Oriented electromagnetic steel plate and manufacturing method thereof

A technology of electromagnetic steel sheet and manufacturing method, applied in the direction of manufacturing tools, inorganic material magnetism, furnace type, etc., can solve the problems of not being able to obtain low iron loss, unable to improve magnetic properties, etc., and achieve the effect of low iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

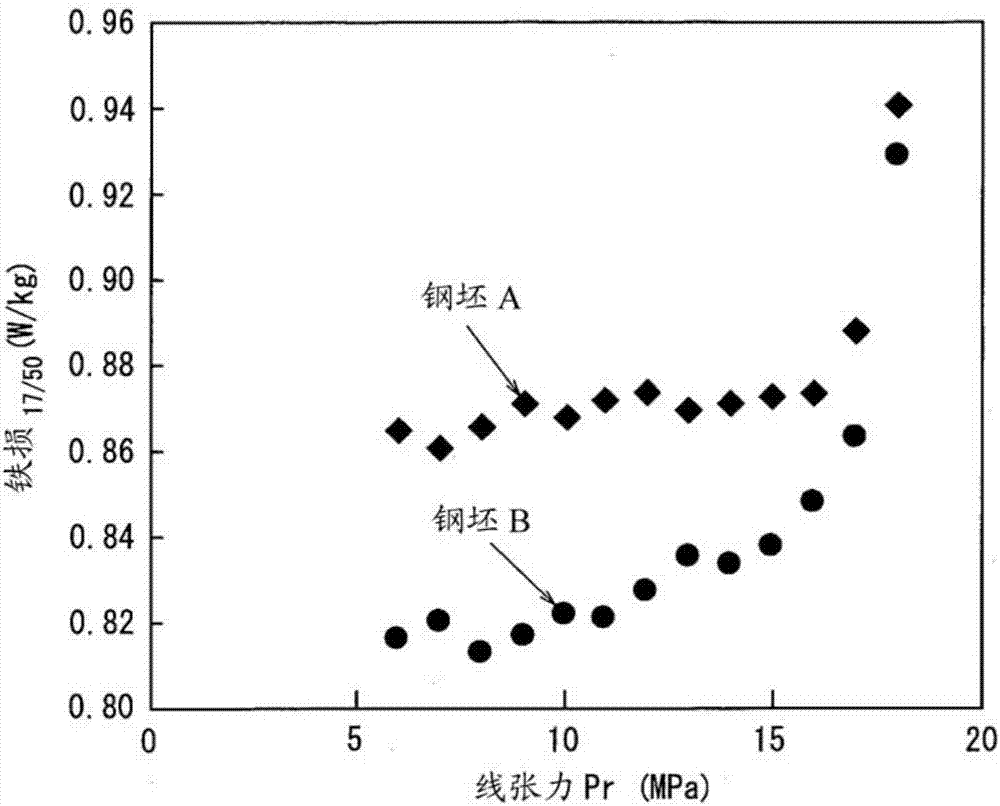

[0090] Steel slabs are manufactured by continuous casting and heated at 1220°C, and the slabs contain C: 0.032%, Si: 3.25%, Mn: 0.06%, N: 0.0026%, sol.Al: 0.0095%, Sn: 0.120%, P: 0.029%. Then, this steel slab was hot-rolled, and it finished-rolled it into the hot-rolled plate of 2.7 mm in thickness. Subsequently, the hot-rolled sheet was subjected to hot-rolled sheet annealing at 1025° C. for 30 seconds, and then finished cold-rolled into a cold-rolled sheet having a sheet thickness of 0.23 mm. Then, at 55% H 2 -45%N 2 , Under a humid gas atmosphere with a dew point of 58° C., the cold-rolled sheet was subjected to primary recrystallization annealing at 840° C. for 100 seconds as decarburization annealing to obtain a primary recrystallization sheet. Then, an annealing separator mainly composed of MgO is coated on the surface of the primary recrystallization plate, and the2 The final annealing for secondary recrystallization was carried out in a gas atmosphere for 5 hours to...

Embodiment 2

[0098] Various slabs containing the components described in Table 2 were produced by continuous casting, and the slabs were heated at 1380°C. Then, these slabs were hot-rolled and finished into hot-rolled sheets with a thickness of 2.5 mm. Subsequently, the hot-rolled sheet was subjected to hot-rolled sheet annealing at 950° C. for 30 seconds, and then cold-rolled so as to have a sheet thickness of 1.7 mm. Then, intermediate annealing was performed at 1100° C. for 30 seconds, followed by finish rolling by warm rolling at 100° C. to form a cold-rolled sheet having a thickness of 0.23 mm. Then, at 60% H 2 -40%N 2 1. In a humid gas atmosphere with a dew point of 64° C., the cold-rolled sheet was subjected to primary recrystallization annealing at 850° C. for 100 seconds as decarburization annealing to obtain a primary recrystallization sheet. Then, an annealing separator mainly composed of MgO is coated on the surface of the primary recrystallization plate, and the 2 Final an...

Embodiment 3

[0104] Steel slabs were produced by continuous casting and heated at 1220°C, the slabs contained C: 0.058%, Si: 3.68%, Mn: 0.34%, N: 0.0011%, sol.Al: 0.0023% by mass % , Sb: 0.090%, P: 0.077%. Then, this steel slab was subjected to hot rolling, and was finished rolled into a hot-rolled sheet having a thickness of 2.0 mm. Subsequently, the hot-rolled sheet was subjected to hot-rolled sheet annealing at 1060° C. for 100 seconds, and then cold-rolled to finish rolling into a cold-rolled sheet having a sheet thickness of 0.23 mm. Then, at 55% H 2 -45%N 2 1. Under a humid gas atmosphere with a dew point of 60°C, the cold-rolled sheet was subjected to primary recrystallization annealing at 840°C for 100 seconds as decarburization annealing to obtain a primary recrystallization sheet. Then, an annealing separator mainly composed of MgO is coated on the surface of the primary recrystallization plate, and the 2 The final annealing for secondary recrystallization was carried out in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com