Multifunctional integrated device for coiled material processing

A multi-functional, coiled material technology, applied in the direction of strip winding, transportation and packaging, thin material handling, etc., to achieve a high degree of integration and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

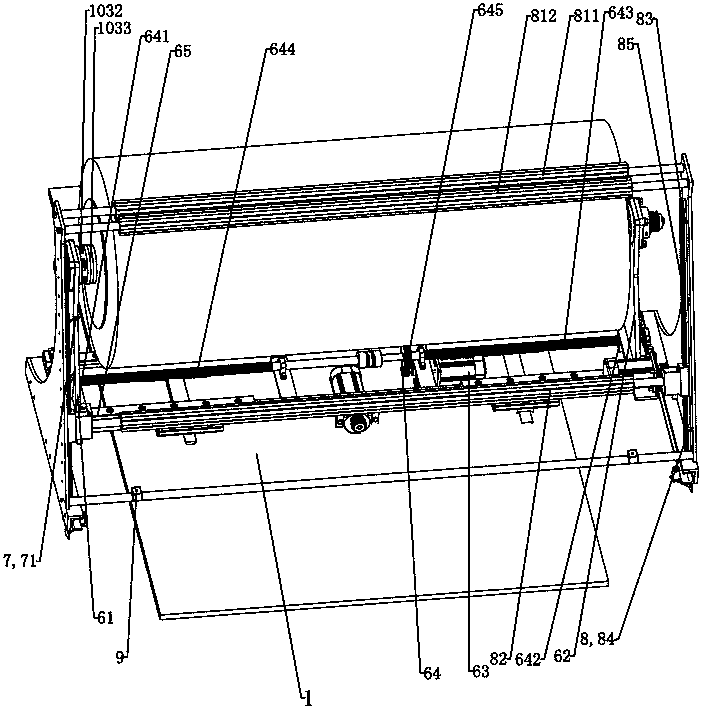

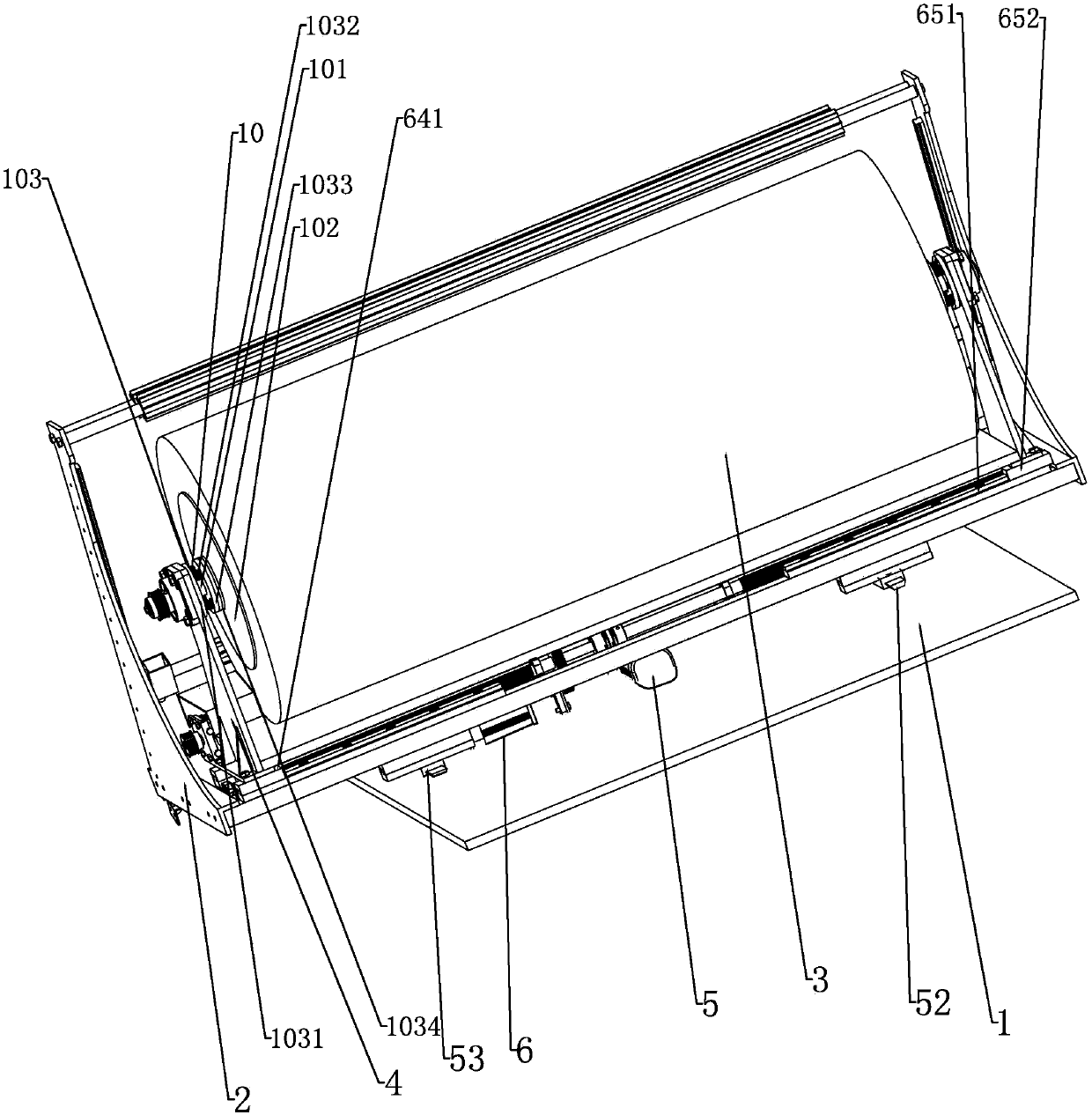

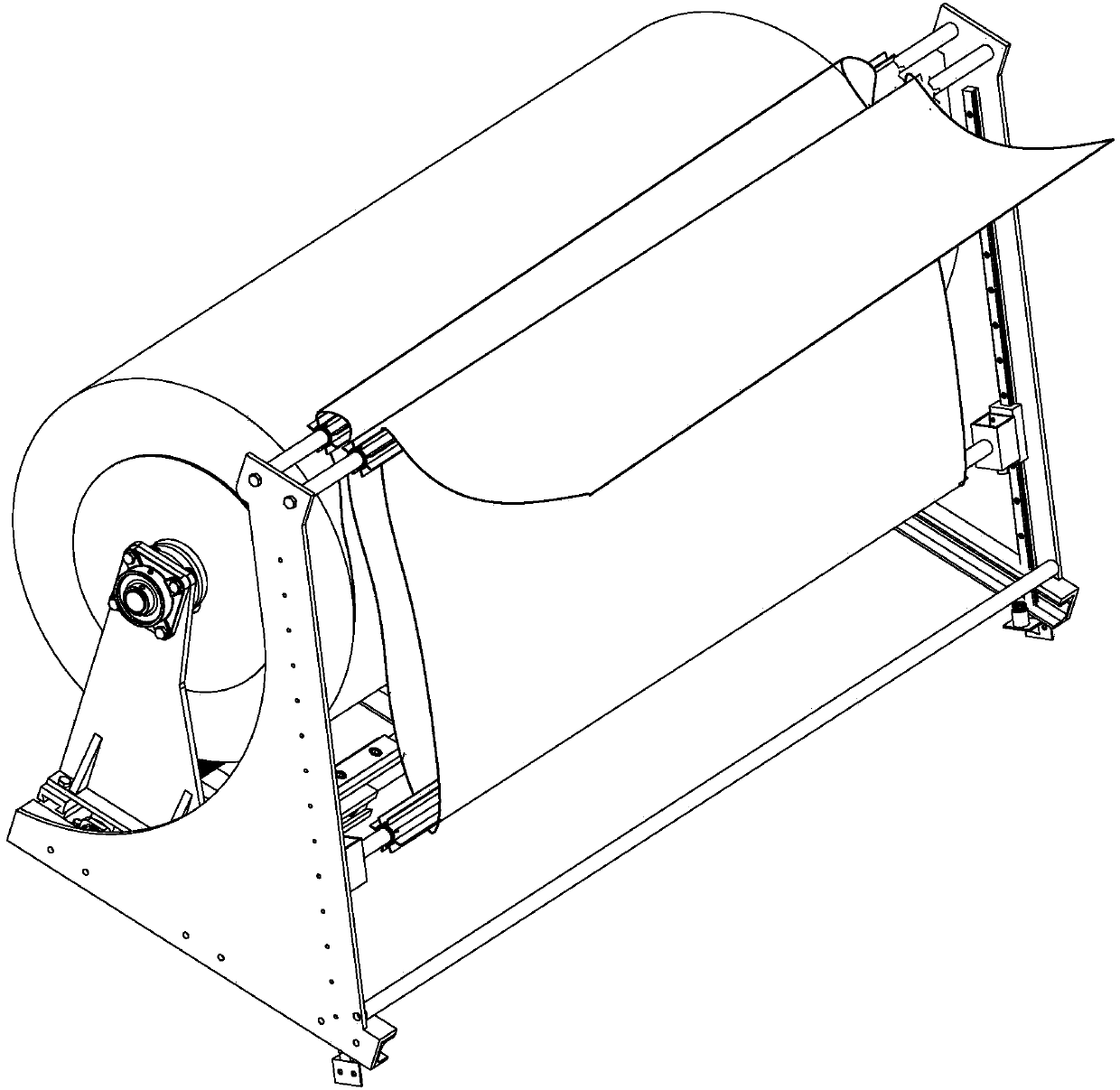

[0022] As shown in the figure, a multi-functional integrated device for coil processing includes a base frame 1, on which a material rack 2 is provided, and a support frame 4 for supporting the rolled material 3 is provided on the material rack 2 , the roll material 3 is installed on the supporting frame 4 . On the bottom of the material rack 2, there is an in-out device 5 for convenient material replacement and unloading; on the material rack 2, there is an automatic clamping and centering device 6 that realizes the centering function after the roll material 3 is loaded; on the base frame 1 A material amount sensing device 7 and a material storage sensing device 8 are provided. In addition, it also includes an alignment device 9 that realizes the automatic edge correction function when the roll material 3 is pulled. A pressure sensing device 10 for clamping t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com