Method suitable for tension stringing of ultra-high voltage wire

An ultra-high voltage, wire technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of wear and tear of pulley pulleys, worn wires, etc., to achieve the effect of small tonnage, small force, and reliable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

[0024] A tension pay-off method suitable for UHV electric wires:

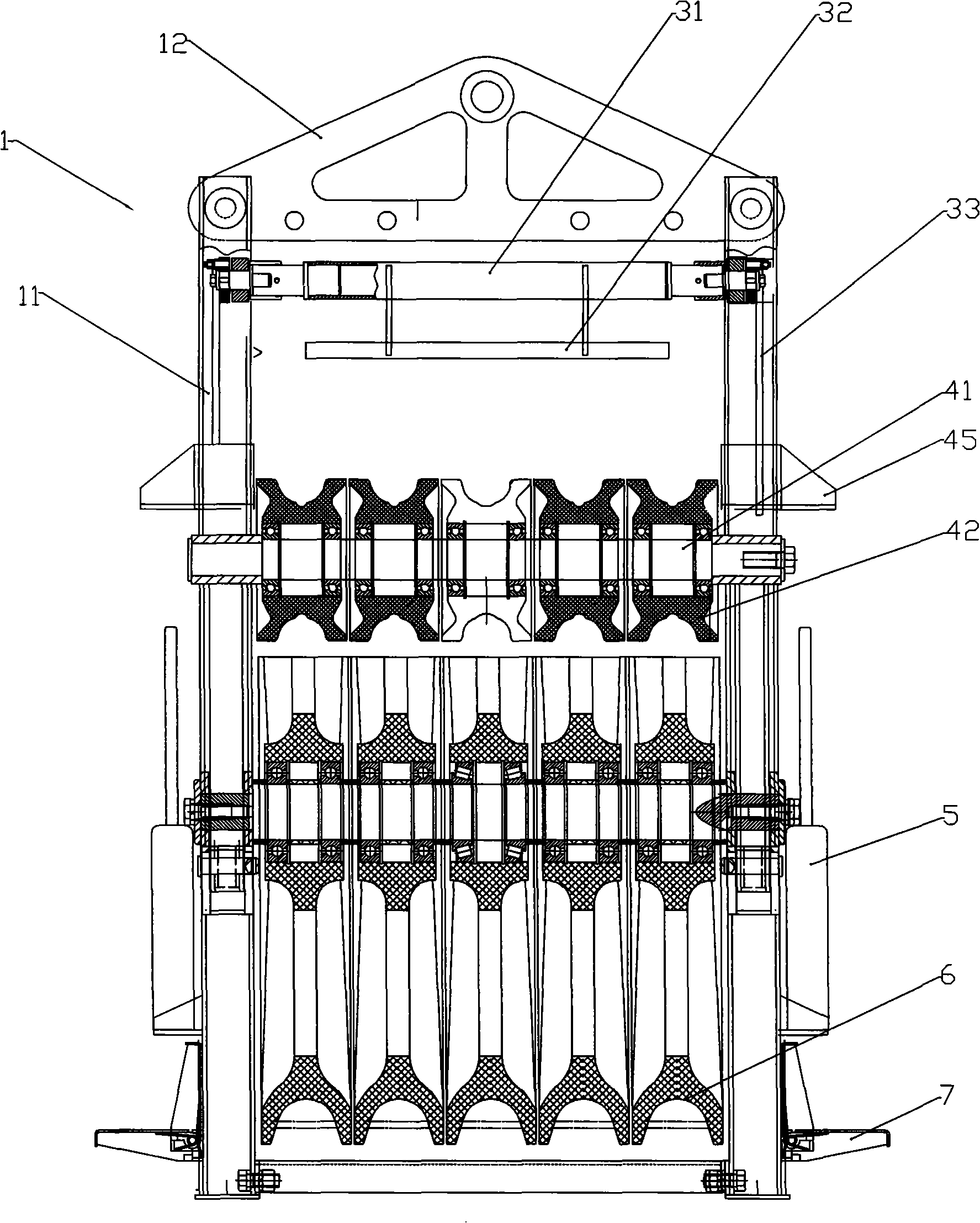

