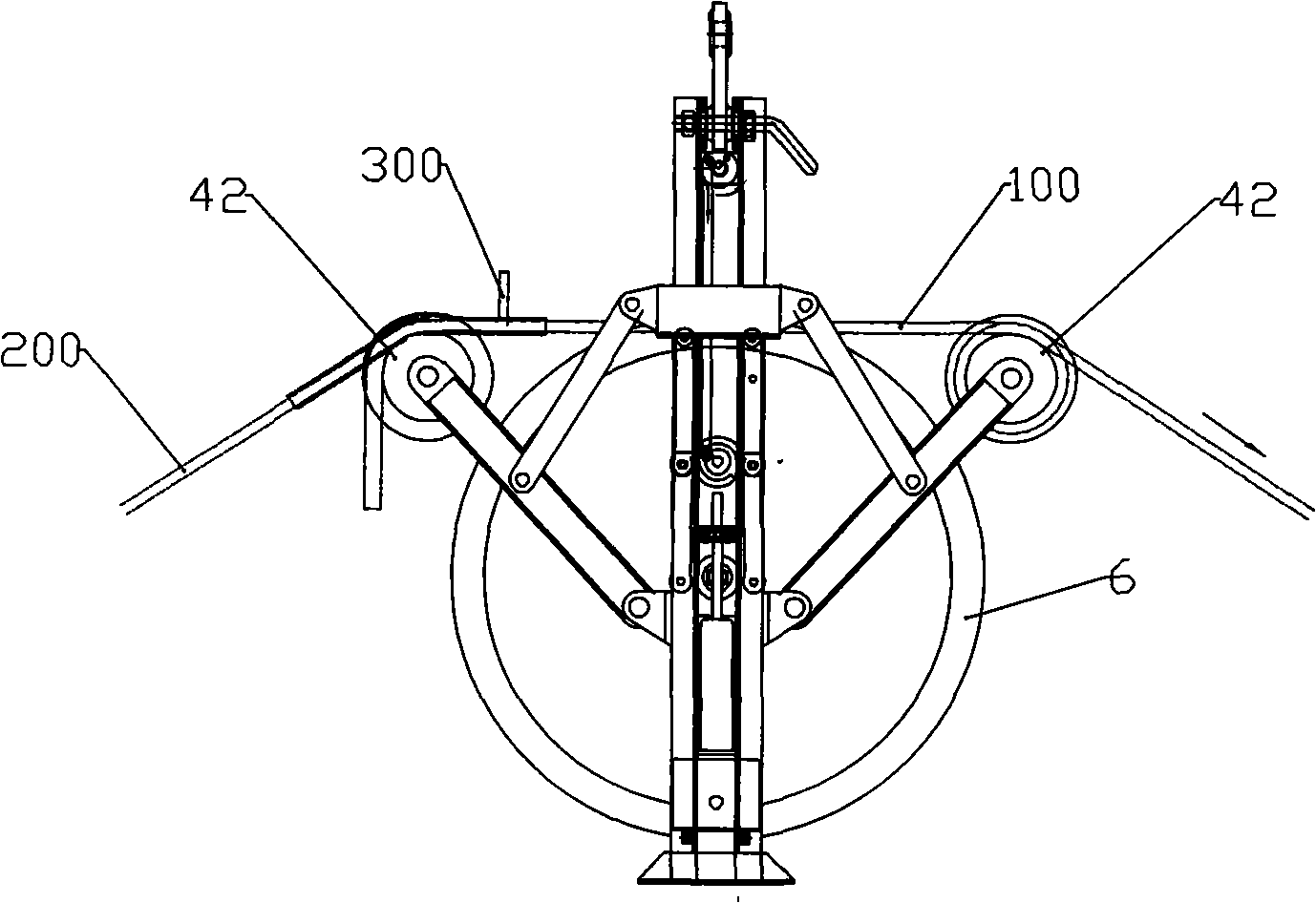

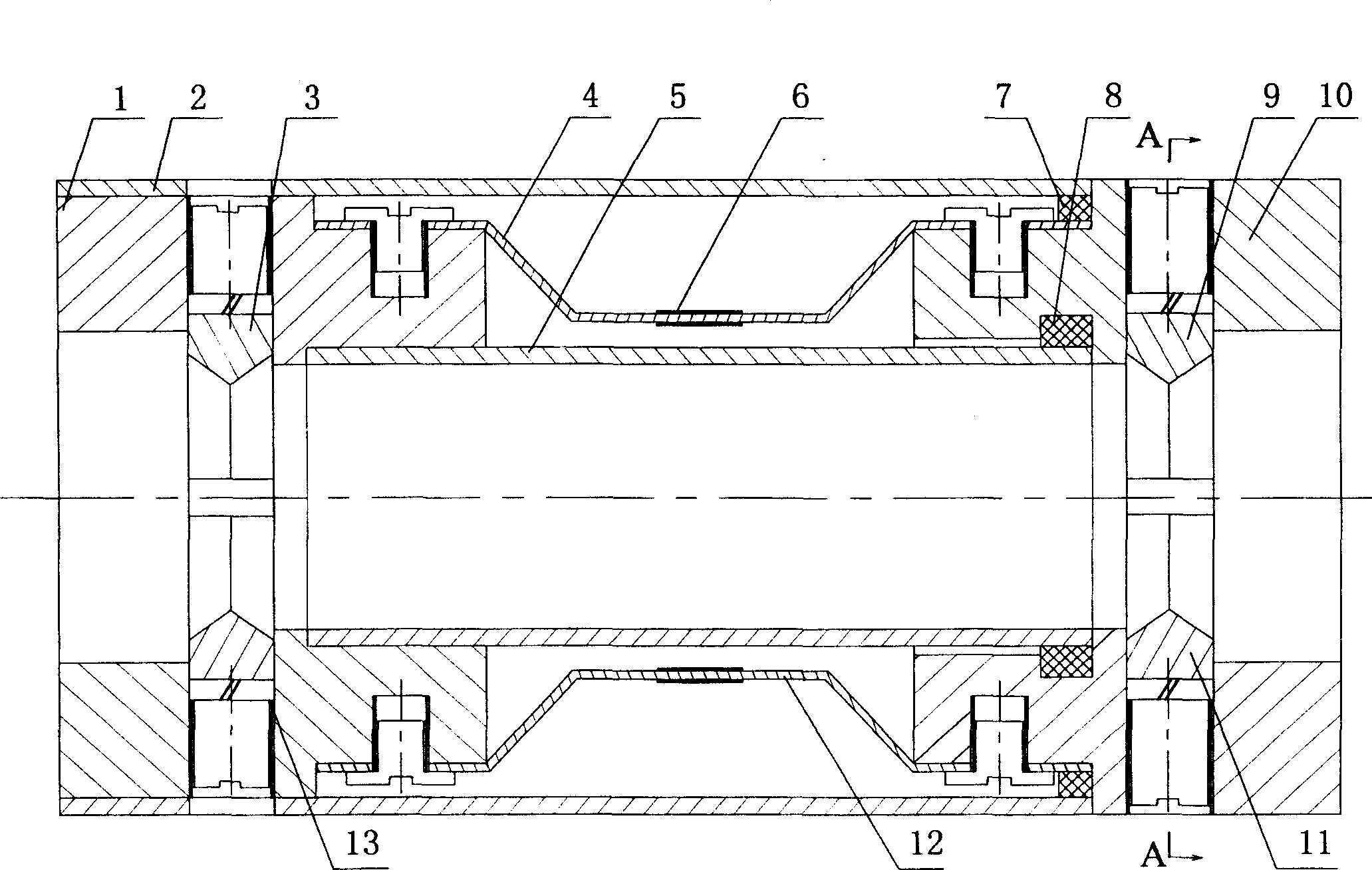

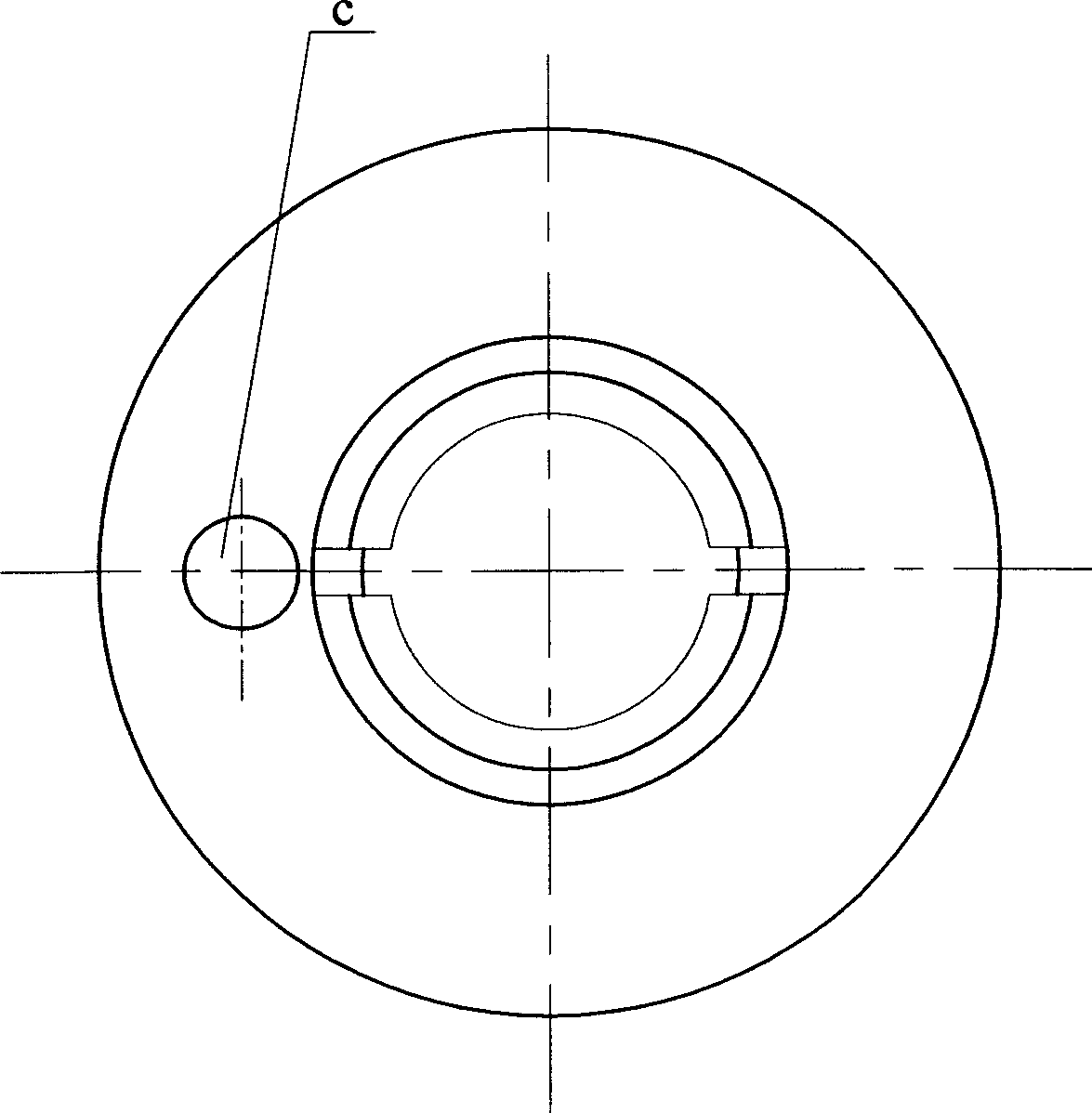

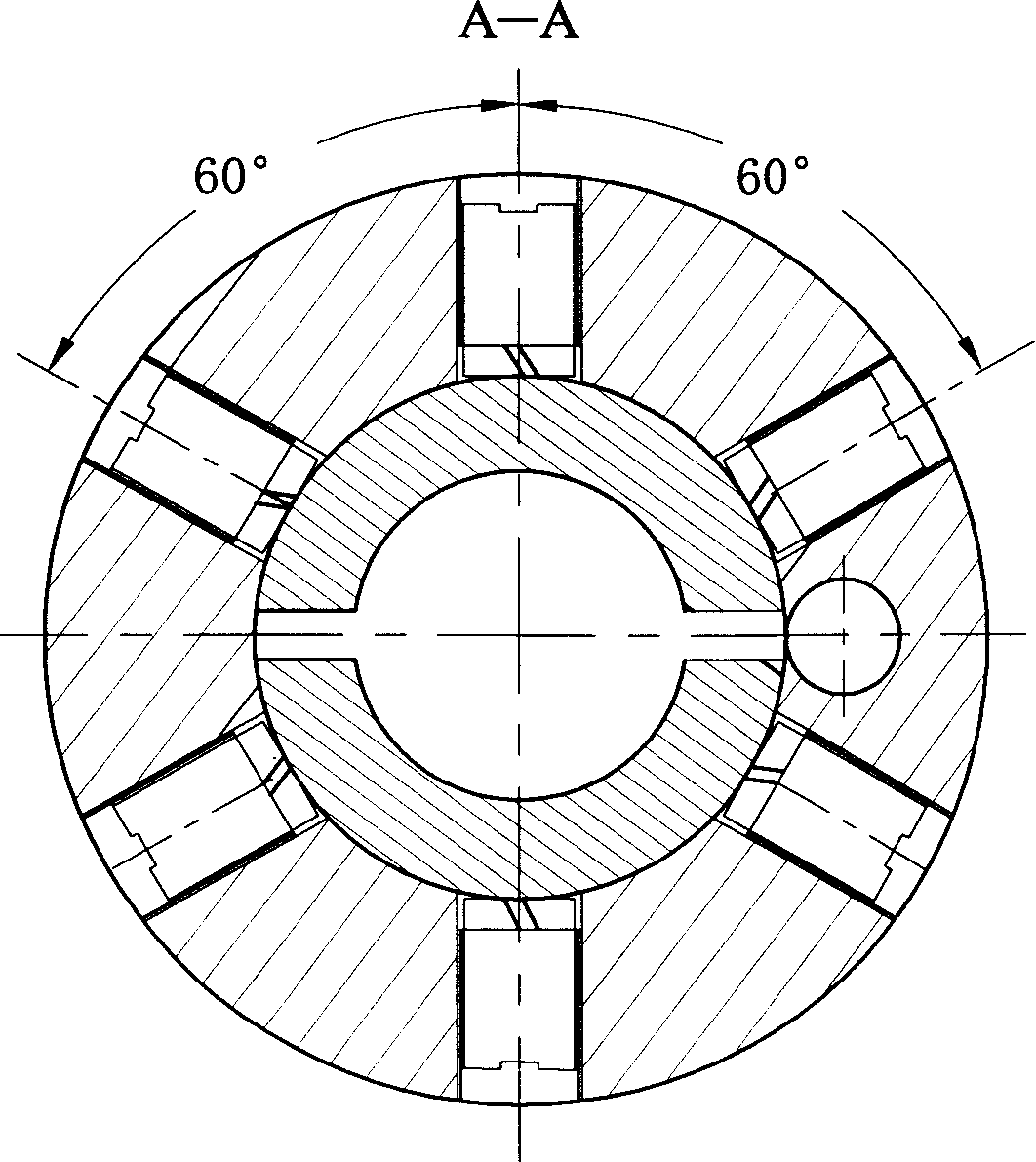

Device for winding superconducting coil

InactiveCN101719408AAchieve constant tension controlSimple structureSuperconducting magnets/coilsCoils manufactureSuperconducting CoilsHigh torque

The invention relates to a device for winding a superconducting coil, belonging to the technical field of superconducting coil winding equipment. The device is characterized by comprising a stepless speed change transmission unit, a superconducting coil frame supporting unit, a superconducting line tension detecting unit and a superconducting line paying off unit, wherein the stepless speed change transmission unit drives a superconducting coil frame to do axial rotation motion, and the superconducting line tension detecting unit and the superconducting line paying off unit also slide parallel with the direction of the central axis of the superconducting coil frame during the process that the superconducting line winds on the superconducting coil frame so as to ensure that under the condition of guaranteeing that the superconducting line stress in a superconducting coil tends to be consistent under the control of the superconducting line tension detecting unit, the stepless speed control of less than 50 turns per minute to winding rotating speed is achieved so as to meet the requirement on low rotating speed and high torque winding.

Owner:杭州生物医药科技创业园有限公司 +1

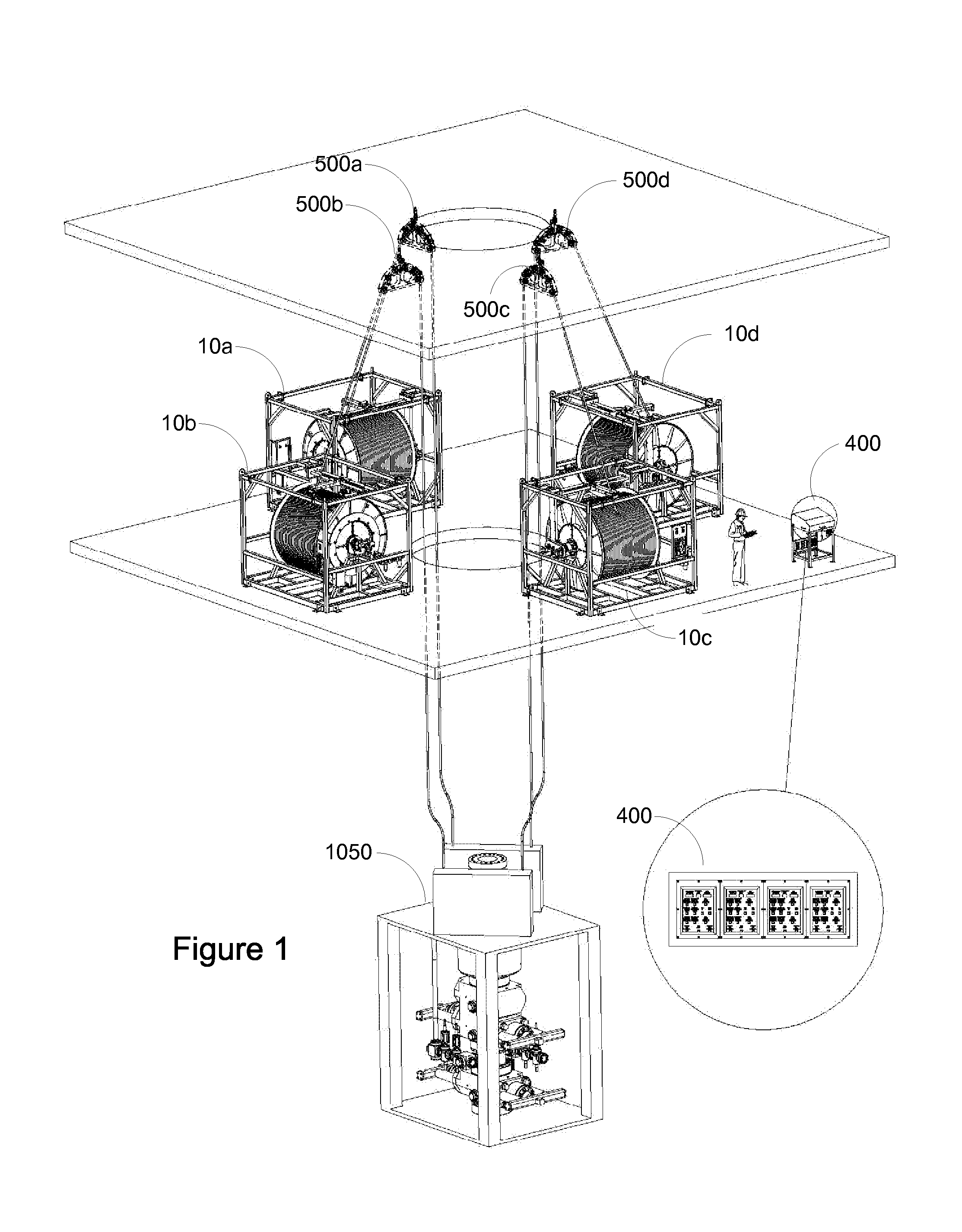

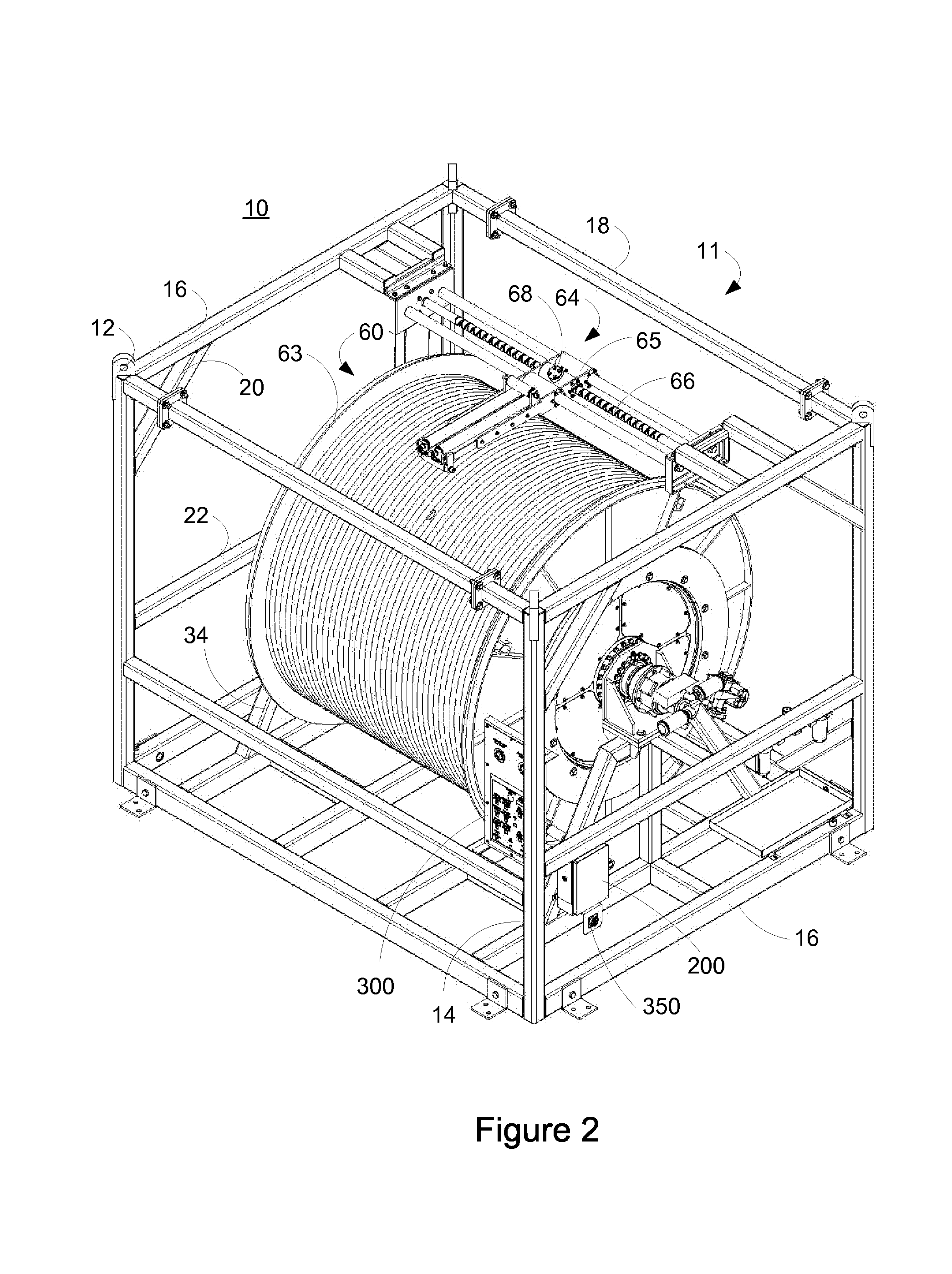

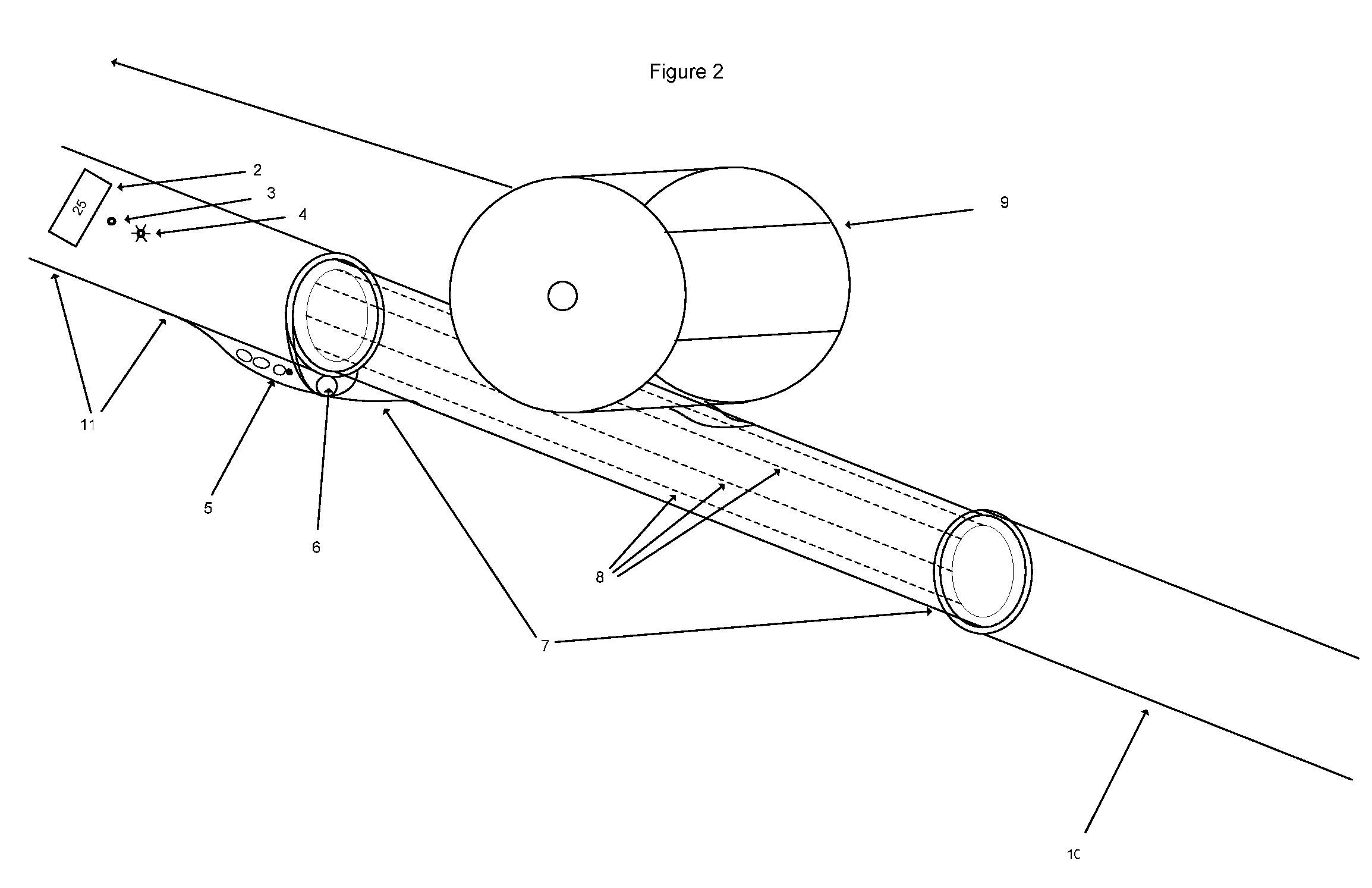

Cable Spools with Sheaves

A spooling system for deploying cable, hose, and / or umbilical connections may include a drum, an air motor, a sheave having one or more sensor, and an electronic control unit coupled to an electro-pneumatic drive for controlling the system. The sensors may provide information to the electronic control unit, such as a measured line tension and / or a length of cable, hose or umbilical connection that has been deployed, and the information may be displayed on the electronic control unit. The electronic control unit also may allow an operator to rotate the reel, stop rotation of the reel, increase or decrease the speed of rotation of the reel, increase or decrease pressure and / or line tension, and / or select between a normal mode of operation and a tensioning mode of operation.

