Patents

Literature

30results about How to "Precise clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

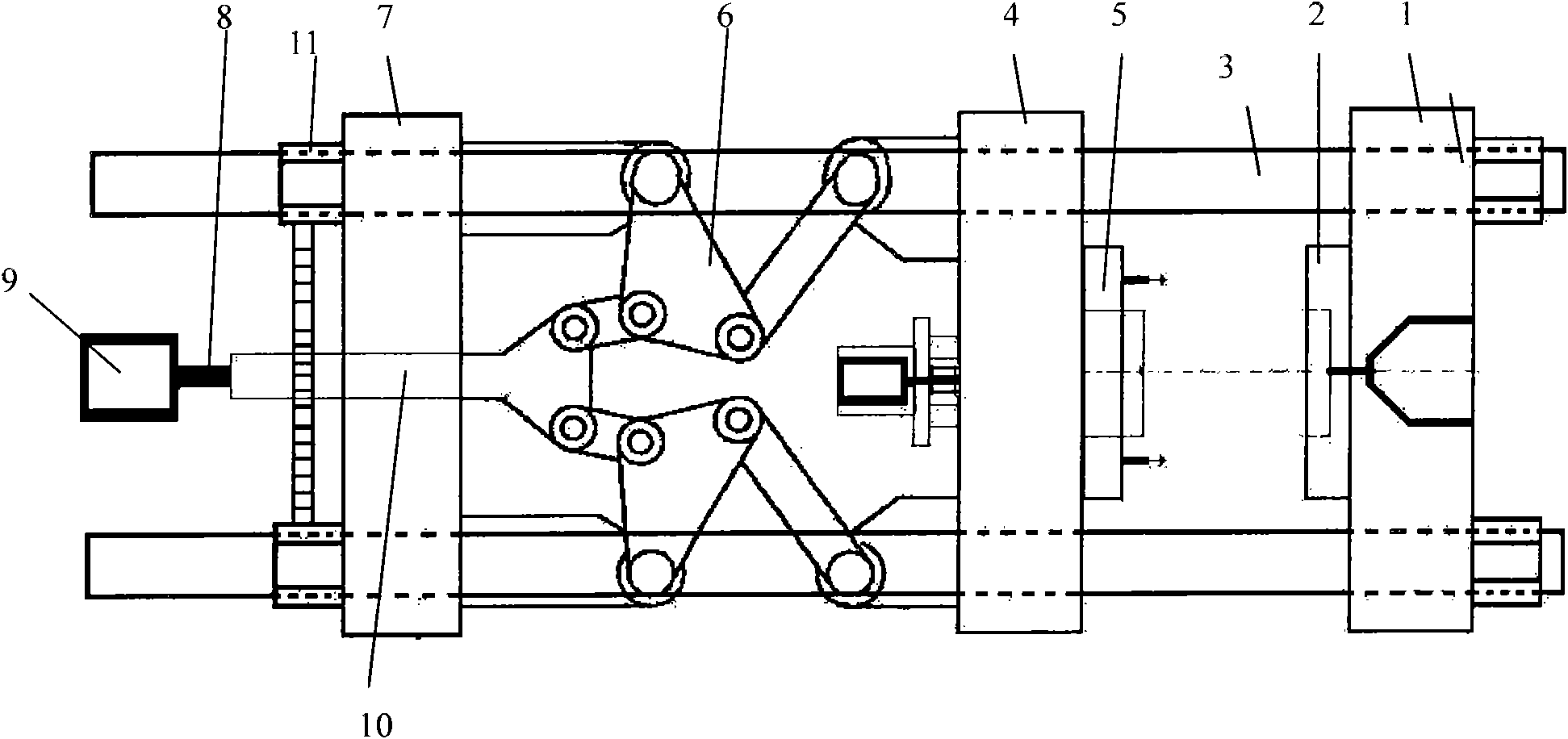

System and method for automatically regulating clamping force of motor-driven injection molding machine

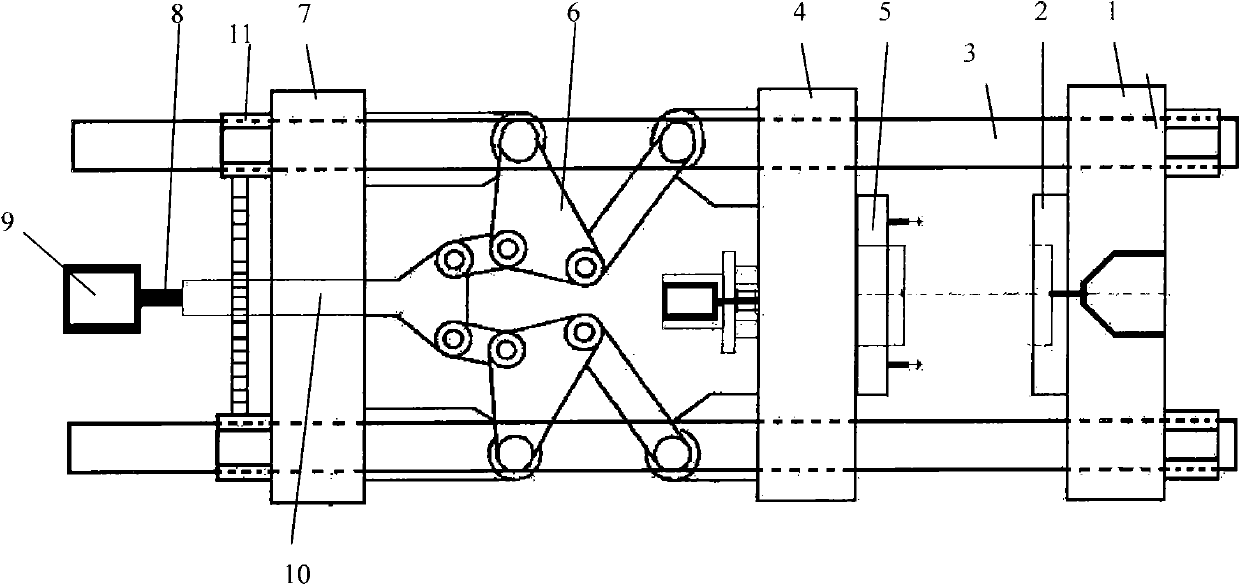

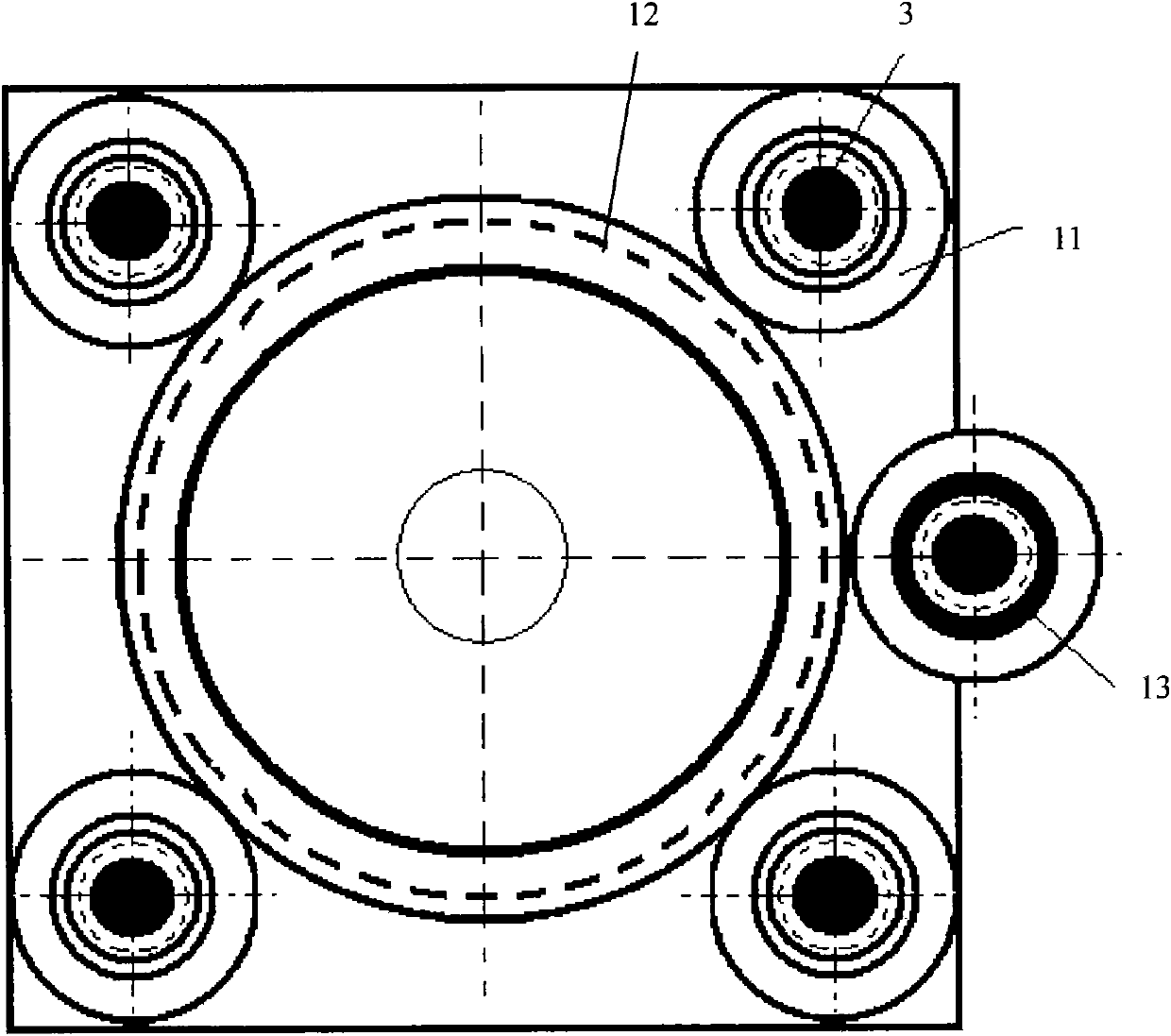

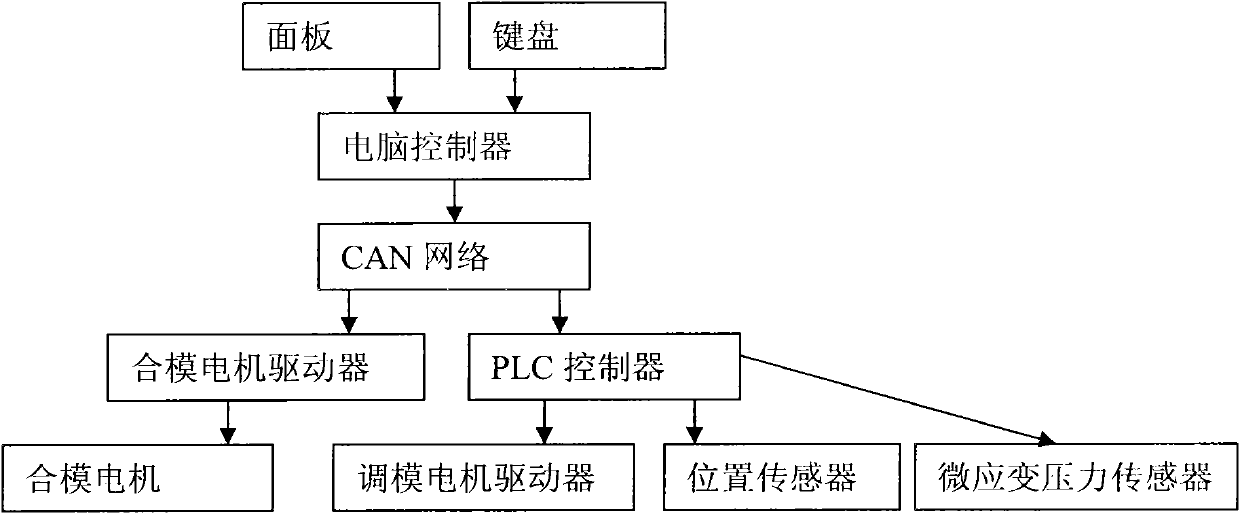

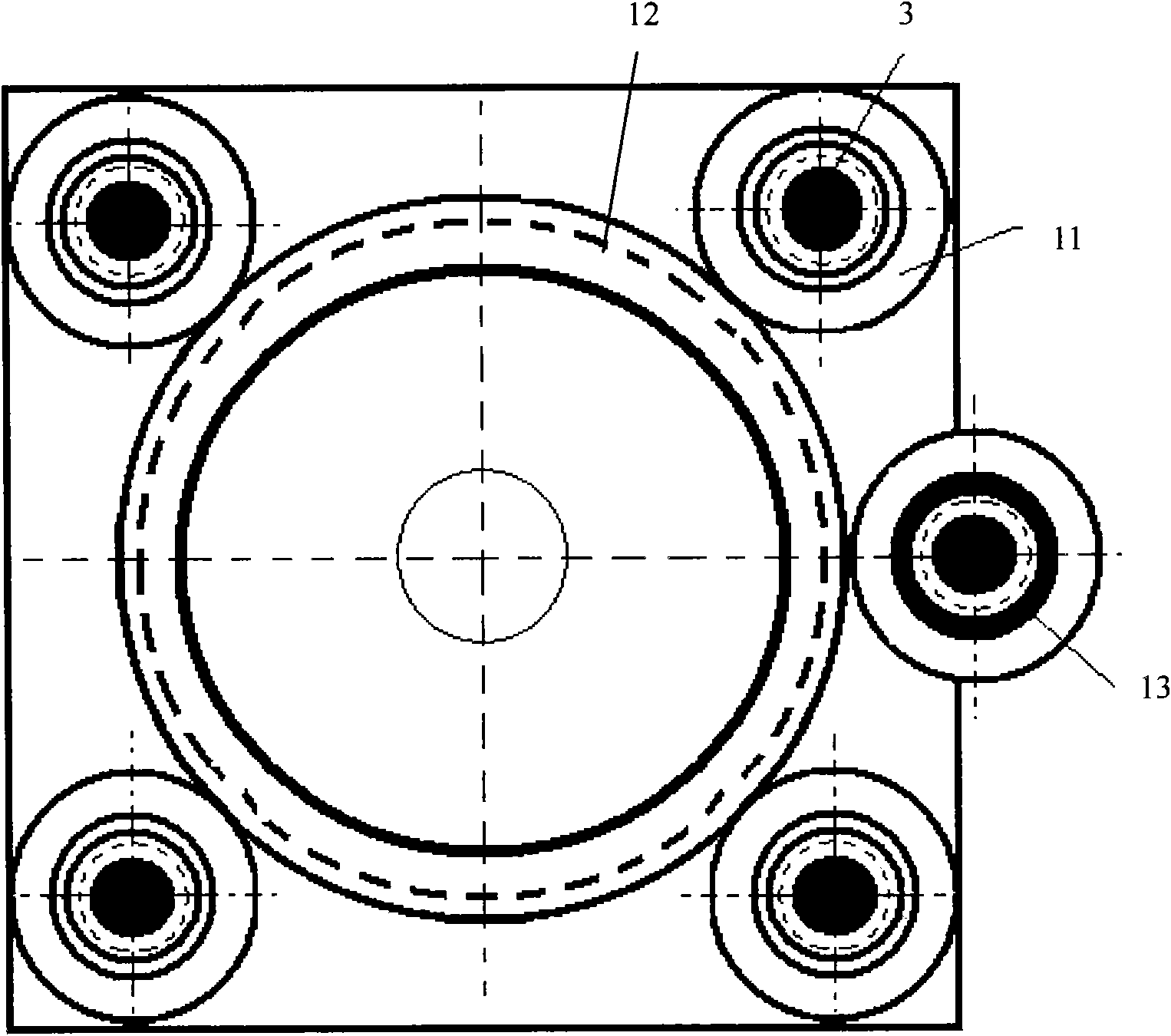

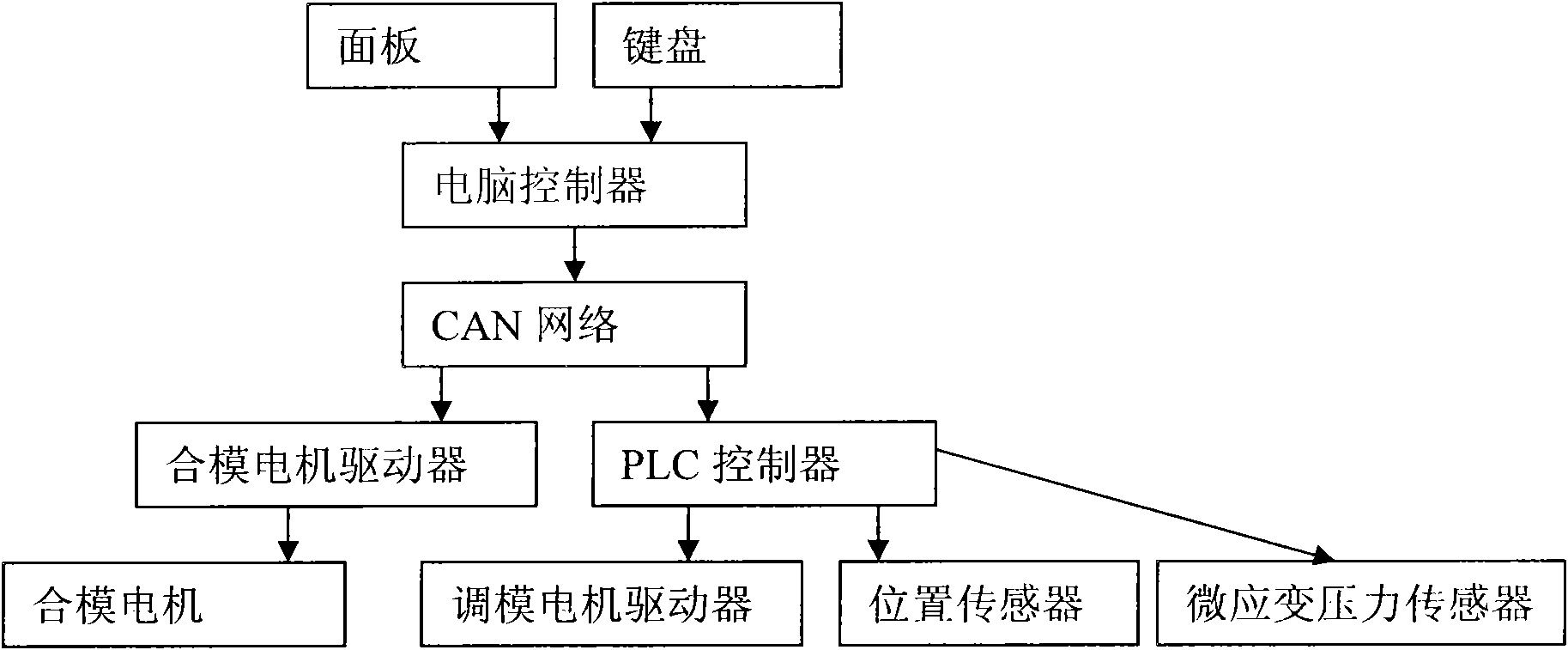

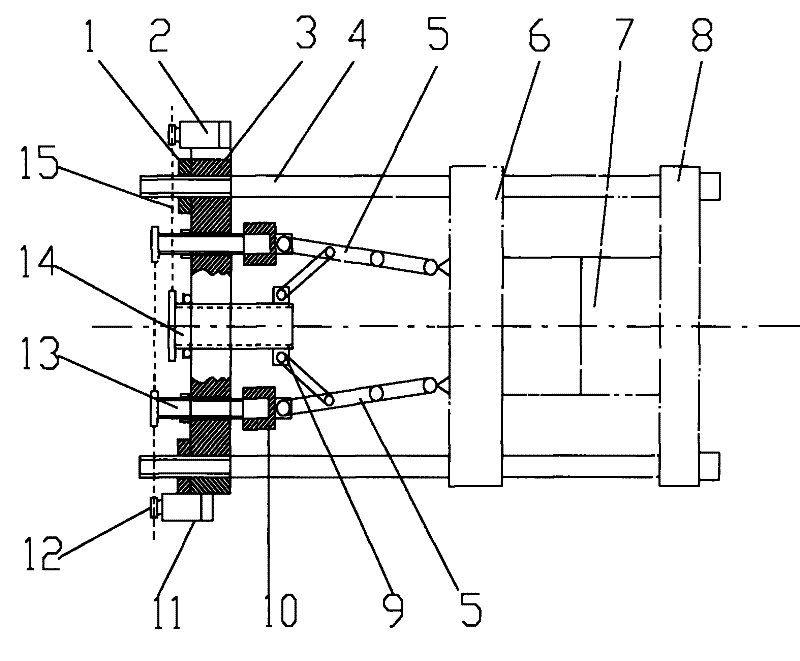

The invention discloses a system for automatically regulating the clamping force of a motor-driven injection molding machine. The system is characterized in that four draw bars penetrate through a static template, a movable template and a rear template, and the static template is fixed on the draw bar; a five-point toggle mechanism is connected between the movable template and the rear template, and the crosshead thereof penetrates through the rear template and is sleeved outside a ball screw; the ball screw is driven by a spotting motor; the rear template is connected with the four draw bars through four regulating nuts; a bearing is arranged between each regulating nut and the rear template; the peripheries of the regulating nuts are provided with gear teeth; a rack wheel is arranged at the neutral position of the four regulating nuts and is meshed with the gear teeth of the four regulating nuts; the crosshead of the five-point toggle mechanism and the ball screw pass through the center of the rack wheel; the output gear of a mold-adjustment motor is meshed with the rack wheel; and the mold-adjustment motor is connected with an injection molding machine control system. The invention also aims at providing a method for automatically regulating the clamping force of a motor-driven injection molding machine. The invention has the advantages that the mold-adjustment accuracy is high.

