Steel twisted line tension test sensor

A technology of tension measurement and sensor, which is applied in the field of force measurement, can solve the problems that the size and distribution of the channel friction resistance cannot be detected, it cannot be judged whether the force of the steel strand is uniform, and the magnitude of the tension cannot be detected, etc., so as to achieve simple structure and easy use Long life, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

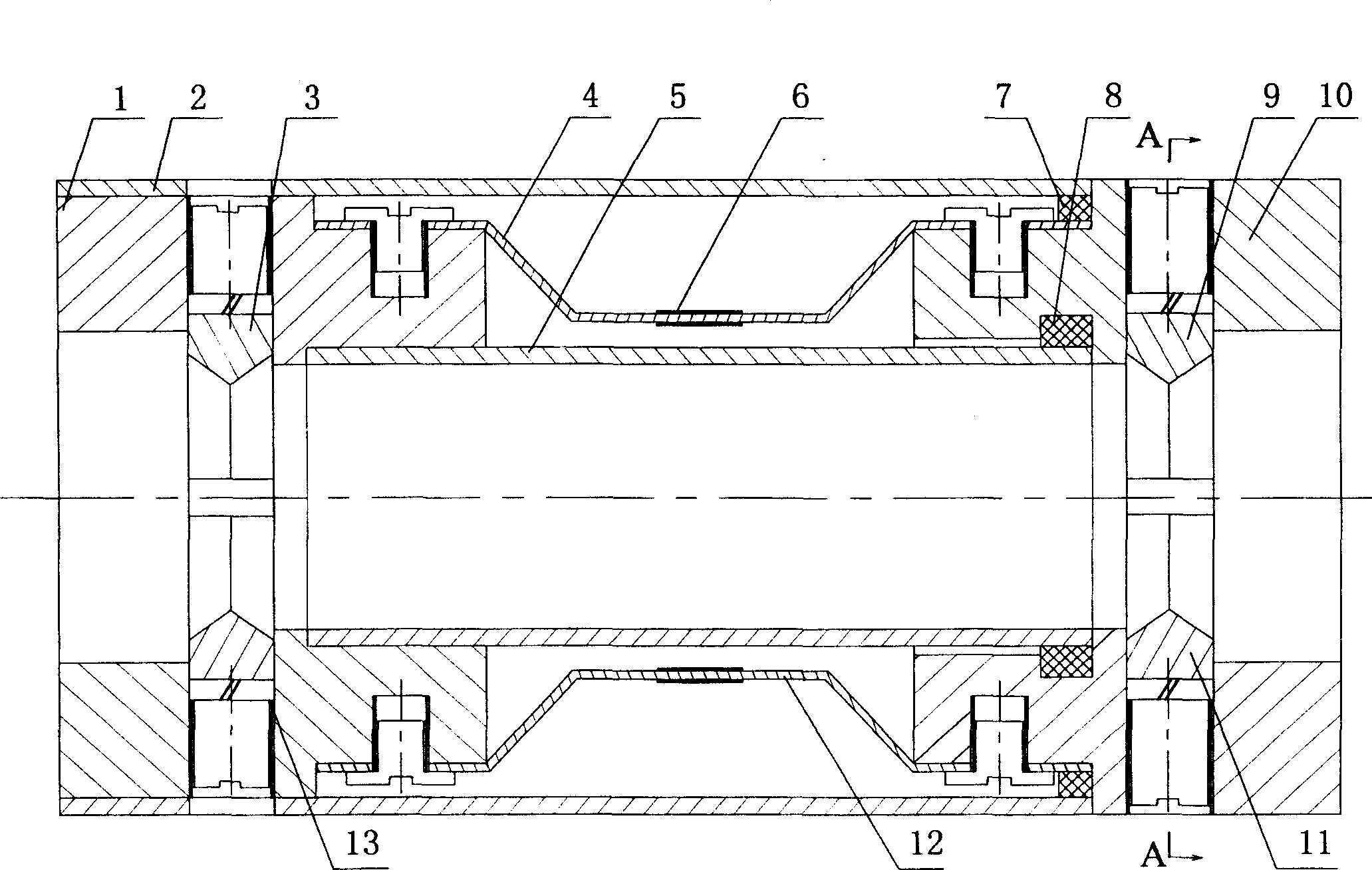

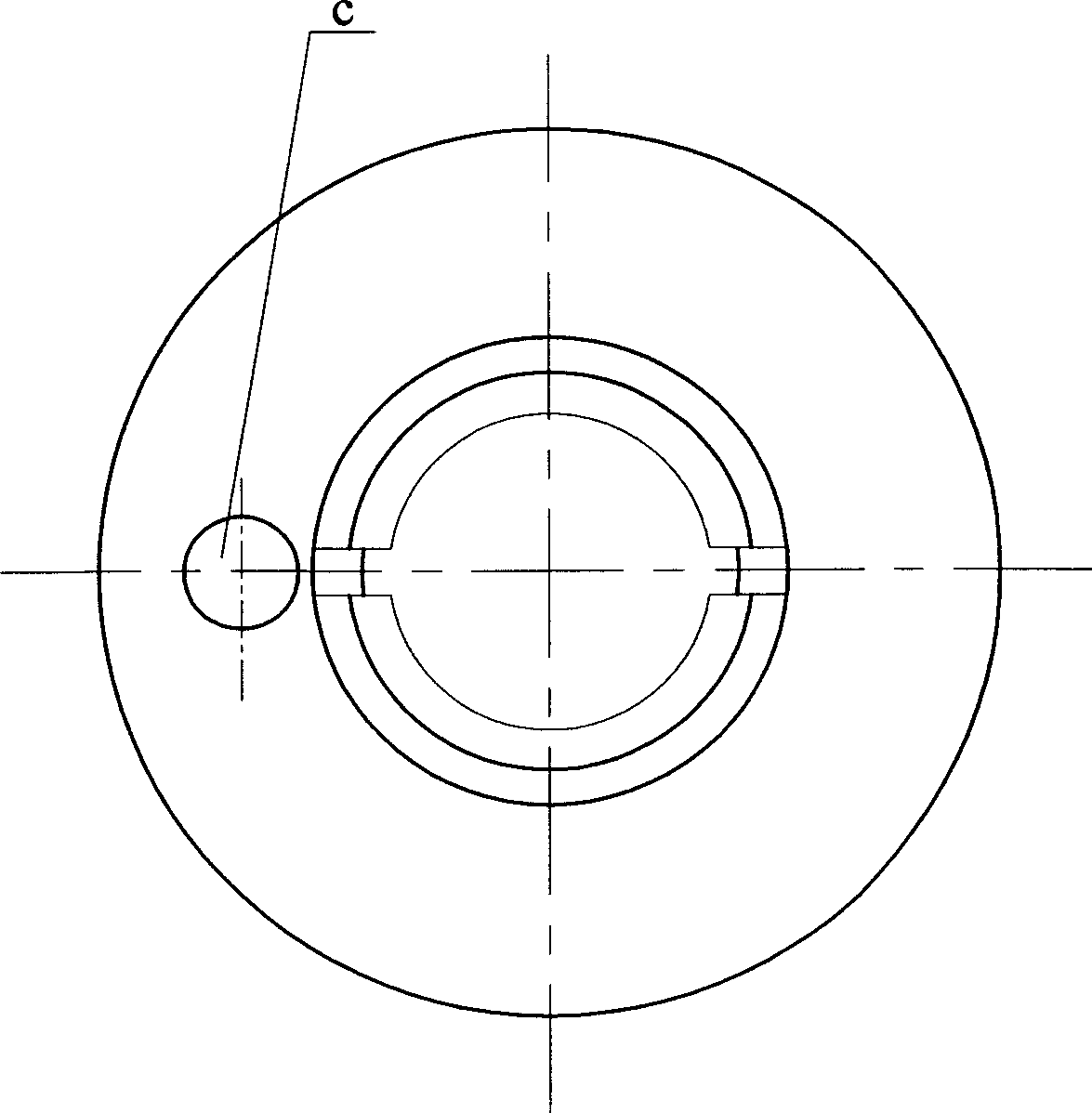

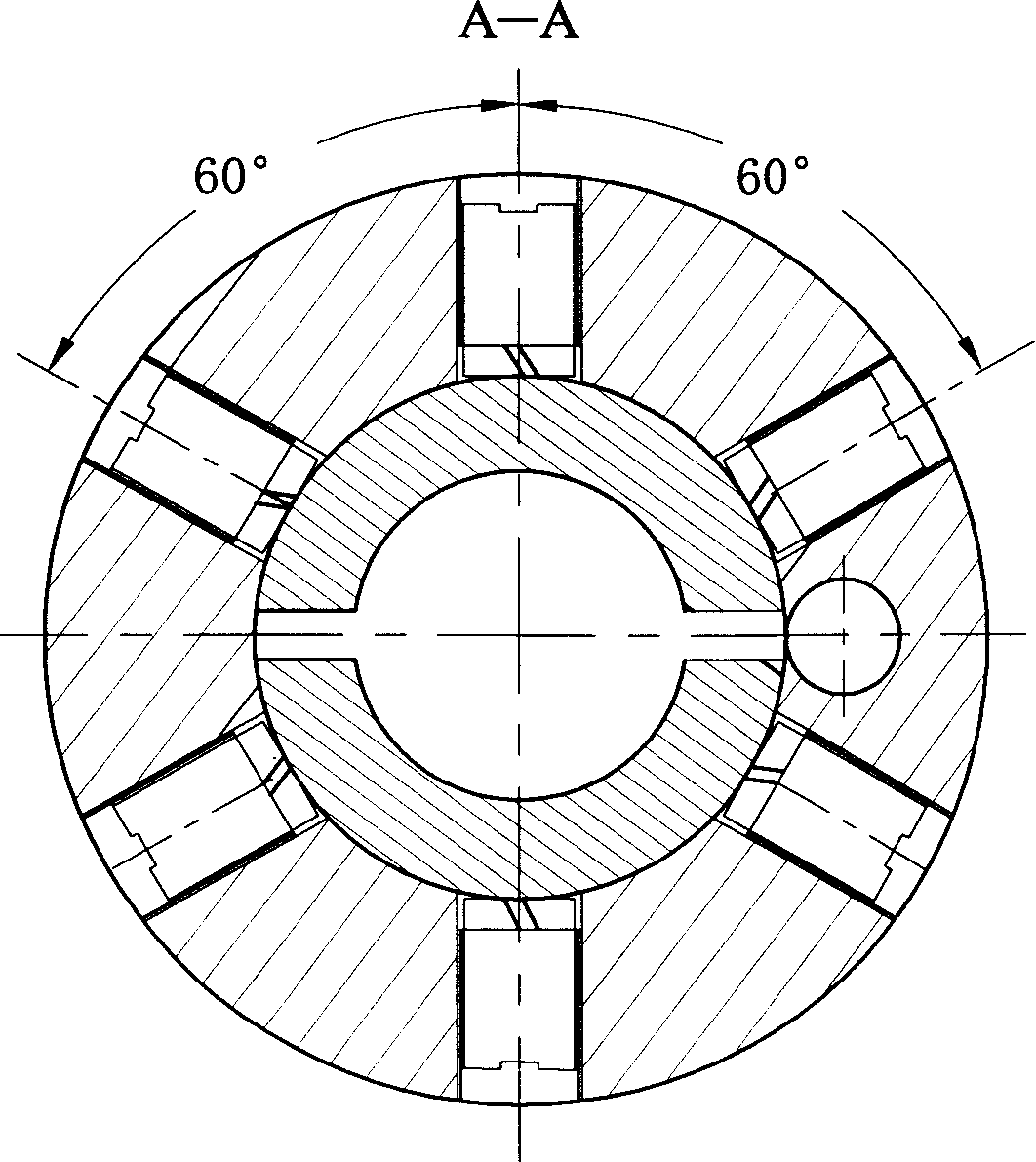

[0021] exist figure 1 , 2 , 3, 4, and 5, the steel strand tension measuring sensor of the present embodiment consists of the left end fixed sleeve 1, the outer casing 2, the upper left clamping wedge ring 3, the upper spring leaf 4, the inner casing 5, the strain gauge 6, Outer rubber ring 7, inner rubber ring 8, upper right clamping wedge ring 9, right end fixed cover 10, right lower clamping wedge ring 11, lower spring leaf 12, left lower clamping wedge ring 13 are connected to form.