Owner:PATCO MACHINE & FABTING

Reversibly disengaging slidable strike indicator, positioning system, and method of using same

Owner:DREAM WATERS

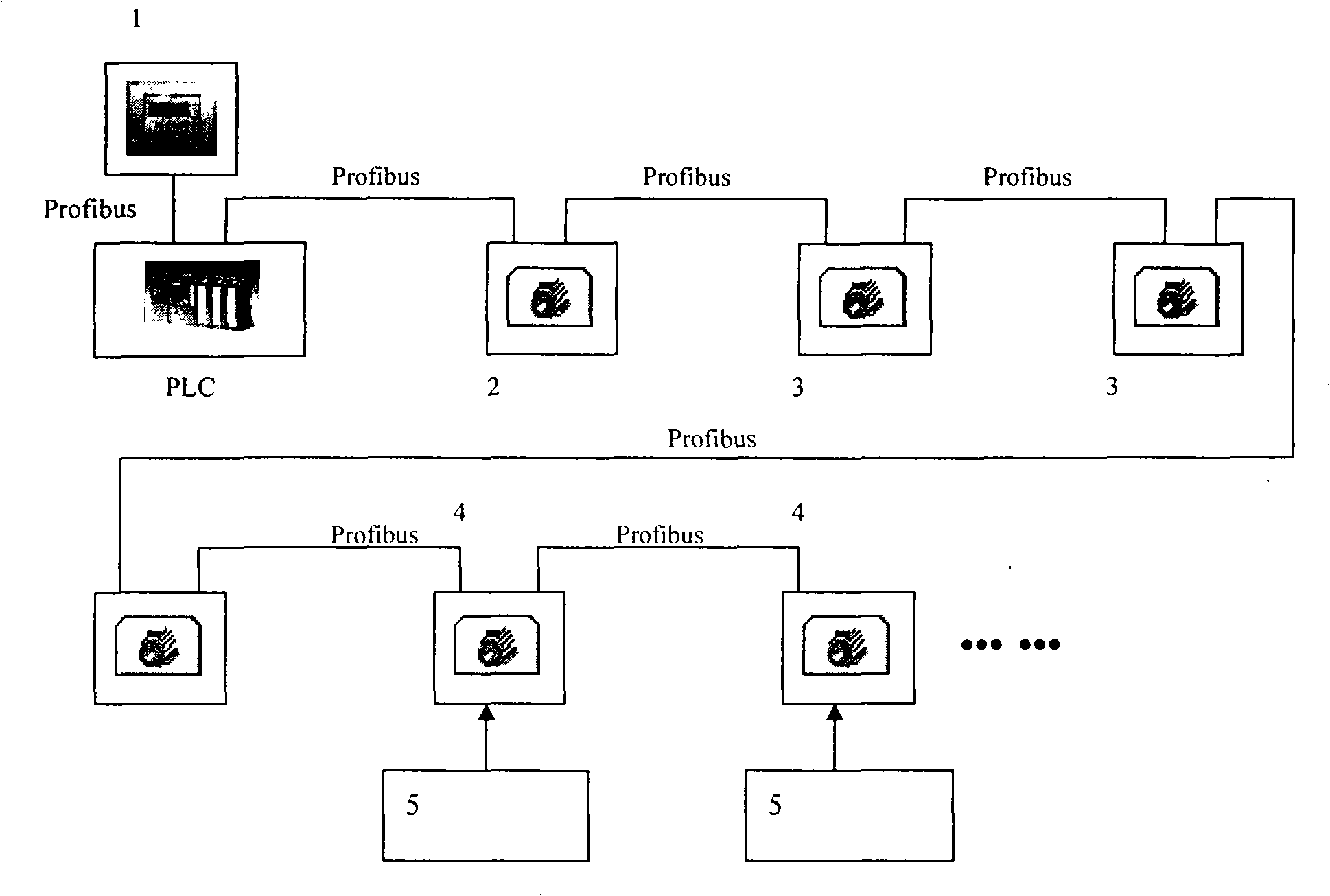

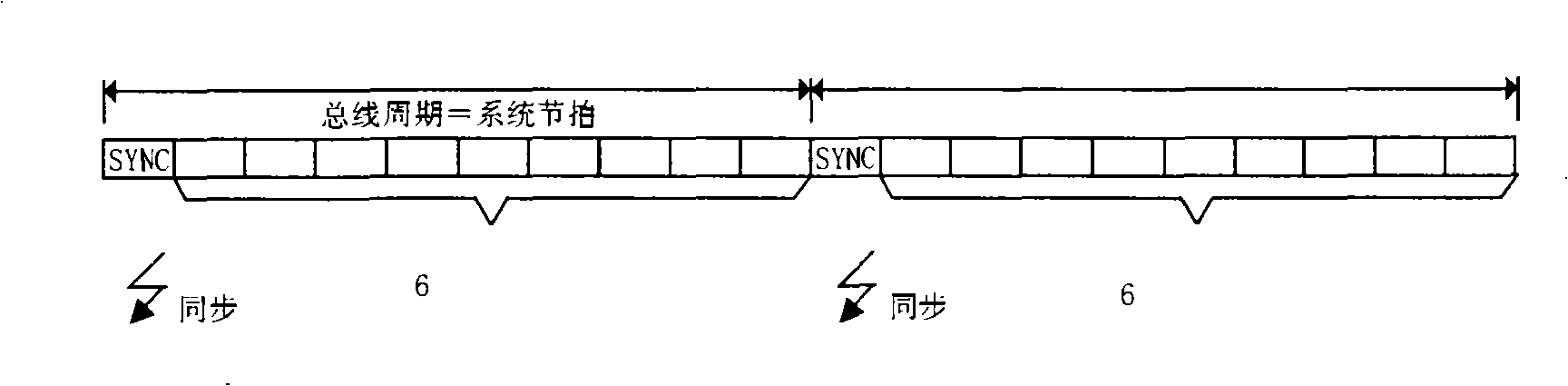

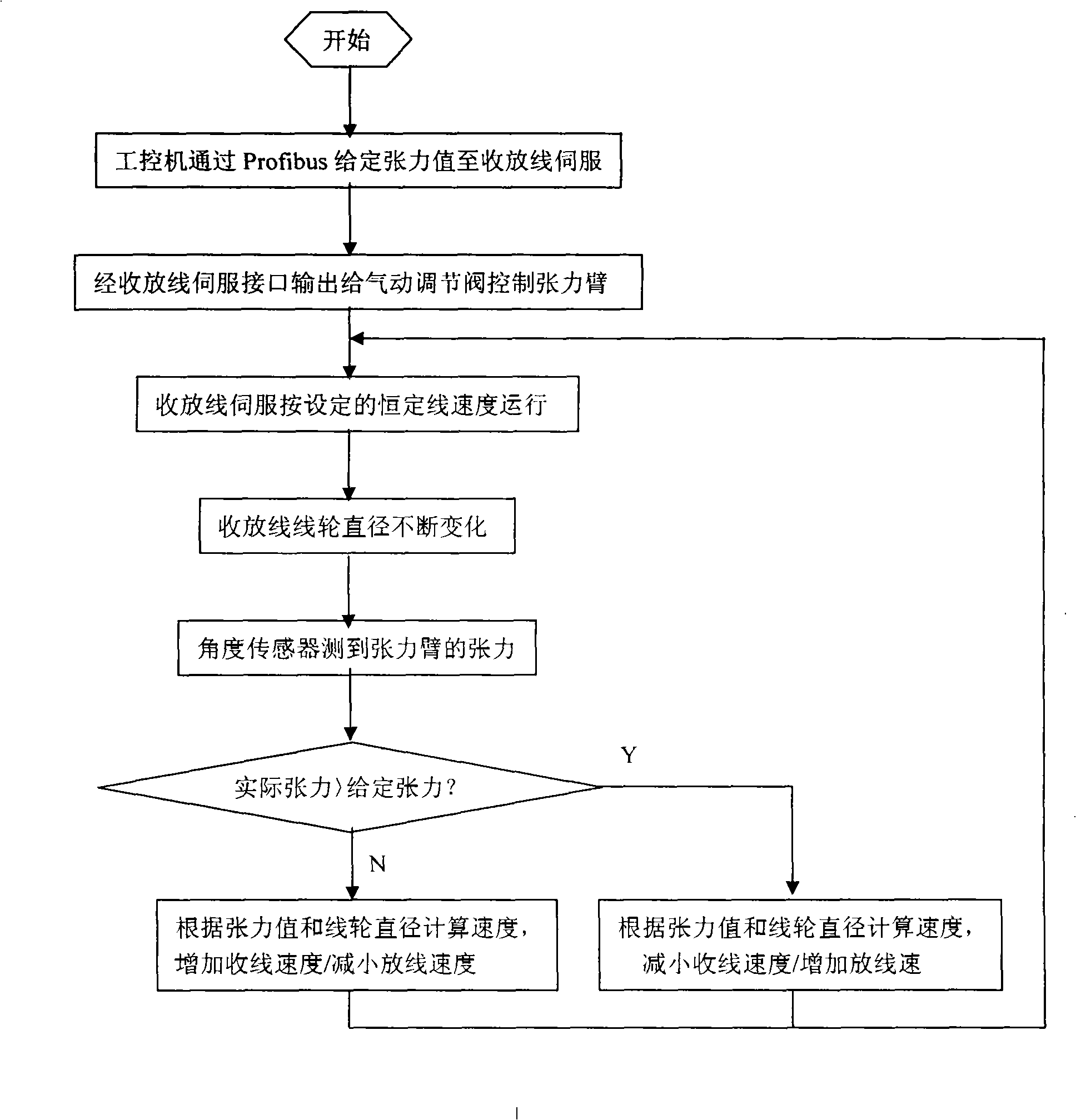

Multi-line cutting machine in-phase servo drive and constant tension control system

ActiveCN101284401ASolve communication tasksTempo syncFine working devicesElectric machineryWire cutting

The invention relates to a control system for a multi-wire cutting machine. A multi-wire cutting machine synchronous servo drive and constant tension control system includes an industrial personal computer, a main serve motor, a secondary serve motor and a take-up and pay-off serve motor. The invention is characterized in that the industrial personal computer sets a standard specified value which is sent to a main servo drive, at the same time, high-speed data transmission is carried out between the industrial personal computer and each servo drive via Profibus, the specified value and the data of the main drive are quickly sent to three secondary drive serve motors and the take-up and pay-off serve, the dependence on the synchronous character of each message is synchronously realized, the value synchronous with the main servo is calculated by the take-up and pay-off serve according to the above data and the diameter of the prior take-up reel and the line tension in the industrial personal computer, and the result is transferred to the take-up and pay-off serve via the Profibus bus.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

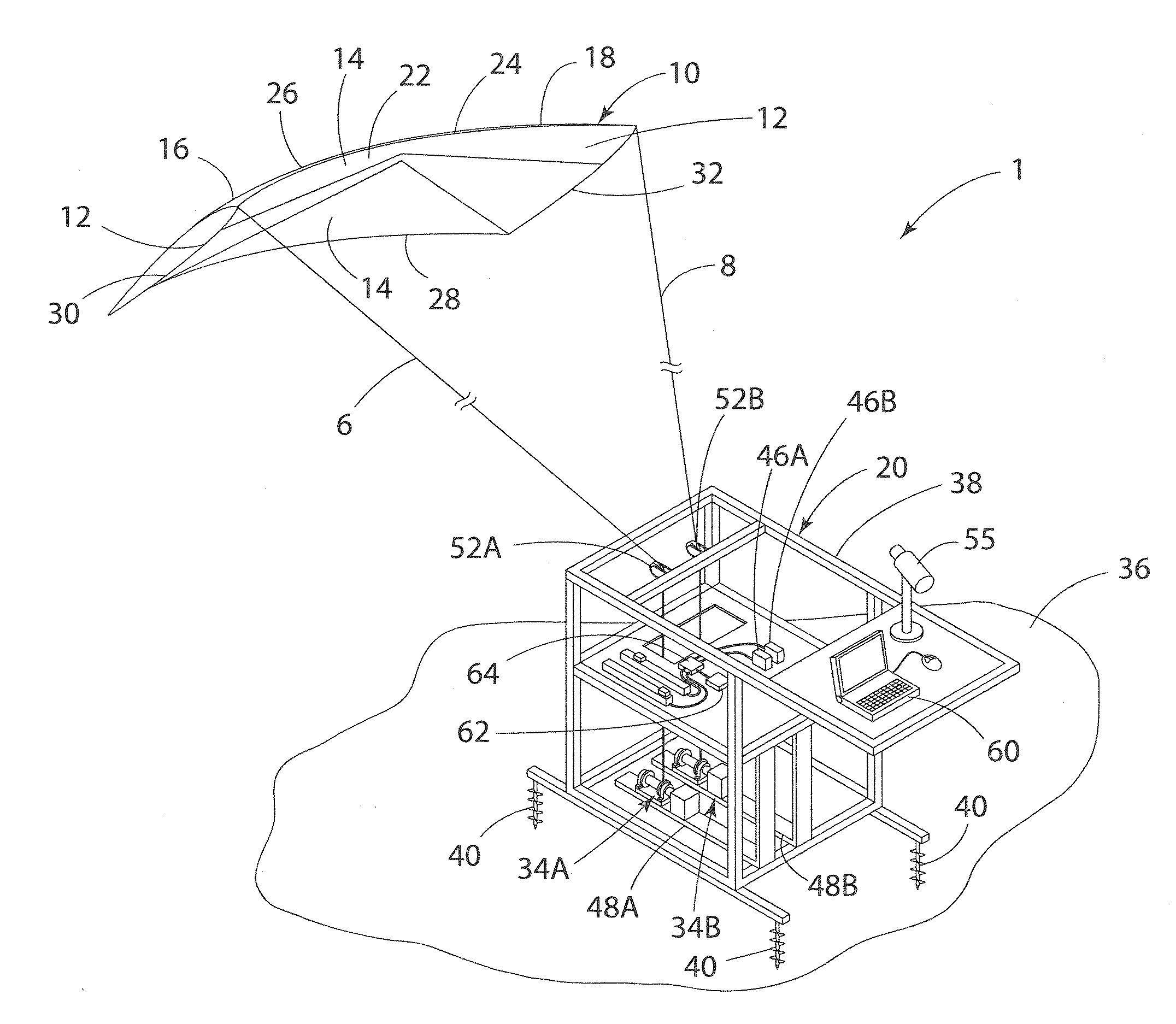

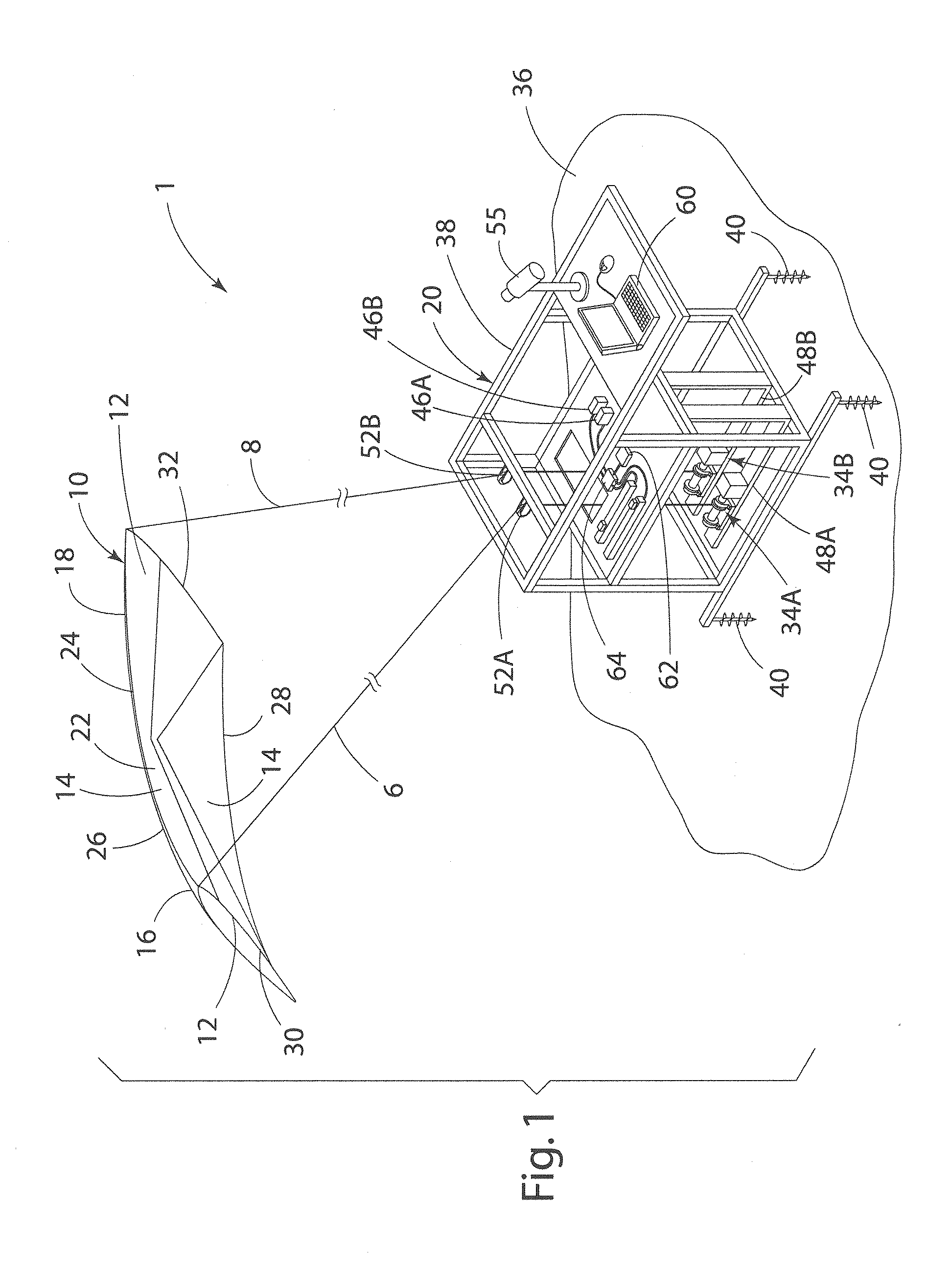

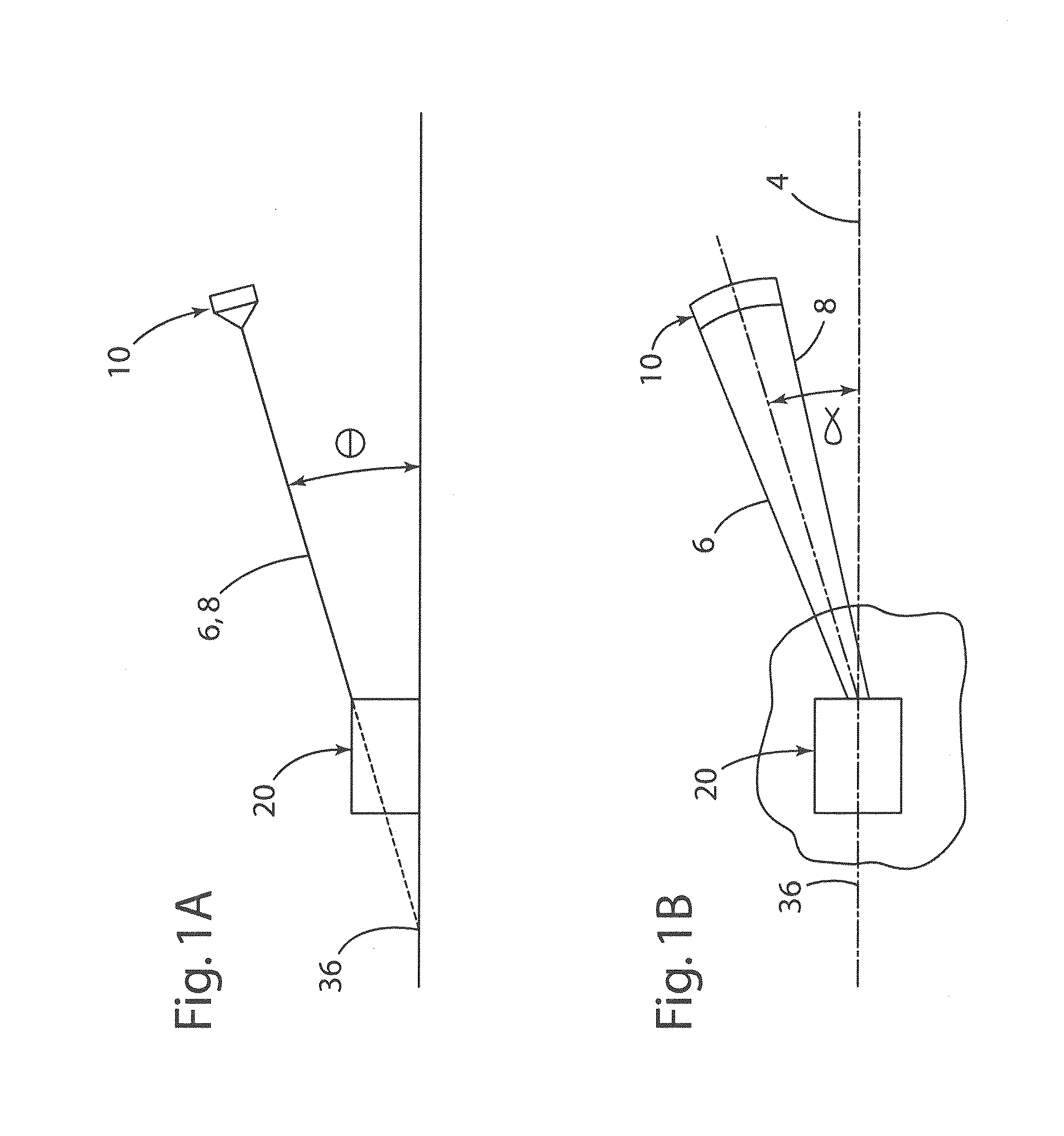

Tethered Vehicle Control and Tracking System

A kite system includes a kite and a ground station. The ground station includes a sensor that can be utilized to determine an angular position and velocity of the kite relative to the ground station. A controller utilizes a fuzzy logic control system to autonomously fly the kite. The system may include a ground station having powered winding units that generate power as the lines to the kite are unreeled. The control system may be configured to fly the kite in a crosswind trajectory to increase line tension for power generation. The sensors for determining the position of the kite are preferably ground-based.

Owner:NASA

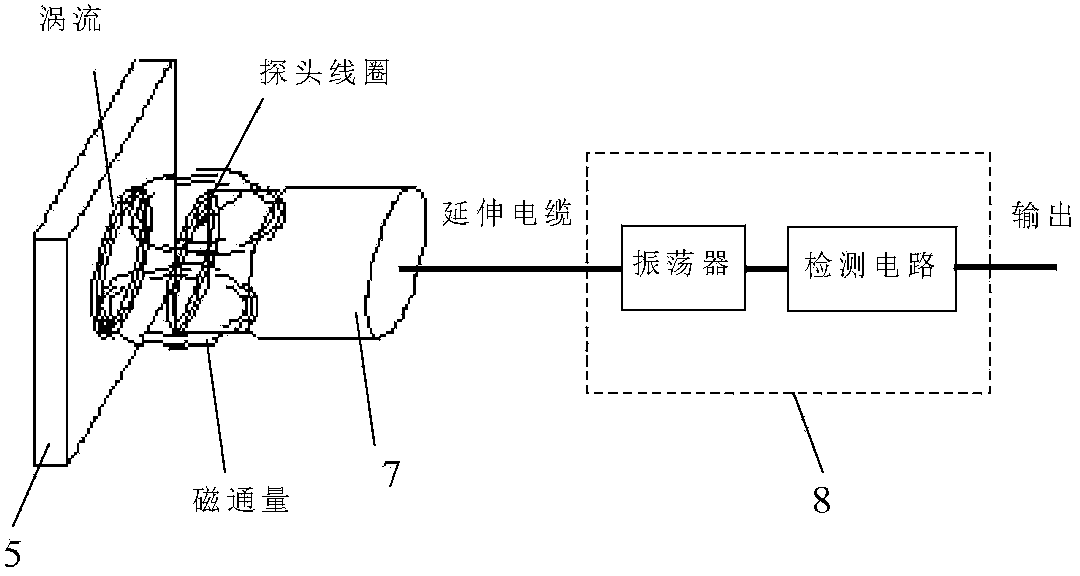

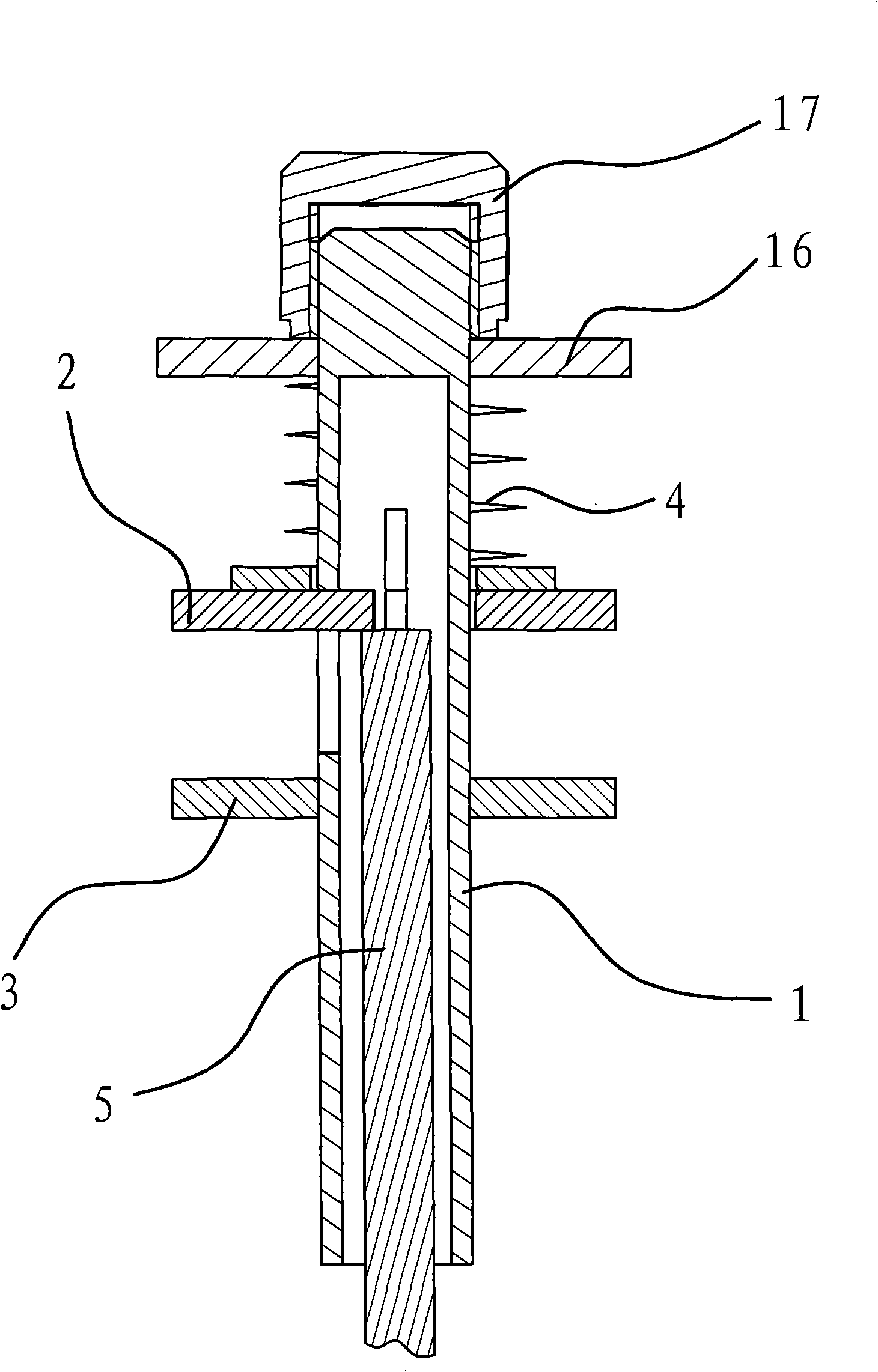

On-line tension force detecting mechanism

InactiveCN101190447AProduction is of great significanceGood tension optimizationMeasuring devicesTension measurementResistProduction line

The invention relates to a cold rolling production line upper plate aligning device, in particular to an online tension detection mechanism. The invention is characterized in that the invention comprises at least one tension detection mechanism; a tension detection roller (4) is fixed on an oil cylinder base (1) with lifting function; the tension detection roller (4) is arranged between a hydraulic shear and an upper crease-resist roller (3), leading a cold rolling plate strip (5) on the upper surface of the tension detection roller (4) to the hydraulic shear at the front end and form an angle with the upper crease-resist roller (3) on the rear surface when the cold rolling plate strip (5) passes through a fixed roller (2), the tension detection roller (4) and the upper crease-resist roller (3); the lower surface of the tension detection roller (4) forming the angle is provided with a tension sensor (6) which is connected with a detection circuit; the value of the horizontal distance between the fixed roller (2), the tension detection roller (4) and the upper crease-resist roller (3) is fixed. The invention has the advantages of simple structure, safe and reliable performance, being used for direct tension closed loop control.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