Owner:SOUTH CHINA UNIV OF TECH

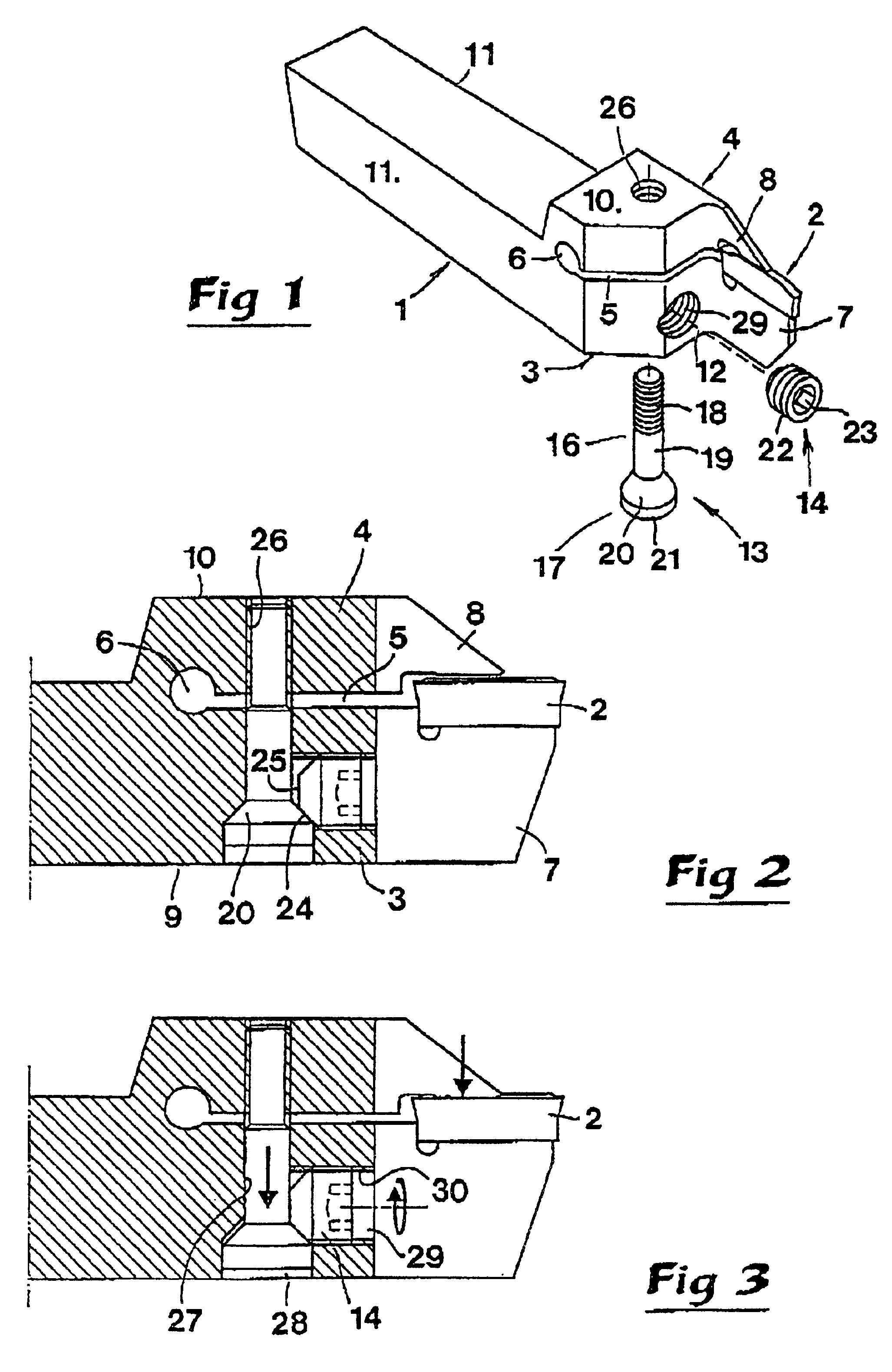

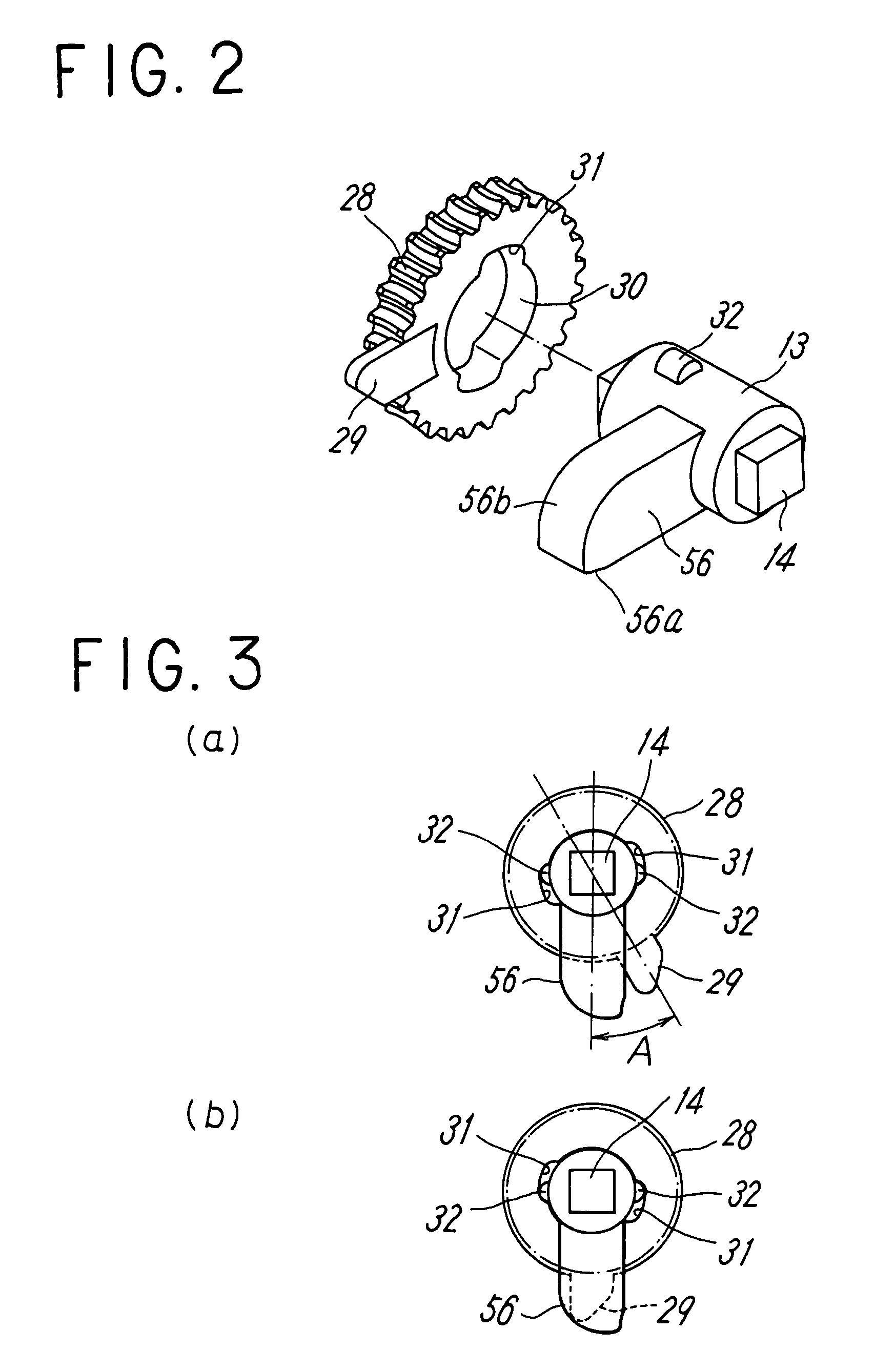

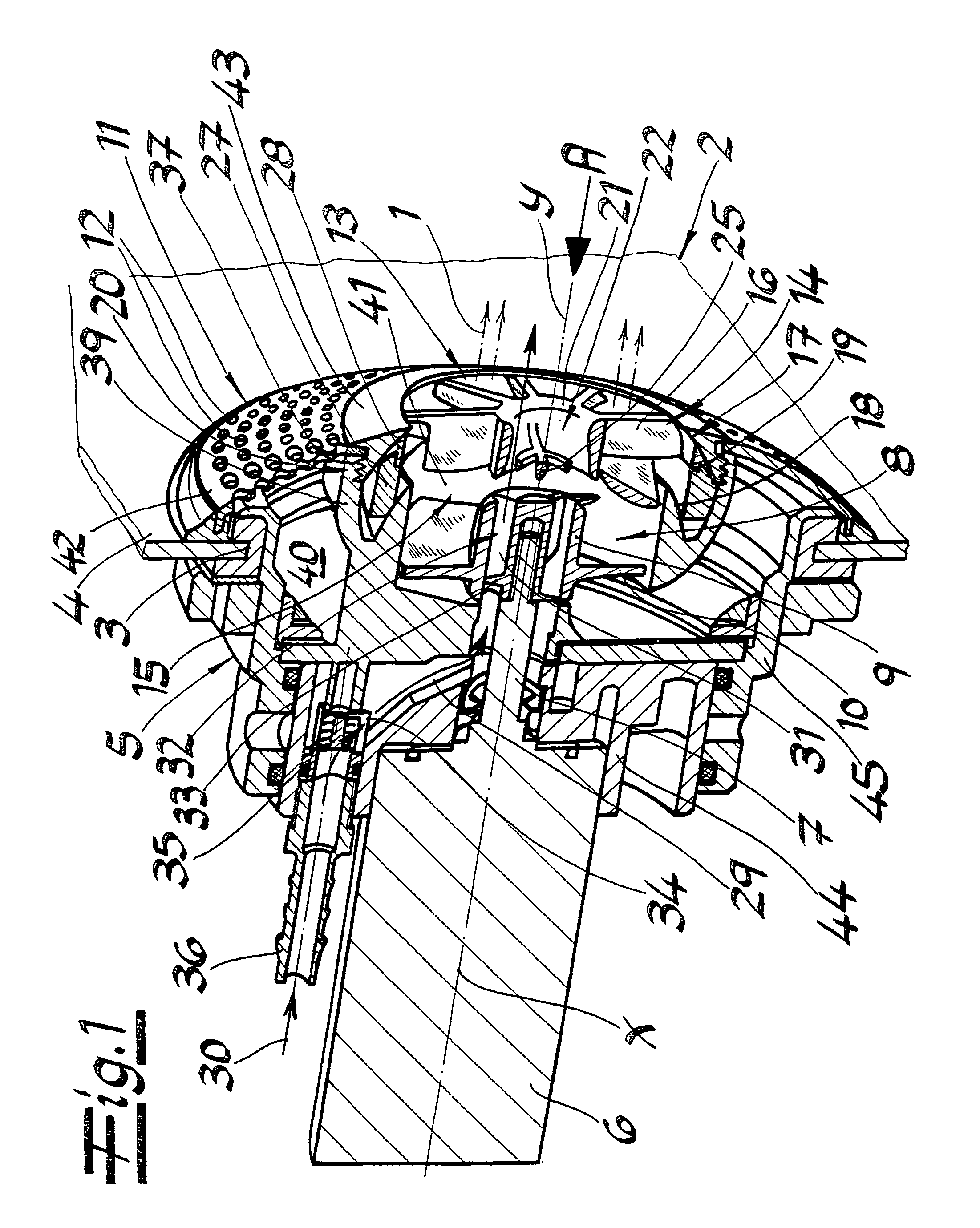

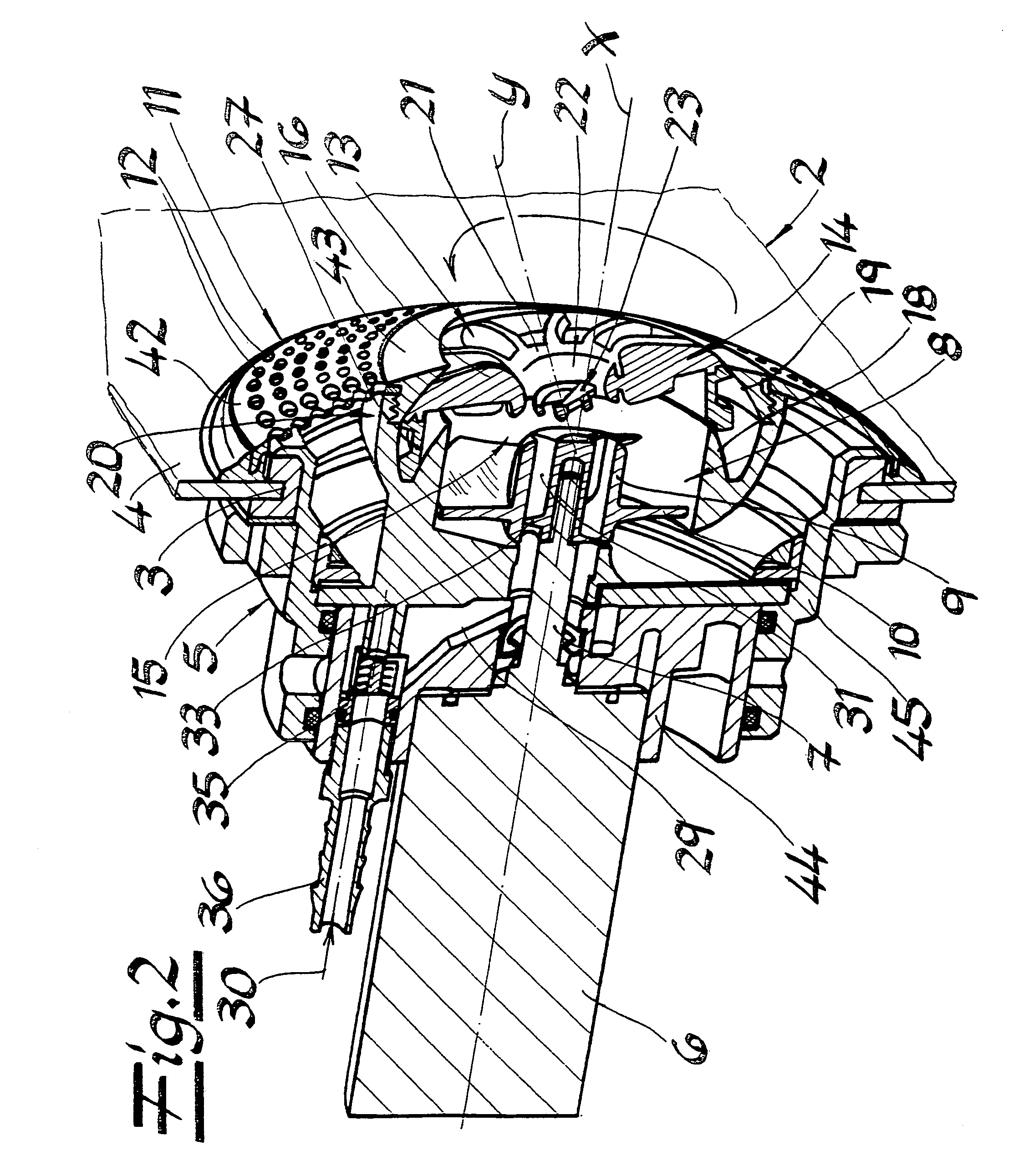

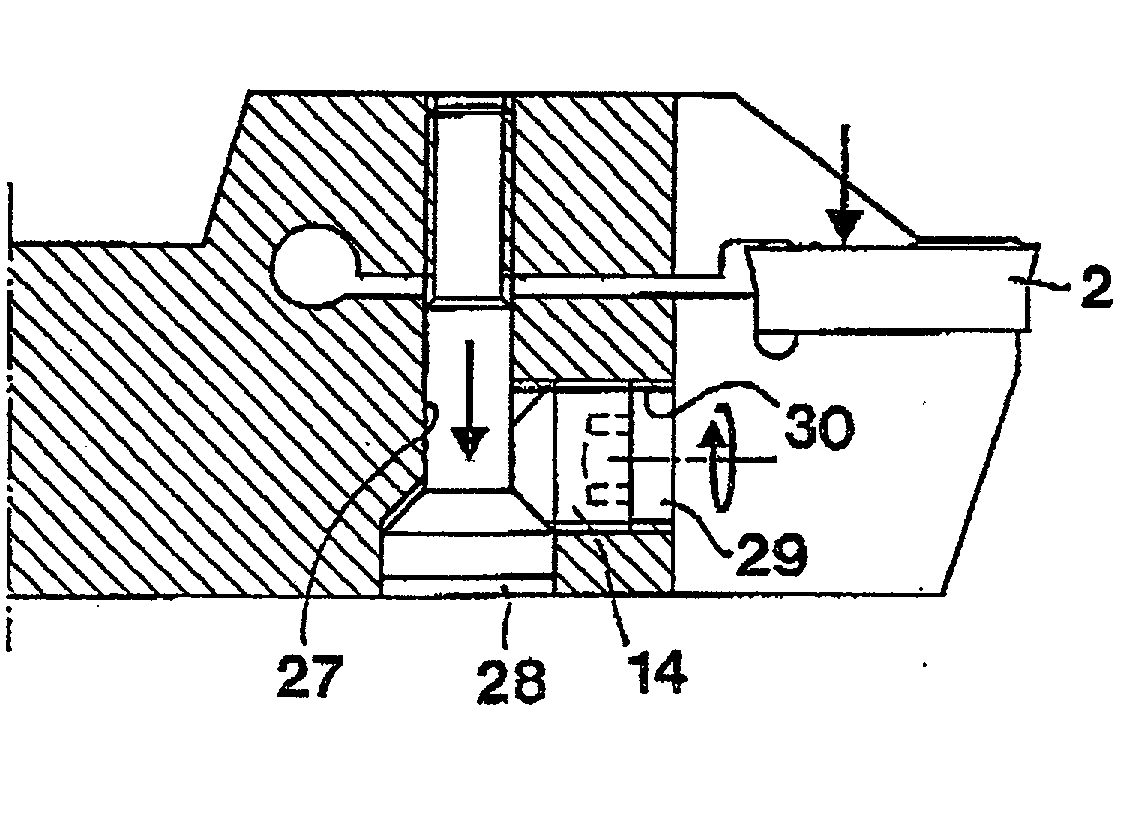

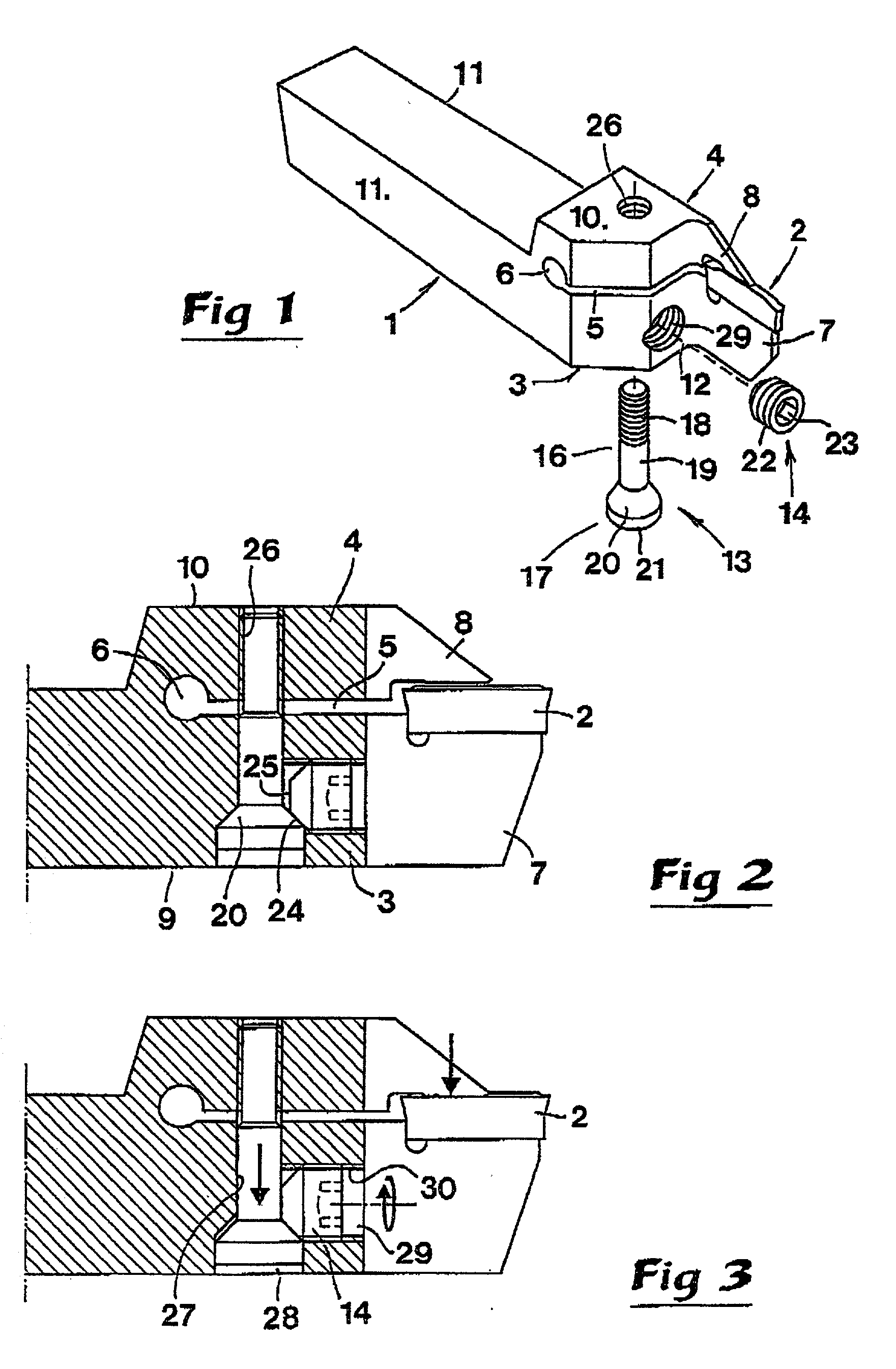

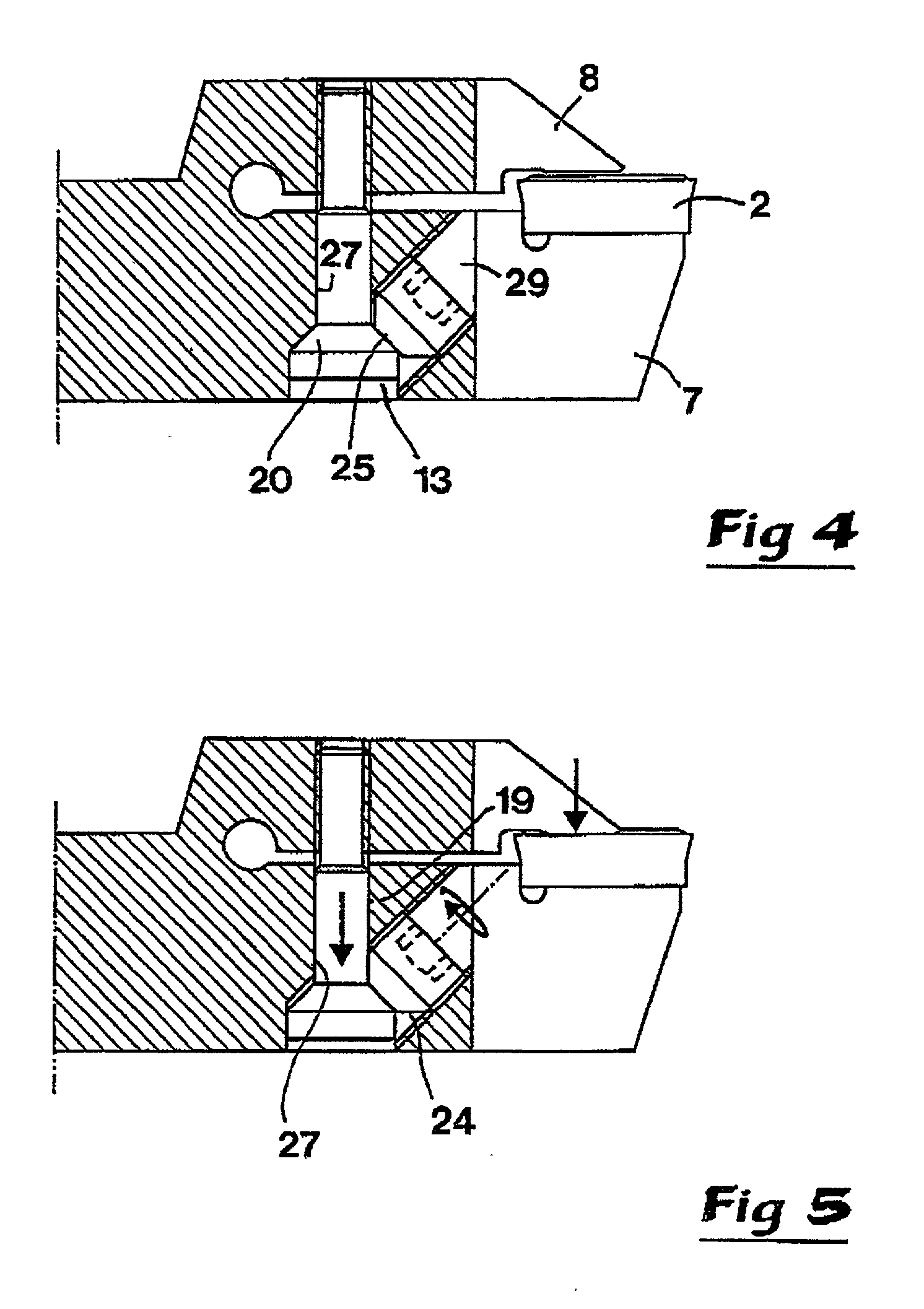

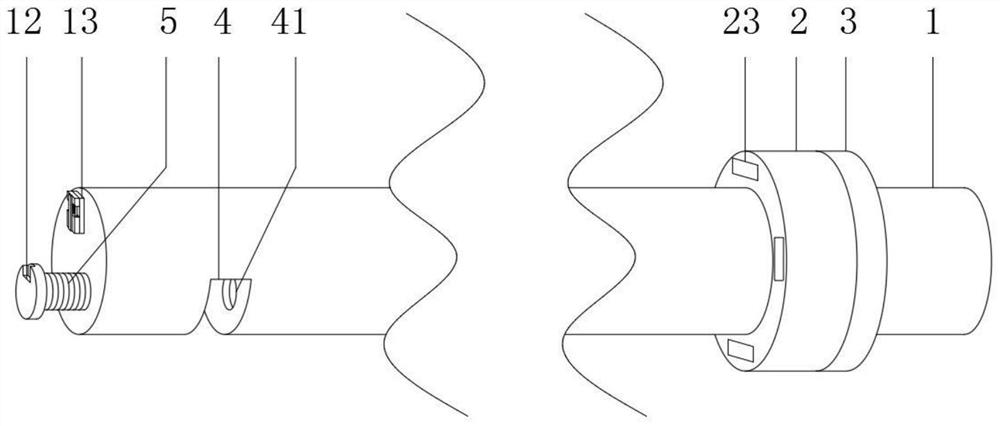

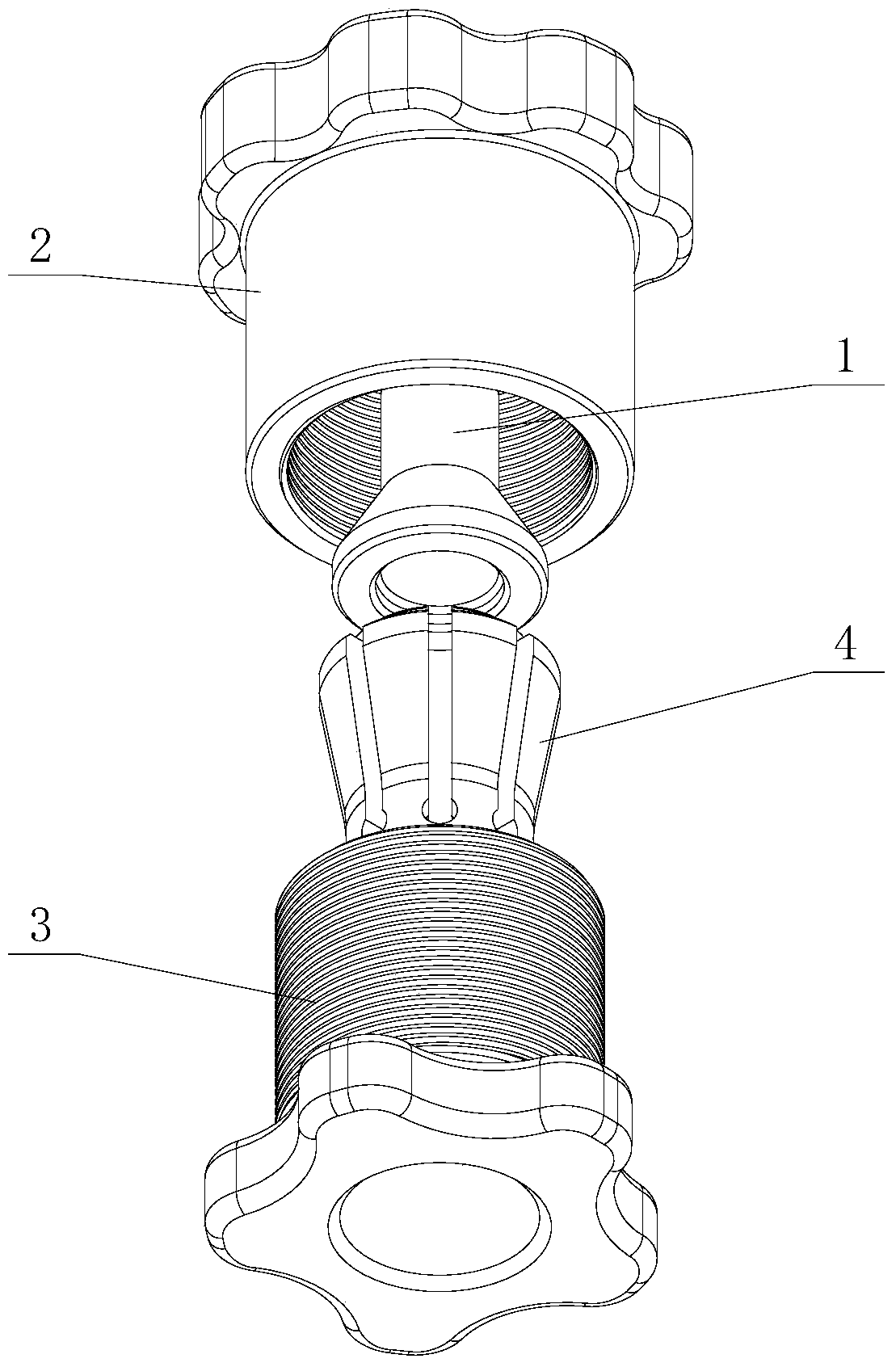

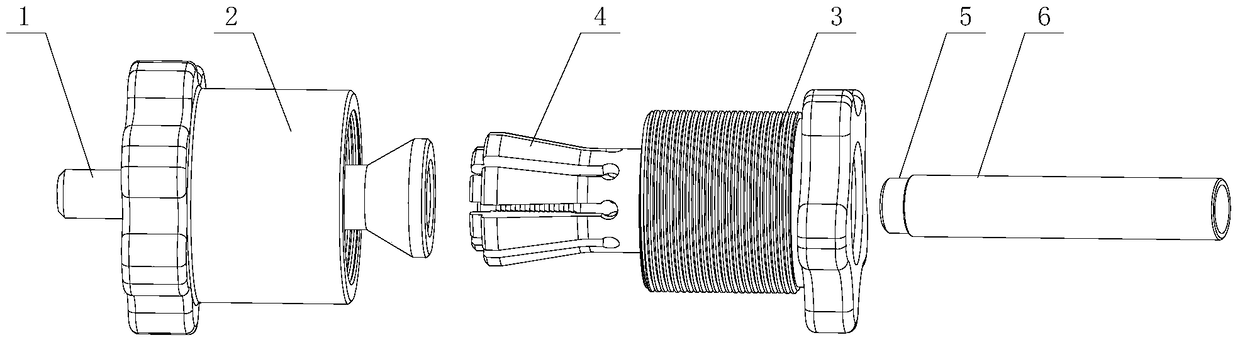

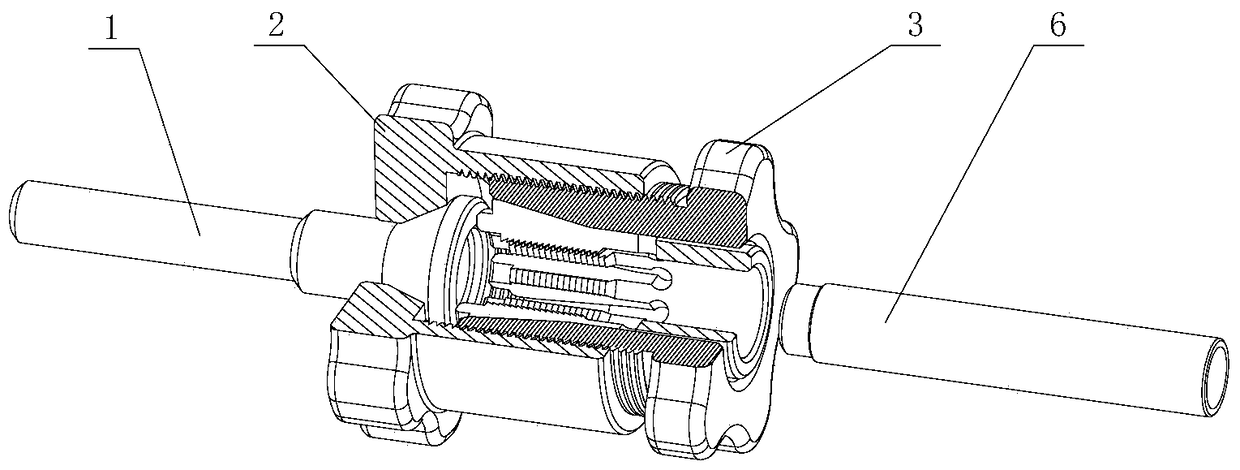

Insert holder for parting and grooving operations

InactiveUS6814526B2Conveniently accessibleEliminate disadvantagesCutting insertsTurning toolsAbutmentScrew thread

A holder is designed to receive a cutting insert intended for parting and grooving operations. The insert is clampable in a seat formed between a blade tongue and a clamping finger which respectively extend from lower and upper front parts of the holder. A gap separates those front parts in order to enable those parts to be forced towards each other by means of a clamping mechanism mounted in the holder. The clamping mechanism comprises a drawbar, a first end portion of which is movable within a bore formed in one of the front parts, and a second end portion of which is fixed in the other front part. The first end portion of the drawbar includes a head having a frusto-conical abutment surface. A tightening screw is threadedly mounted in the same front part as the head and is arranged to contact the abutment surface to displace the drawbar in a direction forcing the clamping finger and the tongue together to clamp the cutting insert in place.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

