Method and device for detecting cutting line tension of non-contact multi-line cutting machine

A multi-wire cutting machine, non-contact technology, used in tension measurement and other directions, can solve the problems of easy contamination of varistors, damage to tensiometers, poor adaptability to harsh environments, etc. The effect of value drift and strong anti-environmental interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

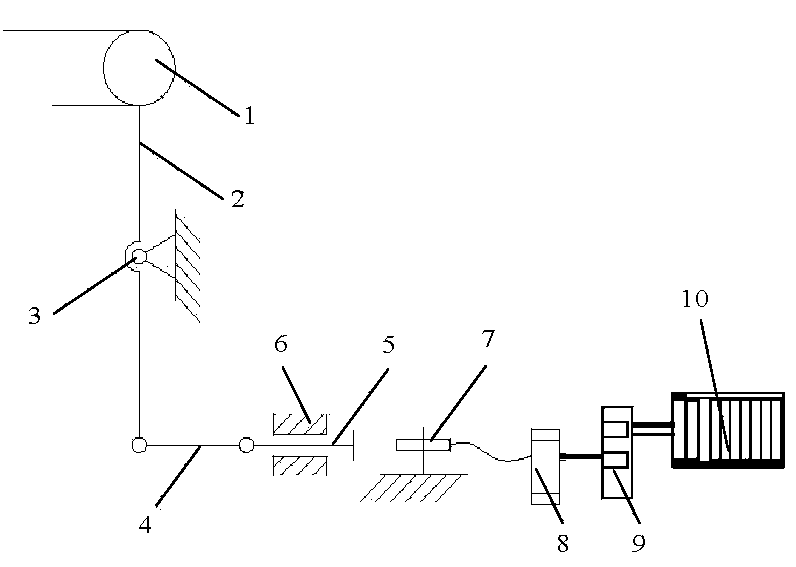

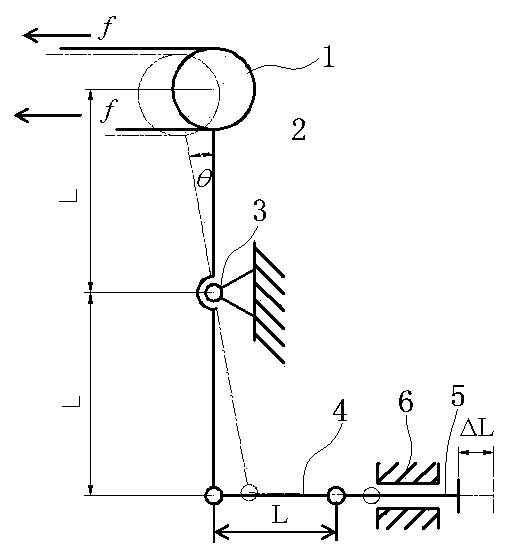

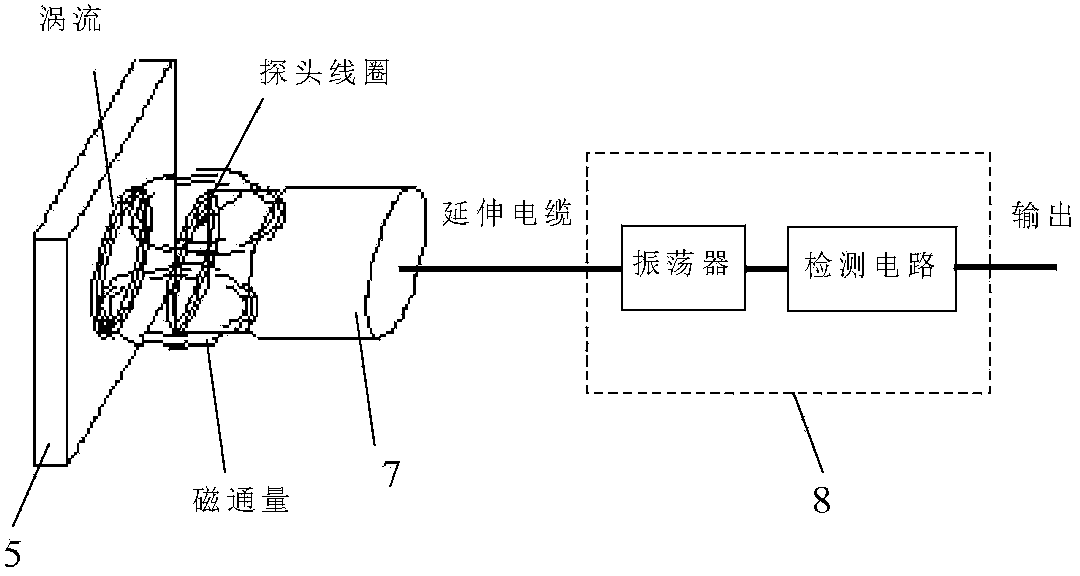

[0052] A non-contact multi-wire cutting machine cutting wire tension detection method and device adopts the "position measuring" tension detection idea, first converts the cutting wire tension into the linear displacement of the metal rod measured in the tension detection device, and then uses non-contact The eddy current displacement sensing element detects the linear displacement of the measured metal rod, and finally the data processor calculates the tension of the cutting line indirectly according to the relationship between tension and displacement.

[0053] A non-contact multi-wire cutting machine cutting wire tension detection device of the present invention includes: a wire wheel 1, a tension arm 2, a torsion spring 3, a movable connecting rod 4, a metal rod to be tested 5, a guide sleeve 6, and a non-contact probe 7 , a high-frequency oscillator 8 , an analog-to-digital converter 9 , and a data processor 10 . Described tension arm 2, its one end installs wire wheel 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com