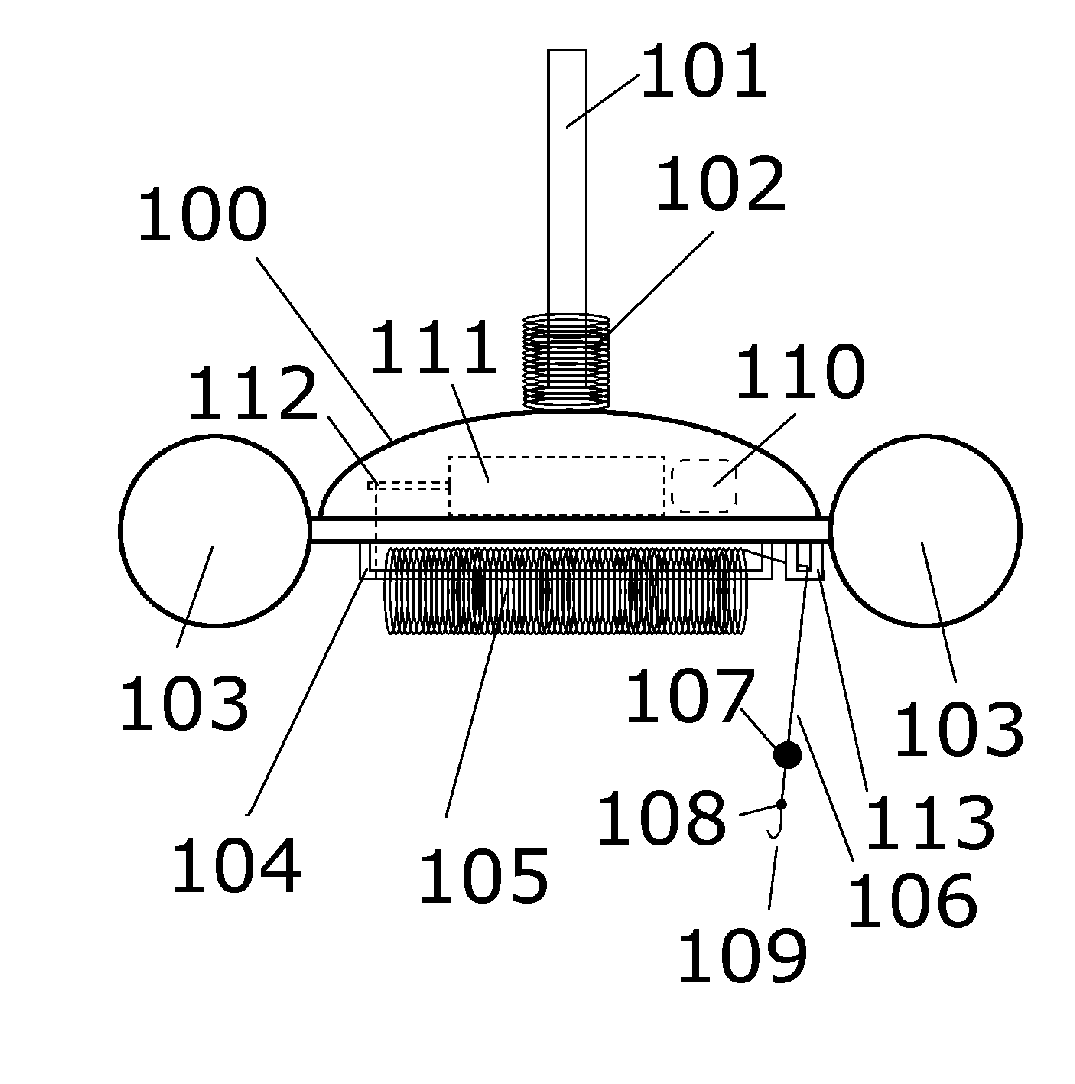

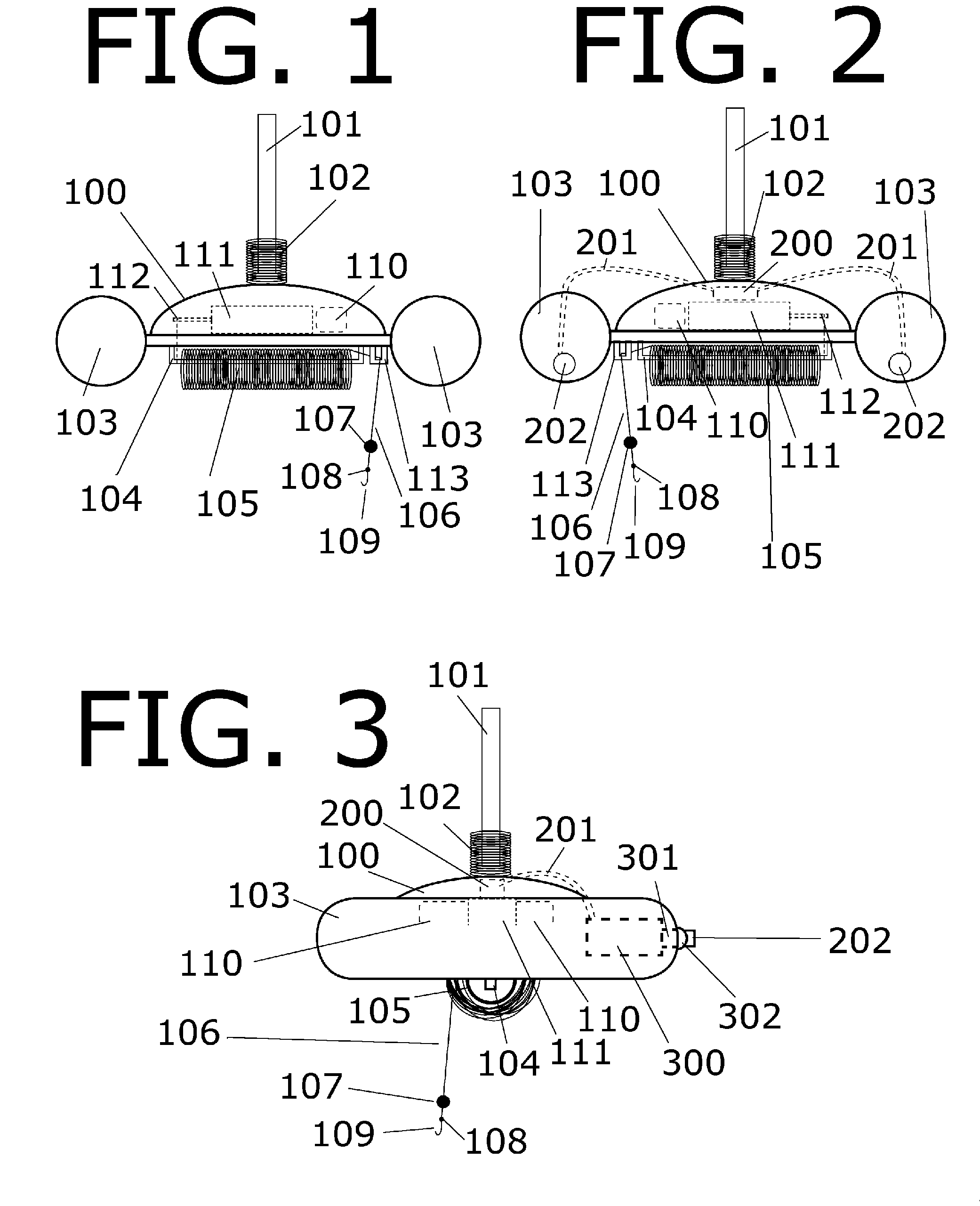

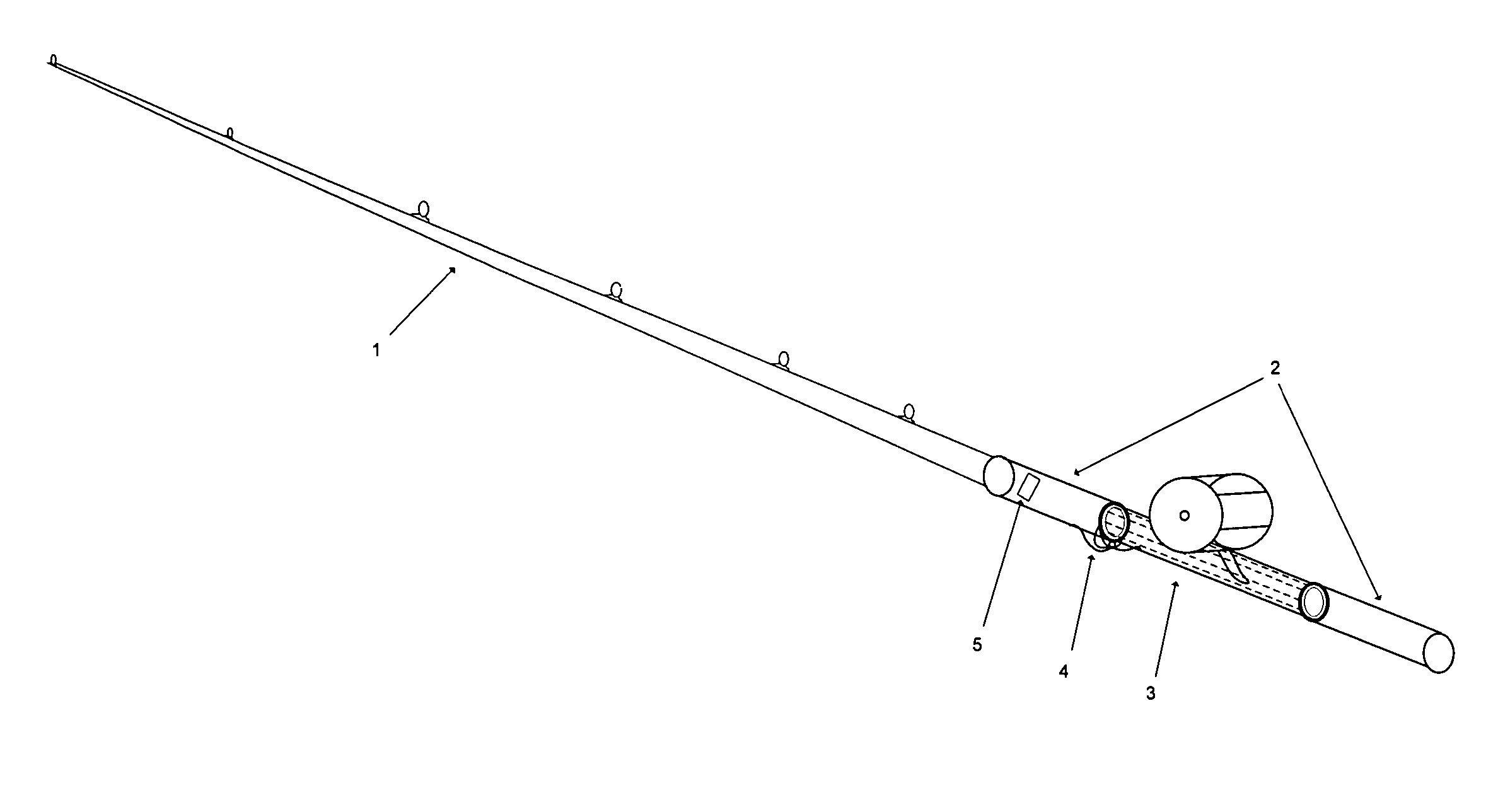

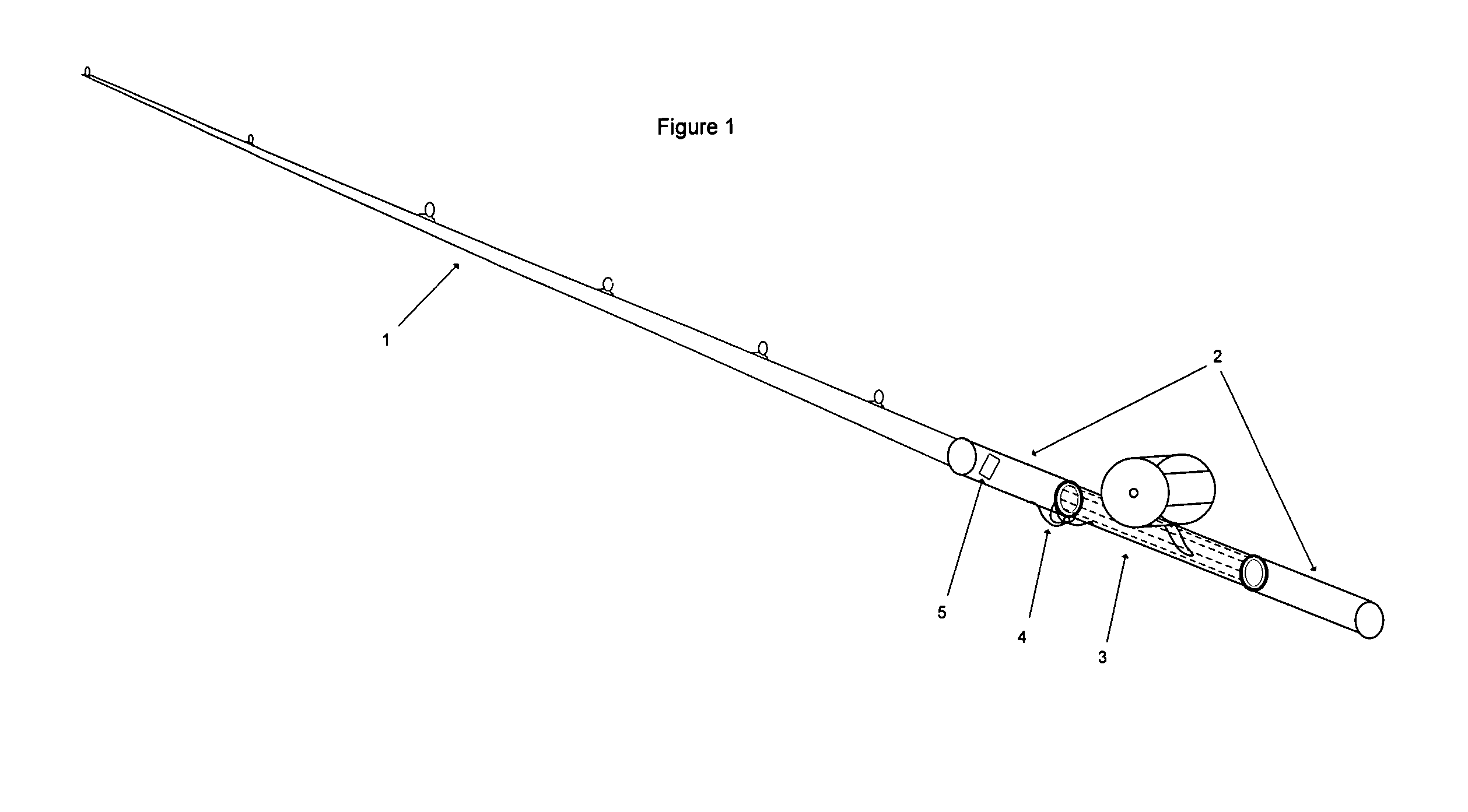

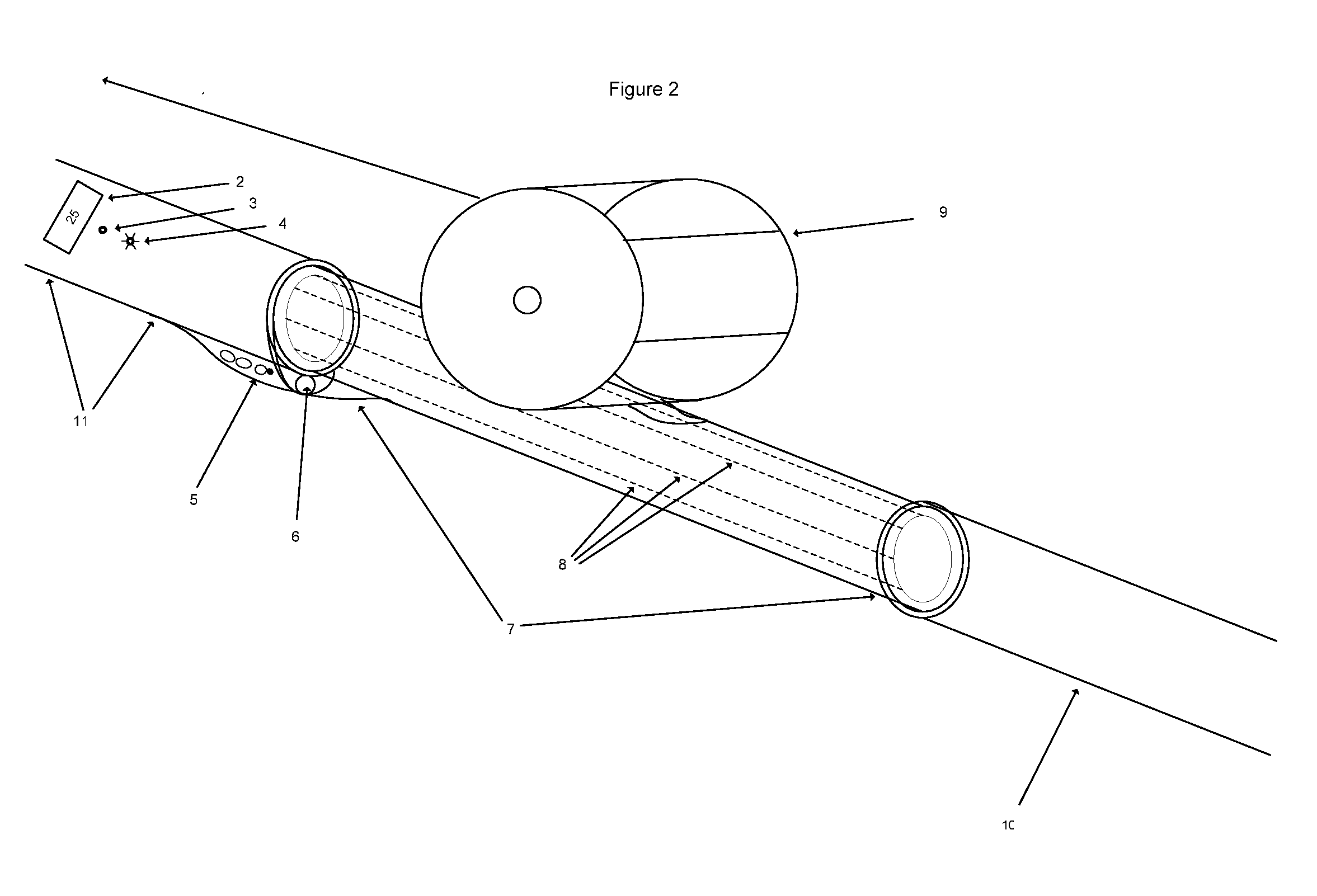

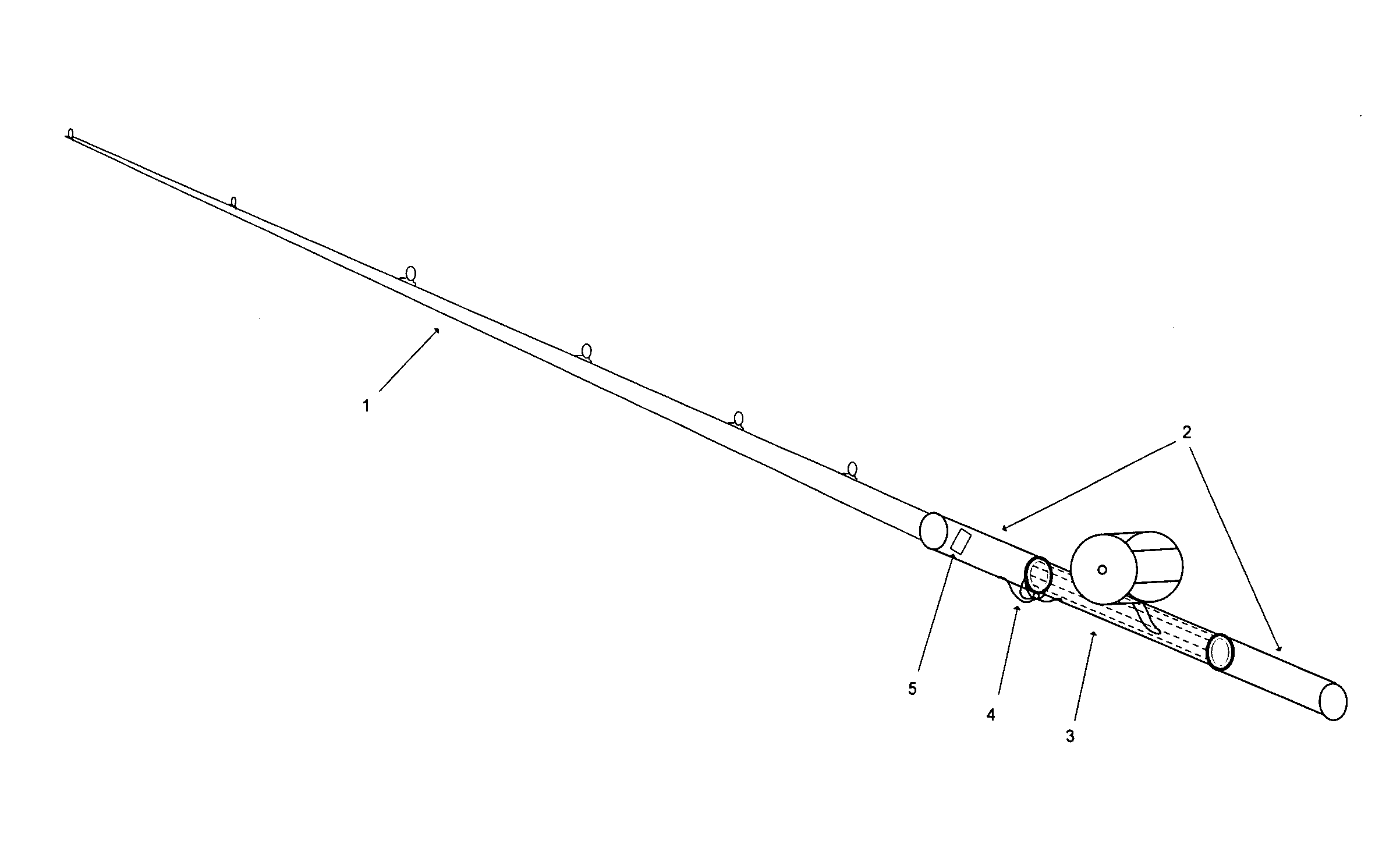

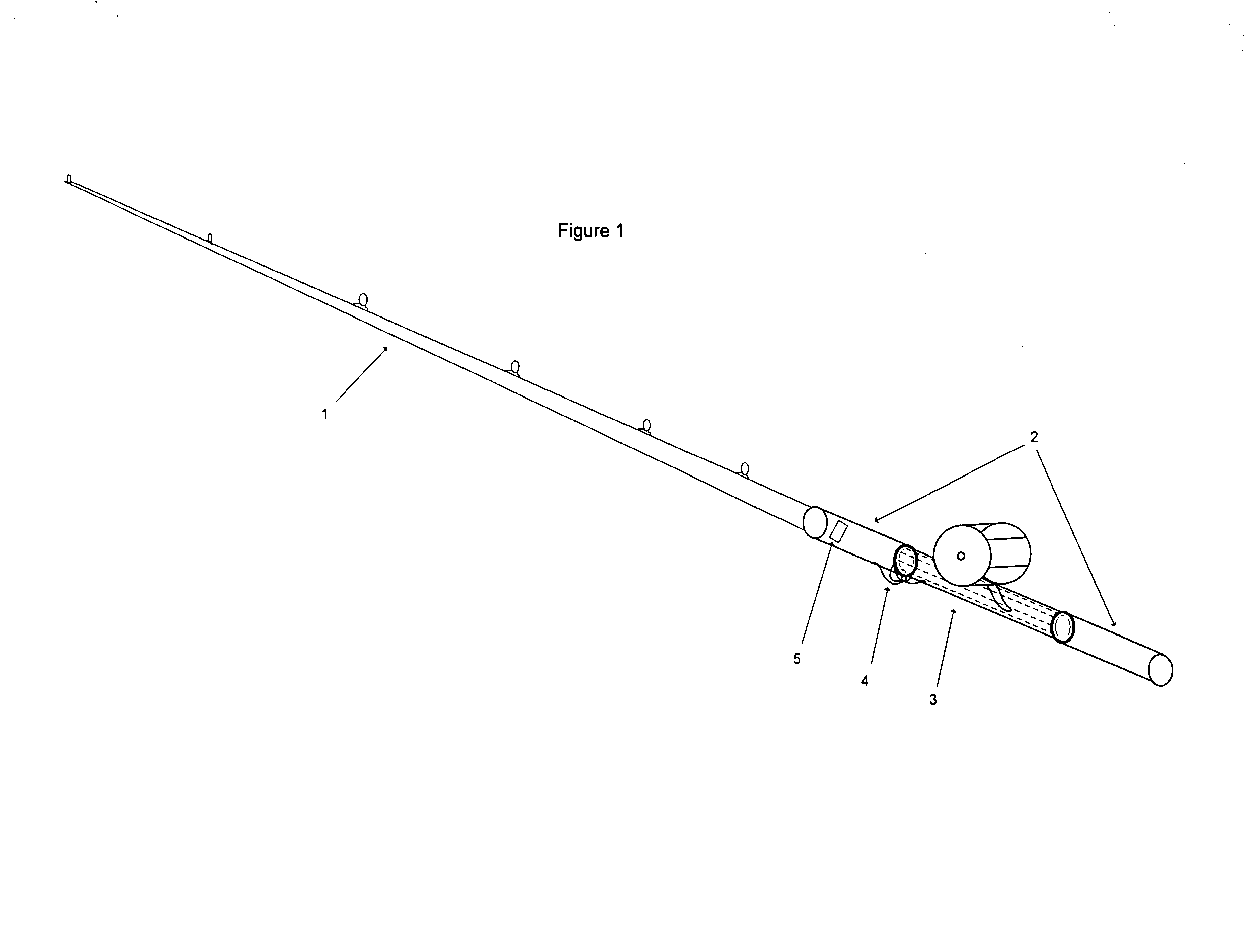

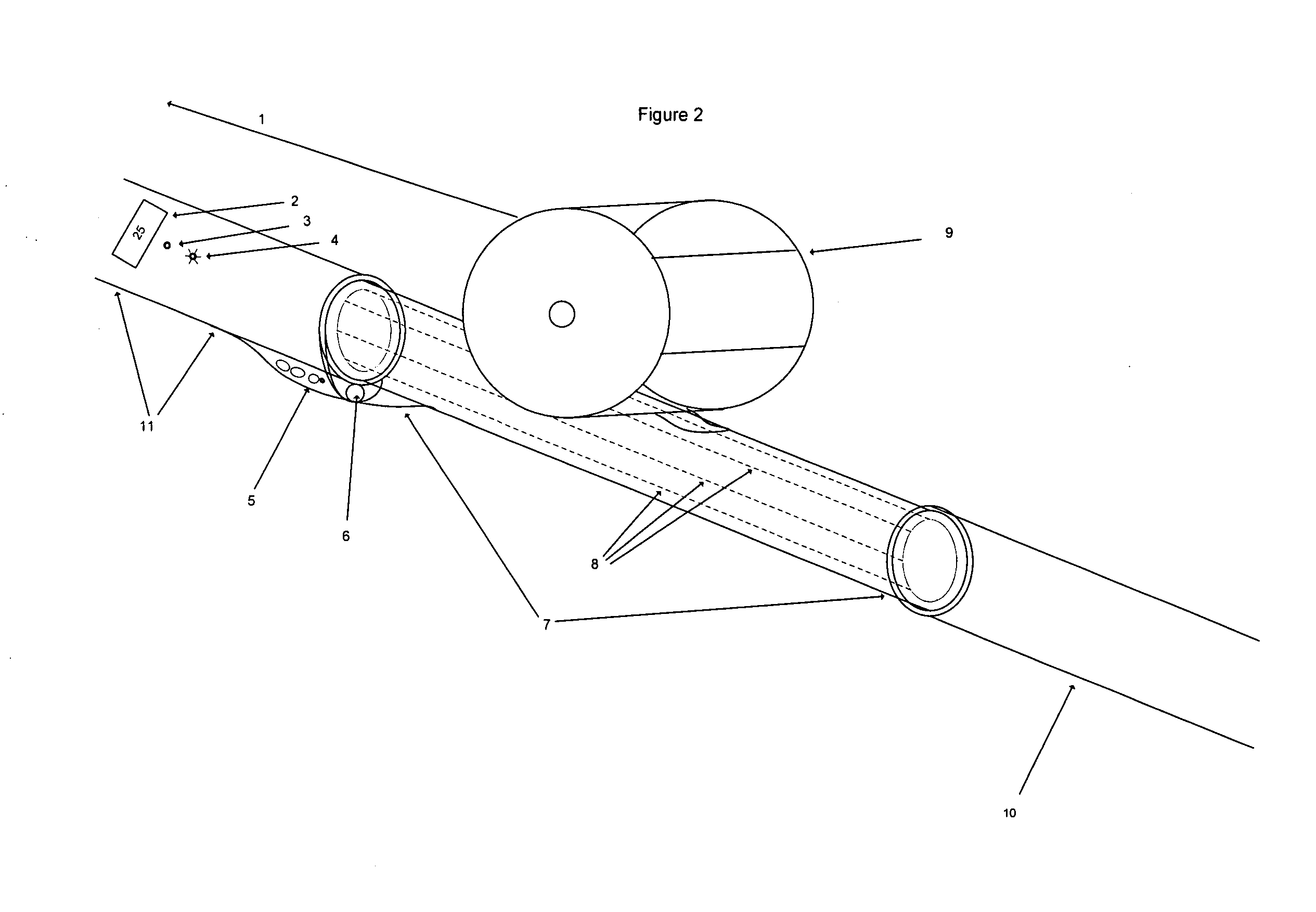

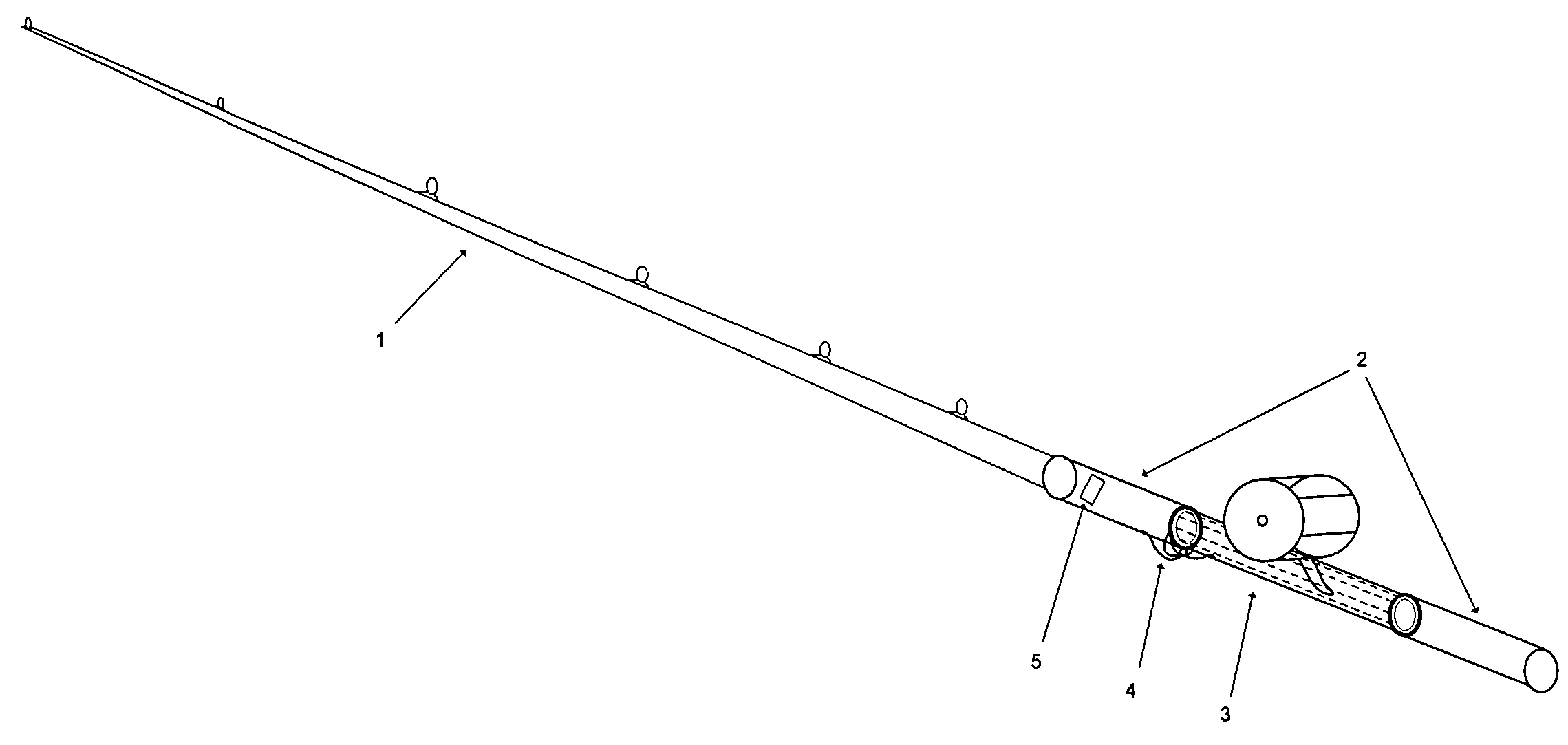

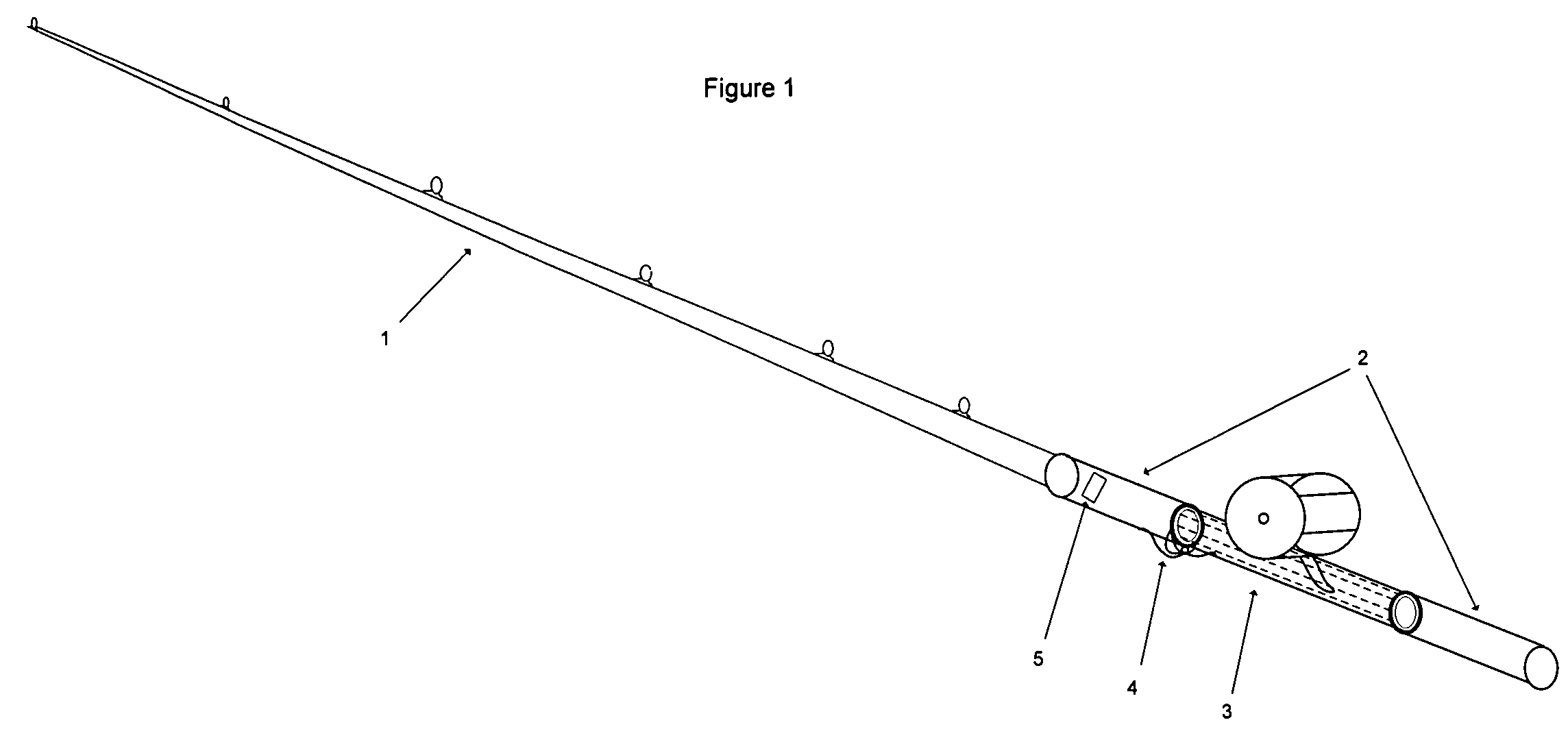

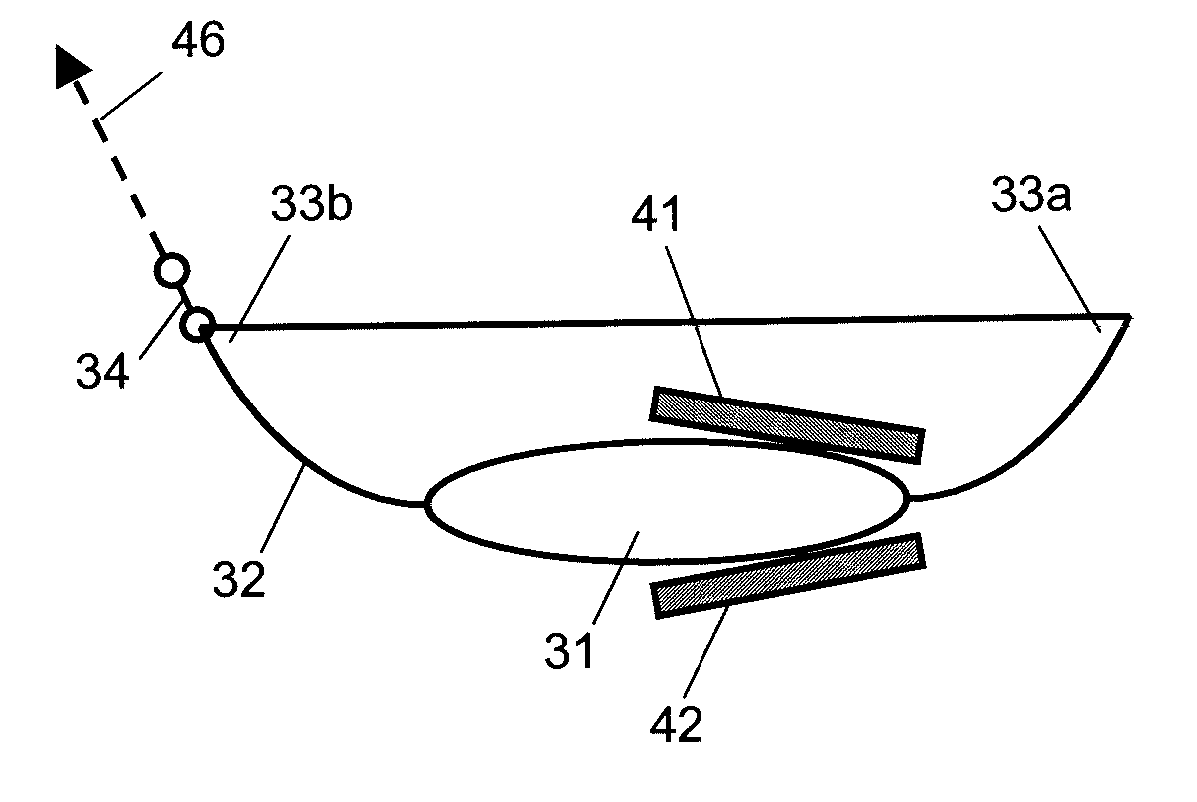

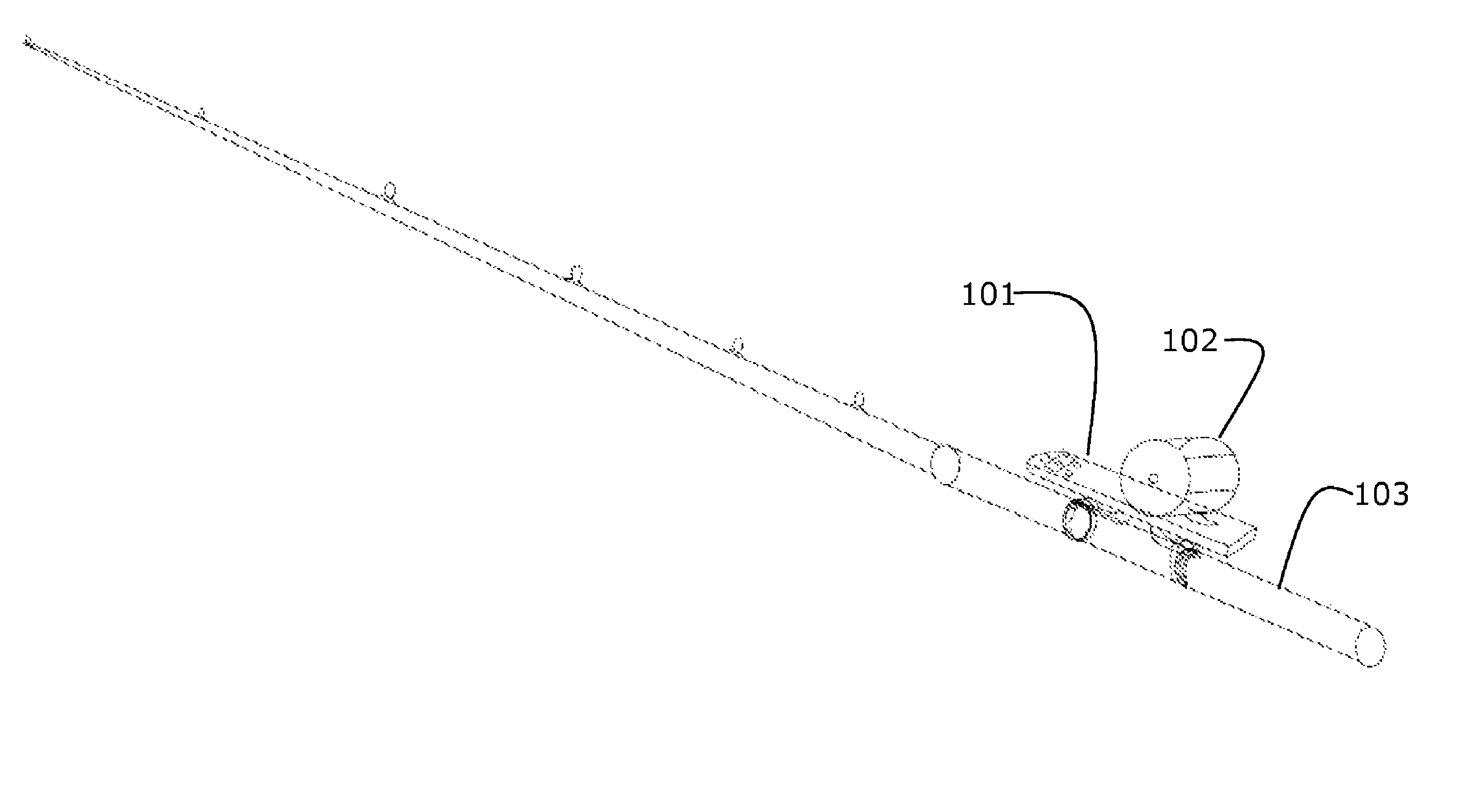

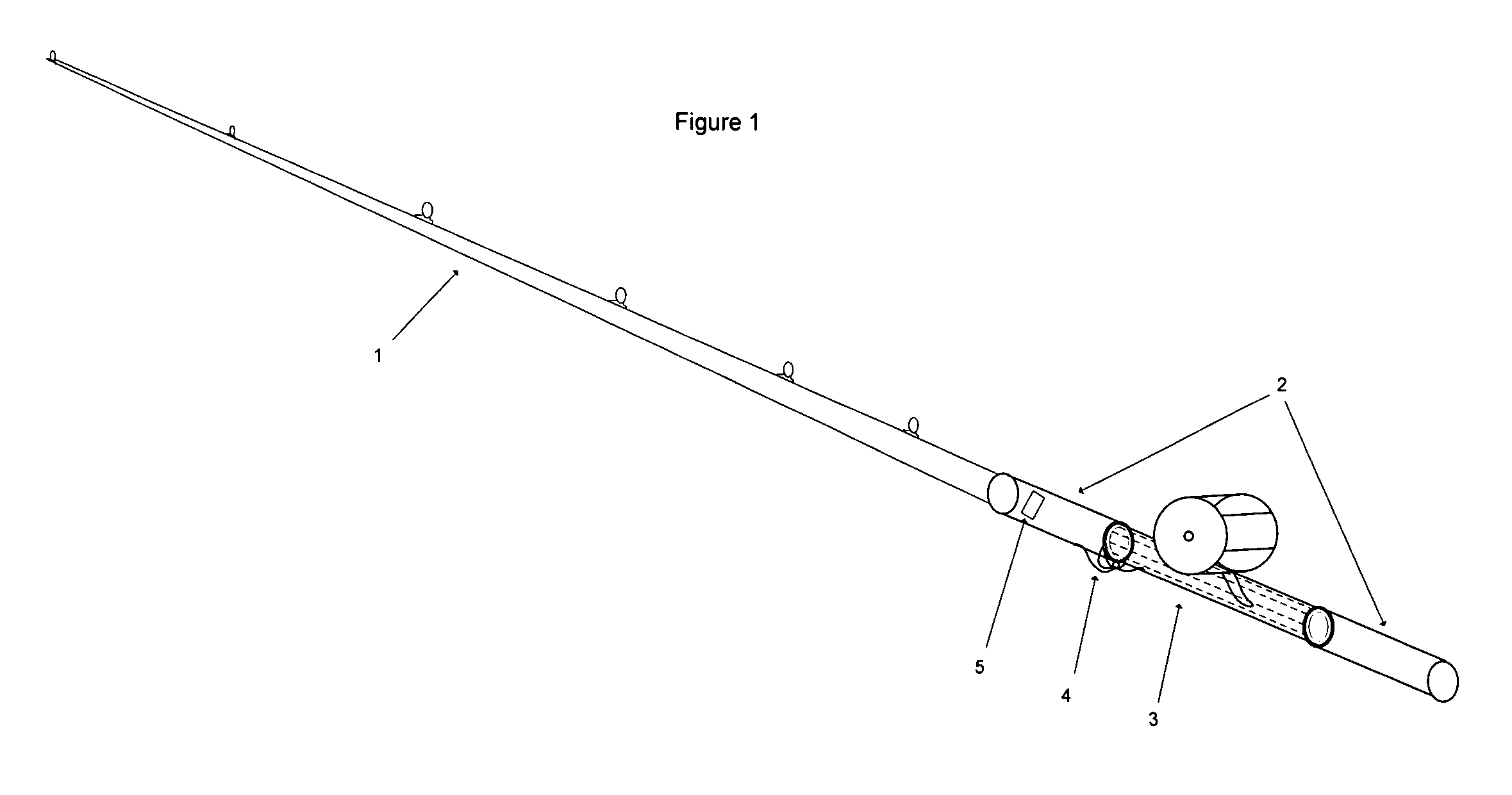

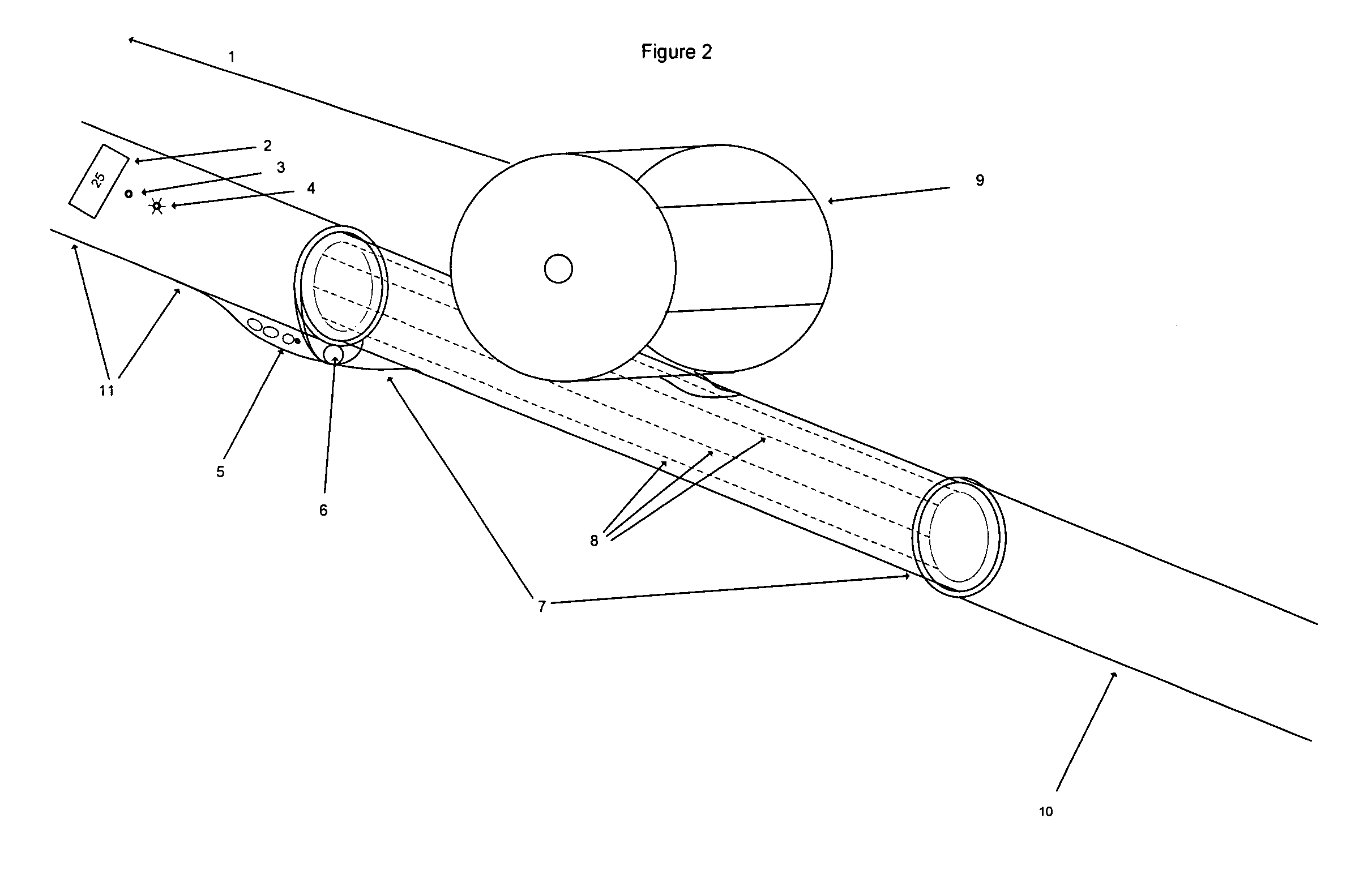

Fishing pole with integrated line tension measuring device

The invention is a fishing pole with an integrated line tension measuring device. Measured line tension is displayed in quantitative units, pounds or kilograms. A line tension warning system activates when the sensed line tension exceeds a threshold set by the fisherman. The line tension measuring device does not touch the fishing line so the fishing pole with integrated line tension measuring device fishes and operates like a normal fishing pole. The line tension measuring device may be integrated into the fishing reel seat which, in turn, is an integral part of the fishing pole.

Owner:LRP

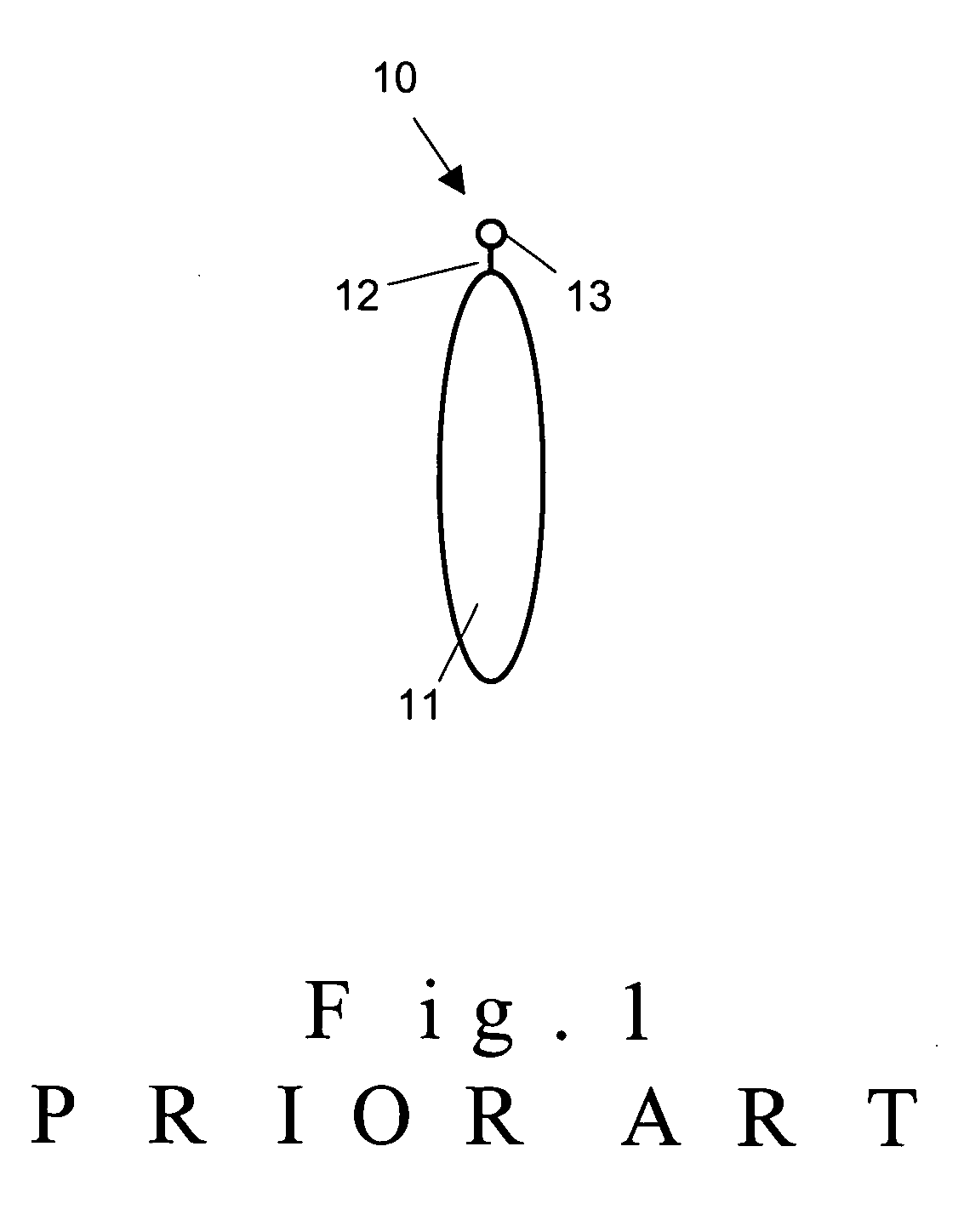

Snag resistant line reversing device for fishing tackle

InactiveUS20060137239A1Avoid environmentAvoid entanglementLinesOther angling devicesFishingIndustrial engineering

This disclosure is directed to a fishing system capable of reducing loss due to entanglement with environmental obstacles. The most common form of device is a sinker. The construction of this system allows the user tension the line in different direction to extricate the fishing element from obstacles by easily reversing the direction of line tension.

Owner:SKIRTS PLUS

Disconnection method and device for obtaining exact off-line length of conductor of overhead transmission line

ActiveCN103236658ALower permanent elongationImprove securityApparatus for overhead lines/cablesLeg lengthEngineering

The invention relates to a disconnection method and device for obtaining the exact off-line length of a conductor of an overhead transmission line. The disconnection method comprises the following steps: firstly eliminating plastic creep deformation of the conductor; and secondly when the conductor is spread horizontally, applying a tension force as same as an equivalent on-line tension force to the conductor in the axial direction of the conductor, measuring the length of the conductor under the tension force, marking or cutting off the conductor at a position on which the length of the conductor is the same as the on-line length, and obtaining the conductor, the completion sag of which is matched with a designed sag requirement, after the conductor is singly suspended under the specific working condition. According to the disconnection method and device disclosed by the invention, before the length of the conductor is measured and obtained, the permanent extension of the conductor caused by the plastic creep deformation is reduced to maximum; the completion sag of the obtained conductor after being mounted meets the designed sag requirement, the completion sag is relatively stable in the certain period during the operation of a later line, and the safety and the reliability of the line operation are improved.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +1