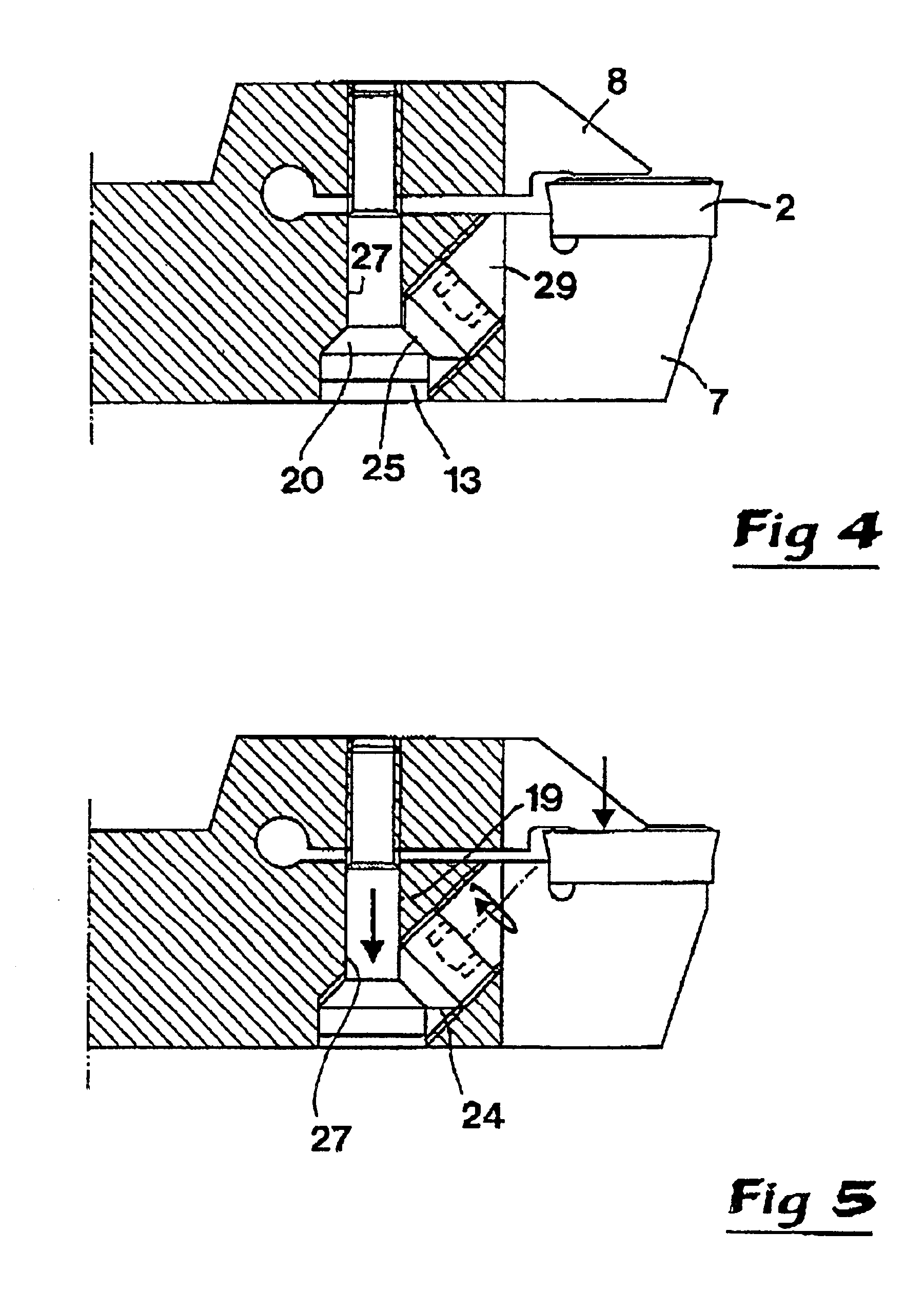

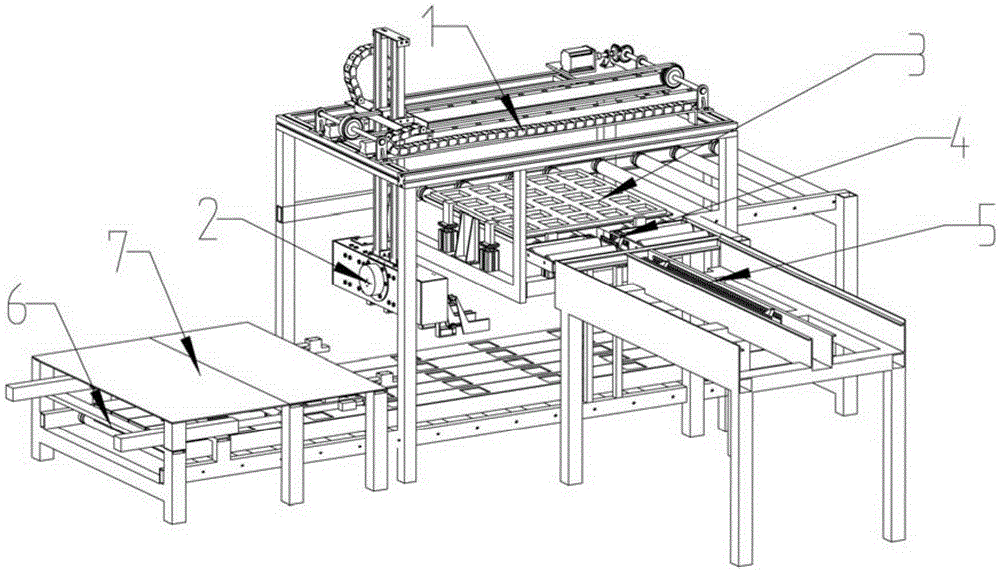

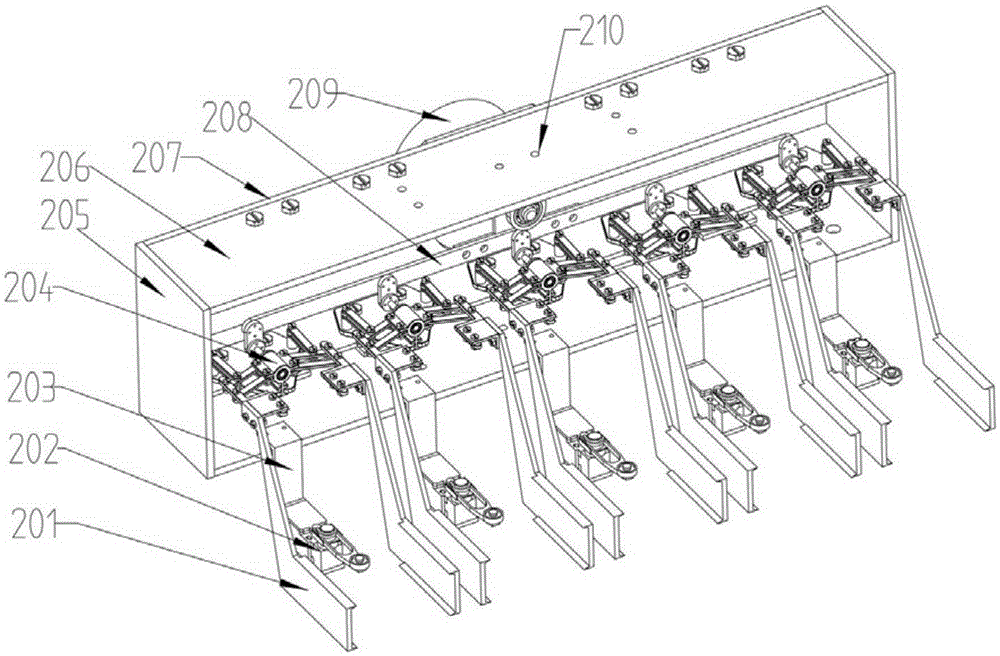

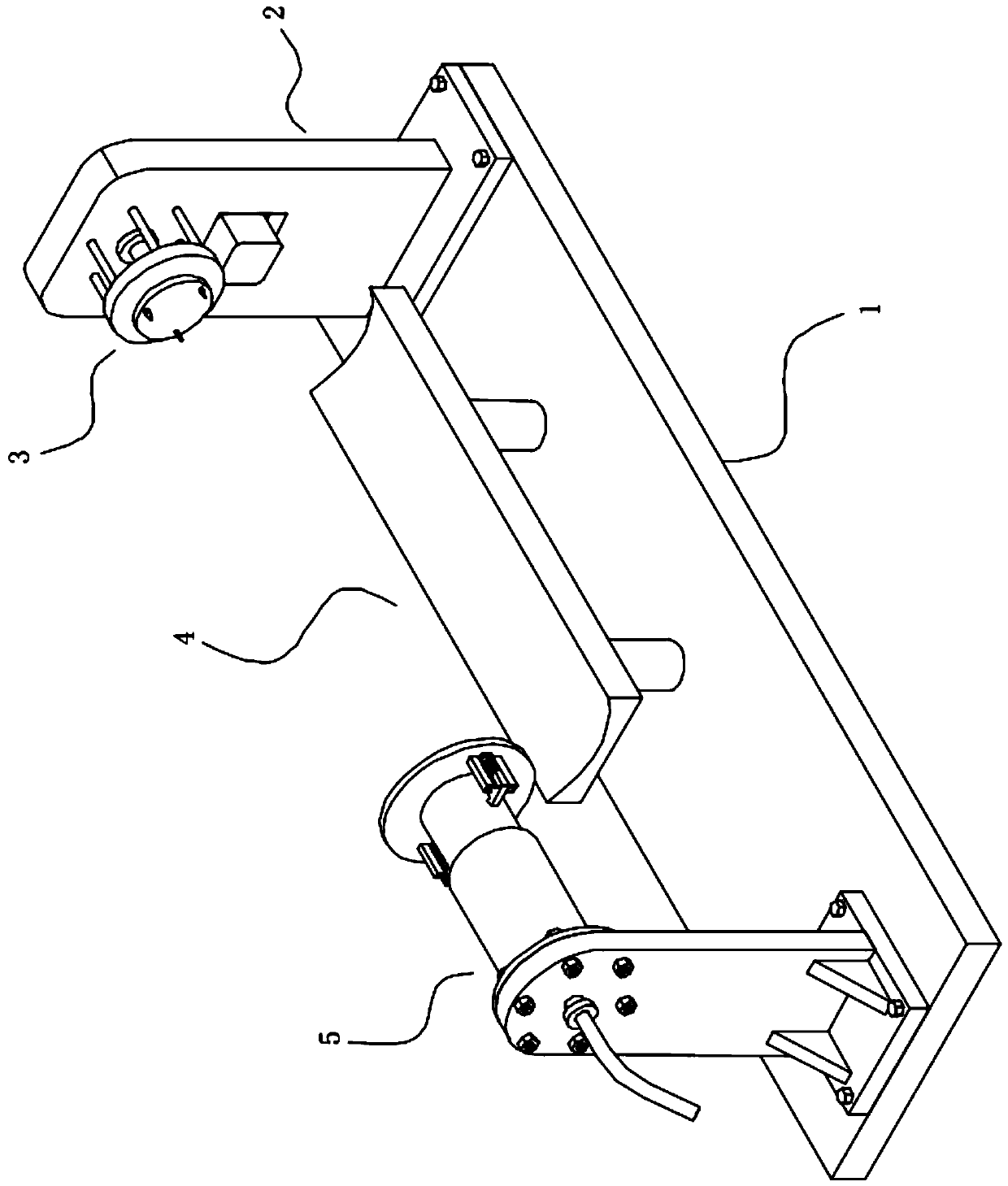

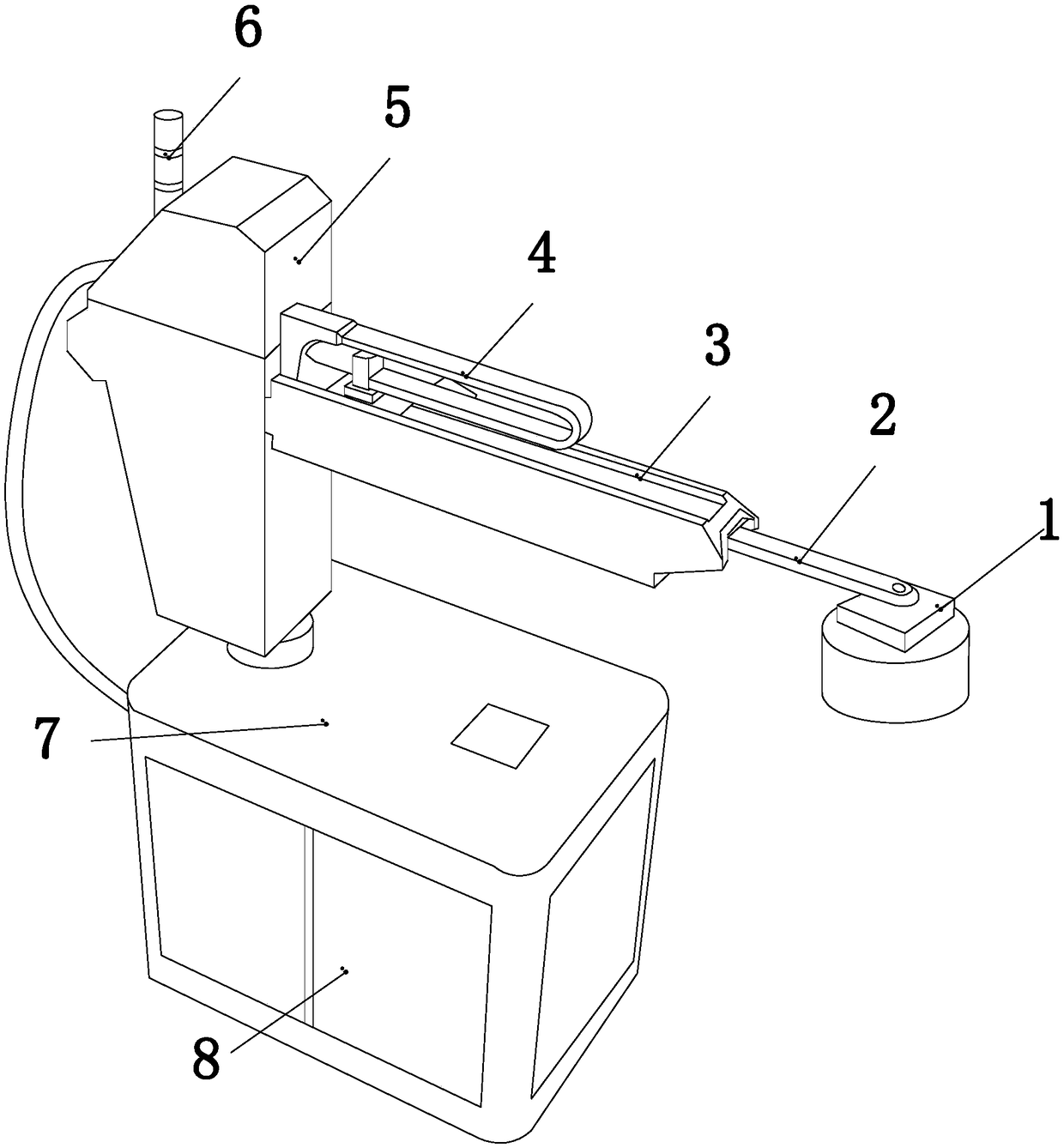

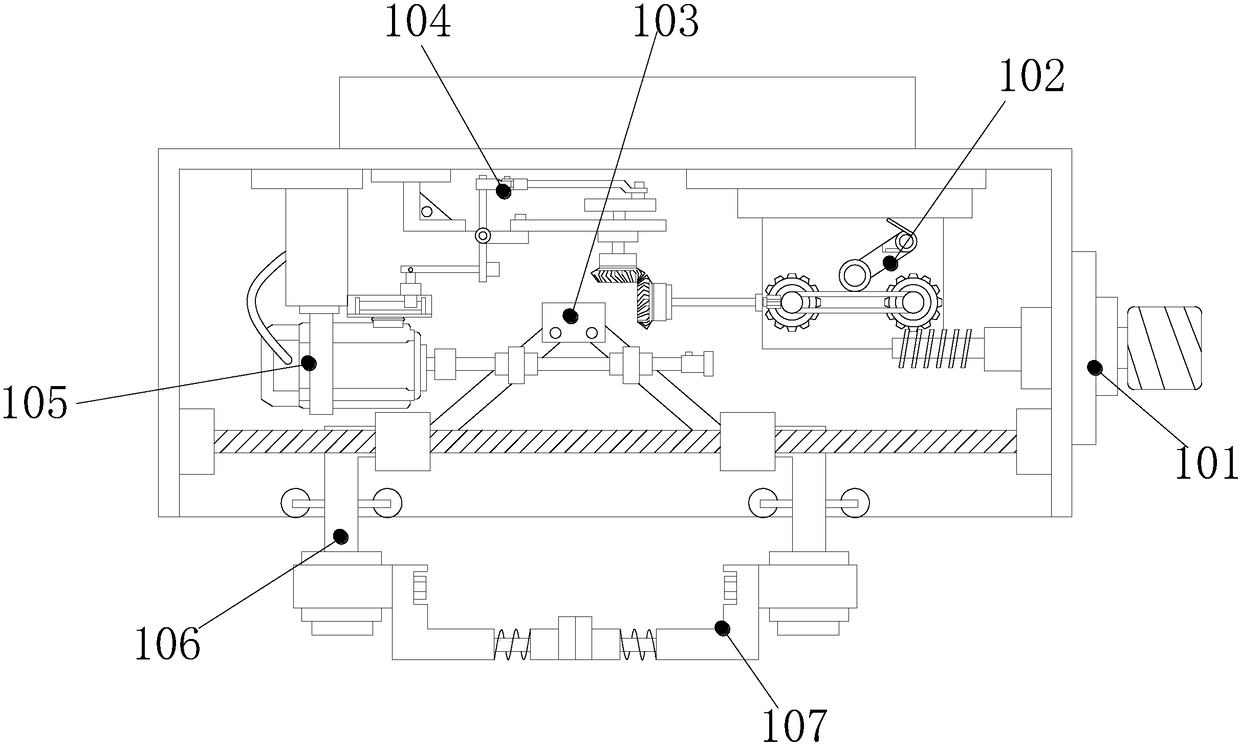

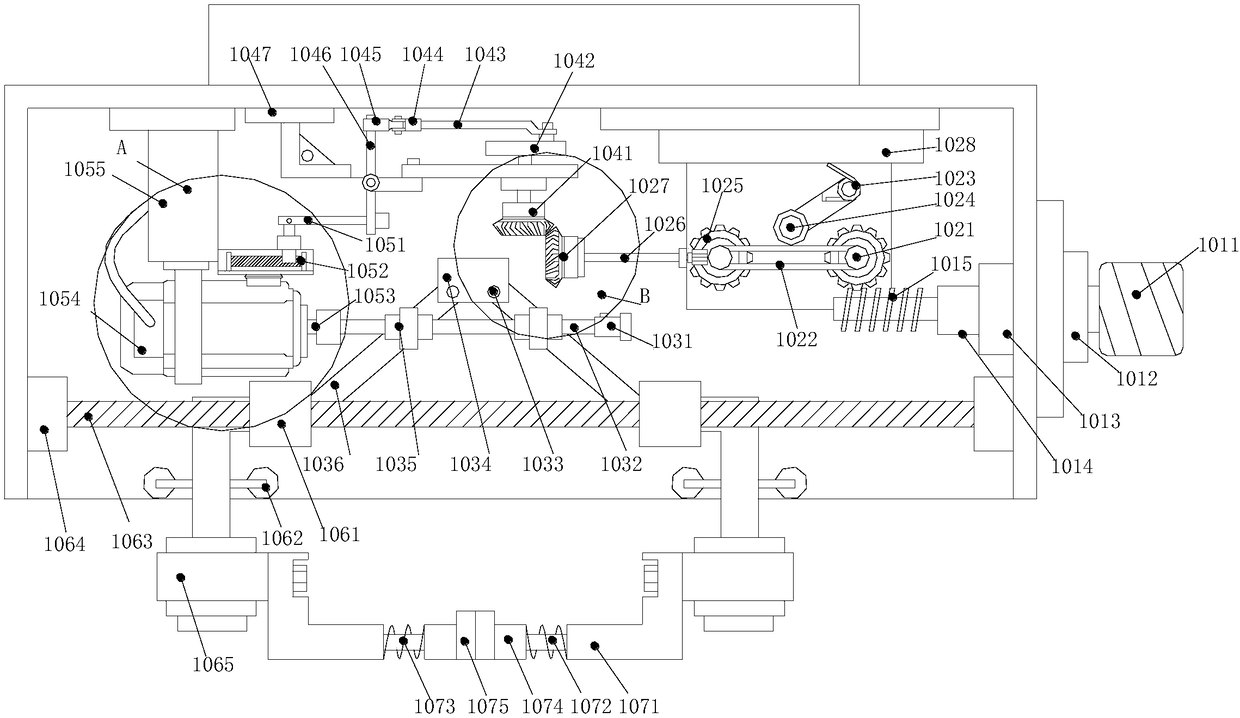

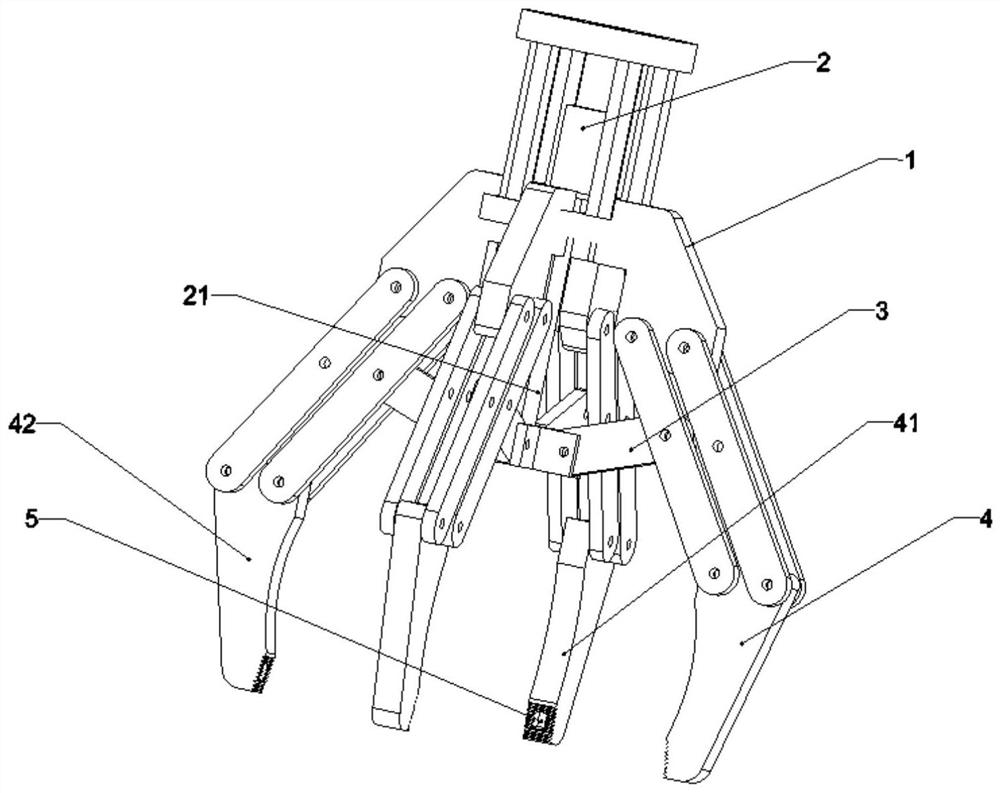

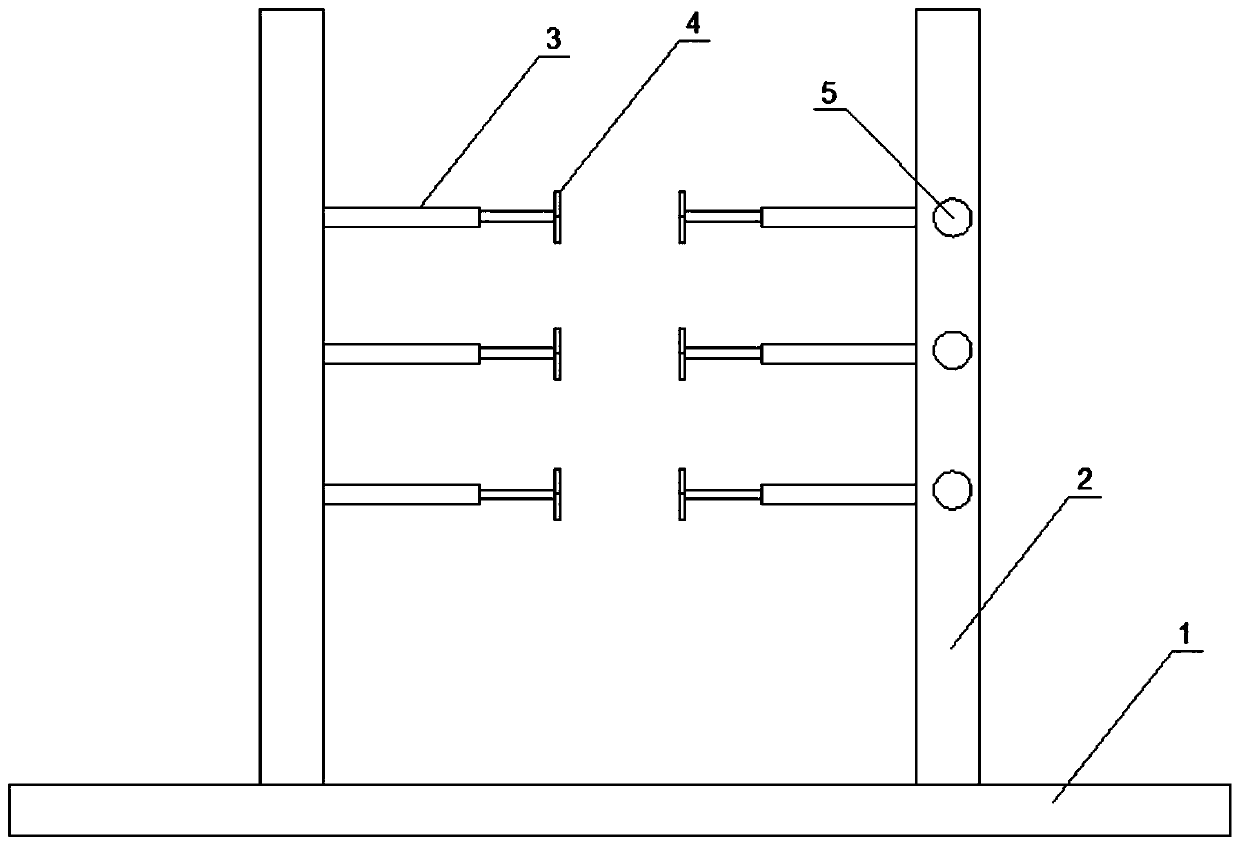

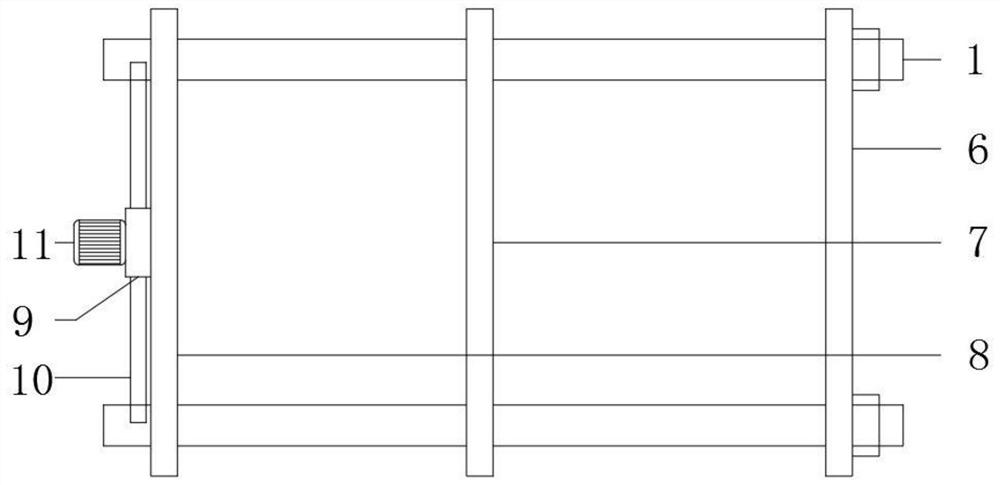

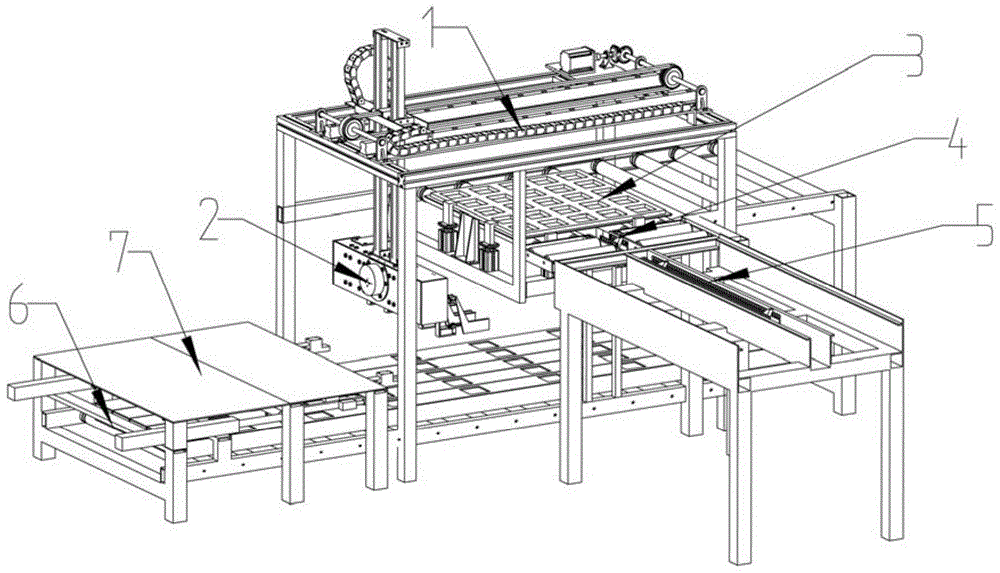

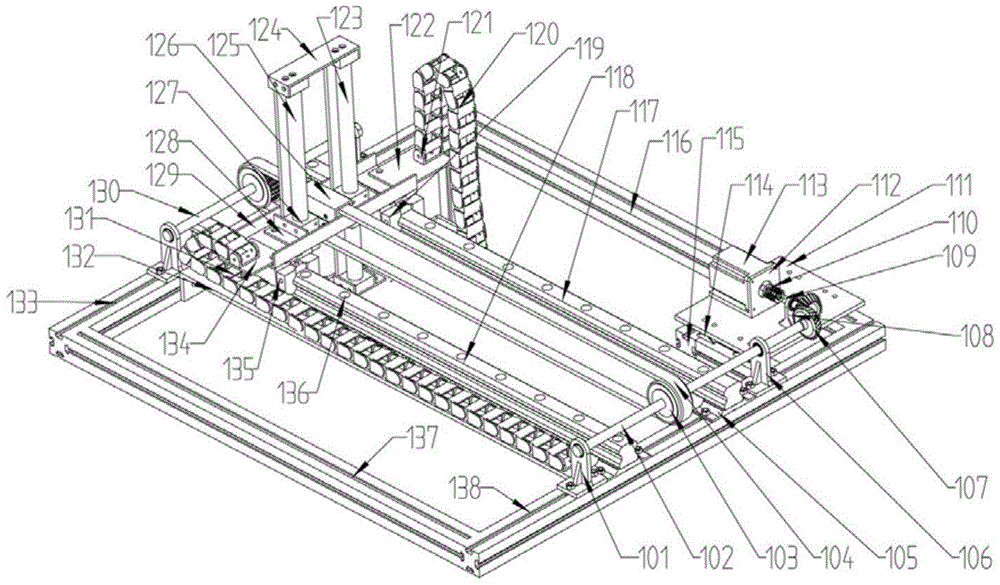

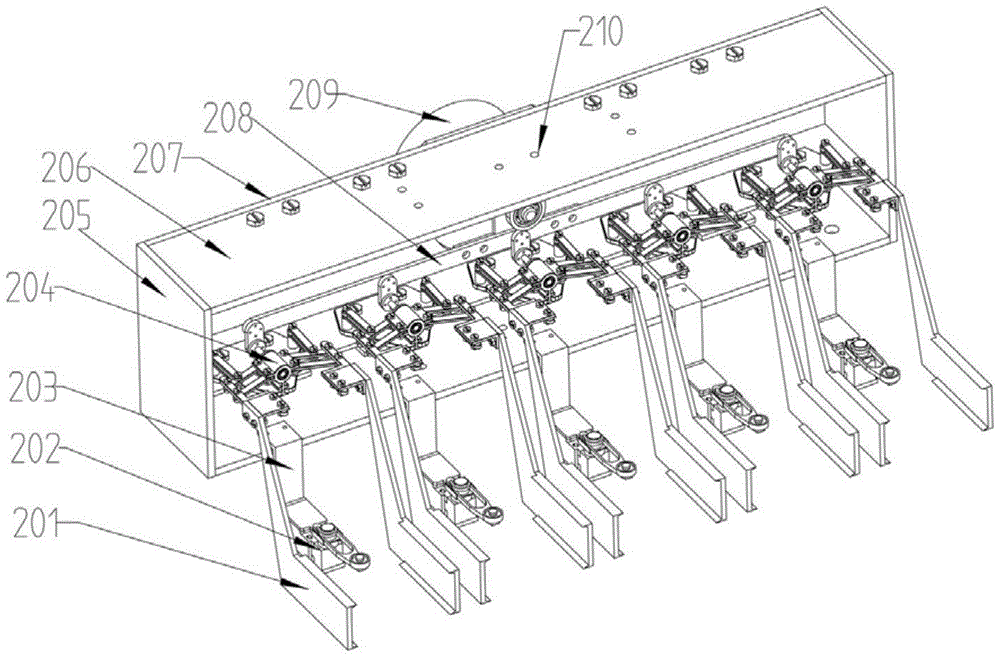

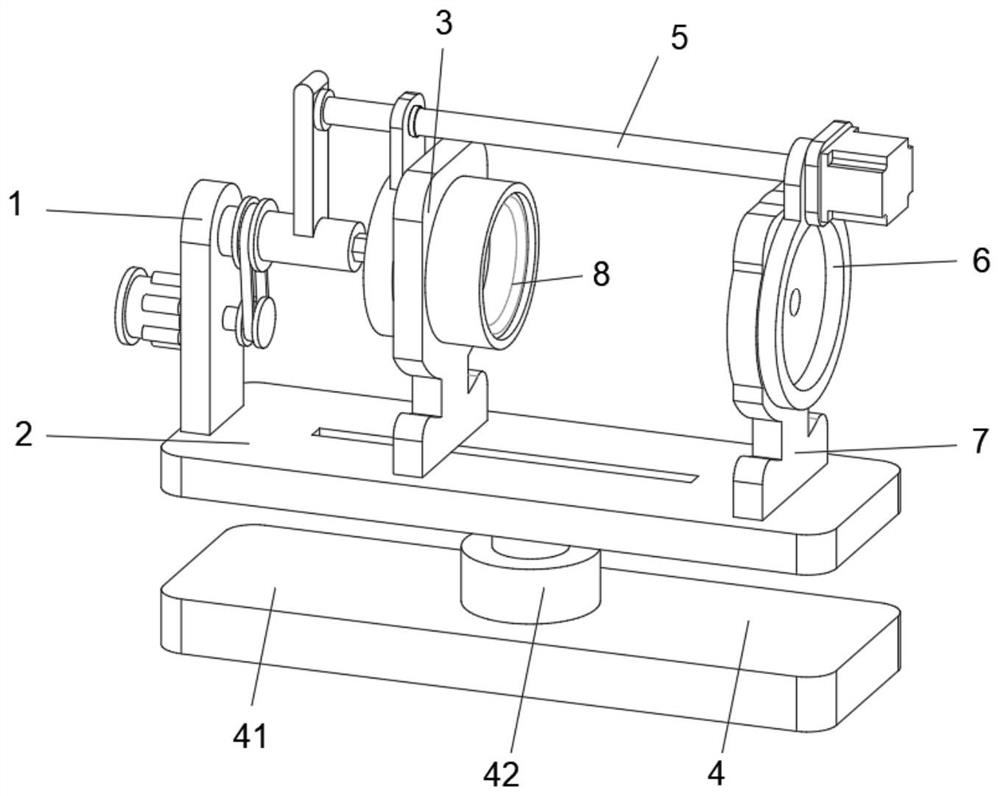

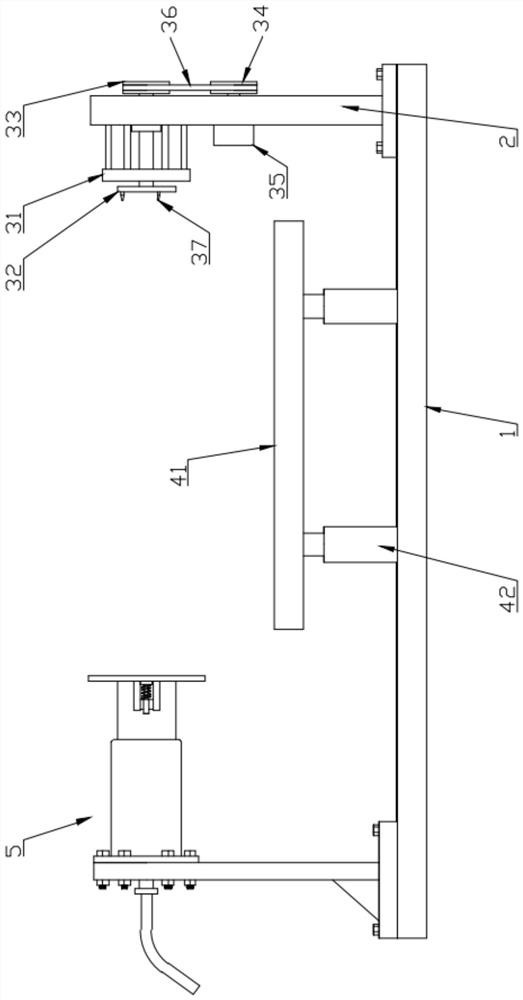

Transplanter for greenhouse vegetable seedlings

ActiveCN105409407ASuitable for transplantingIncrease productivityTransplantingAgricultural scienceAgricultural engineering

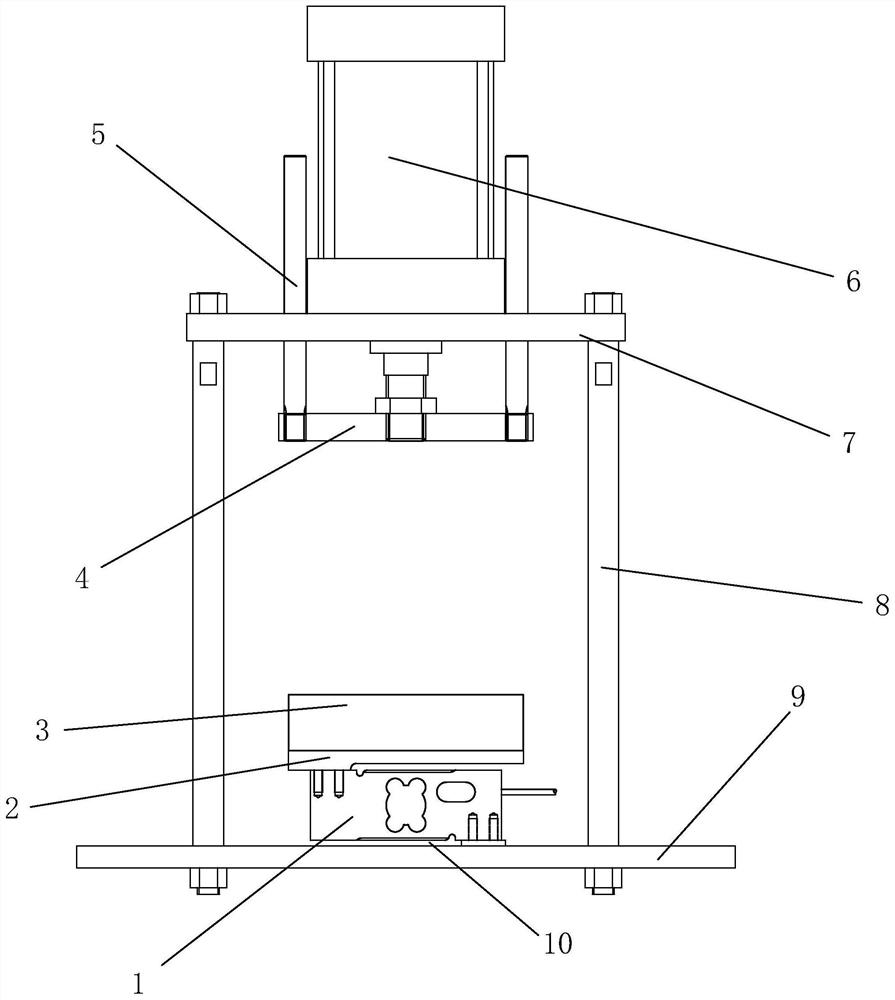

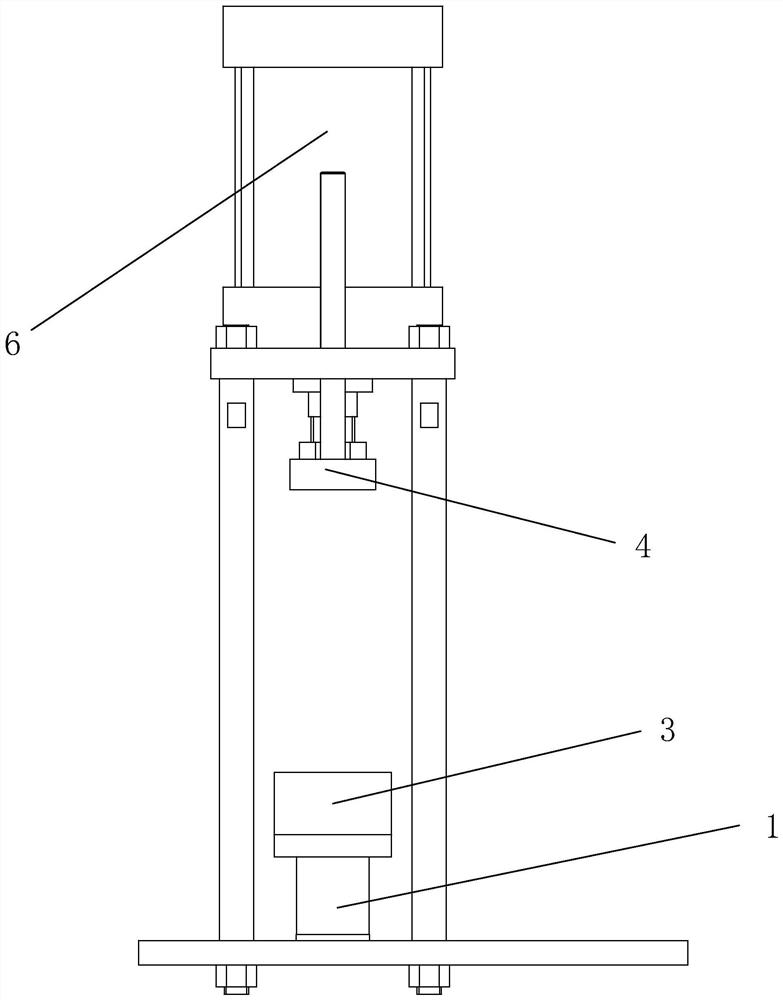

The invention discloses a transplanter for greenhouse vegetable seedlings. The transplanter comprises a mechanical arm (1), a mechanical hand (2) and an automatic feeding system; the automatic feeding system comprises a seedling conveying device (3), a steering device (4), an empty tray recovering device (5), a seedling receiving device (6) and a protective pedal (7), wherein the seedling conveying device (3) is connected with the empty tray recovering device (5) through the steering device (4), the mechanical arm (1) is arranged above the seedling conveying device (3), the mechanical hand (2) is installed on the mechanical arm (1), the seedling receiving device (6) is arranged below the seedling conveying device (3), and the protective pedal (7) is arranged above the seedling receiving device (6). The greenhouse vegetable seedlings can be automatically transplanted through the transplanter, the transplanter is used for automatically conveying and receiving the seedlings, collecting seedling trays and conveying planting floating plates in the transplanting process of the greenhouse vegetable seedlings, the transplanting operation is not limited by manual seedling feeding speed and intensity any more, and the production efficiency of greenhouse vegetables is substantially improved.

