Multi-line cutting machine in-phase servo drive and constant tension control system

A technology of multi-wire cutting machine and servo drive, which is applied in the field of its control system to achieve high efficiency and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

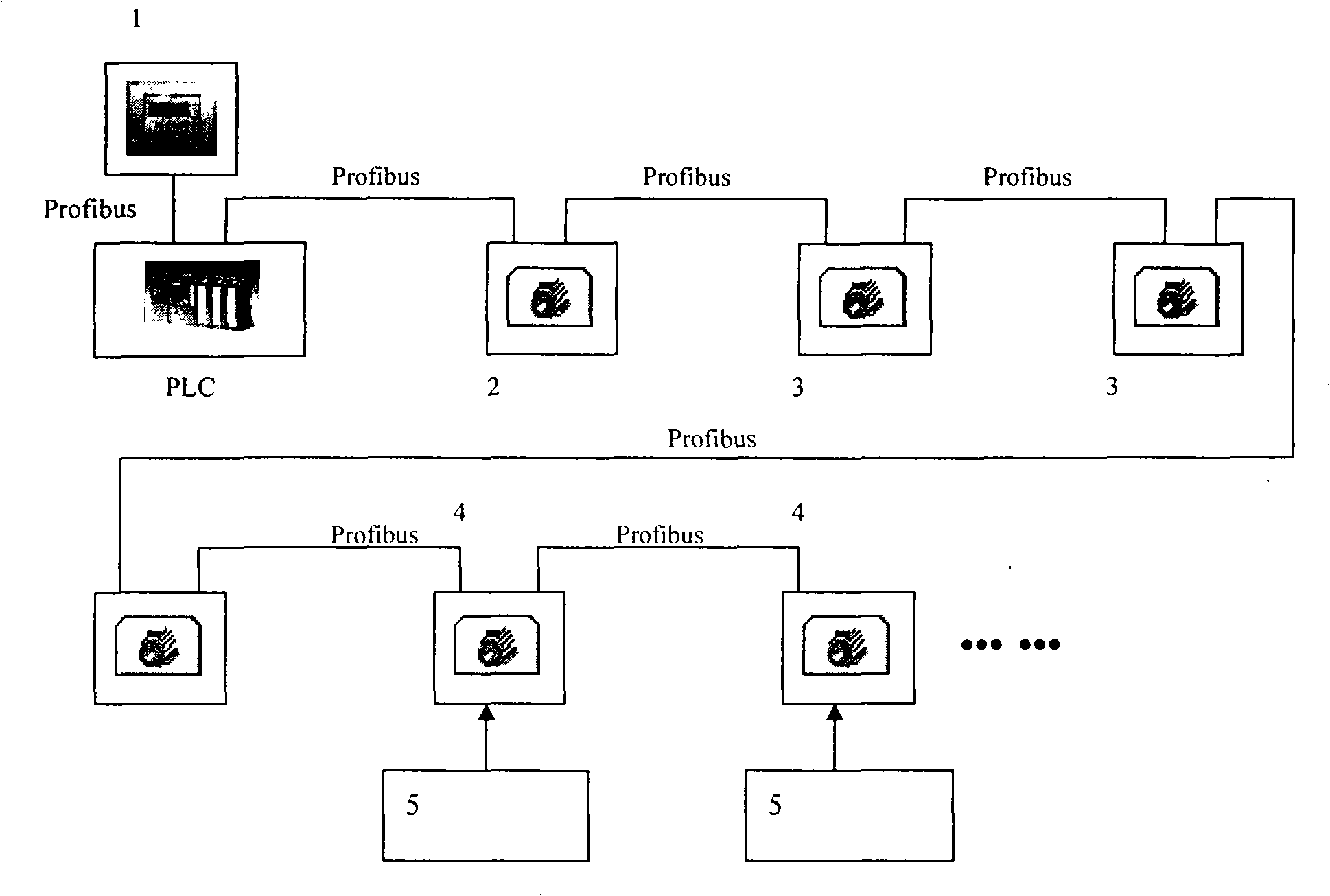

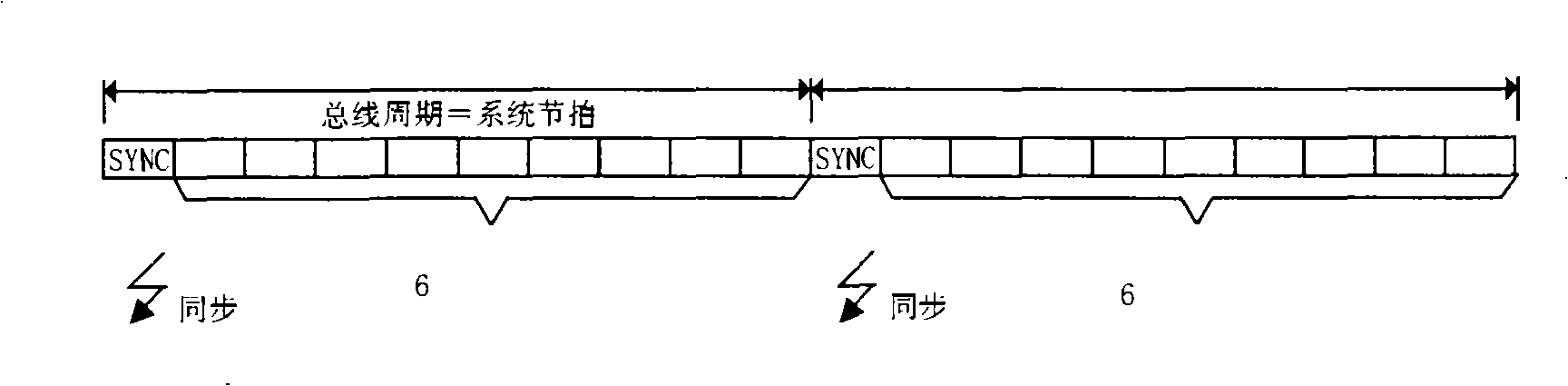

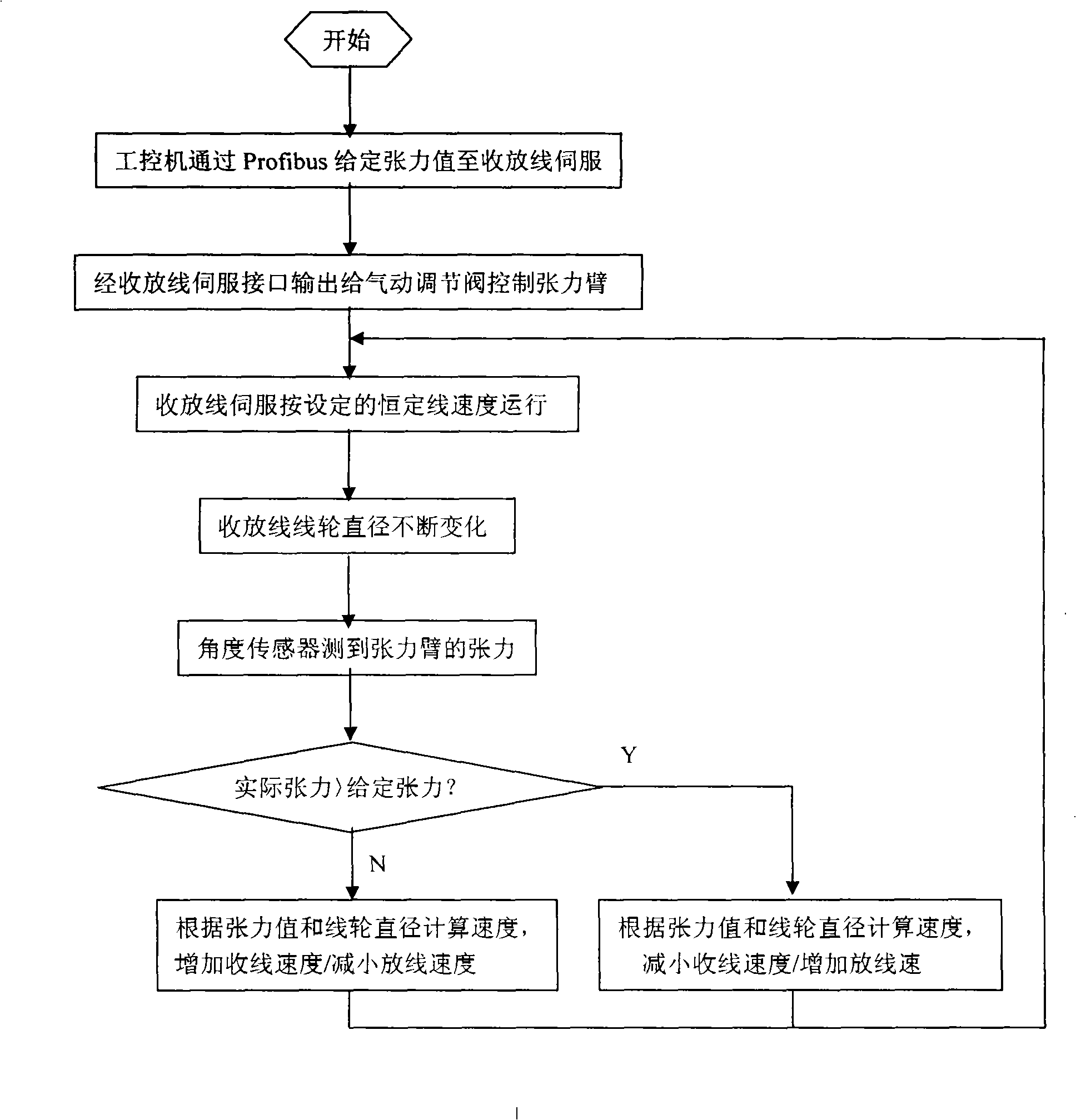

[0012] like figure 1 The synchronous servo drive and constant tension control system of the multi-wire cutting machine shown includes the industrial computer 1, the main servo motor 2, the slave servo motor 3 and the take-up and release servo motor 4, and the industrial computer and each servo drive are connected through Profibus high-speed data For transmission, firstly, the industrial computer sets a standard given value, and the given value is transmitted to the main drive servo, and at the same time, the given value and the actual data and status of the main drive are quickly transmitted to the three slave drive servos and the take-up and release reel servo. In terms of hardware, the industrial computer and the servo are respectively designed with synchronization function option boards, and in terms of software, it depends on the synchronization characters of each message (such as figure 2 As shown), each frame message transmitted on the bus contains a synchronization cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com