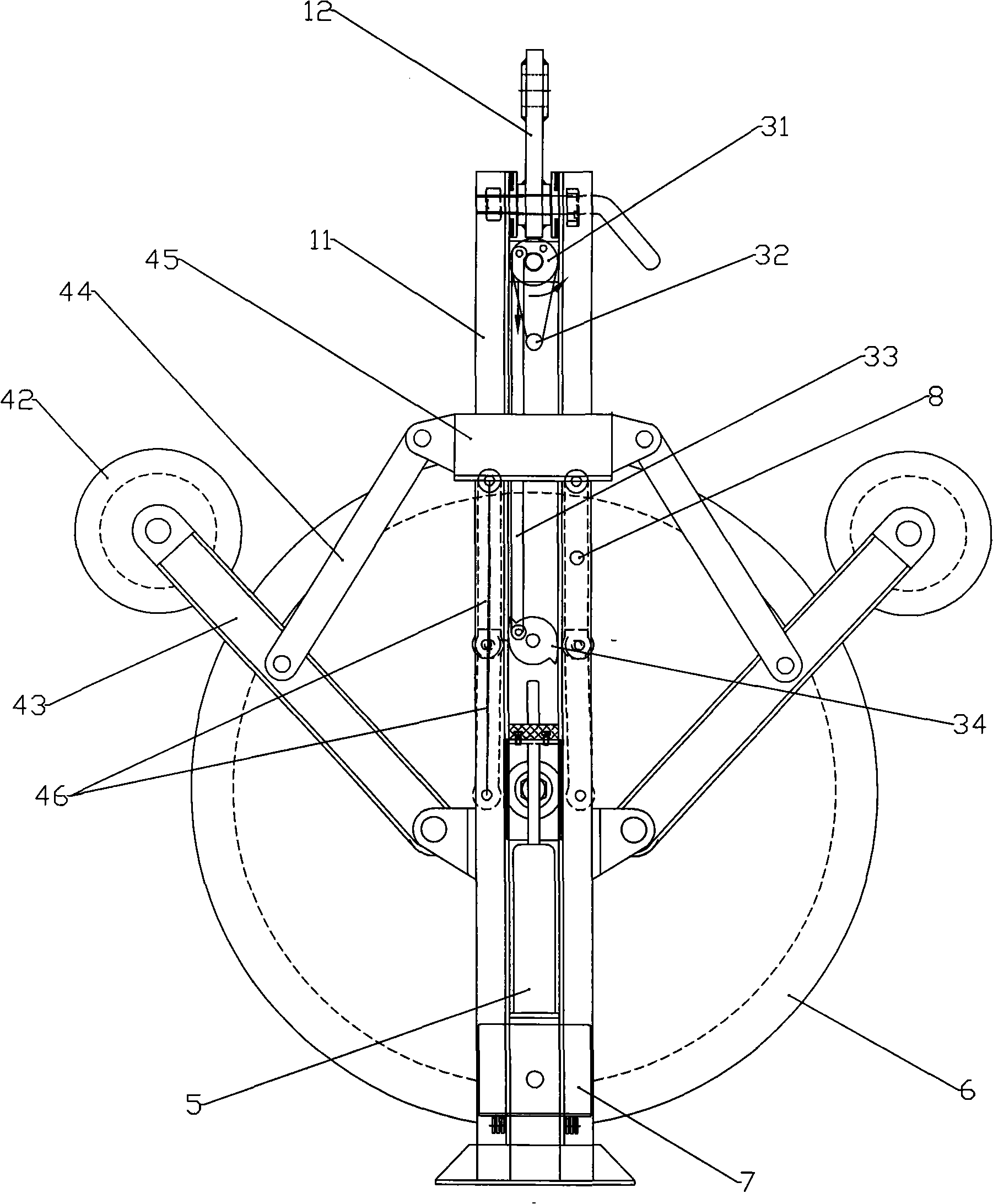

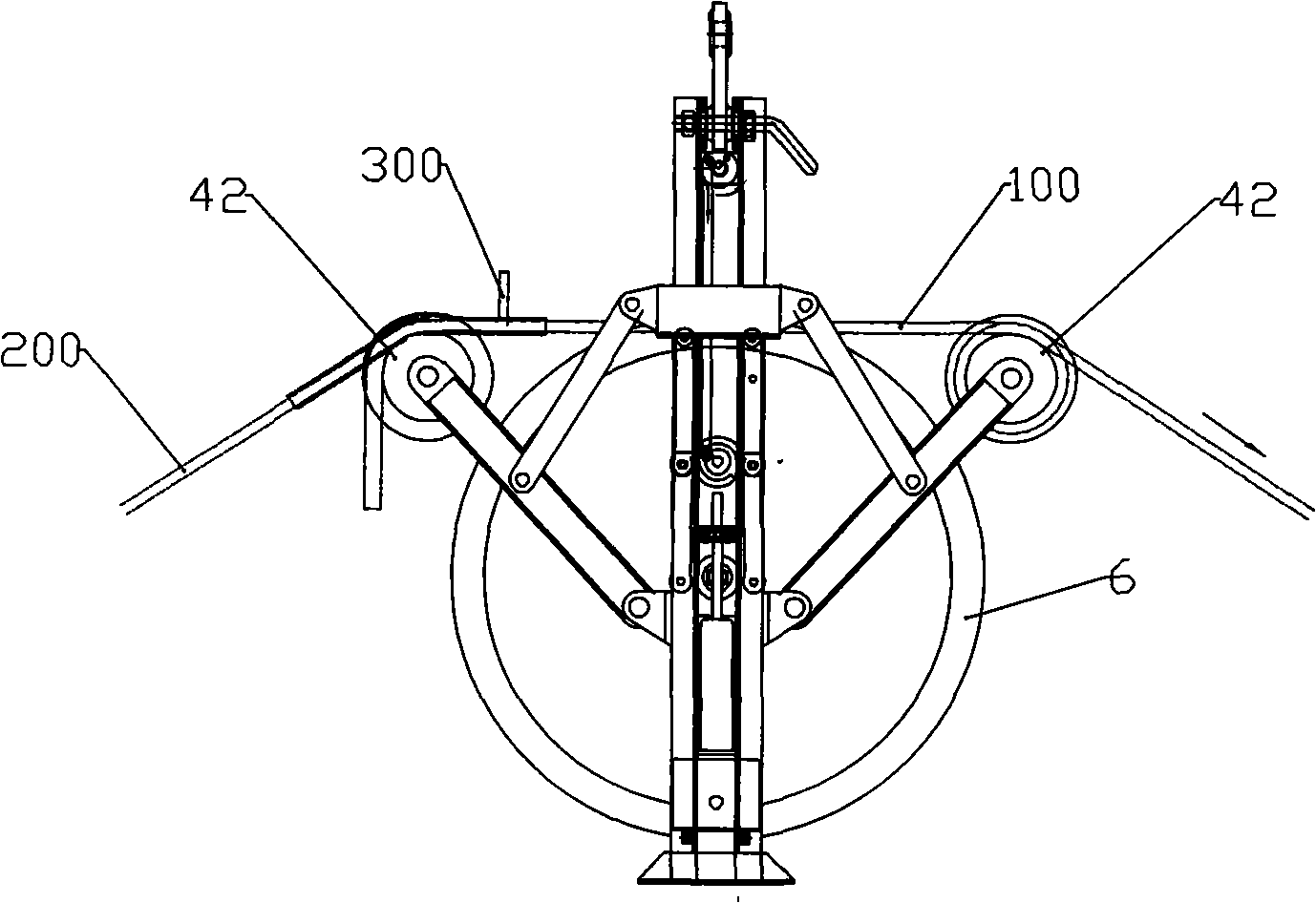

[0025] (1) Set up four "second-line tension machines" in the traction field as the main traction equipment, set up four "second-line tension machines" in the Zhang stand, and hang two sets of independent pay-off tackles on each phase of the iron tower;

[0026] (2) 8 wire traction ropes were deployed in the early stage, and each 4 traction ropes respectively passed through four auxiliary pulleys on a set of pay-off tackle. The eight-split sub-conductor is drawn and released in the way of ", and through four "second-line tension machines" and four "second-line tension integrated machines" as traction machines, each of them is interconnected through electronic synchronization control devices to realize the synchronous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com