Owner:WENZHOU UNIVERSITY +1

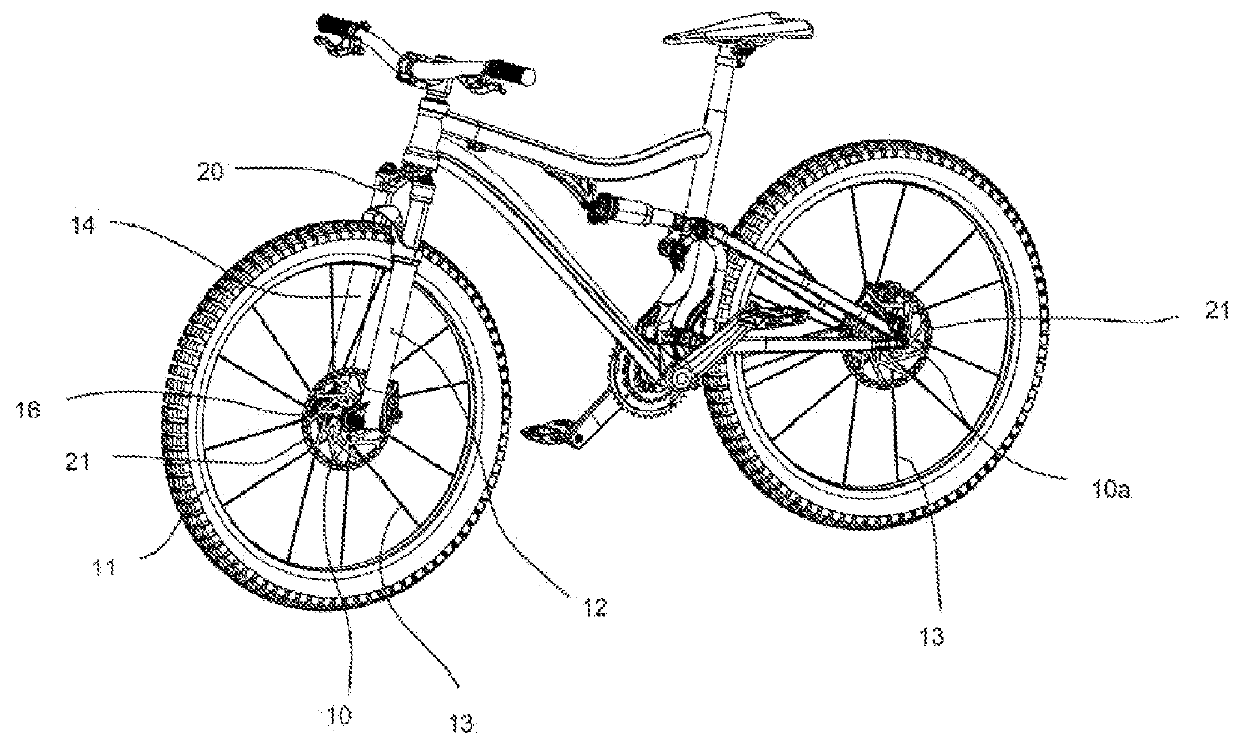

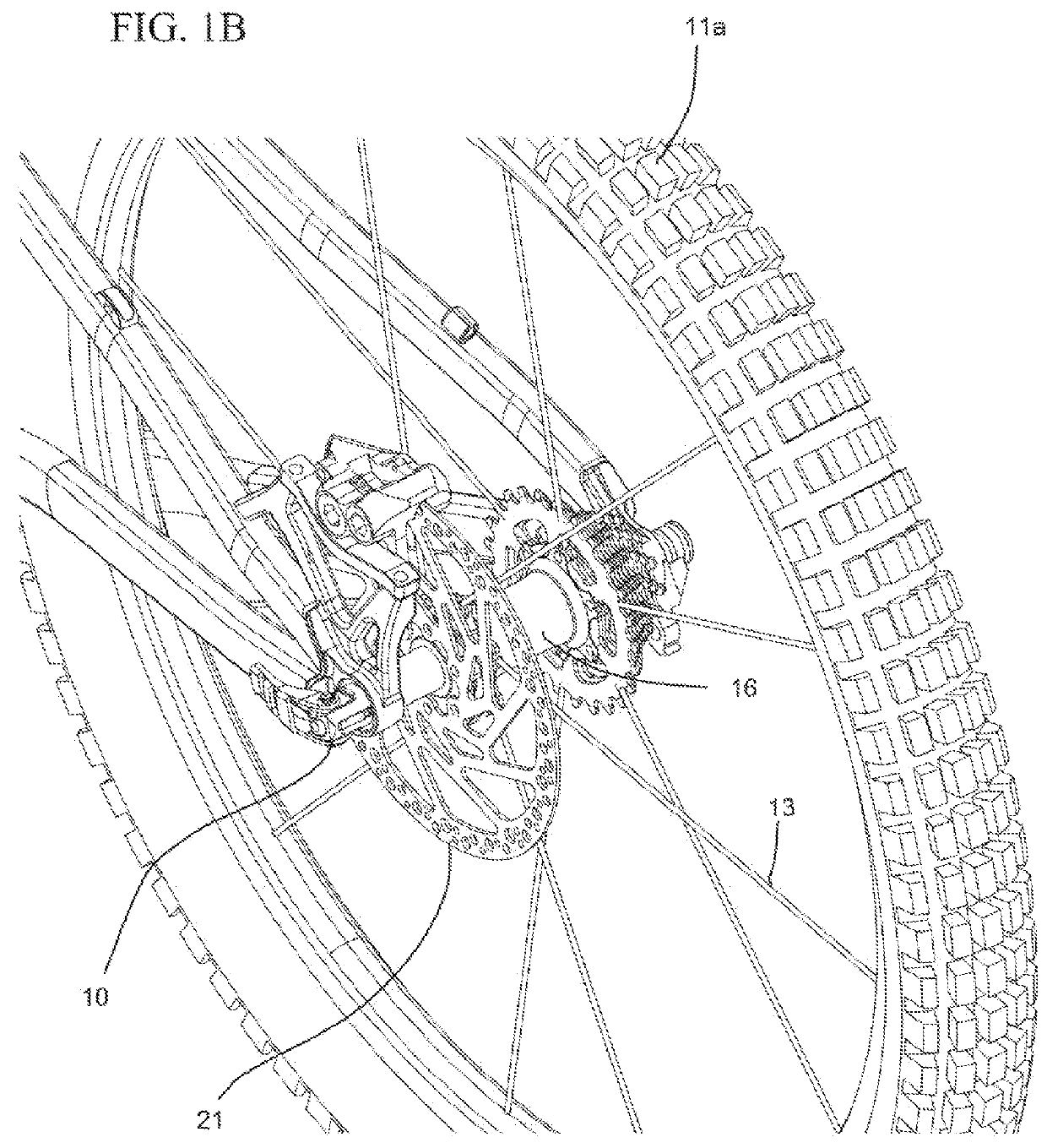

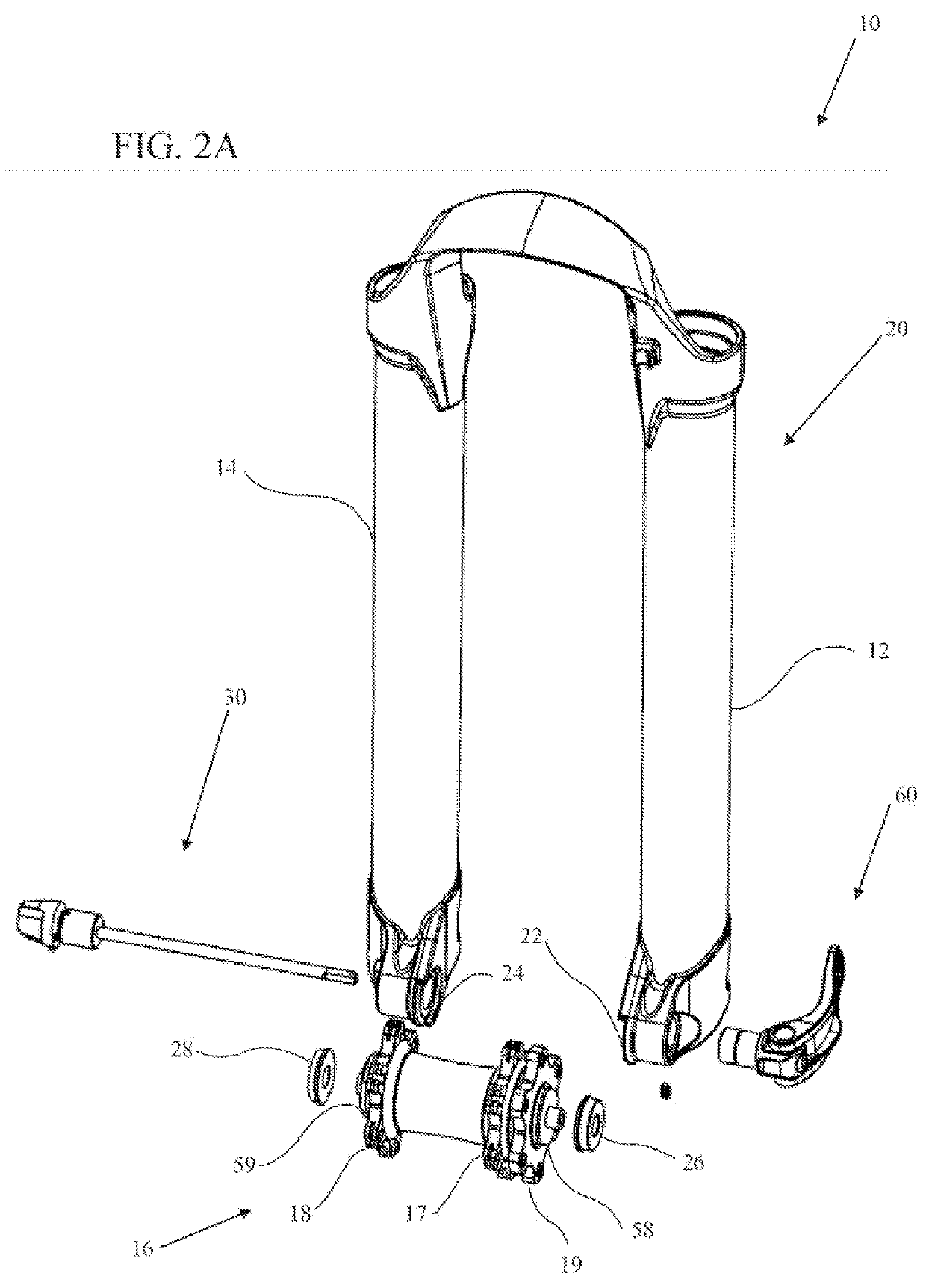

Bicycle tensioning device

A tensioning device for bicycle front and rear wheel assemblies. A skewer assembly with a thumbnut is securable to the wheel assembly with a quick-release assembly. Portions of the skewer assembly are removable from the quick-release assembly by turning the thumbnut a partial turn, such as a quarter of a turn. Removal of the skewer assembly allows the front wheel to be removed. In another embodiment, the skewer assembly is able to be removed by turning the quick-release assembly by a partial turn, such as a quarter of a turn.

Owner:VOSS DARRELL W

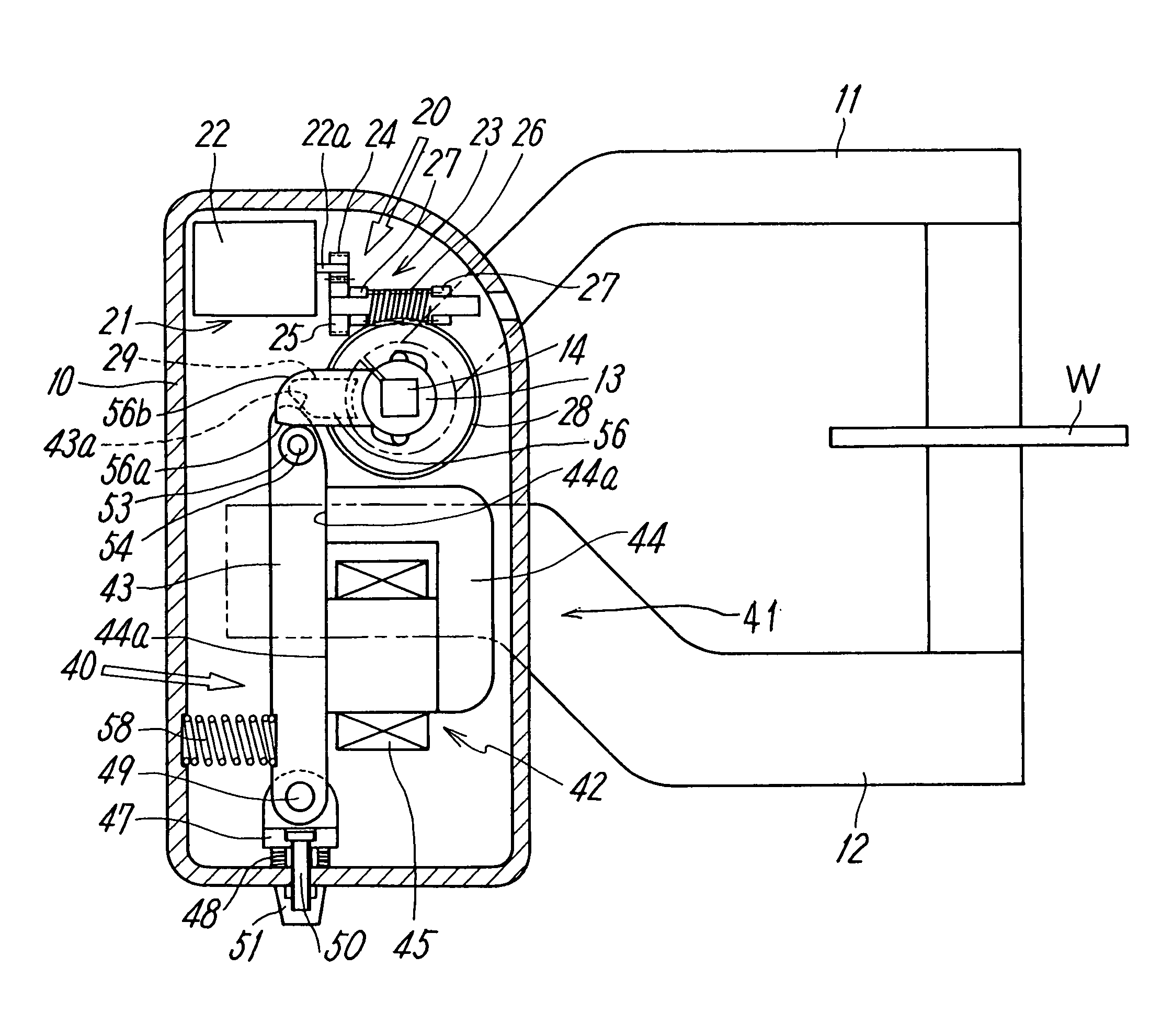

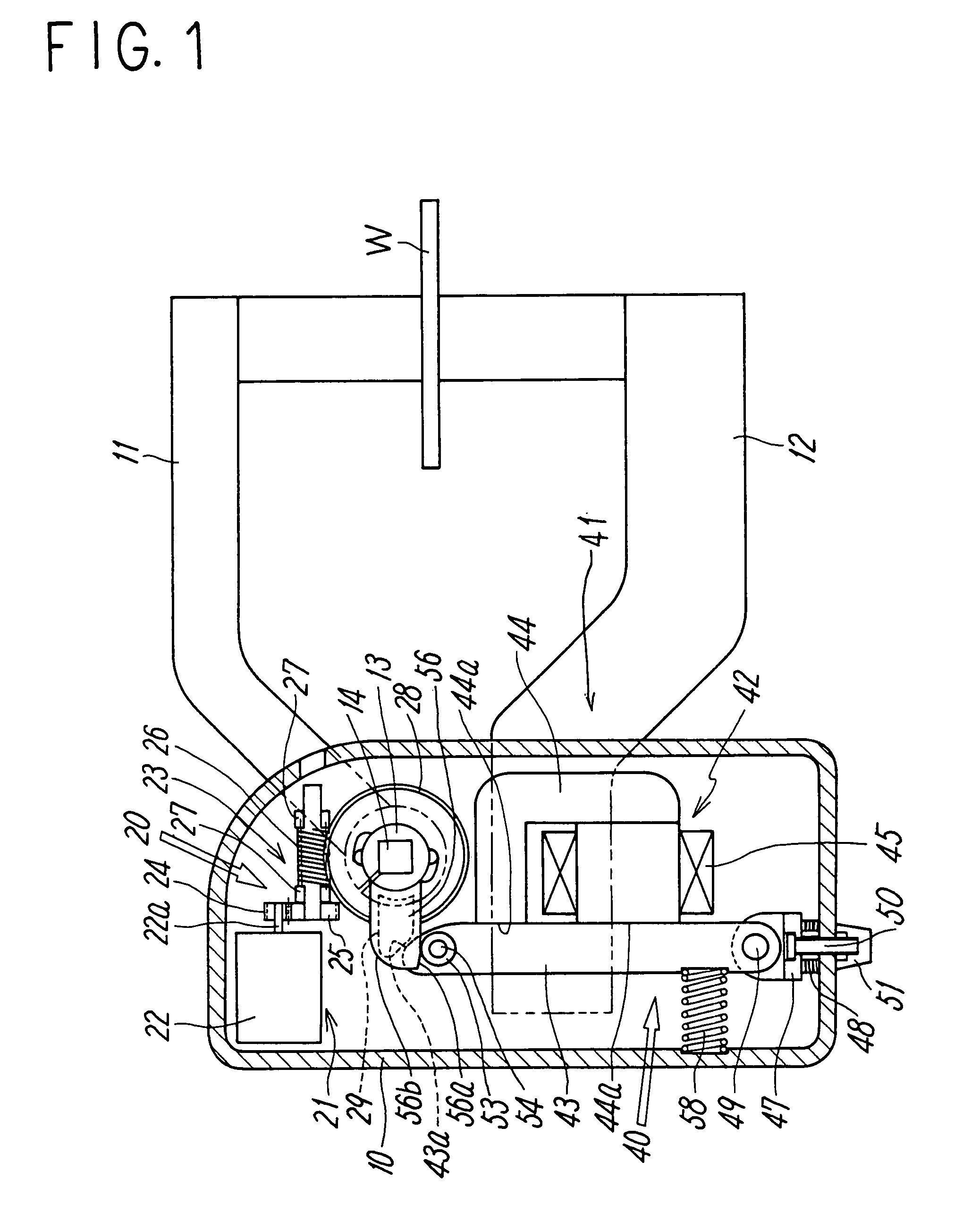

Clamping device

ActiveUS7004459B2Guaranteed uptimeSimple structurePositioning apparatusVicesMechanical engineeringPower transmission

A clamping device includes a first clamping arm and a second clamping arm, an arm driving portion for displacing the first clamping arm to a clamping position and a non-clamping position, and a clamping force applying portion for applying a required clamping force to the clamping arm. The arm driving portion has a first driving source for displacing the first clamping arm and a power transmission mechanism. The clamping force applying portion has a pressing member for applying the clamping force to the first clamping arm by applying a rotating force in a clamping direction to the rotary shaft and a second driving source for displacing the pressing member from a non-operating position to an operating position for applying the clamping force.