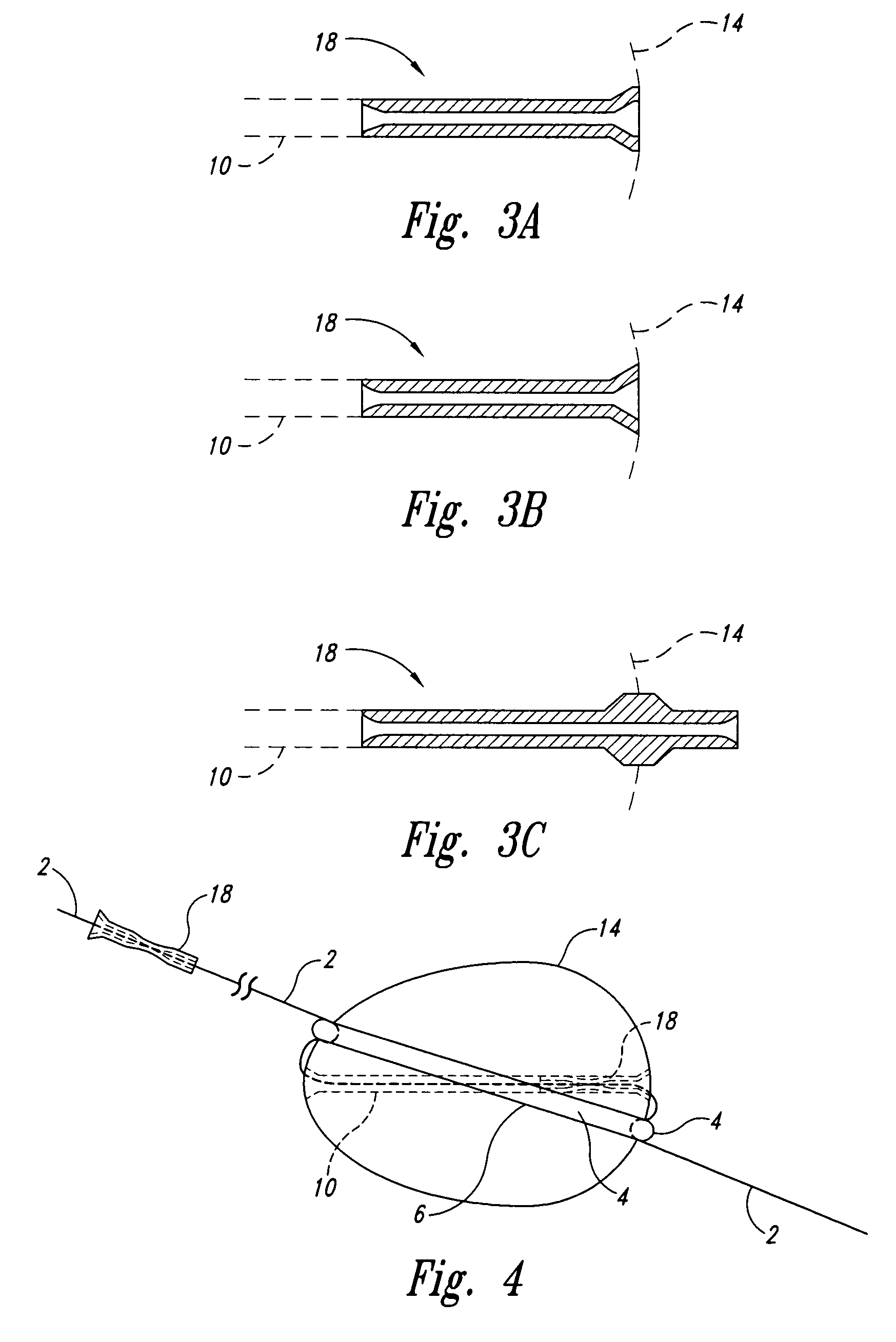

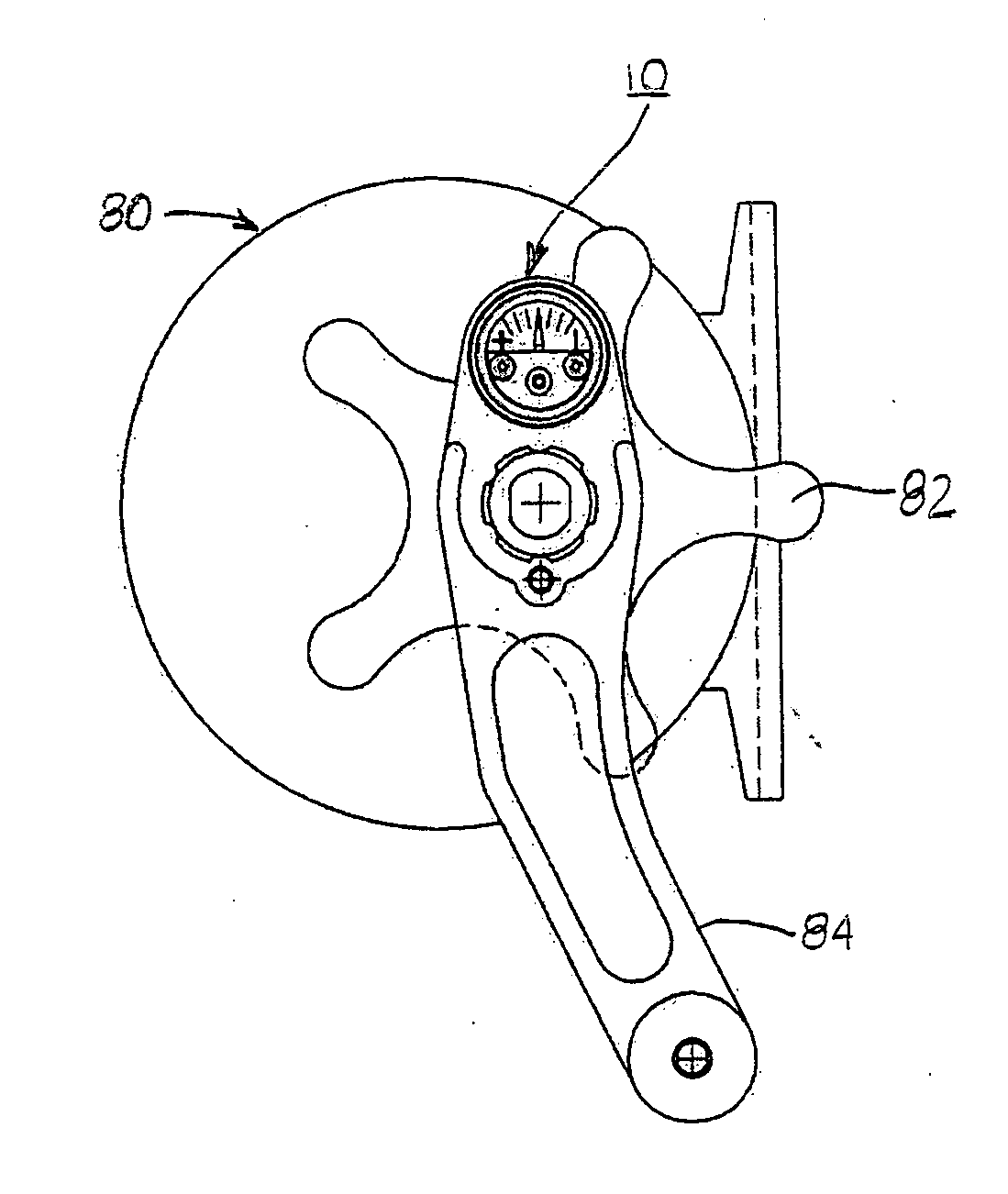

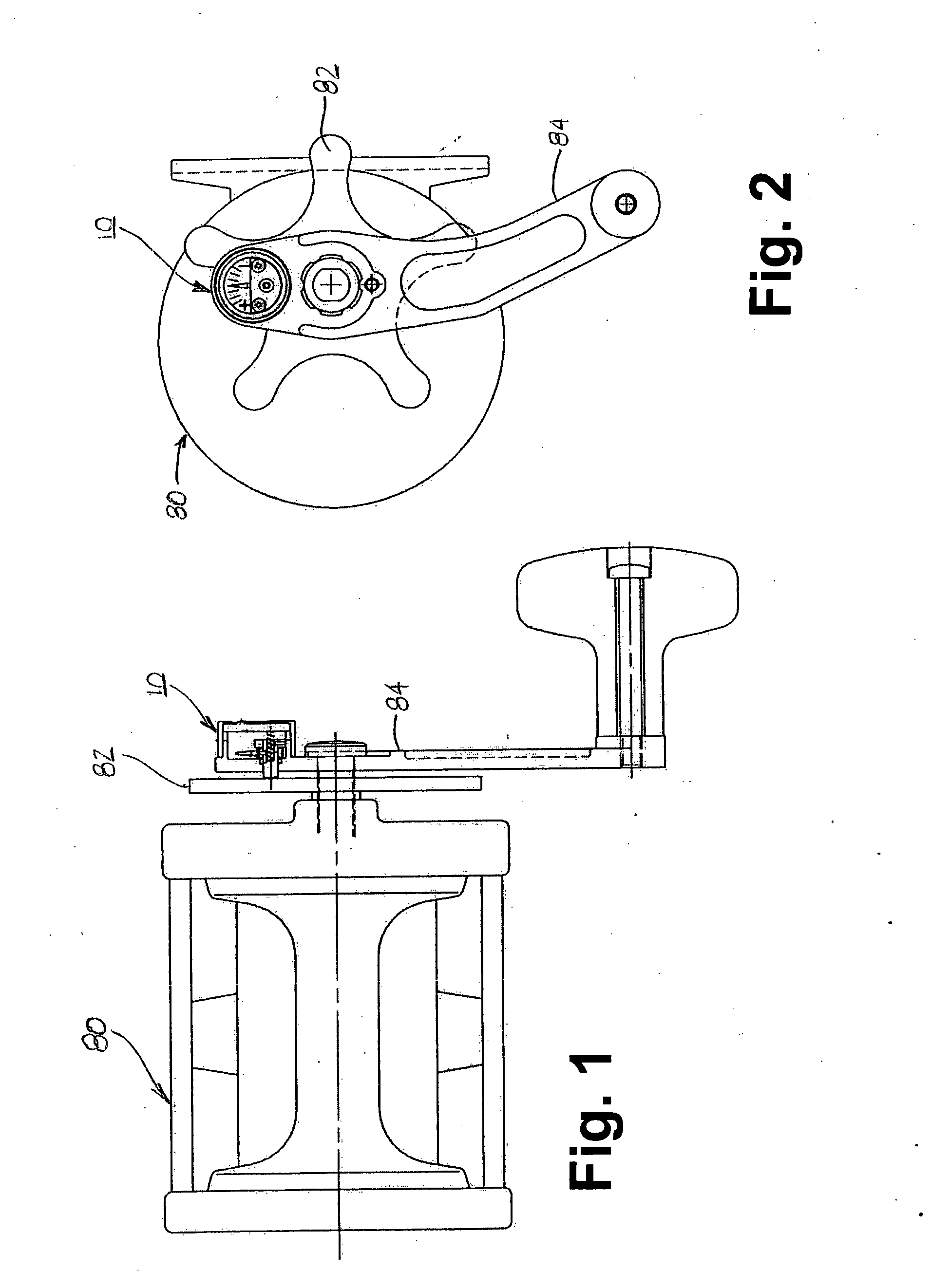

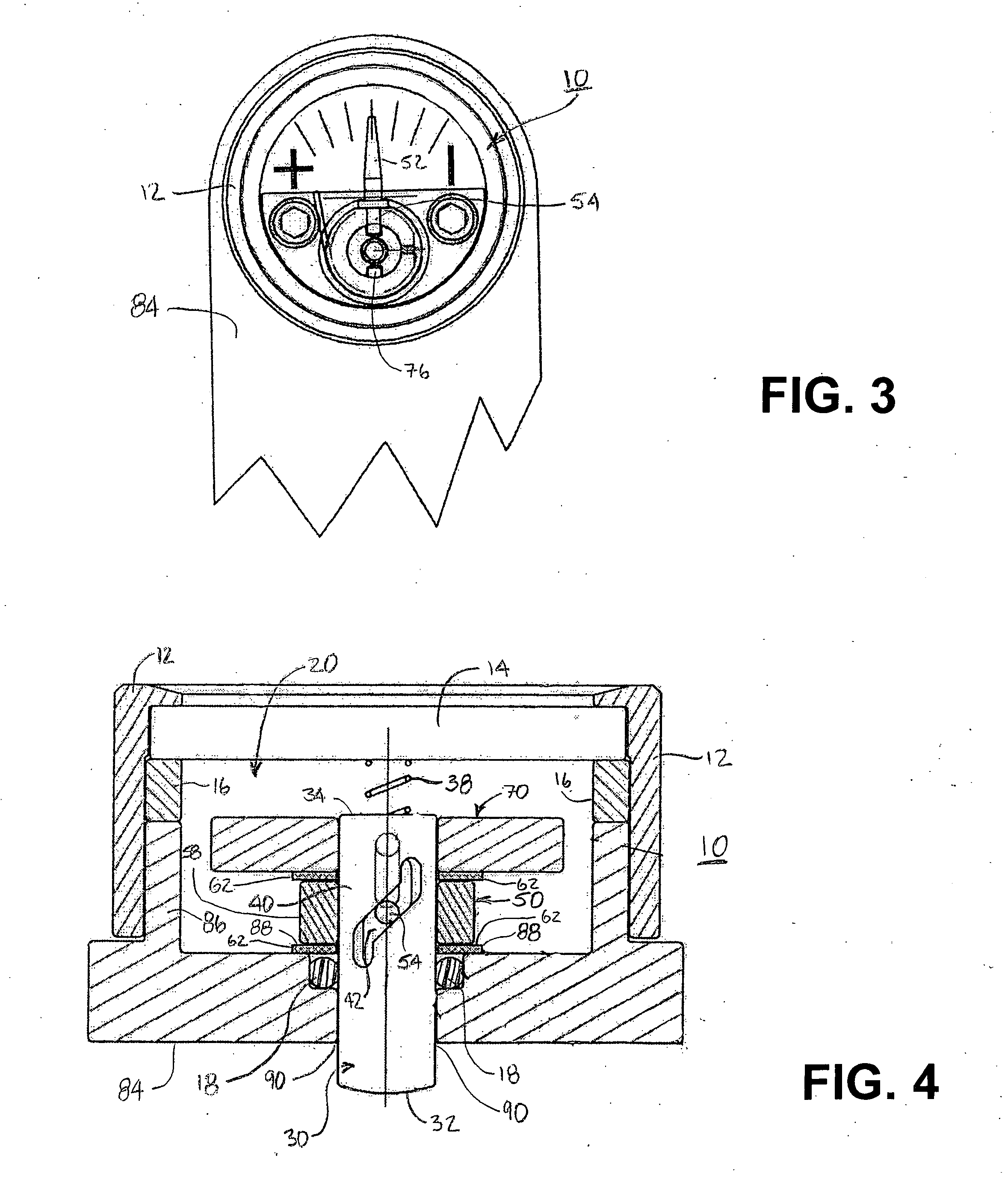

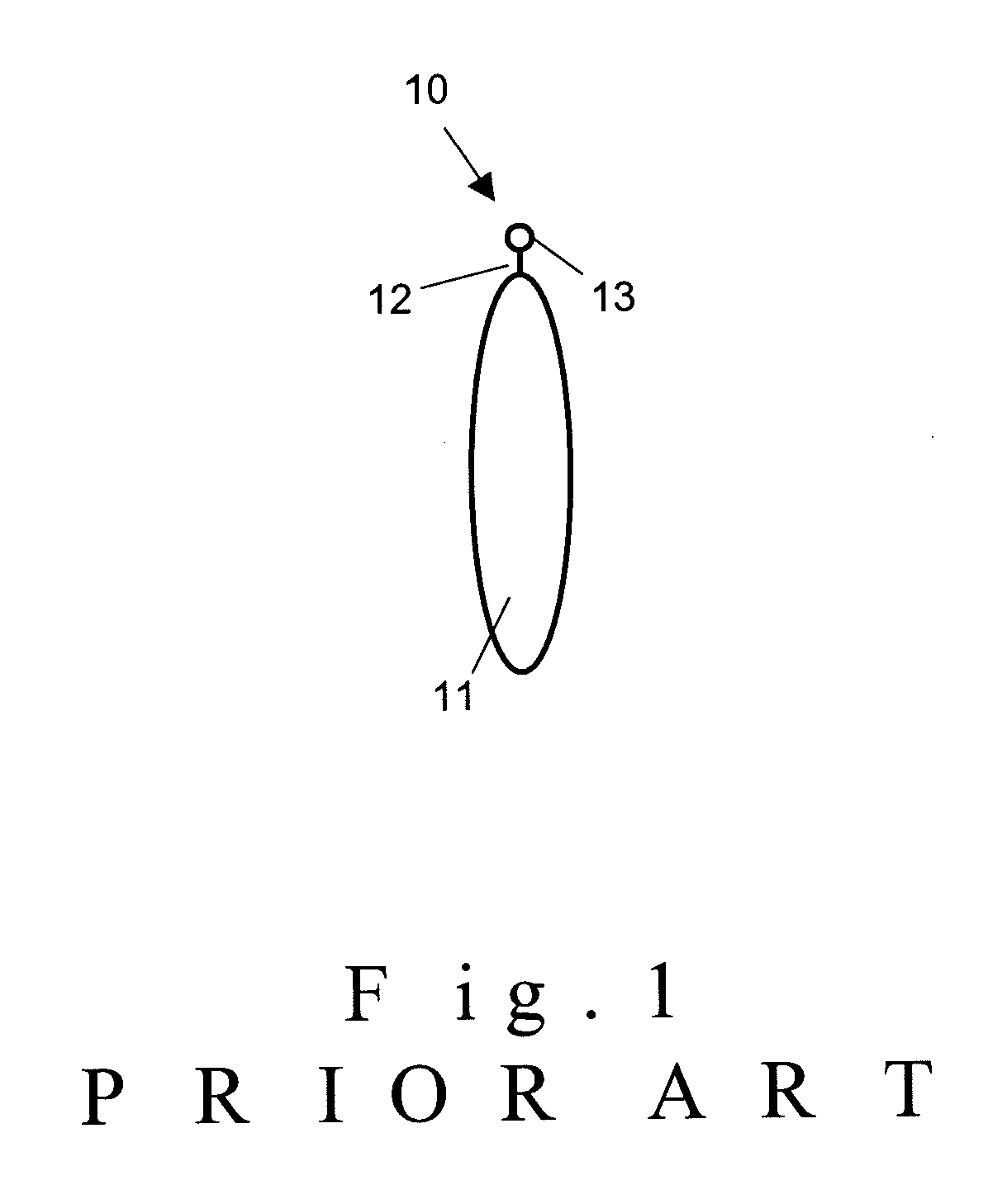

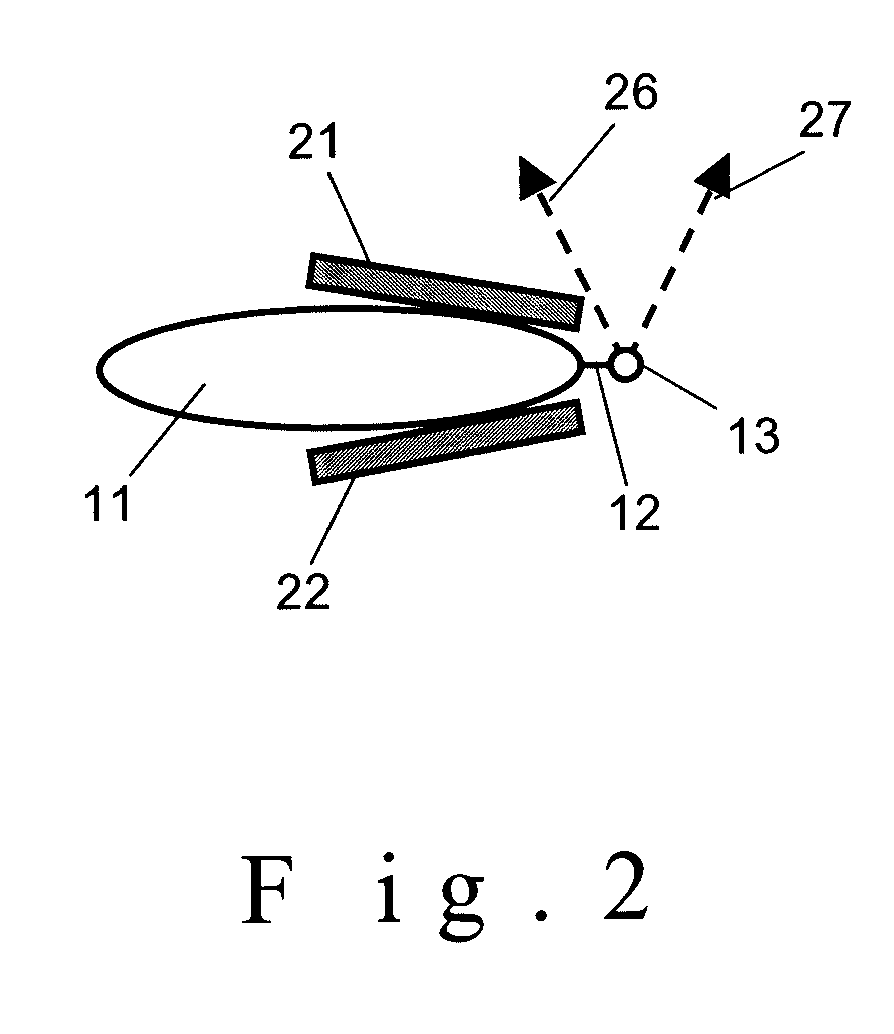

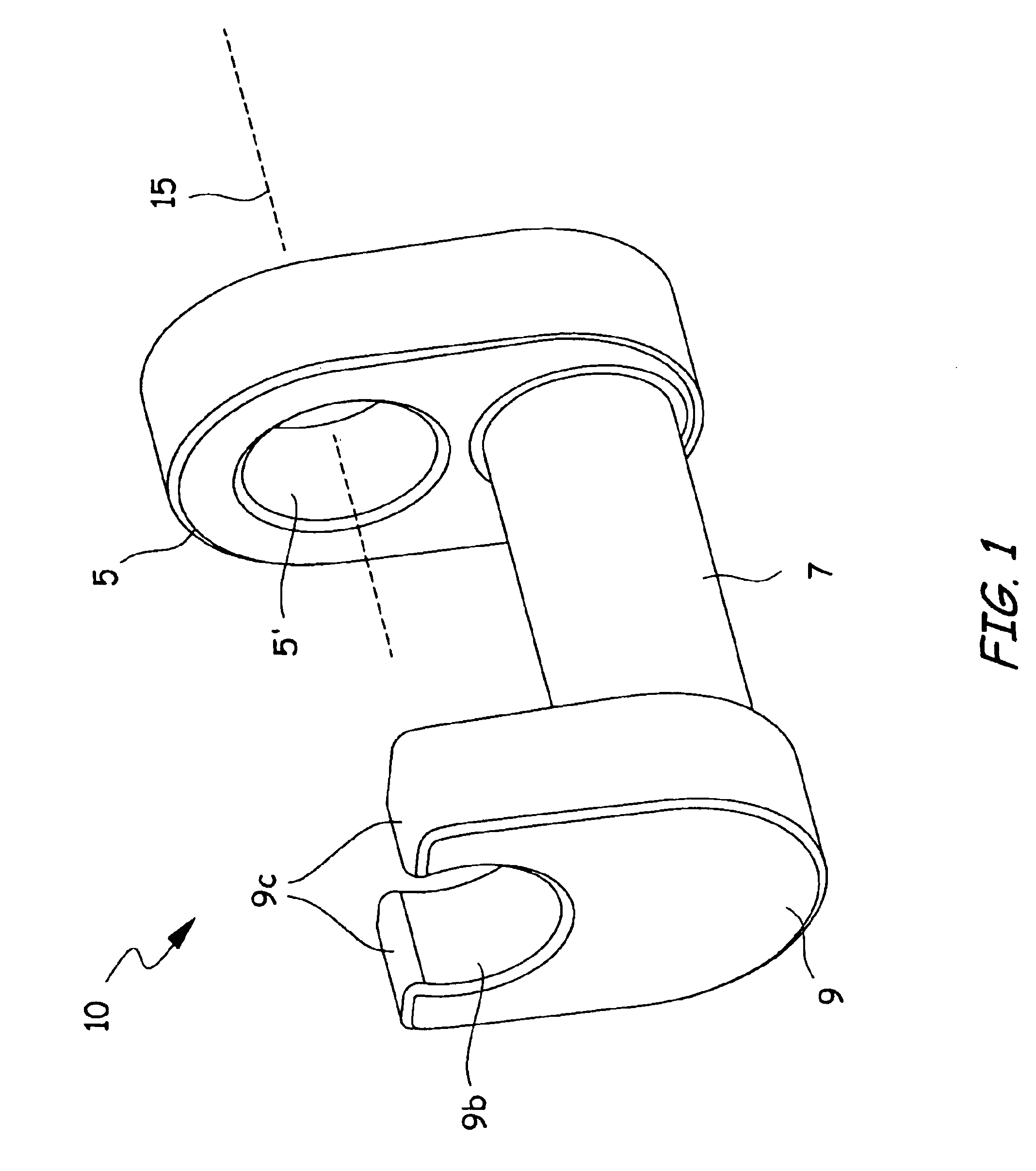

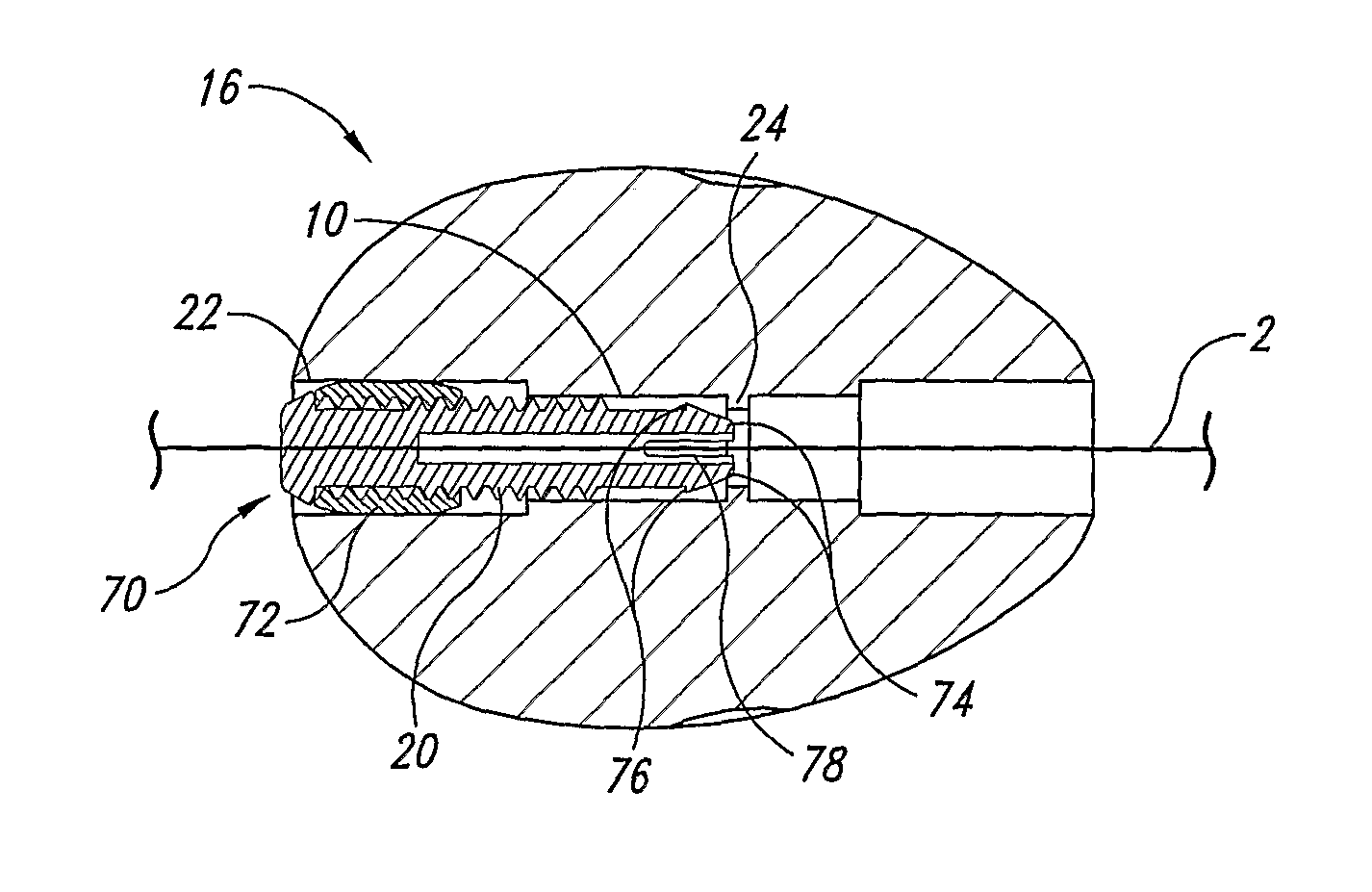

Relative line tension indicator and methods for fishing reels and the like

InactiveUS20070200023A1Easy user adjustmentEasy to adjustReelsIdentification meansEngineeringActuator

Relative line tension indicators and related methods particularly for fishing reels where the indicators include a body; a mechanical distance determining arrangement housed in the body, such as an axially translating probe shaft / actuator pin, or an electronic distance determining arrangement such as an optical distance determining integrated circuit; and a mechanical display arrangement, such as an indicator linked to the probe shaft / actuator pin, or an electronic display coupled to the distance determining arrangement. In select embodiments, the indicator is mounted to or integrated with the handle of a fishing reel, which is directly proximate to a line tension adjustment wheel. By determining and indicating the axial position of the adjustment wheel relative to an axially constant reference such as the reel handle, a user can determine where, along the continuum of relative positions, the adjustment wheel is positioned. By correlating this axial position with an actual drag value or level, the user can determine the relative over and under drag state from this reference.