[0022] The left end of the inner casing 5 is covered with a left end fixed sleeve 1, and the right end is covered with a right end fixed sleeve 10. An inner rubber ring 8 is installed between the inner casing 5 and the right end fixed sleeve 10, and the inner rubber ring 8 acts as a seal. A gap is left between the inner casing 5 and the right-end fixed sleeve 10 to allow relative movement between the inner casing 5 and the right-end fixed sleeve 10 . There are 6 screw holes uniformly distrib...

Embodiment 2

[0029]In this embodiment, the inner arc radius R of the upper left clamping wedge ring 3 and the lower left clamping wedge ring 13 is 2.5 mm, and the inner arc radius R of the upper right clamping wedge ring 9 and the lower right clamping wedge ring 11 is 2.5mm. The width b of the upper spring sheet 4 is 5 mm, the thickness t is 0.2 mm, the arc length L of the upper spring sheet 4 is 10 mm, the arc height h is 2 mm, and the angle α between the arc side and the bottom surface is 10°. The shape and structure of the lower spring leaf 12 are exactly the same as the upper spring leaf 4 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0031] In this embodiment, the inner arc radius R of the upper left clamping wedge ring 3 and the lower left clamping wedge ring 13 is 7.6 mm, and the inner arc radius R of the upper right clamping wedge ring 9 and the lower right clamping wedge ring 11 is 7.6mm. The width b of the upper spring sheet 4 is 10 mm, the thickness t is 0.5 mm, the arc length L of the upper spring sheet 4 is 80 mm, the arc height h is 7 mm, and the angle α between the arc side and the bottom surface is 30°. The shape and structure of the lower spring leaf 12 are exactly the same as the upper spring leaf 4 . Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com