Owner:SMC CORP

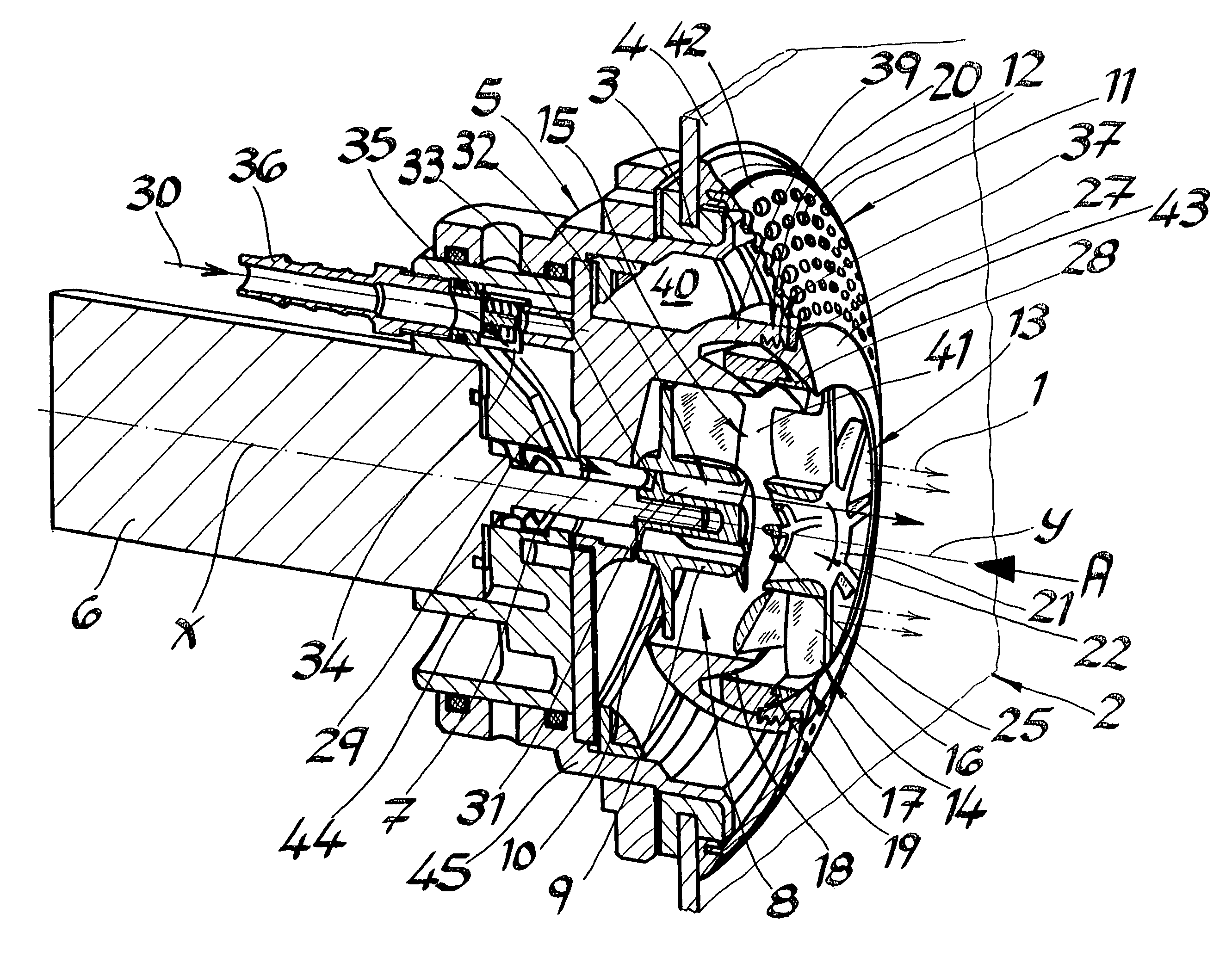

Device for generating a massage stream in a sanitary tub

Owner:FRANZ KALDEWEI GMBH & CO KG

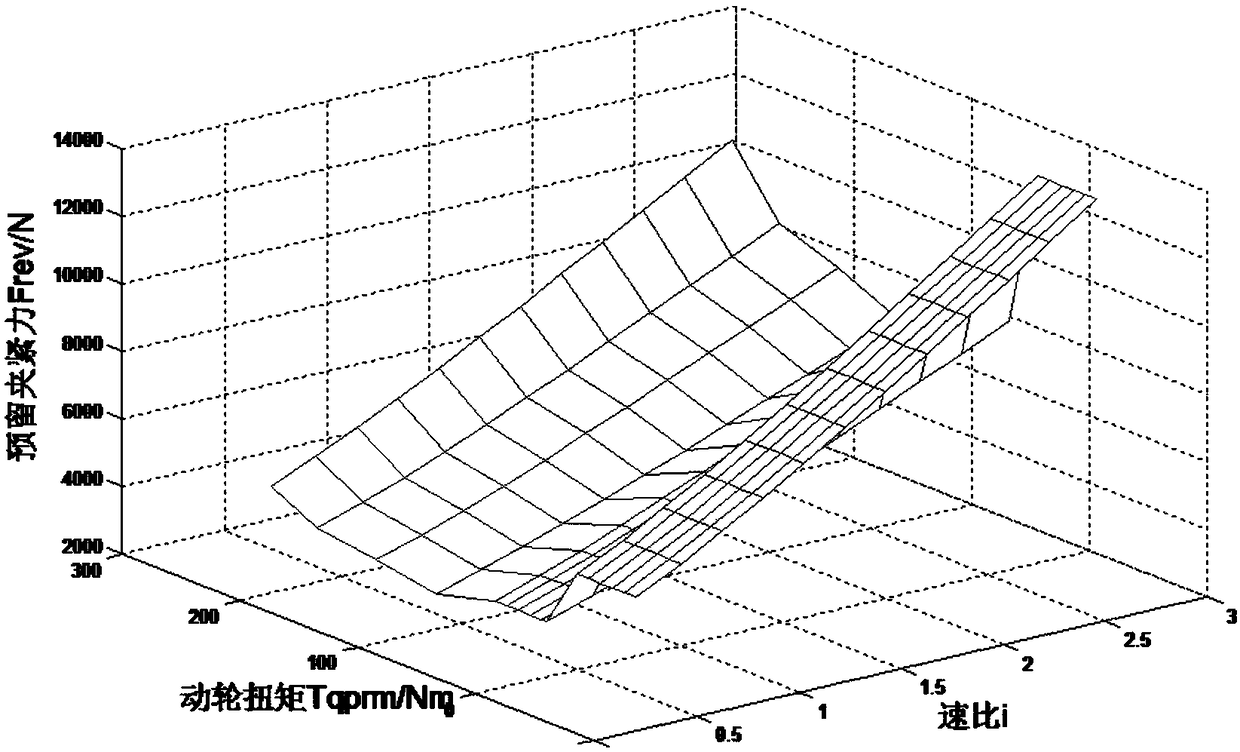

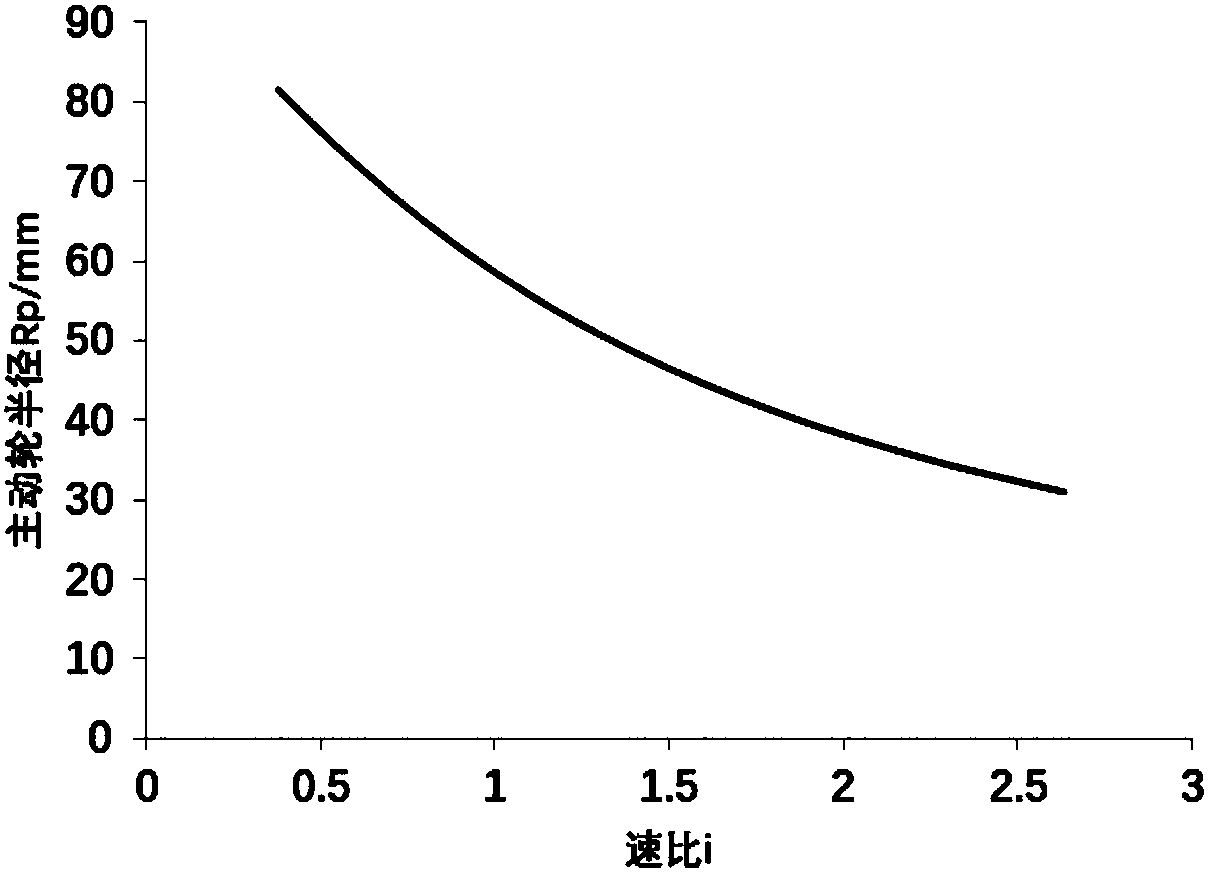

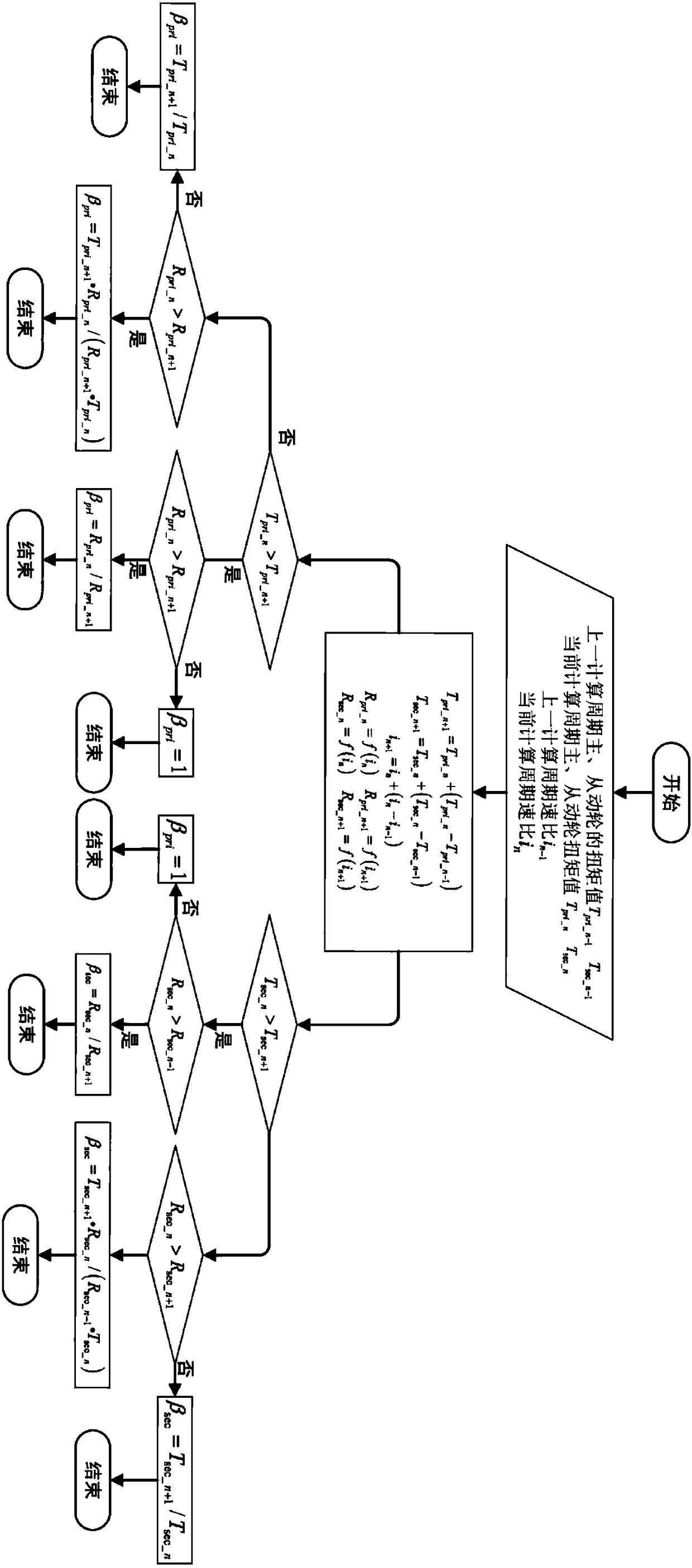

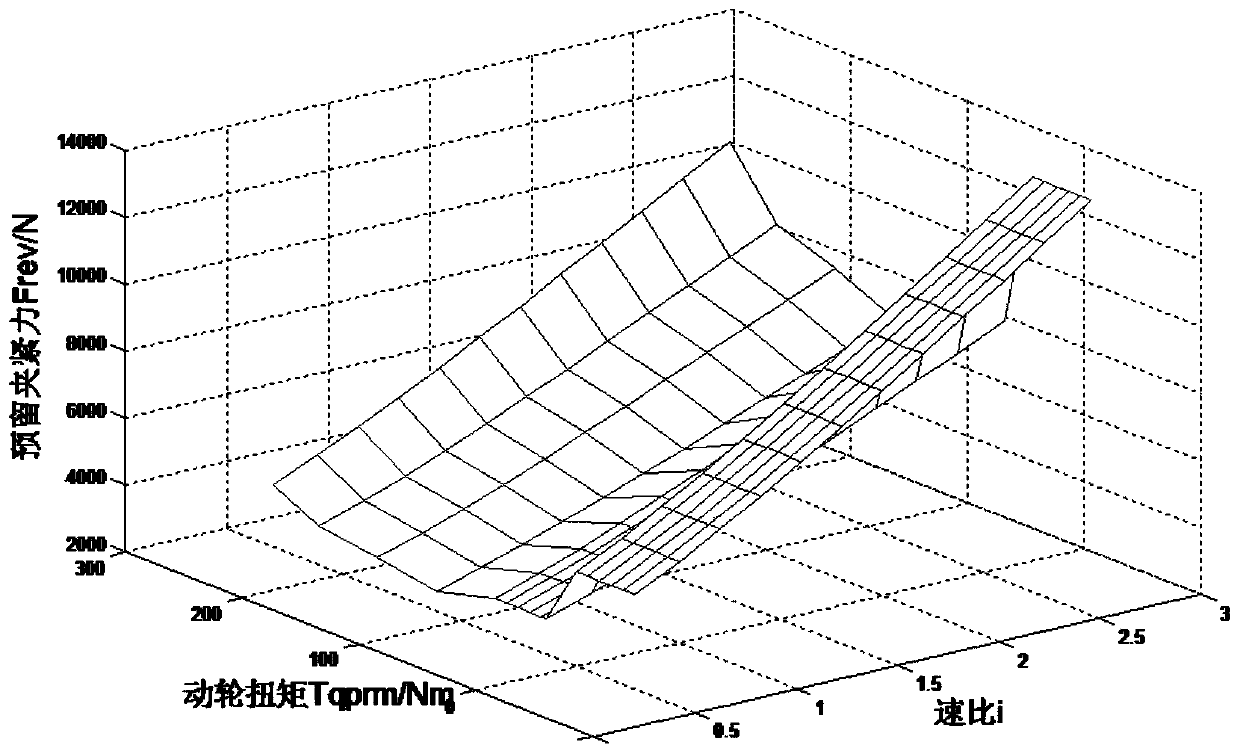

Metal belt-type stepless transmission target clamping force calculation method based on reserved clamping force

ActiveCN108361367AAccurate calculationAccurate calculation of pulley clamping forceGearing controlEngineeringMechanical engineering

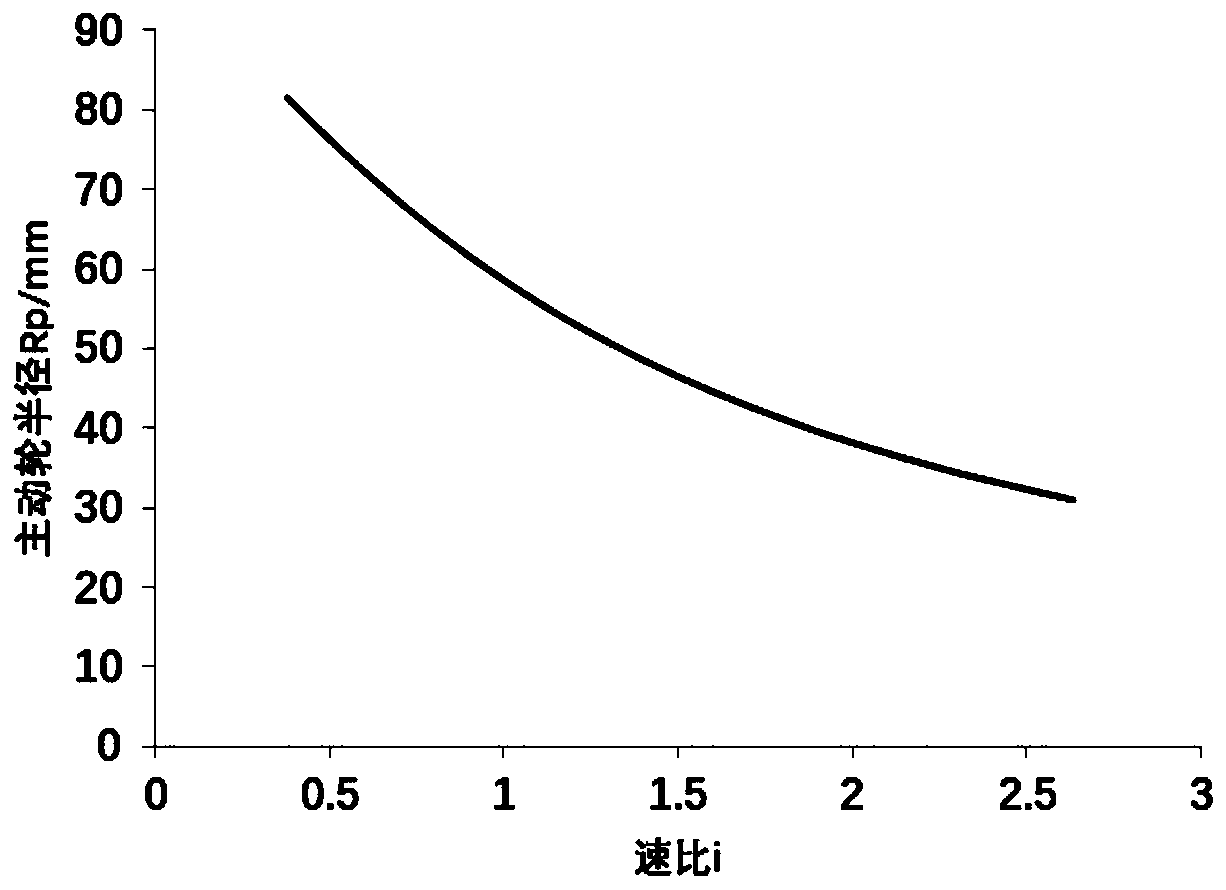

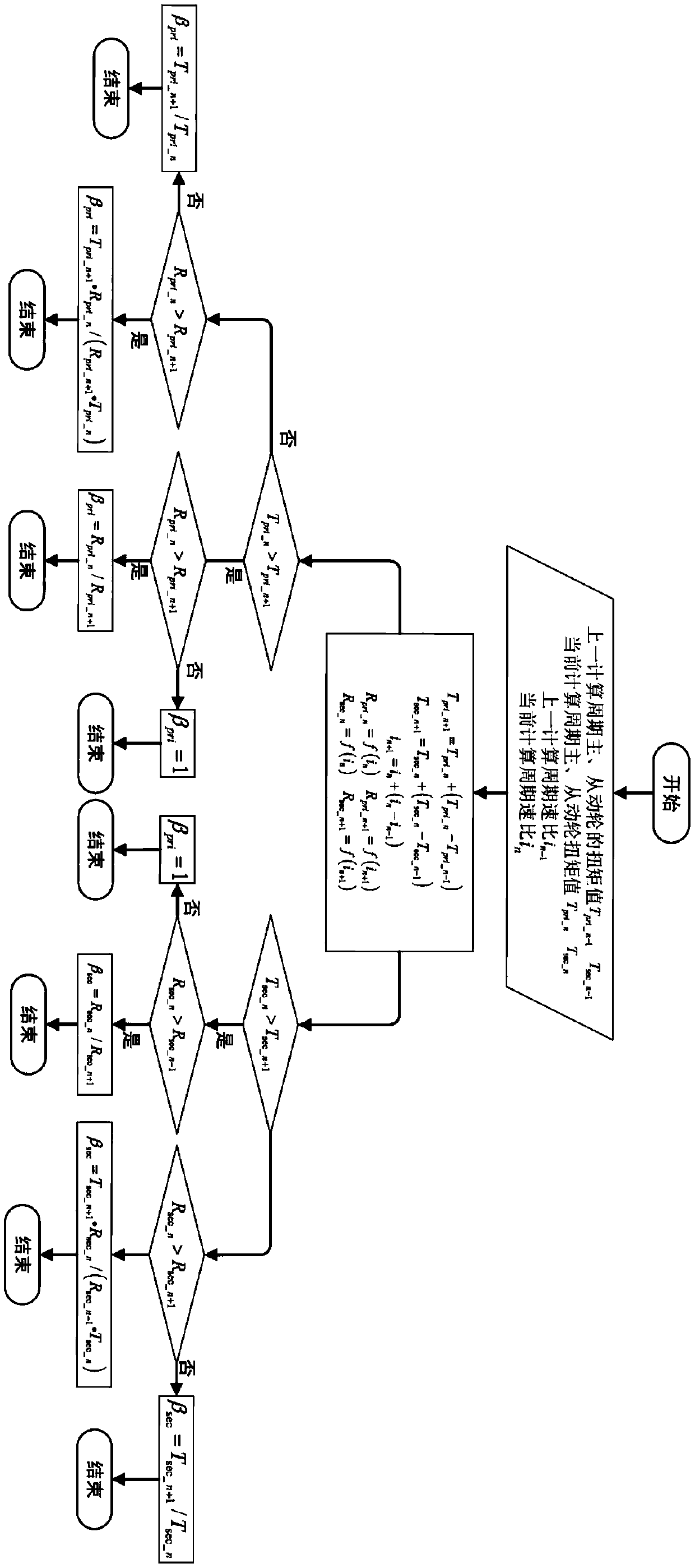

The invention discloses a metal belt-type stepless transmission target clamping force calculation method based on reserved clamping force. The method comprises the steps that according to formulas, the minimum target clamping force F<pri> of a driving belt wheel and the minimum target clamping force F<sec> of a driven belt wheel are calculated; and then according to the current target speed ratioand the corresponding clamping force ratio, the driven belt wheel target clamping force F<sec_KPKS> corresponding to the driving belt wheel and the driving belt wheel target clamping force F<pri_KPKS>corresponding to the driven belt wheel are calculated.