Owner:ENGINEERED CONTROLS INT

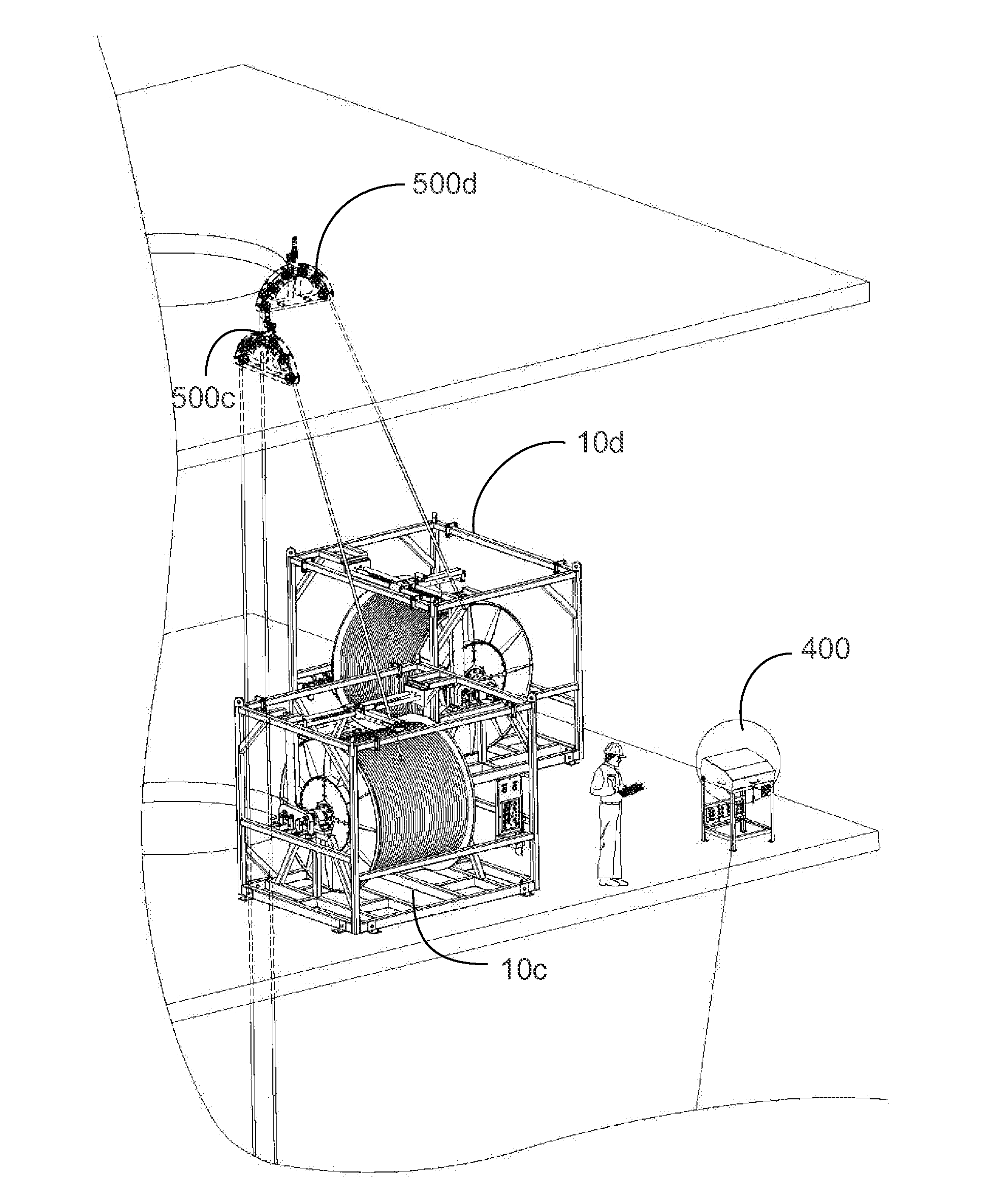

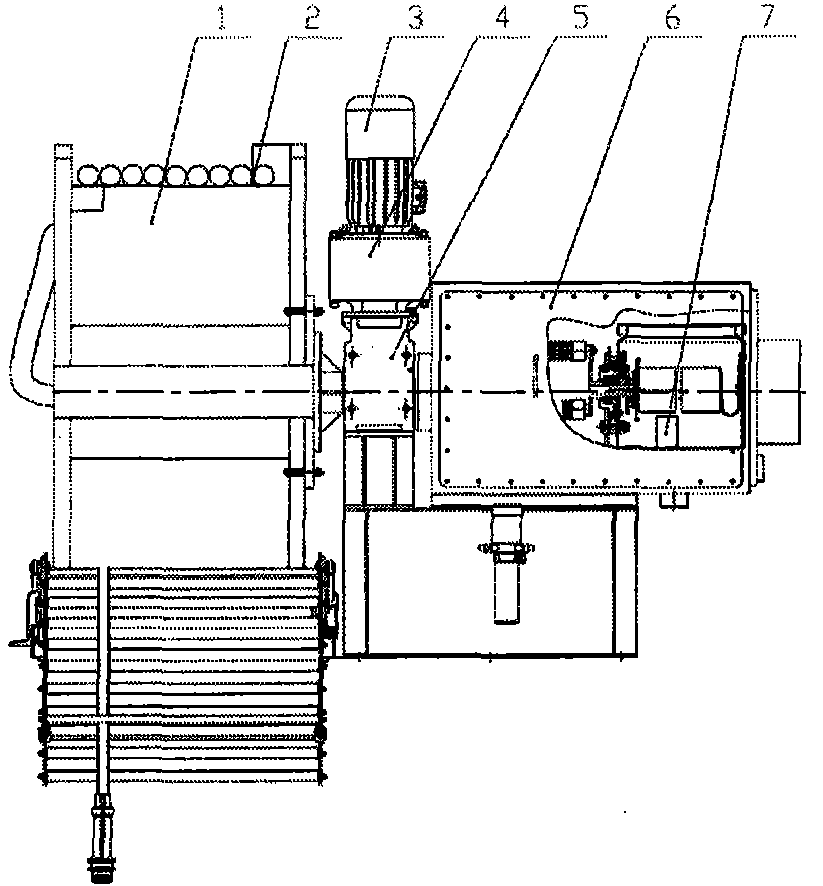

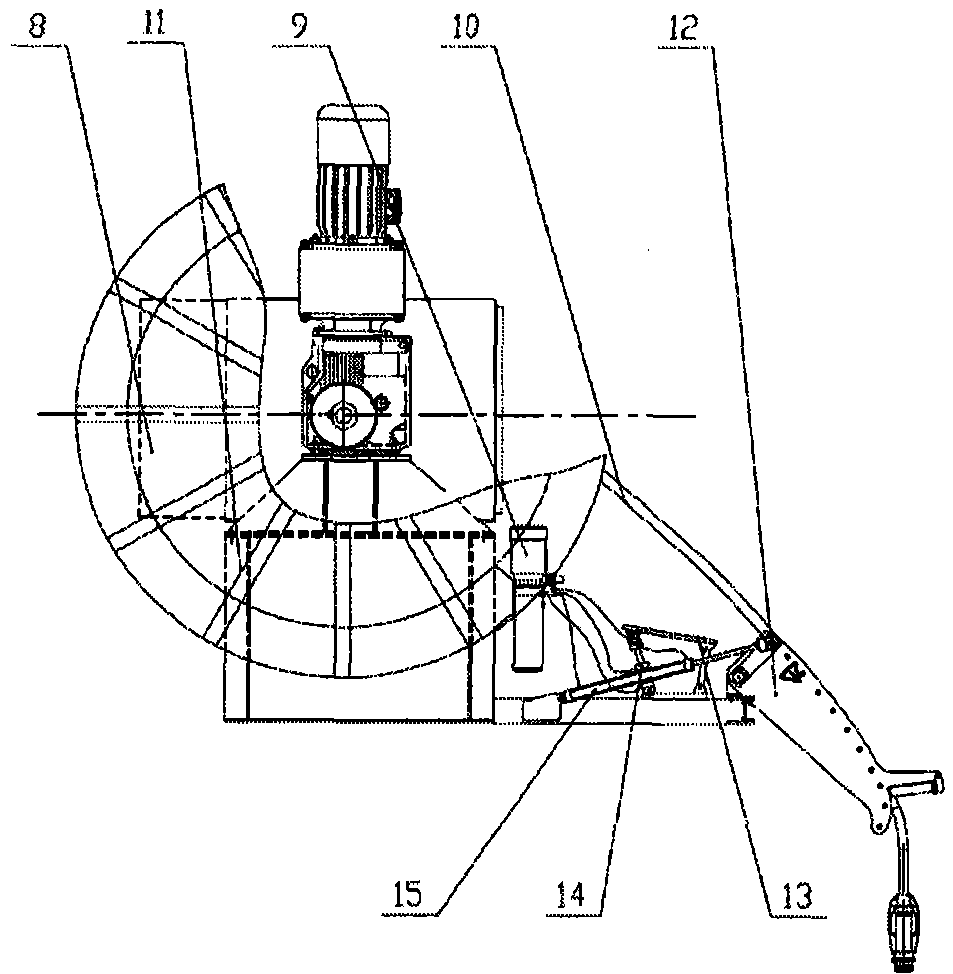

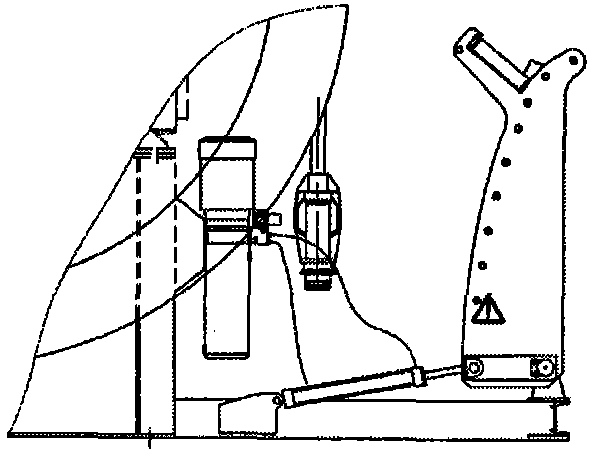

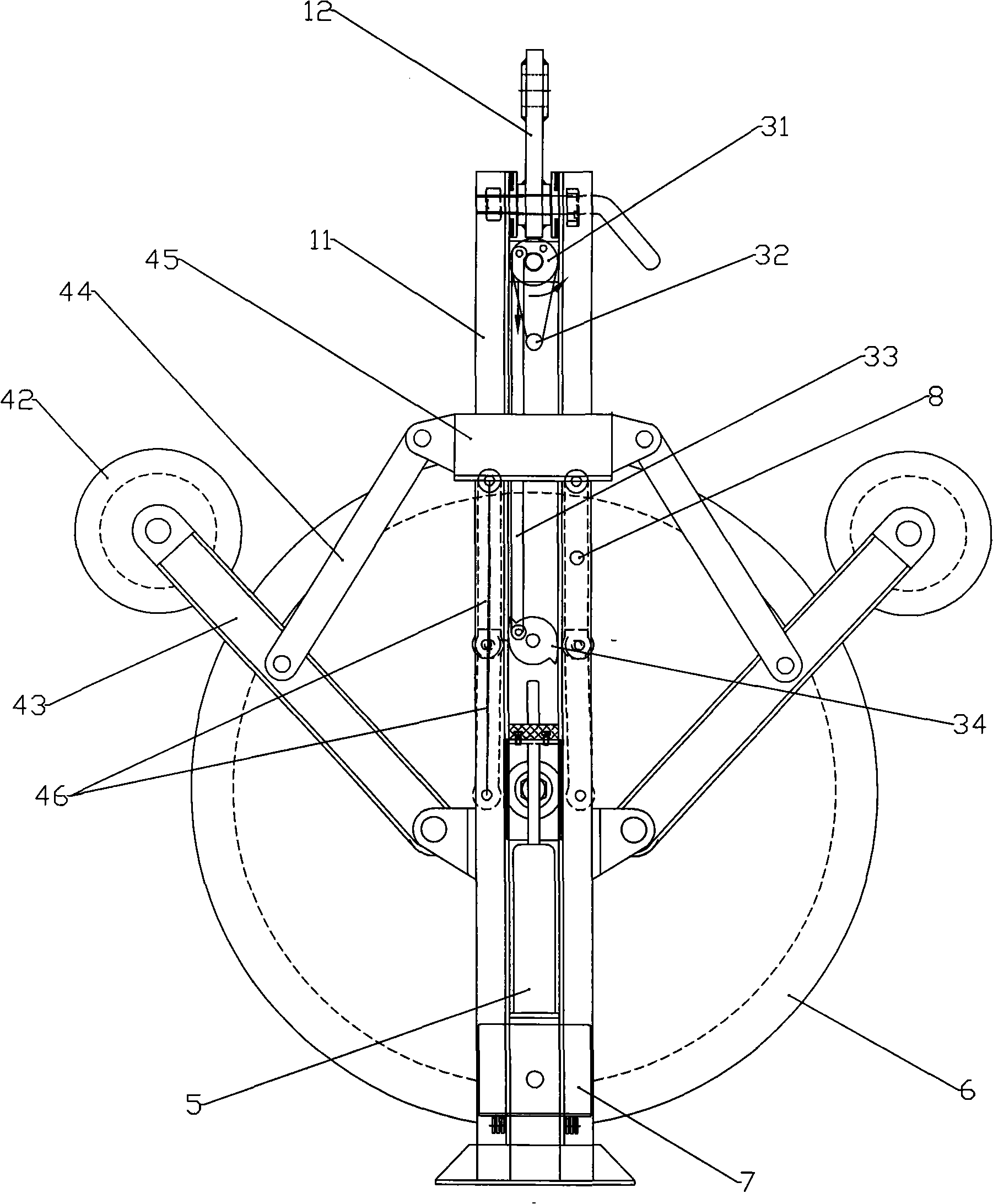

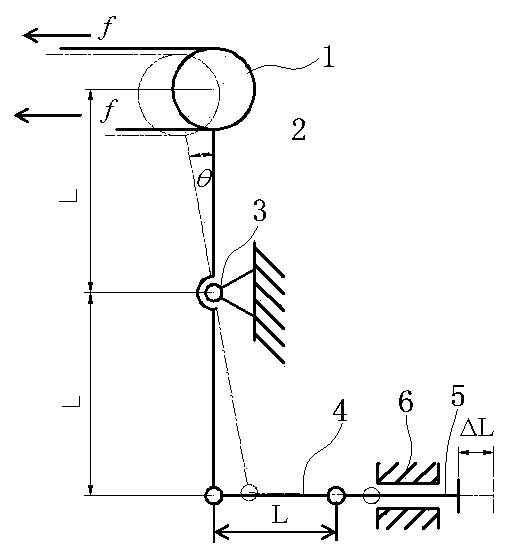

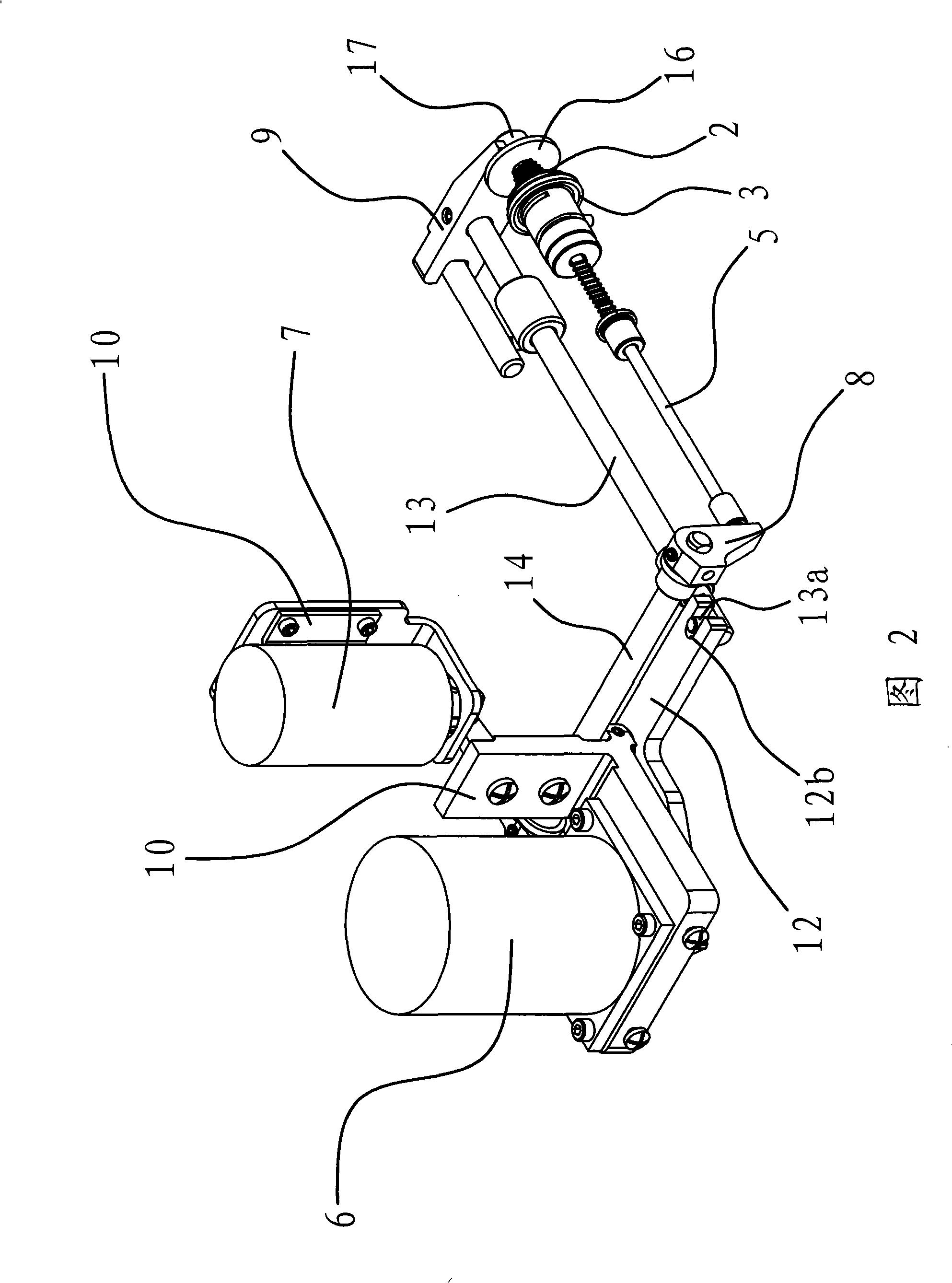

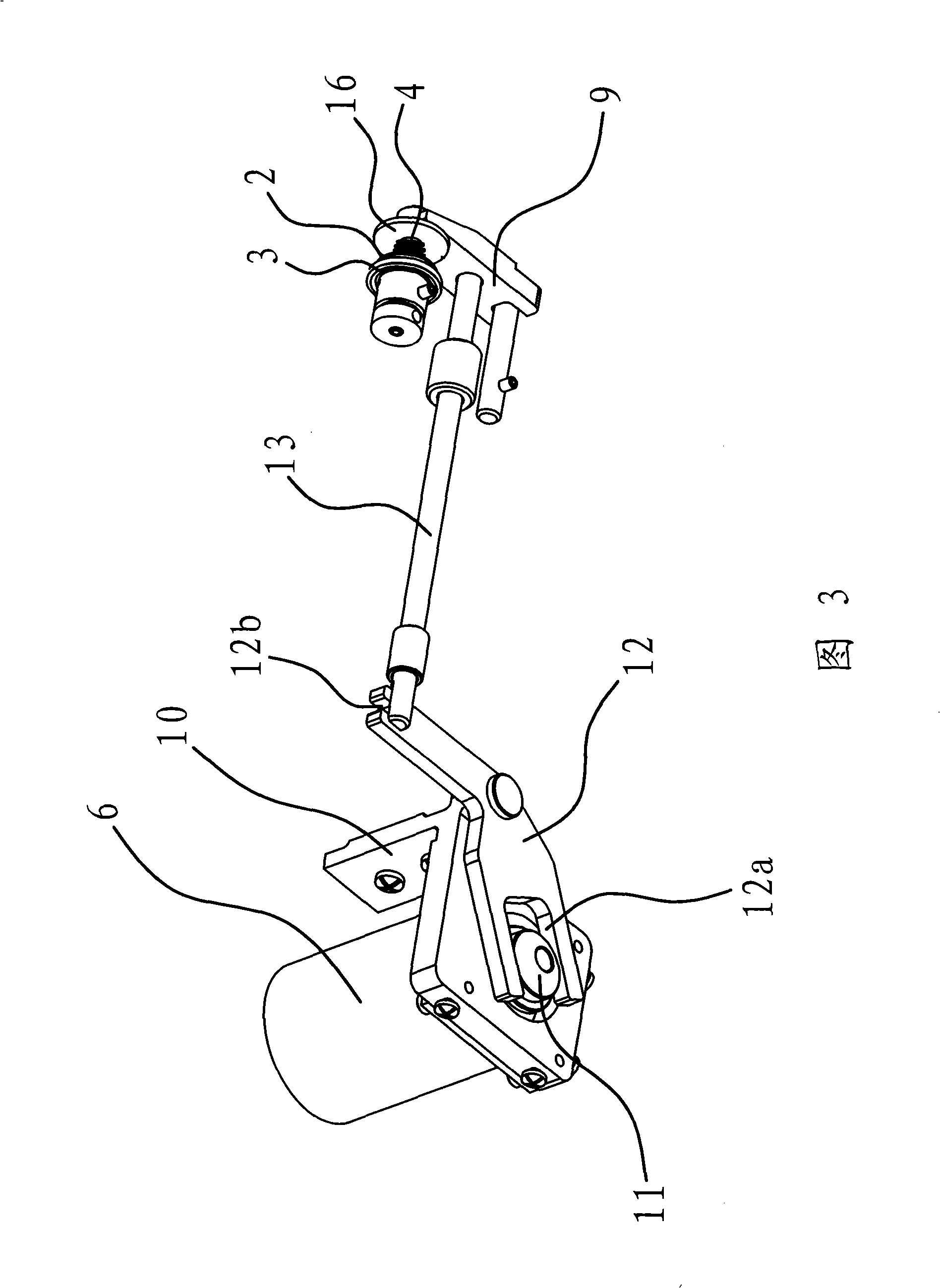

Cable reel used for shore power system

InactiveCN105006796AAutomatically adjust retractable torqueRealize one-click operationArrangements using take-up reel/drumCouplingControl system

A cable reel used for a shore power system comprises: a reel (1), an on-line tension tester (2), a motor (3), a hysteresis coupling (4), a decelerator (5), a slip ring box (6), a cam limit switch (7), a motor control system (8), a hydraulic bag (9), a base (11), a cable guiding rack (12), a swinging rack (13), a swinging rack oil cylinder (14), and a cable guiding rack oil cylinder (15); wherein the cable reel can detect limit positions of a cable (1) during a take-up and pay-off process through the cam limit switch (7), can measure the tension of the cable (10) on line through the on-line tension tester (2), and can reduce a reeling moment of the reel (1) through the motor control system (8) so as to protect the cable. Through adoption of the cable reel provided by the present invention, one-touch operation can be achieved, and the take-up and pay-off moment required by the cable can be automatically adjusted, thereby bringing good technical effects.

Owner:LIAONING ZHUOYI MFG

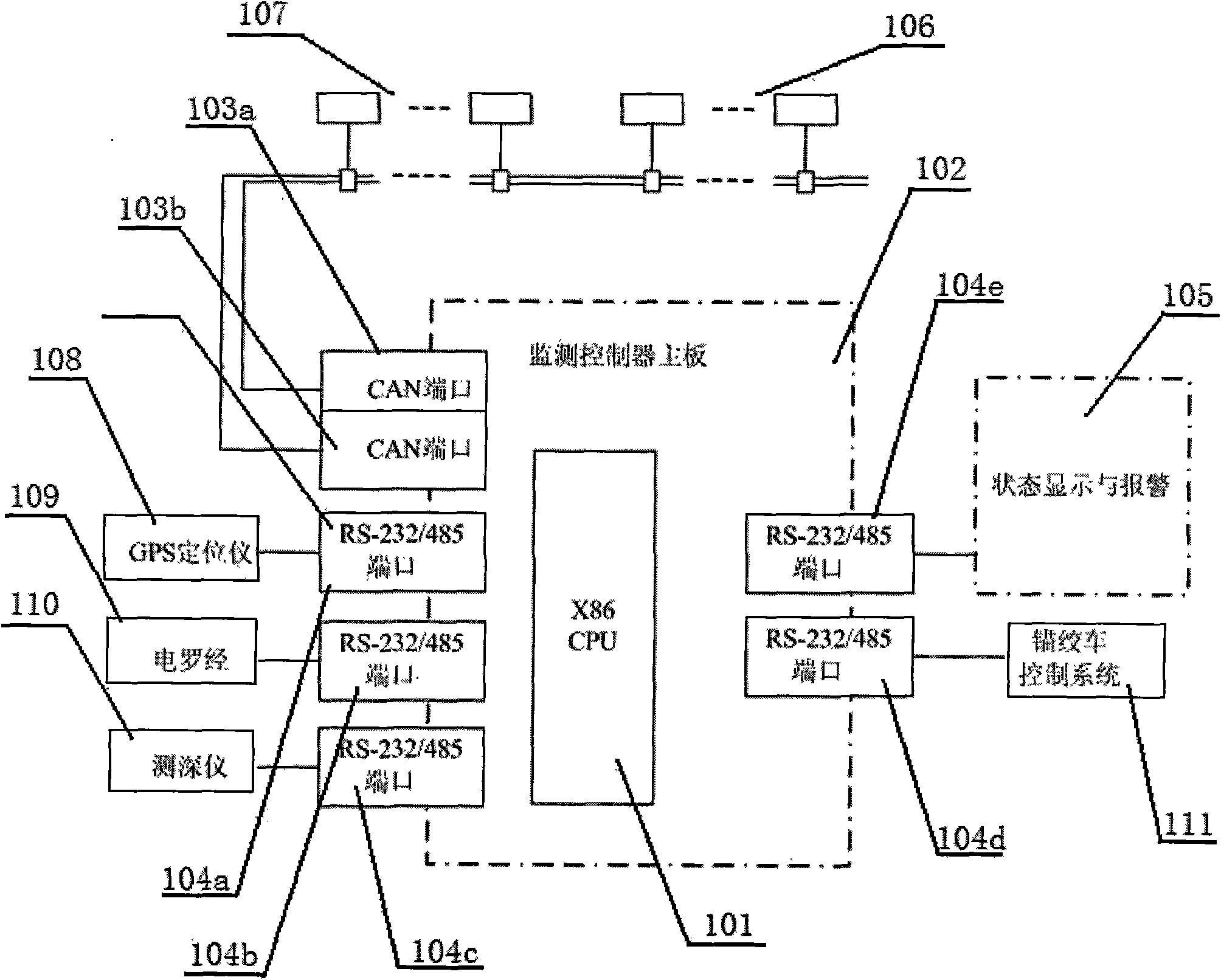

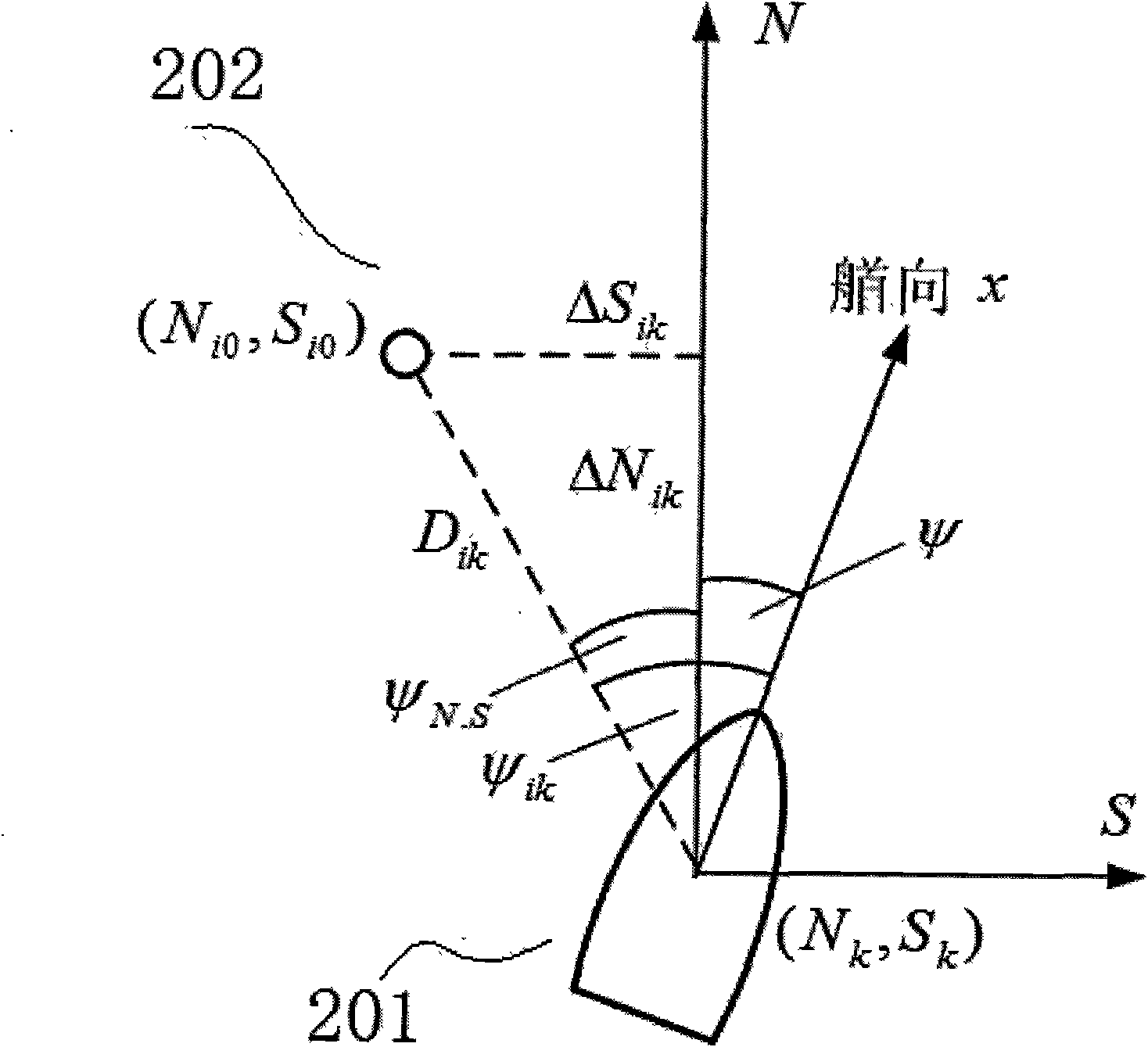

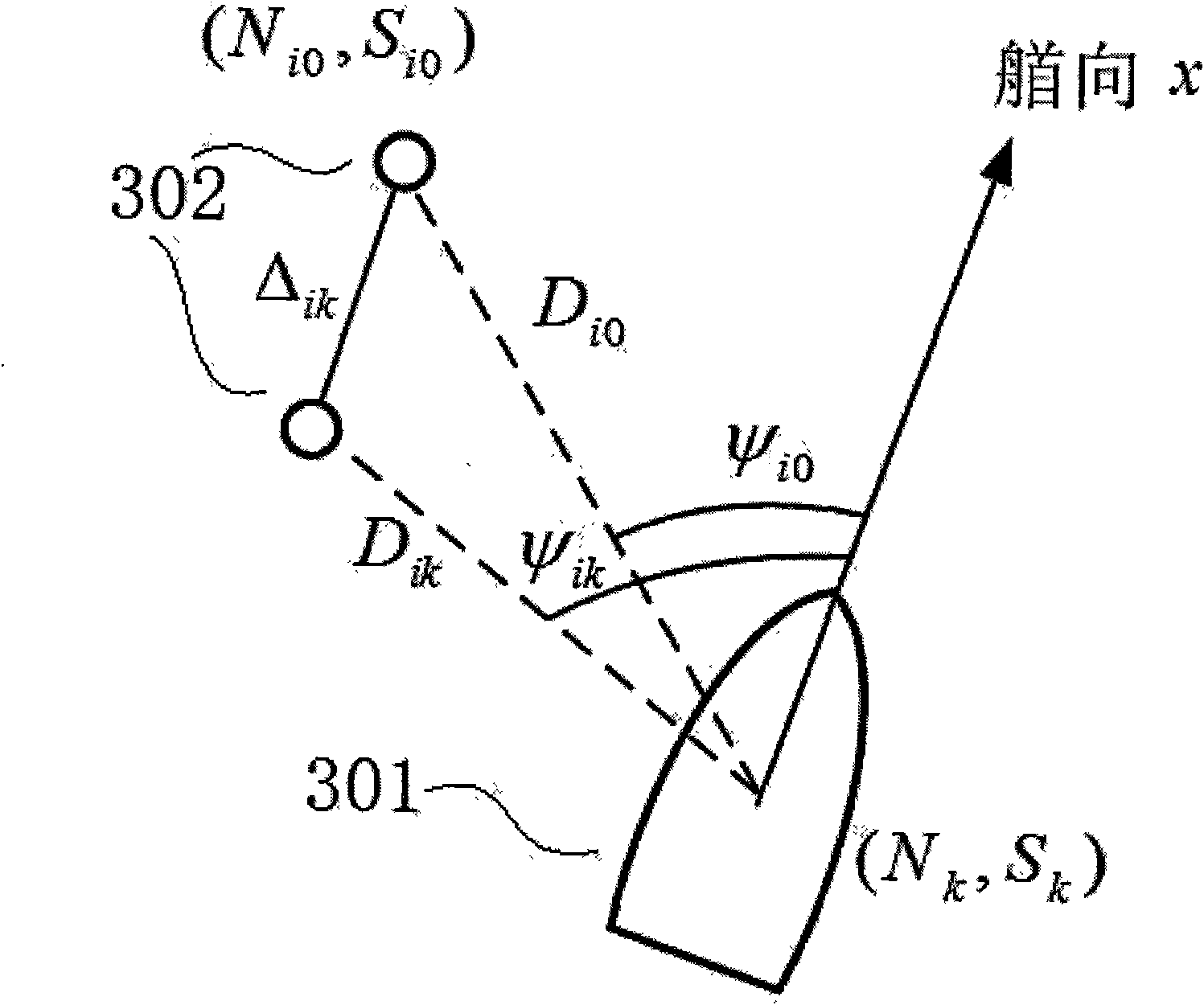

Method for monitoring anchor position and anchor line status of floating-crane anchor winch

InactiveCN101788356AMonitoring anchorMonitoring statusProgramme controlBeacon systems using radio wavesEngineeringWinch

The invention discloses a method for monitoring anchor position and anchor line status of a floating-crane anchor winch, which is implemented on the basis of an anchor position and anchor line status monitoring device for floating-crane anchor winches. In the monitoring method, the tension of the anchor line is monitored in real time by using an anchor-line tension sensor, the length of the anchor line is monitored in real time by using an anchor winch barrel position sensor, and the anchor position is monitored in real time by using a GPS (Global Position System) orientator and a depthometer. The method can be used for accurately monitoring the anchor position and the anchor line status of the floating-crane anchor winch in real time. The method can ensure that the whole monitoring process is stable and accurate, thereby ensuring the operation quality and the operation safety of the floating crane.

Owner:SHANGHAI MARITIME UNIVERSITY

Line tension measuring device

The invention is a fishing pole with an integrated line tension measuring device Measured line tension is displayed in quantitative units, pounds or kilograms. A line tension warning system activates when the sensed line tension exceeds a threshold set by the fisherman. The line tension measuring device does not touch the fishing line so the fishing pole with integrated line tension measuring device fishes and operates like a normal fishing pole. The line tension measuring device may be integrated into the fishing reel seat which, in turn, is an integral part of the fishing pole.

Owner:REEL DRAG TECH

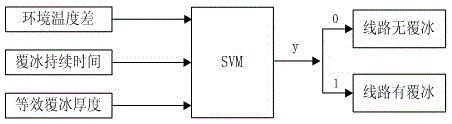

Power line icing assessment method based on filtering and support vector machine

InactiveCN105160599AObjective and accurate descriptionObjective and accurate assessmentData processing applicationsElectric power systemEngineering

The invention provides a power line icing assessment method based on filtering and a support vector machine, relates to the technical field of an electrical power system and is to solve the technical problem of power transmission line assessment. The method is characterized by, to begin with, detecting line tension, line inclination angle, line environment wind speed and line environment atmosphere pressure of a power transmission line in the icing assessment time period; then, carrying out Kalman filtering, median filtering and mean filtering on the detected data in sequence; calculating out environment temperature difference, icing duration time and equivalent icing thickness of the power transmission line in the icing assessment time period according to the filtering data; next, carrying out optimal hyperplane training on the environment temperature difference, icing duration time and equivalent icing thickness by utilizing the SVM to obtain line icing probability of the power transmission line; and judging line icing state according to the obtained line icing probability. The method provided in the invention is suitable for assessing the icing state of the power transmission line.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Snag resistant line reversing device for fishing tackle

This disclosure is directed to a fishing system capable of reducing loss due to entanglement with environmental obstacles. The most common form of device is a sinker. The construction of this system allows the user tension the line in different direction to extricate the fishing element from obstacles by easily reversing the direction of line tension.

Owner:SKIRTS PLUS

Method suitable for tension stringing of ultra-high voltage wire

ActiveCN101359816APlay a proper roleReduce stressApparatus for overhead lines/cablesUltra high voltageEngineering

The invention discloses a tension wire-laying method applies to ultra-high voltage electric wires: (1) four <second-line stretching all-in-one machines> are arranged in a hauling field as main hauling devices, four <second-line tension machines> are arranged in a tension field, two sets of wire-laying tackles that are independent to each other are hanged on the iron tower per phase; (2) in the earlier period 8 lead traction ropes are laid, every four traction ropes go through four auxiliary sliding wheels arranged on one set of wire-laying tackle and haul and lay an eight-multiple lead in theform of <one haul 1>, and realize synchronous laying of leads through four <second-line tension machines> and four <second-line stretching all-in-one machines> as hauling devices; and (3) when the eight-multiple lead reaches the wire-laying tackle, a trigger running board touches a trigger mechanism on the wire-laying tackle, which is used to make the auxiliary sliding wheel on the same tackle drop to the position lower than the main sliding wheel of the wire-laying tackle, and make the eight-multiple lead be synchronously laid by the main sliding wheels on the two sets of wire-laying tackles. The method can meet the tension wire-laying demand of ultra-voltage electric wires without long ton main hauling equipment.

Owner:STATE GRID CORP OF CHINA +1

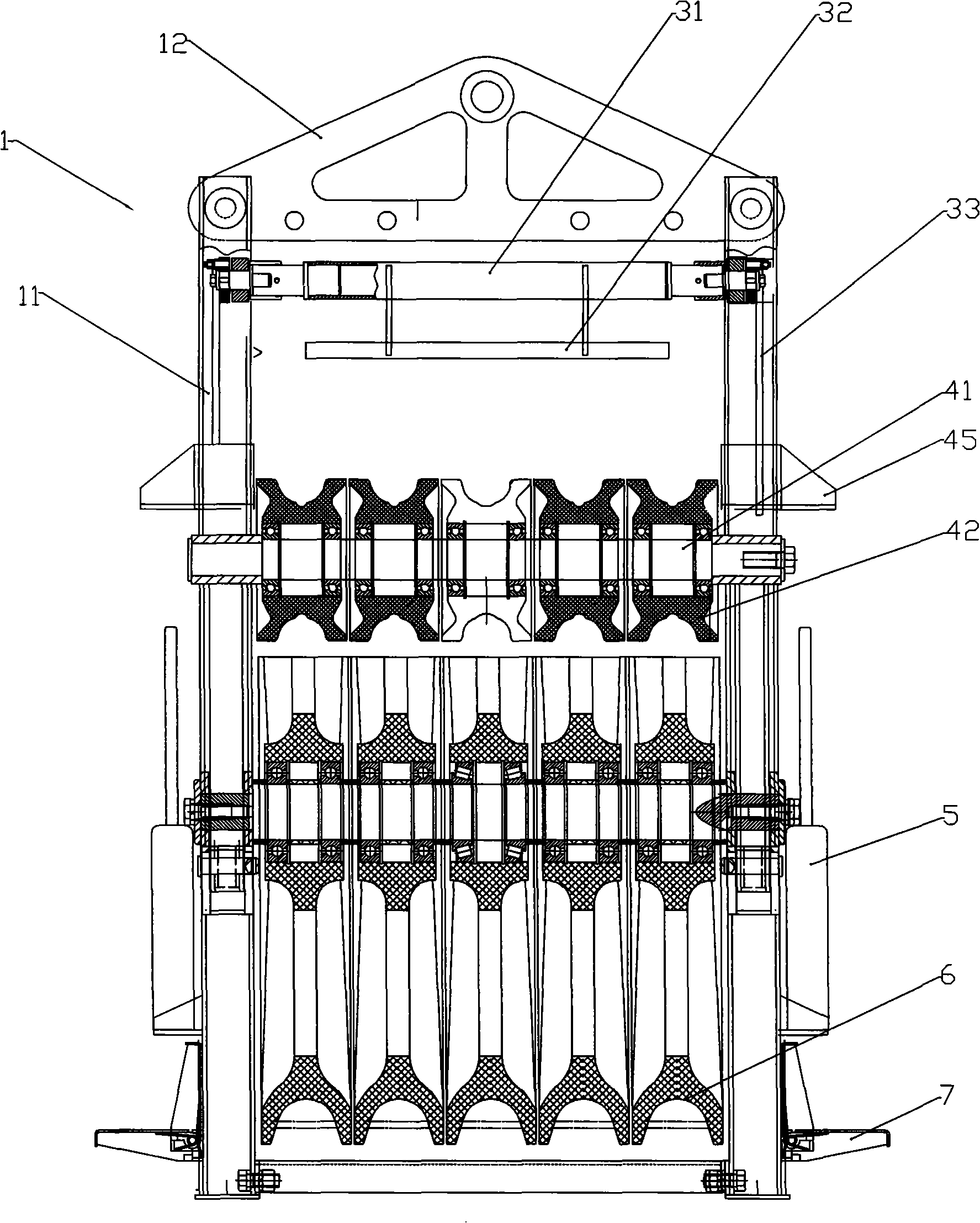

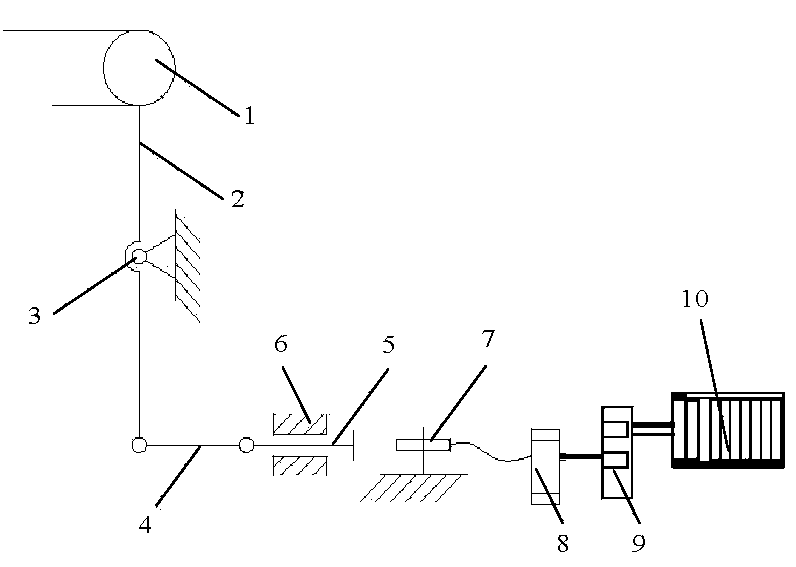

Method and device for detecting cutting line tension of non-contact multi-line cutting machine

ActiveCN103528744AImprove reliabilityAvoid Frequent Damage SituationsTension measurementEngineeringSupport point

The invention discloses a method and a device for detecting the cutting line tension of a non-contact multi-line cutting machine. In order to realize reliable detection of the cutting line tension in a severe environment, the detection device comprises a tension arm which can swing around a supporting point, wherein one end of the tension arm is used for connecting a line wheel wound with a cutting line; the other end of the tension arm can be used for driving a tested metal rod to move linearly in a reciprocating way through a connecting rod; one side of the metal rod is provided with a non-contact probe for detecting the linear displacement delta L of the tested metal rod; an elastic element for preventing the tension arm from swinging is arranged between the tension arm and the supporting point. According to the method and the device, the reliability of the cutting line tension detection of the multi-line cutting machine in a wet and severe environment is enhanced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Control device for yarn trapper in sewing machine

InactiveCN101314897AImprove job stabilityModerate clamping forceSewing-machine control devicesTensioning devicesYarnElectric machinery

The invention provides a control device of a conductor holder in a sewing machine, belongs to the mechanical technology field, and solves the problems of the prior conductor holder, such as low accuracy, etc. caused by manually regulating a line tension pulley of the conductor holder for controlling the line tension. The control device of the conductor holder in the sewing machine is characterized in that the conductor holder is arranged on the frame side part of the sewing machine; the control device comprises an electric motor, an electromagnet, a wire loosing rod and a wire clamping block; the electric motor is permanently connected with the frame; a wire clamping transmission mechanism which enables the wire clamping block to compress a spring is arranged between the electric motor and the wire clamping block; the electromagnet is permanently connected with the frame; and a wire loosing transmission mechanism which enables the wire loosing rod to prop against the outer end of a thimble is arranged between the electromagnet and the wire loosing rod. The control device realizes line tightening by the electric motor and the line clamping transmission mechanism, and the clamping force between an upper chuck and a lower chuck is always maintained to be proper during the process of line tightening. The control device of the conductor holder in the sewing machine has higher working stability and simple structure.

Owner:ZHEJIANG ZOJE SEWING MACHINE

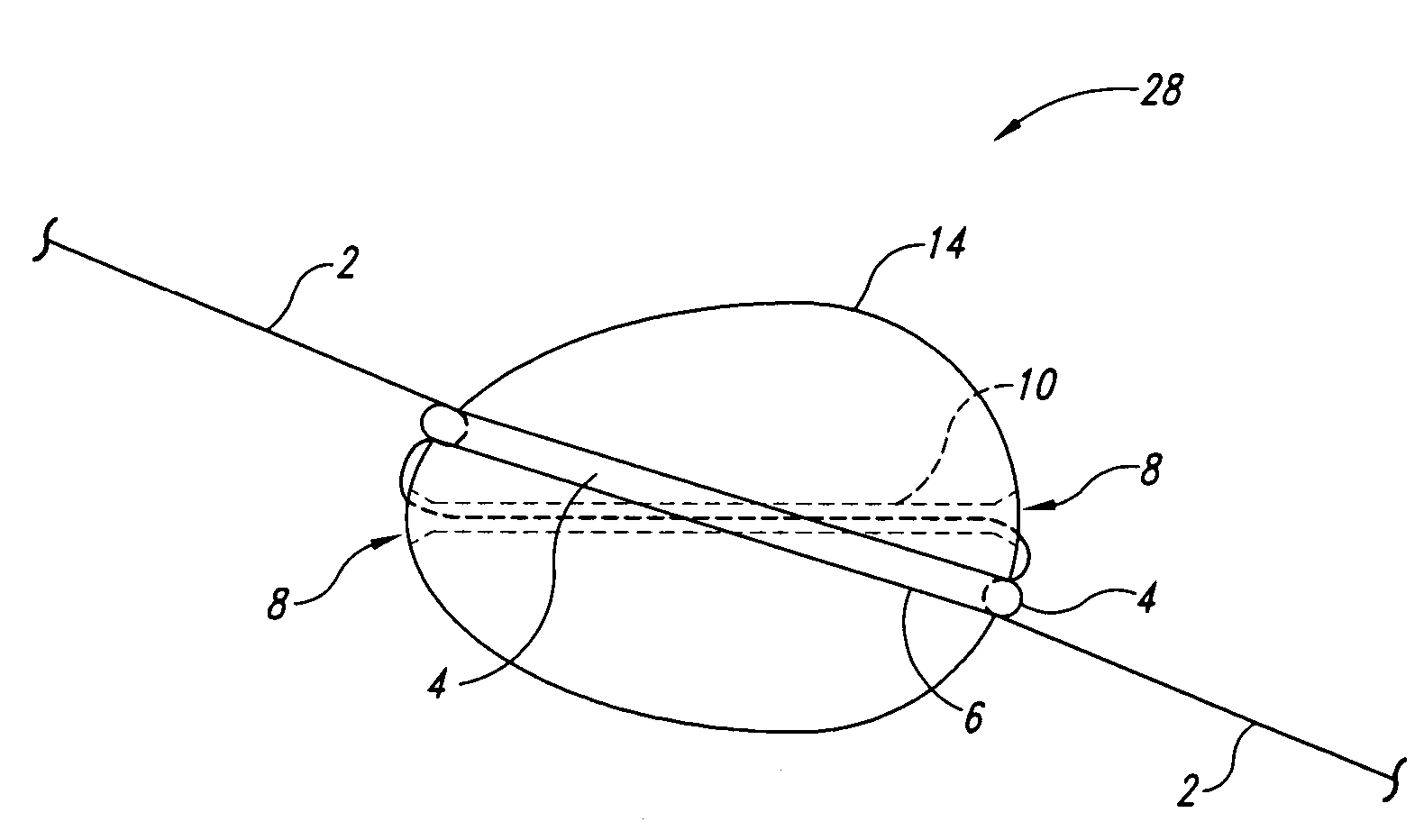

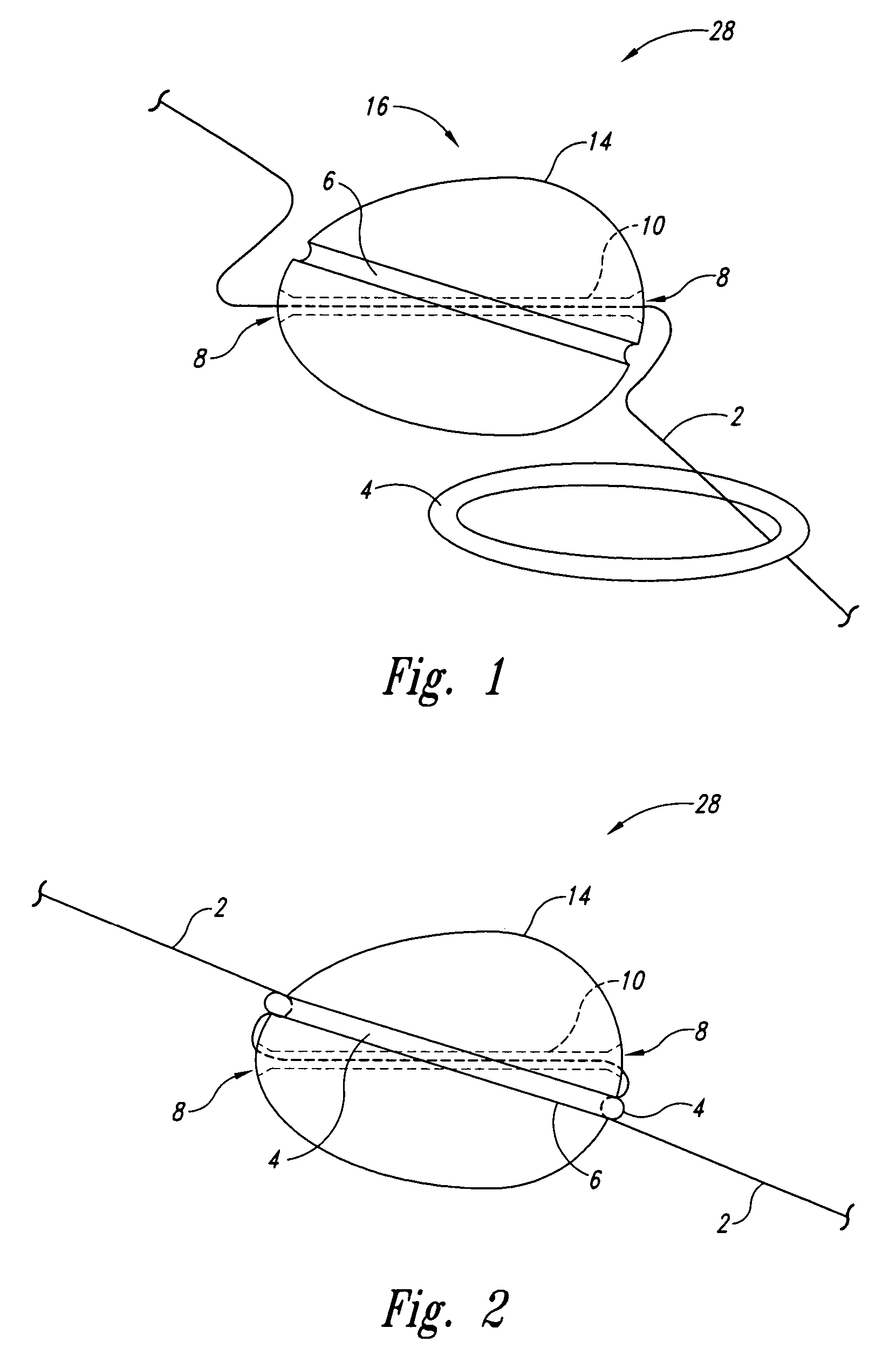

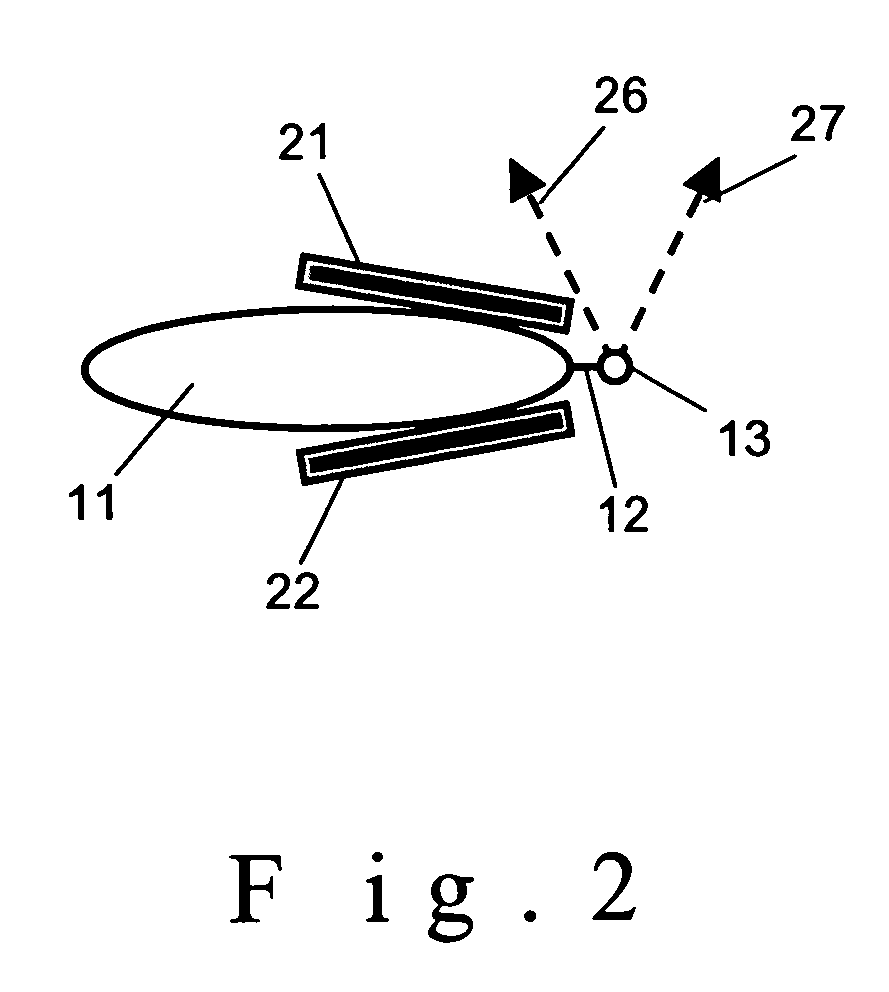

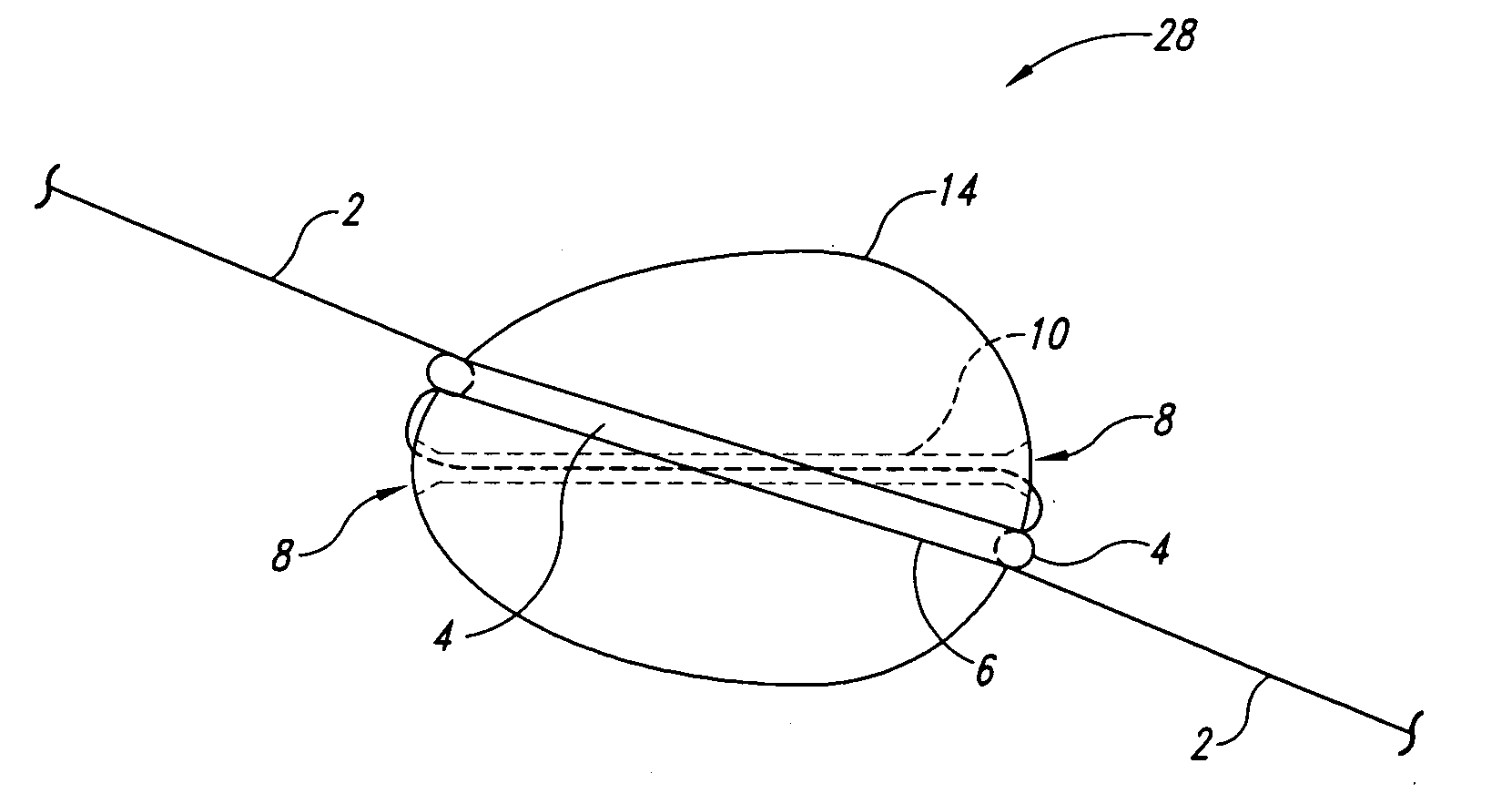

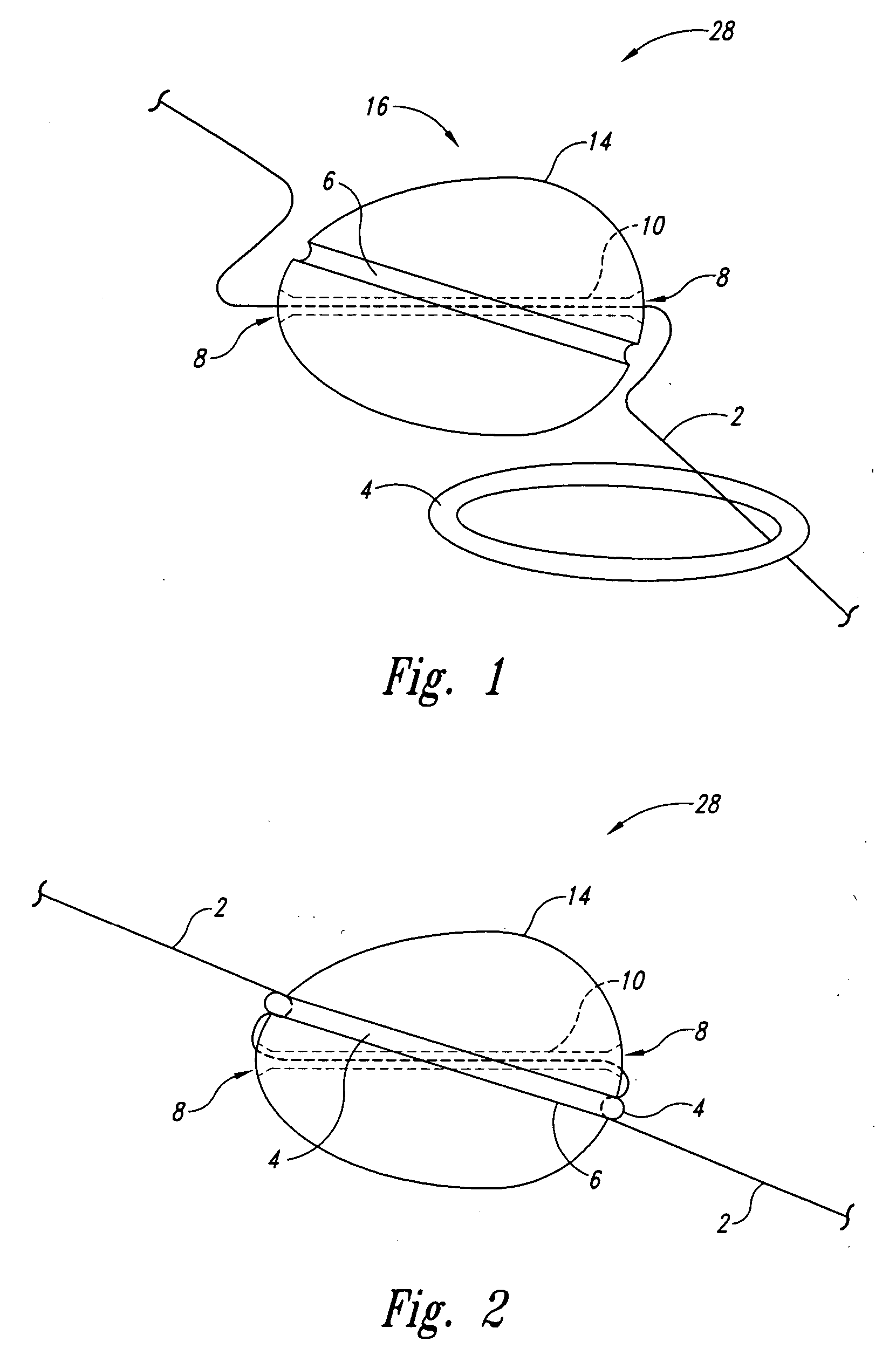

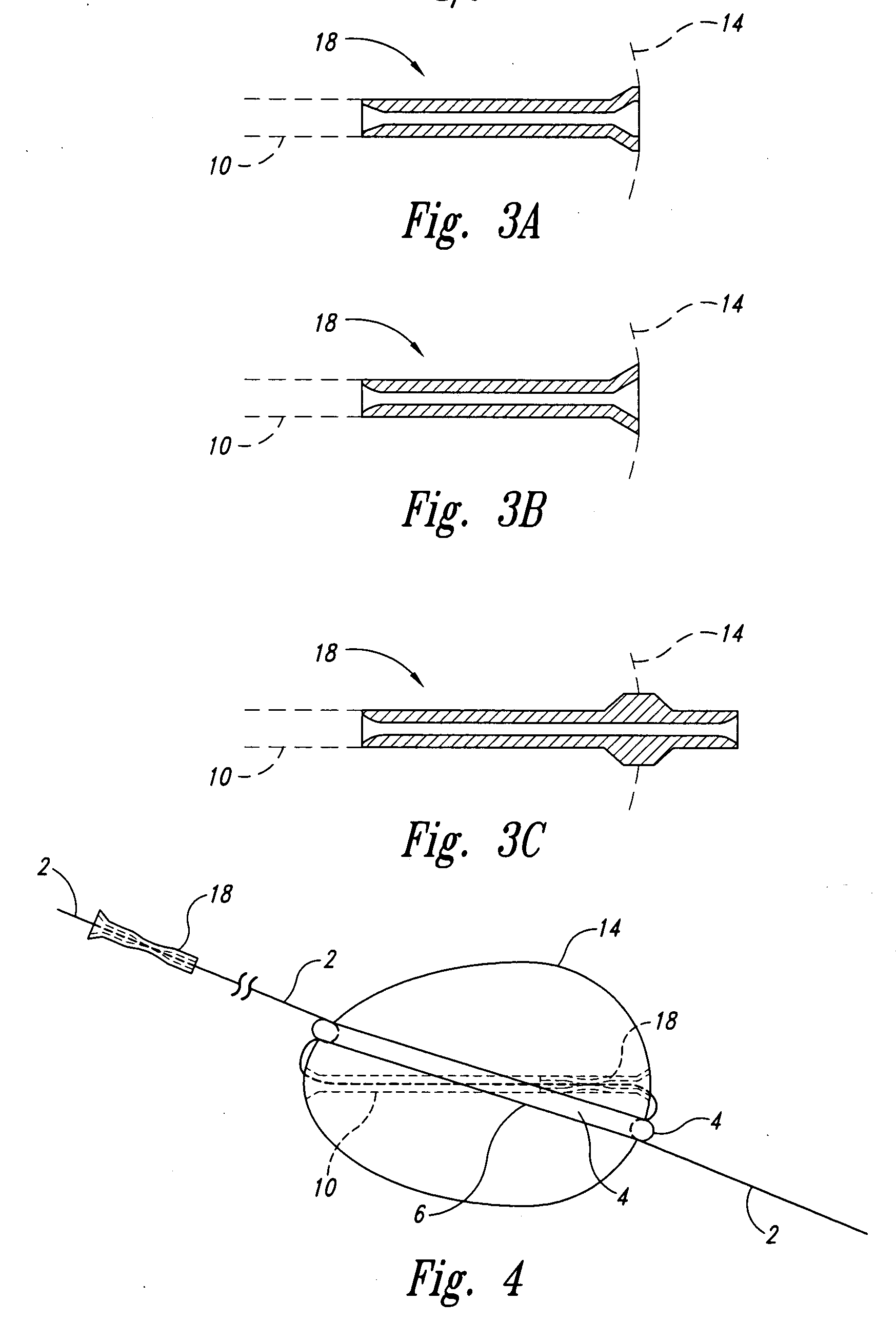

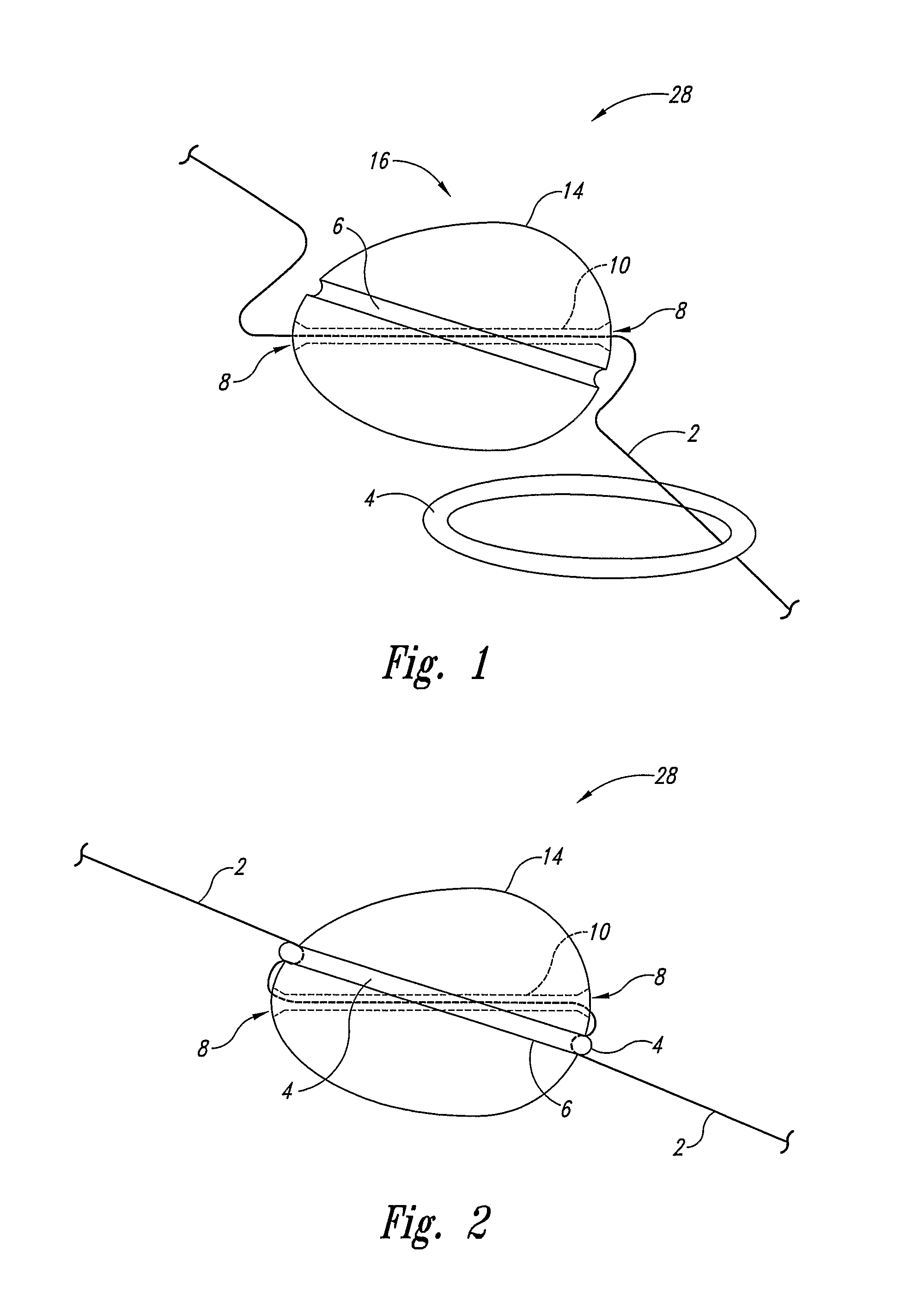

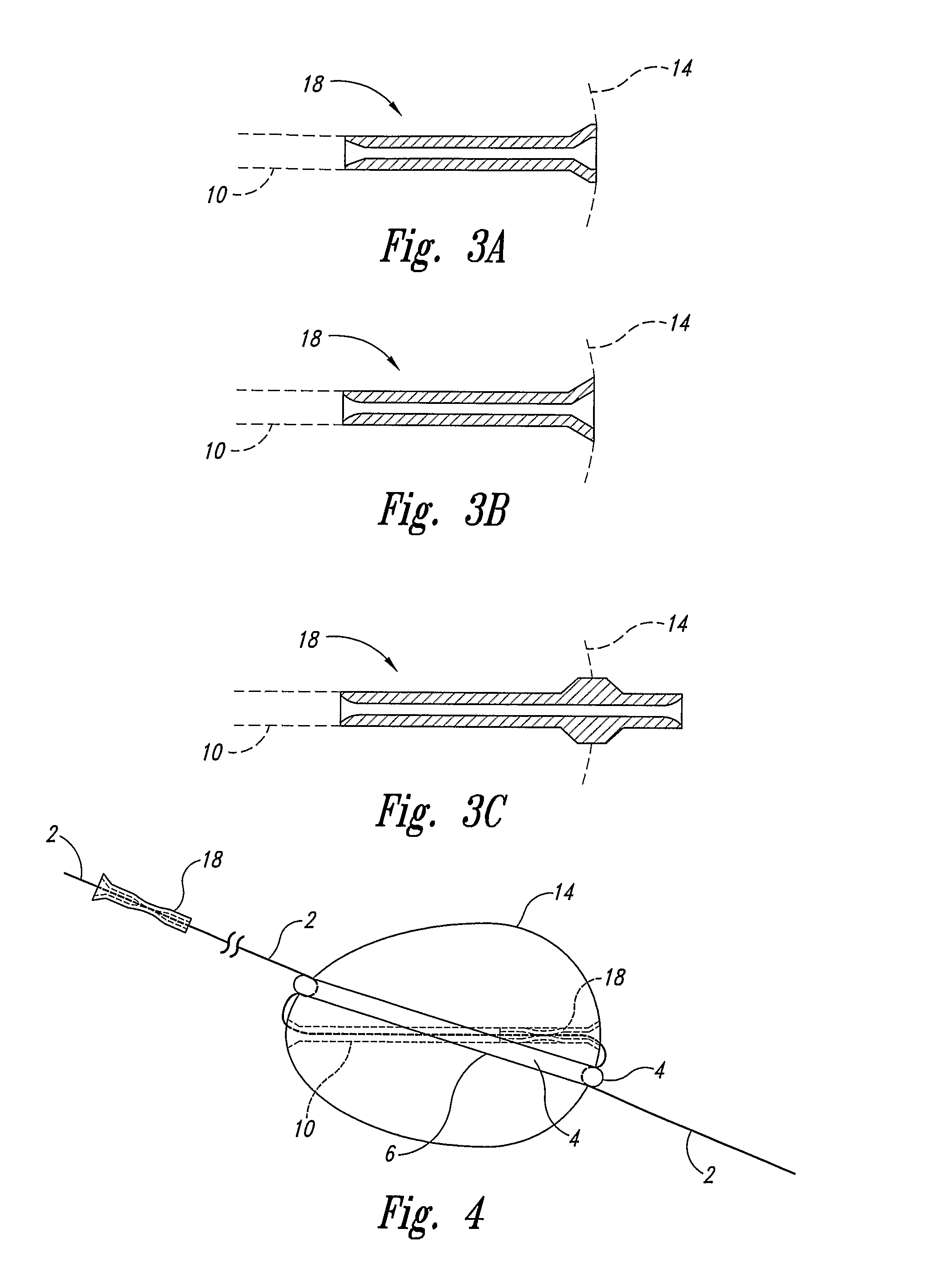

Reversibly disengaging slidable strike indicator, positioning system, and method of using same

InactiveUS20060288632A1Limit slidable travelPracticalLinesOther angling devicesEngineeringPositioning system

Particular aspects provide novel strike indicators attachable to fishing lines, that are reversibly disengagable therefrom and thereafter slidably along the line. Particular embodiments comprise: a buoyant main body having an axial channel with corresponding end surface openings; an retention member seat (e.g., groove, ridge, etc.) running around the main body surface; and at least one line retention member receivable and retainable by the seat, and operative with the seat to retain a line passing therebetween at two points. The retention member is displaceable from the seat by sufficient line tension, thereby disengaging the slidable strike indicator. Particular embodiments comprise two strike indicator stop members attachable at user-selectable line positions, and operative to delimit a slidable range of a disengaged slidable strike indicator. Novel methods for fishing, with a slidable reversibly detachable indicator, at a depth greater than the length of a fishing rod are presented.

Owner:DREAM WATERS

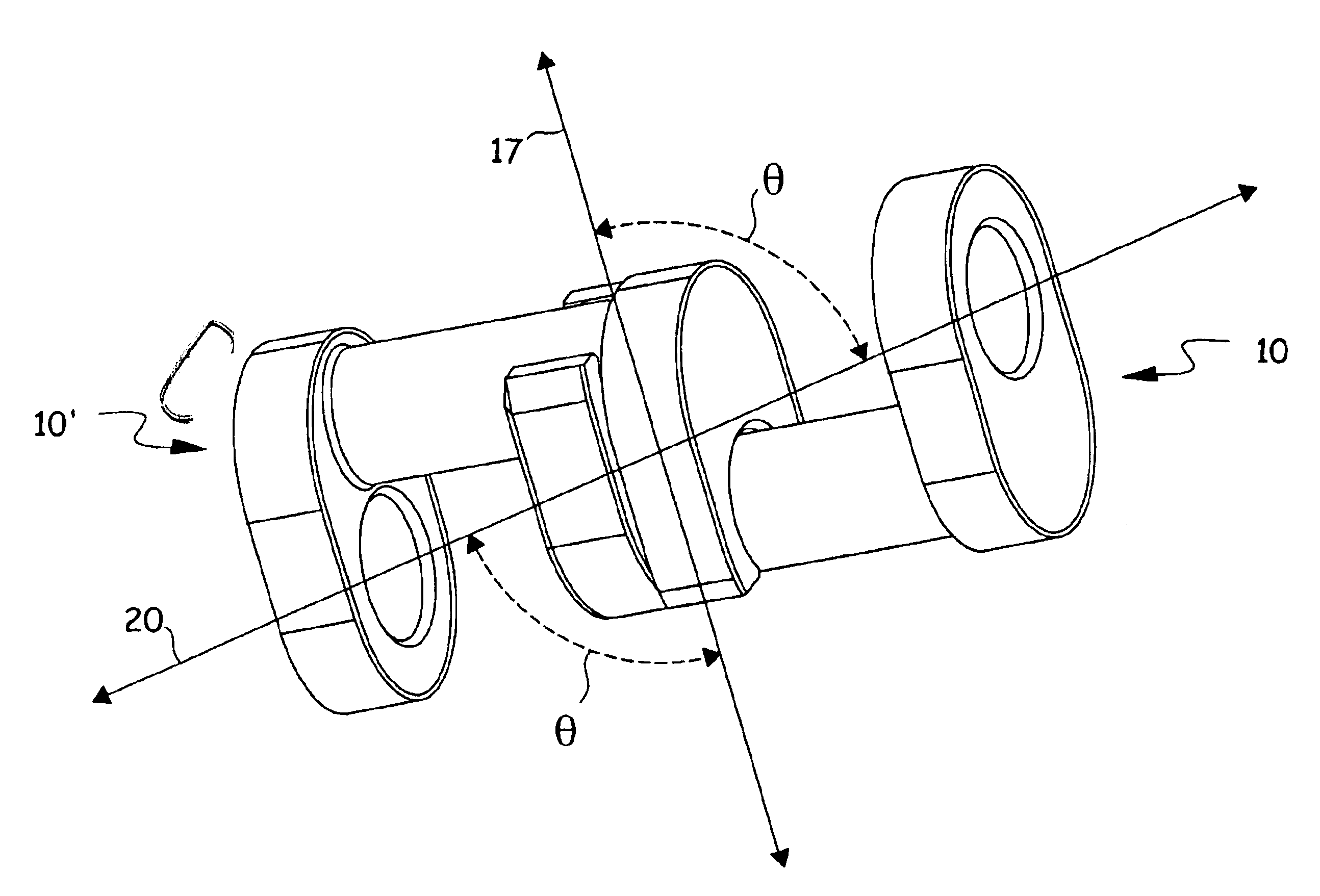

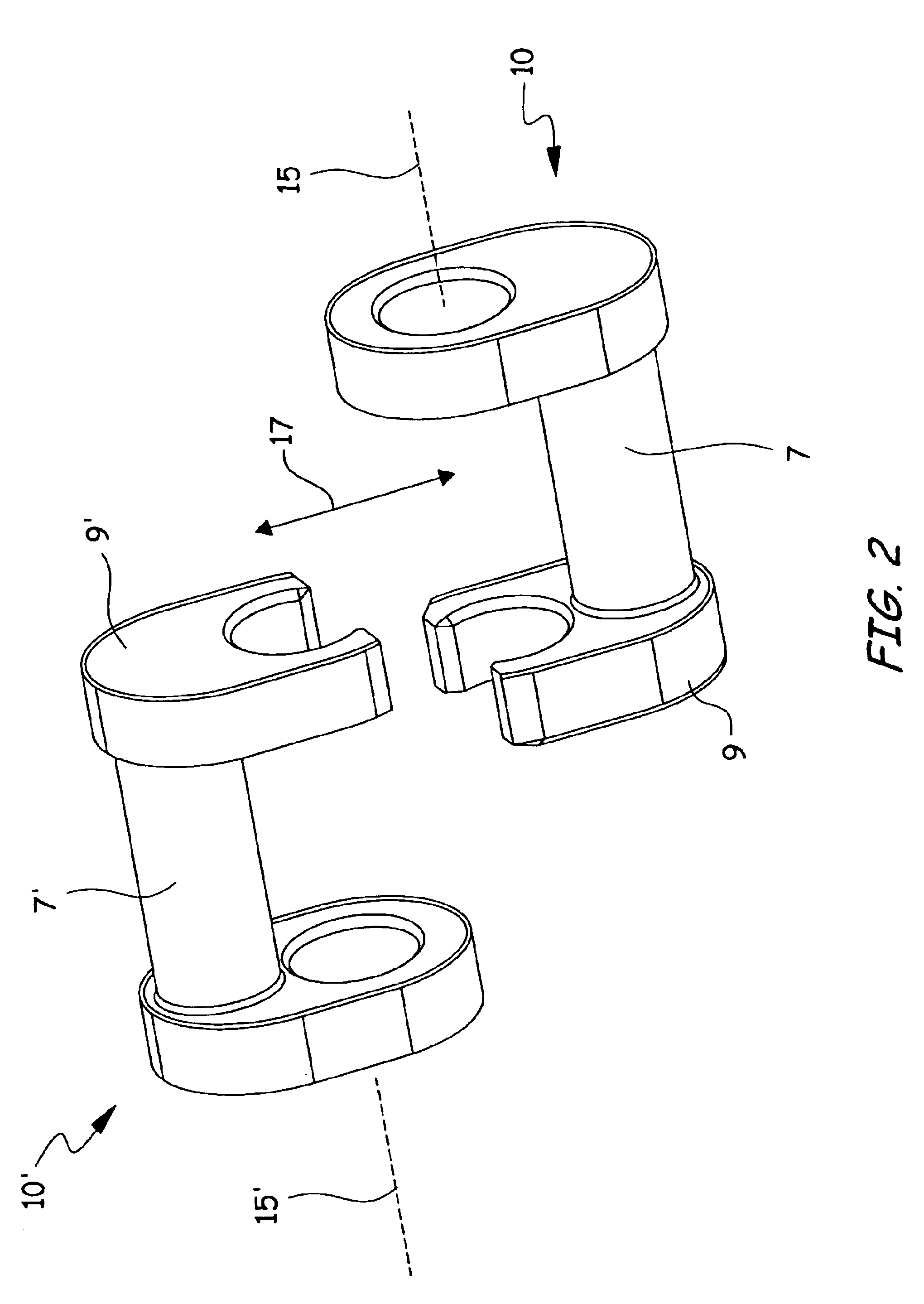

Line connector

ActiveUS6905279B2Flanged jointsRopes and cables for vehicles/pulleyEngineeringMechanical engineering

Owner:THE COLEMAN CO INC

Line tension measuring device

The invention is a fishing pole with an integrated line tension measuring device. Measured line tension is displayed in quantitative units, pounds or kilograms. A line tension warning system activates when the sensed line tension exceeds a threshold set by the fisherman. The line tension measuring device does not touch the fishing line so the fishing pole with integrated line tension measuring device fishes and operates like a normal fishing pole. The line tension measuring device may be integrated into the fishing reel seat which, in turn, is an integral part of the fishing pole.

Owner:REEL DRAG TECH

Reversibly disengaging slidable strike indicator, positioning system, and method of using same

InactiveUS9010016B2Limit slidable travelPracticalLinesOther angling devicesEngineeringPositioning system

Owner:DREAM WATERS

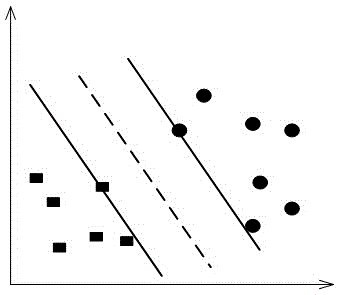

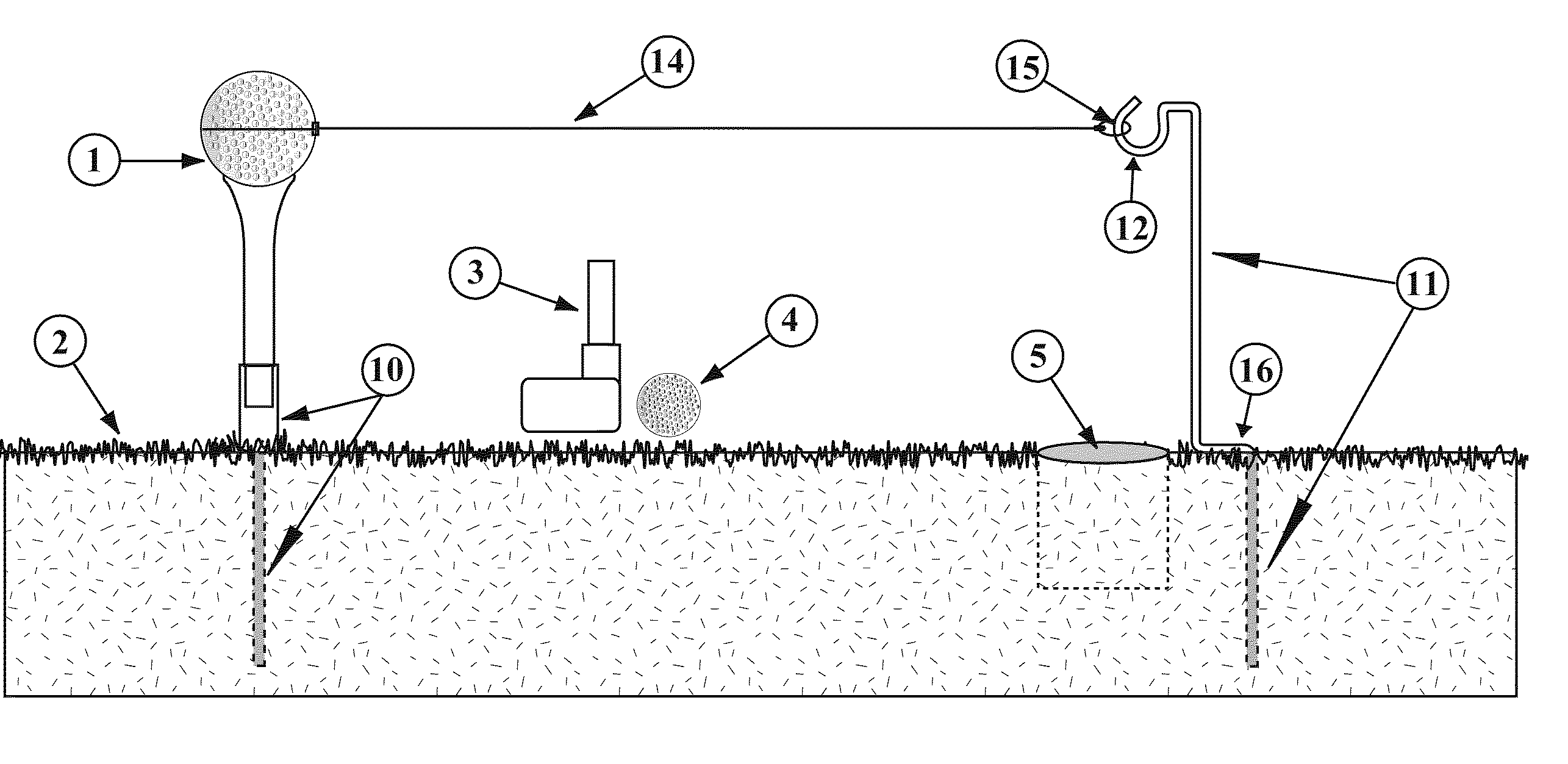

Apparatus For Practicing The Golf Putting Stroke

A retractable putting line aiming / alignment device inserted into a golf green surface, via a stake assembly, for practicing the game of golf putting stroke is disclosed. The apparatus includes: a housing, simulating a golf ball, which houses an extendable / retractable line mechanism; a stake assembly to secure the housing into position on the putting green; and a corresponding and opposing stake to be inserted into the putting green, to attach the receiving extended line. The apparatus is placed into position on a putting green surface at or near the golf hole and the opposite line end is extended and secured to the opposing stake placed into the putting green at a desired distance from the hole or visa versa. The extendable / retractable line mechanism provides the necessary line tension to prevent the line from sagging when extended. The extended putting line represents the target path or reference for aligning a putter with respect to the target hole enabling the user to enhance the practice of proper alignment through the putting stroke.

Owner:YAMANAKA MR RICHARD Q

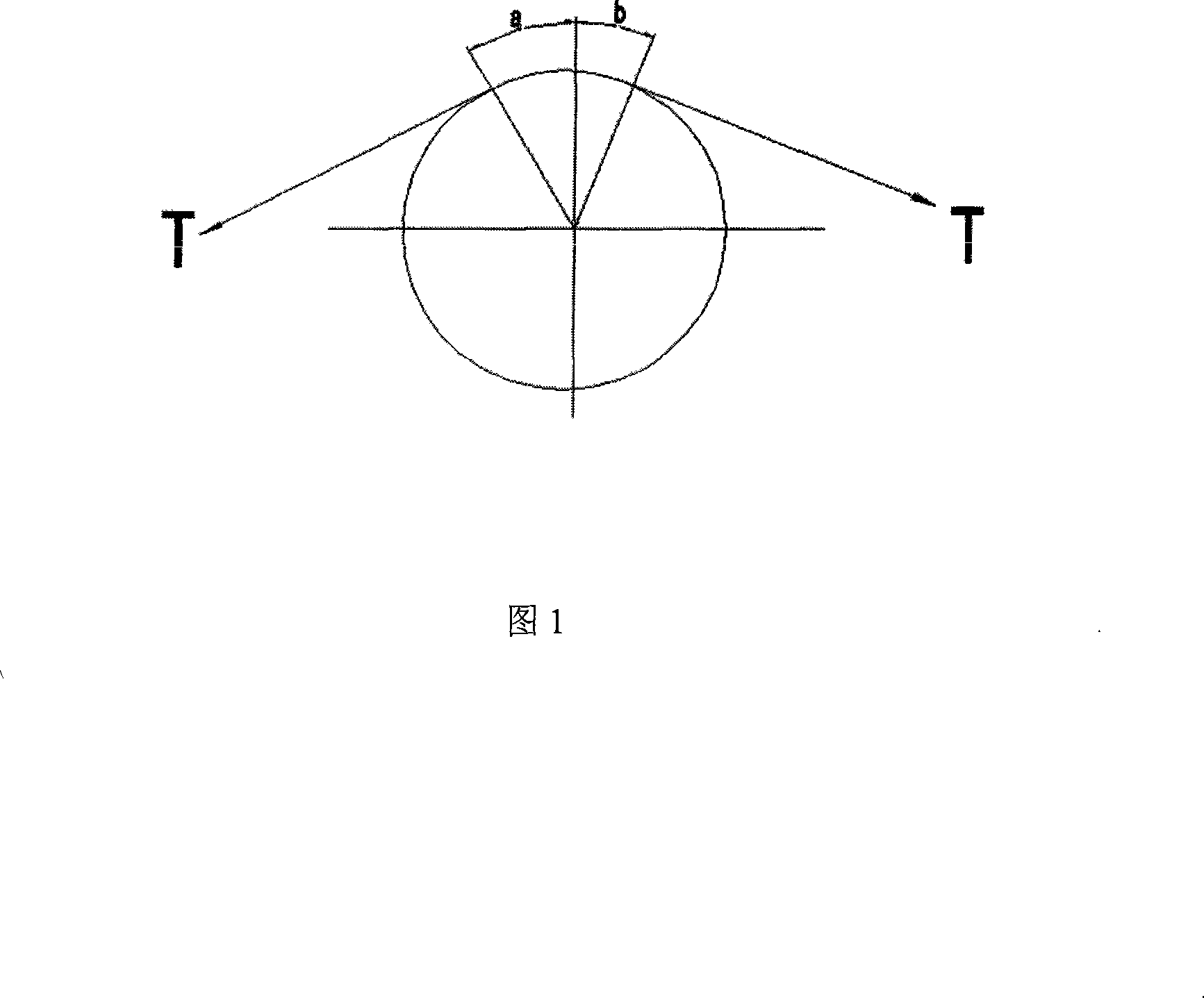

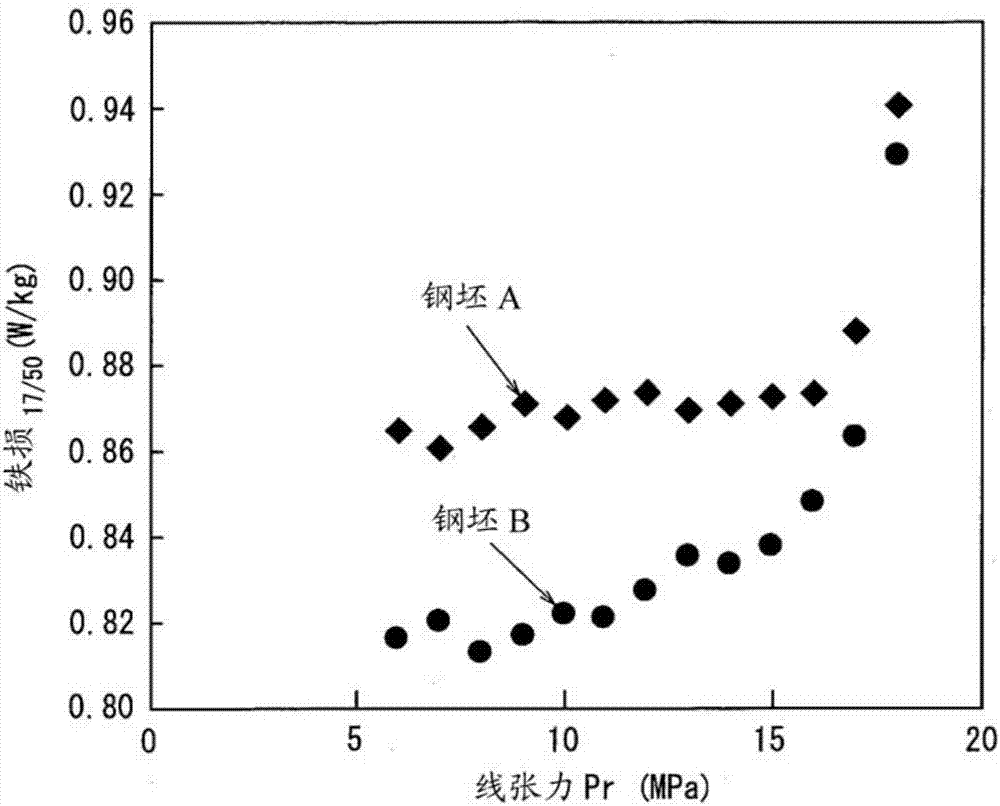

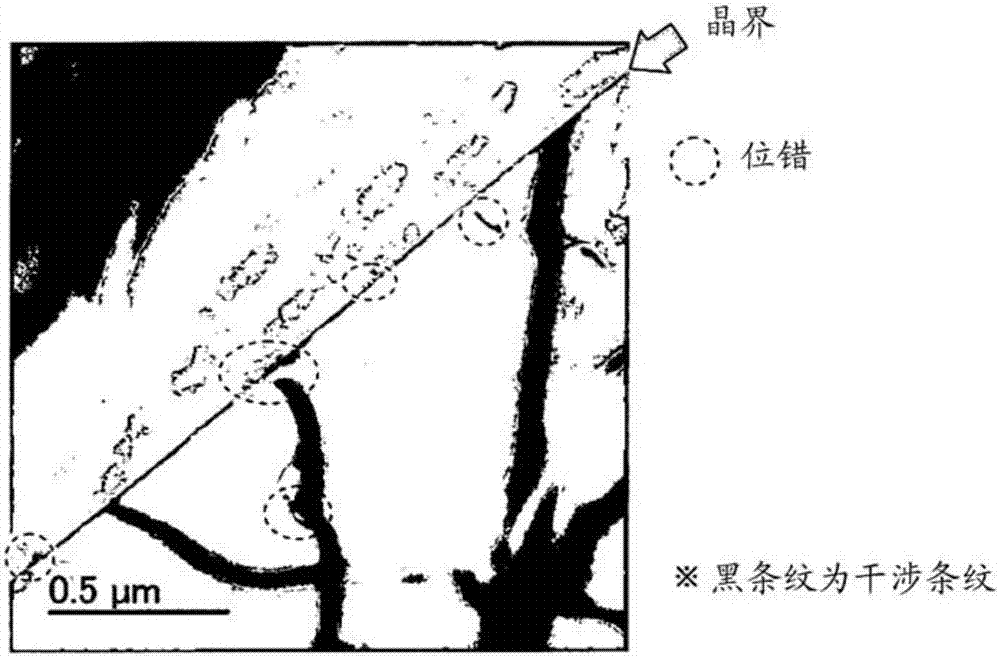

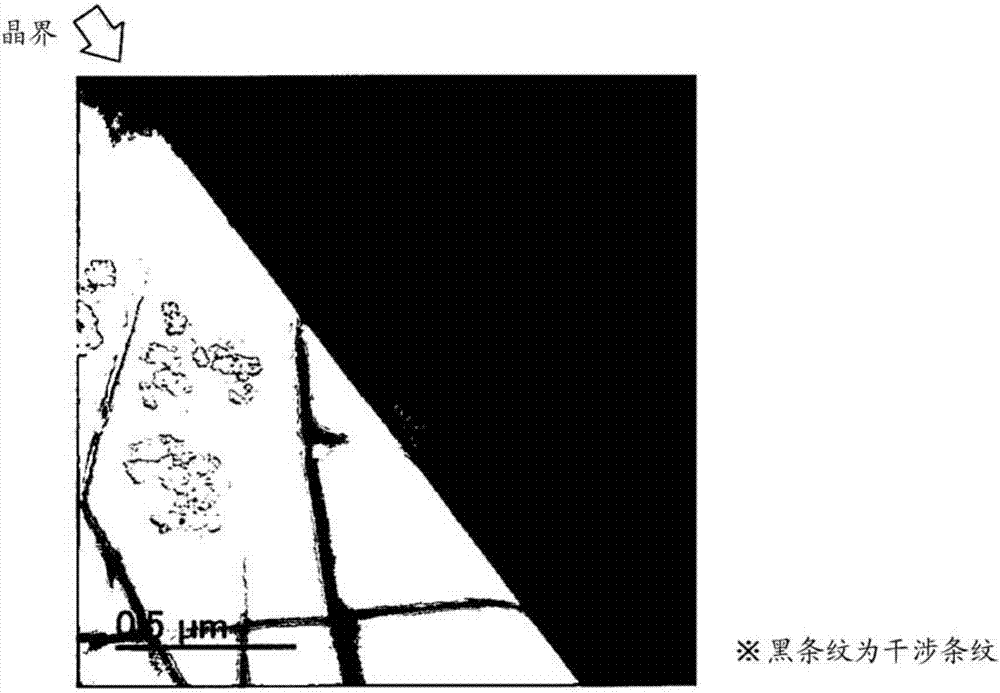

Oriented electromagnetic steel plate and manufacturing method thereof

An oriented electromagnetic steel plate, and a manufacturing method thereof, is provided which has low core loss even in the case of containing at least one of Sb, Sn, Mo, Cu and P, which are grain boundary segregation elements. In this method of manufacturing an oriented electromagnetic steel plate, defining T(hr) as the time needed after finish annealing for the temperature of the secondary recrystallization plate to fall from 800 to 400DEG C, the line tension Pr (MPa) on the secondary recrystallization plate is controlled so as to satisfy Pr <=-0.075T + 18 (here, T > 10, 5 < Pr) in a flattening annealing step. As a result, it is possible to obtain an oriented electromagnetic steel plate which has low core loss and which has a dislocation density near the crystal grain barrier of the base metal of less than or equal to 1.0*1013m-2 even in the case of containing at least one of Sb, Sn, Mo, Cu and P.

Owner:JFE STEEL CORP

Steel twisted line tension test sensor

InactiveCN1851429AReasonable designSimple structureTension measurementPull forceArchitectural engineering

The invention relates to a steel twisted line tension measuring sensor that sets left end fixing cover on the left end of inner protecting canister, sets right fixing cover on the right end, sets inner gum ring between inner protecting canister and the right fixing cover. Left upper clipping wedge ring and left upper clipping wedge ring are set on the left end fixing cover. Right upper clipping wedge ring and right upper clipping wedge ring are set on the right end fixing cover. One end of the 2-8 even number spring tabs are set on the left end fixing cover and the other end is set on the right end fixing cover. Strain gauge is set on every spring tab. The strain gauge is connected by wire to form bridge circuit. The invention has reasonable design, simple structure, high accuracy, long useful file etc. It could be used to measure the tension of steel twisted line.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com