Owner:JILIN UNIV

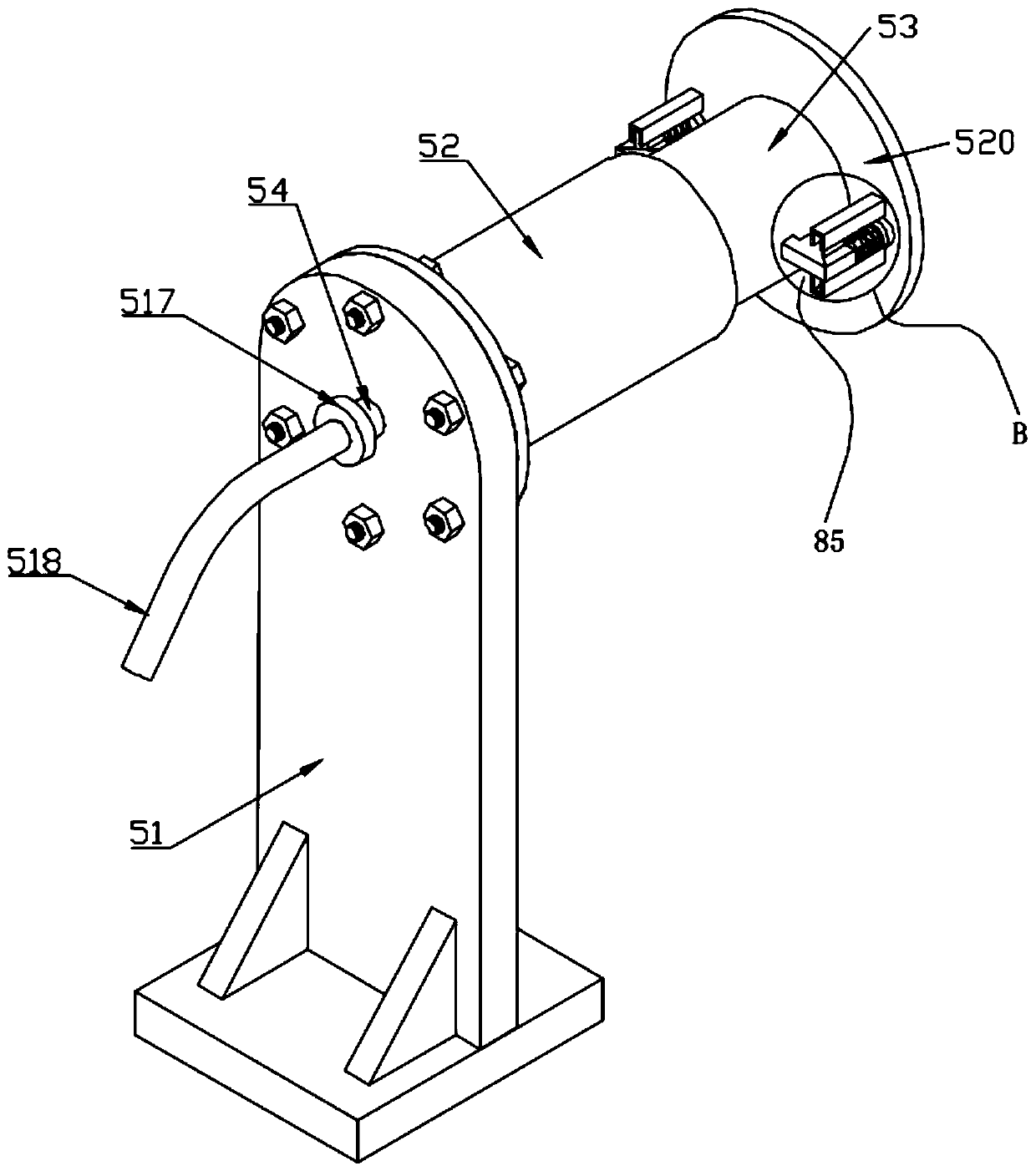

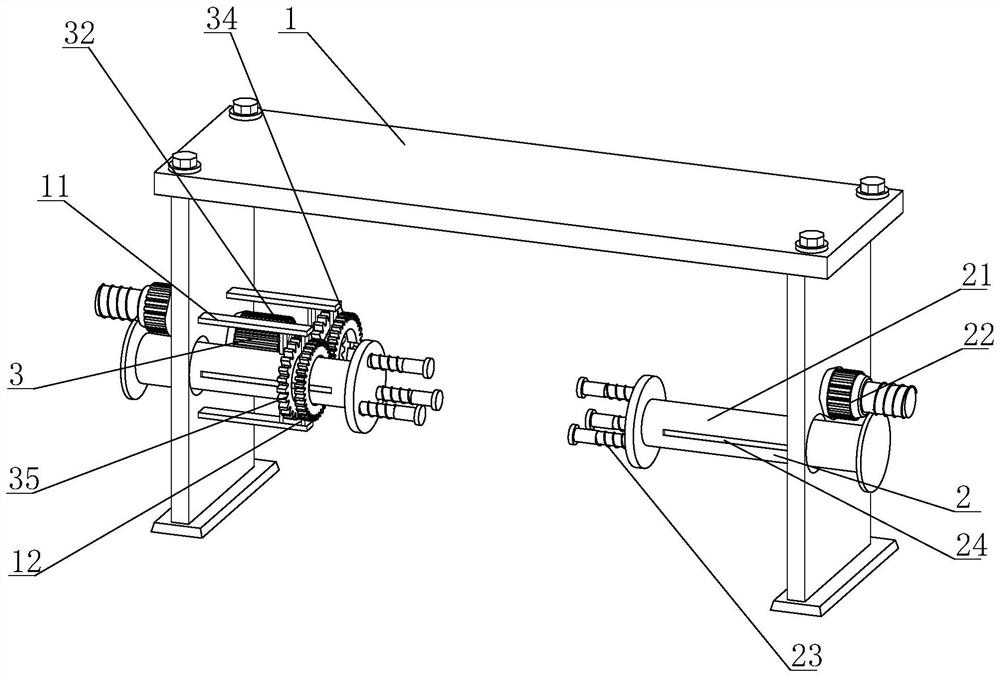

Large-size round timber processing facility for agriculture and forestry

ActiveCN110712254AAchieve axial positioningPrecise positioningMulti-purpose machinesGrinding work supportsAgricultural scienceAgricultural engineering

The invention discloses a large-size round timber processing facility for agriculture and forestry, and relates to the technical field of wood processing. The large-size round timber processing facility for the agriculture and forestry comprises a base, a machine frame, a power assembly, a lifting platform and a locating mechanism. The machine frame and the locating mechanism are installed at thetwo ends of the base correspondingly. The power assembly is installed on the machine frame, cooperates with the locating mechanism and drives a piece of round timber to rotate around the axis of the power assembly. The lifting platform is installed between the machine frame and the locating mechanism and used for achieving feeding and discharging operation of the round timber. By the adoption of the large-size round timber processing facility for the agriculture and forestry, the surface processing treatment work of the large-size round timber is achieved, namely, a driving motor drives the round timber to rotate, the locating mechanism cooperates with a driving disc to achieve the axial locating of the round timber, the clamping and locating operation of one end of the round timber is achieved in the mode that a supporting frame is fixed, and an inner sleeve moves, the process can be achieved under the condition that only the hydraulic oil needs to be fed into the facility, the locating process is simplified, the manpower is saved, the clamping force is more accurate, and the effect of avoiding the round timber rotation situation which happens due to the fact that the torque is excessively high is also achieved.

Owner:芜湖文青机械设备设计有限公司

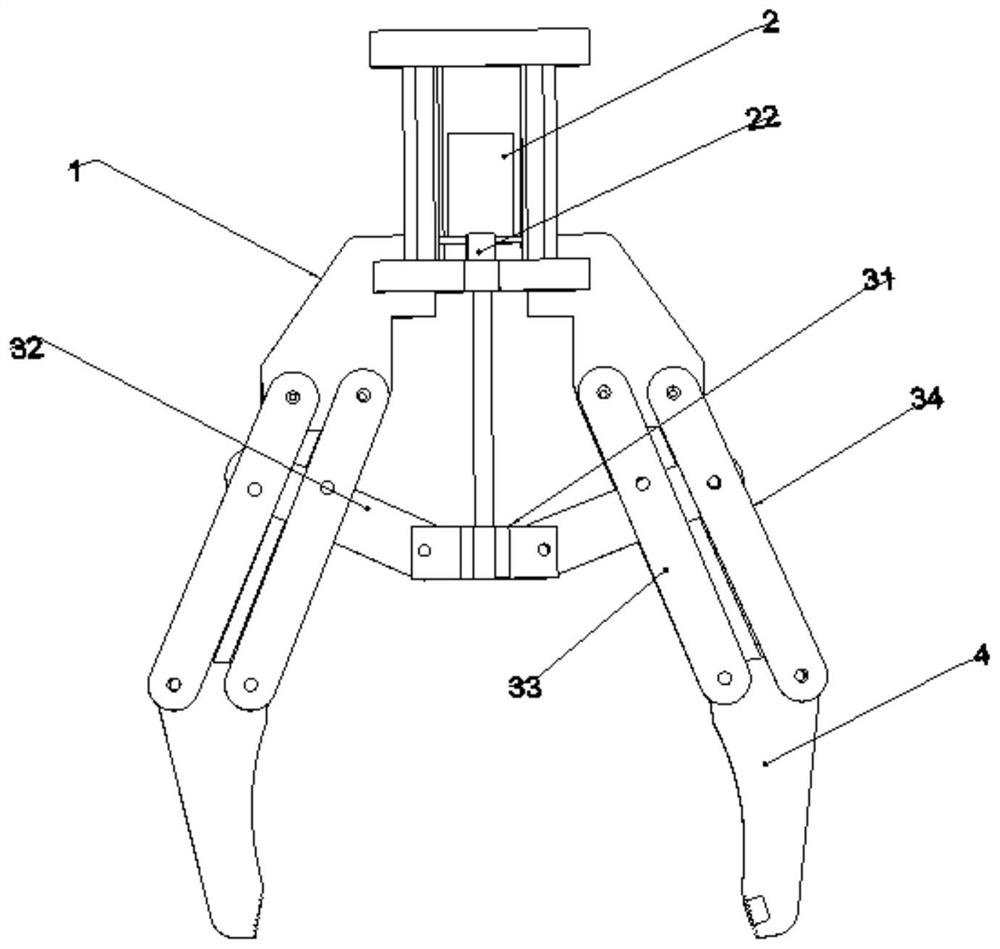

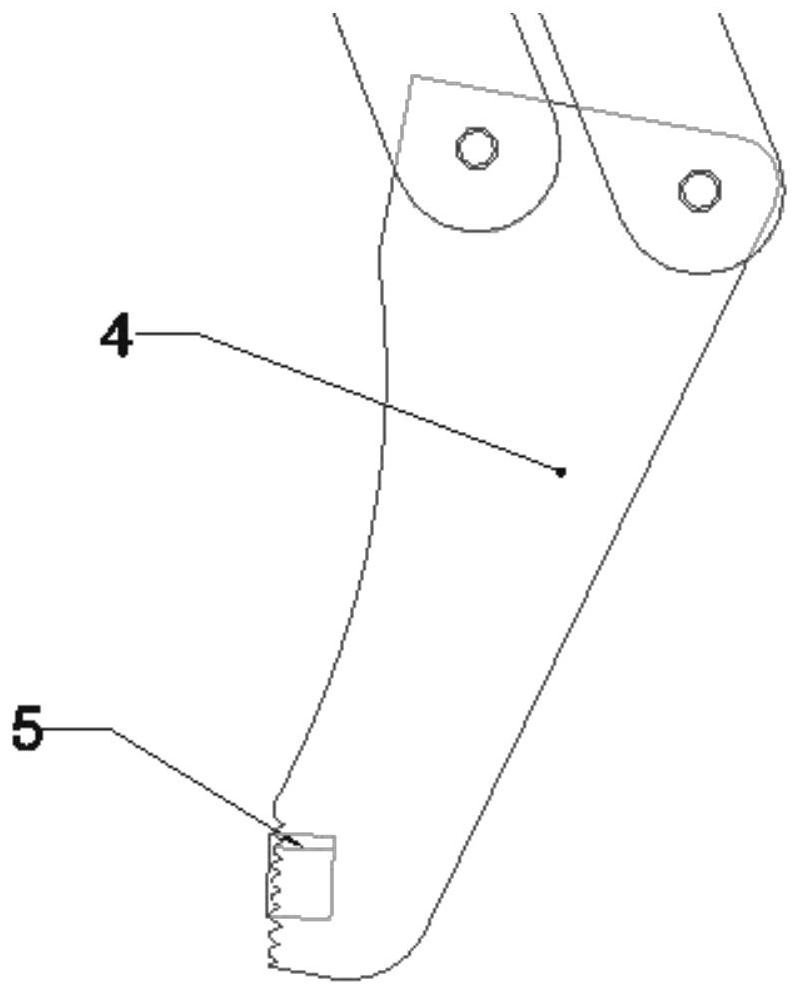

High-precision automatic workpiece clamping manipulator system

The invention discloses a high-precision automatic workpiece clamping manipulator system. The system comprises an adjustable chuck, an extension arm, a support arm, a track wire groove, a rotary support column, an alarm lamp, a base and a control box; the adjustable chuck is fixed at the lower end of the right side of the extension arm through a bolt; the outer wall of the extension arm is mechanically connected with a guide rail in the support arm; the track wire groove is horizontally fixed at the upper end of the outer wall of the support arm; the rotary support column is mounted on the right side of the alarm lamp, and is movably connected with the top of the base; the control box is horizontally fixed on the inner wall of the base; and the adjustable chuck is electrically connected with elements in the control box through the chuck. An adjustable clamping arm adjusts the clamping force more precisely, so that an improved high-precision automatic workpiece clamping manipulator canfreely adjust the clamping force, the workpiece clamping safety can be preferably guaranteed, the clamping speed is high, the workpiece damage degree is lower, and the precision cannot be influenced.

Owner:李志护

Outer circle turning clamp of thin wall bearing ring

InactiveCN104385025ASimple structureEasy clampingPositioning apparatusMetal-working holdersThin walledEngineering

The invention relates to an outer circle turning clamp of a thin wall bearing ring. The outer circle turning clamp is characterized by comprising a disc-shaped clamp body, wherein the front end of the clamp body is provided with a positioning boss for positioning an inner hole of one end of the thin wall bearing ring, the front part of a positioning boss is provided with a slide guide part, a pressing ring glidingly sleeves the slide guide part, and is provided with an outer conical surface, an expansion ring sleeves the exterior of the pressing ring, and is provided with an inner conical hole which is matched with the outer conical surface of the pressing ring, at least two limiting screws penetrate through holes of the pressing ring and are connected with the clamp body, a plurality of bolt holes are respectively and uniformly formed in the clamp body and the pressing ring and are connected with a main shaft of a lathe, and a pressing gap is formed between the inner end surface of the pressing ring and the front end surface of the clamp body. The outer circle turning clamp has the advantages that the structure is simple, the clamping is convenient and rapid, the direction of clamping force is coincided with the positioning point of the bearing ring, the positioning is accurate, the clamping force is stable, the error of processing size is reduced, the turning qualified rate of the thin wall bearing ring is improved, the processing efficiency is improved, and the production cost is reduced.

Owner:JIANGYIN JIB WD PRECISION

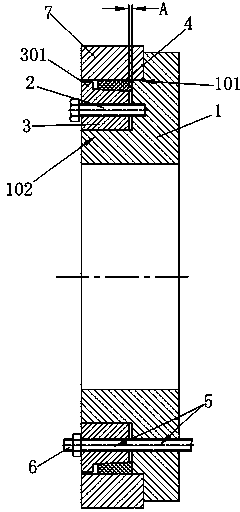

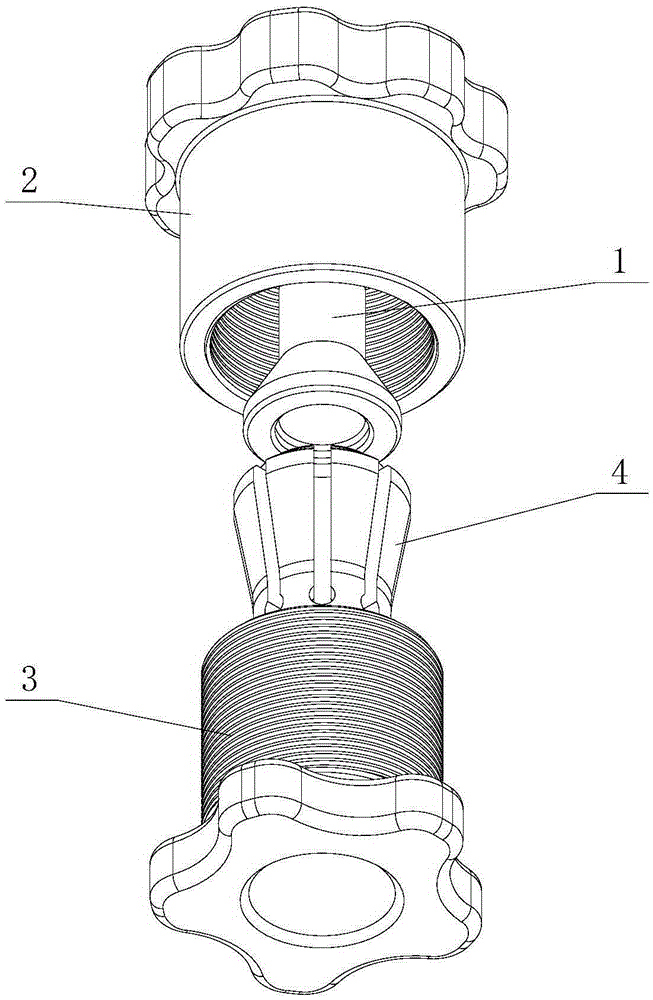

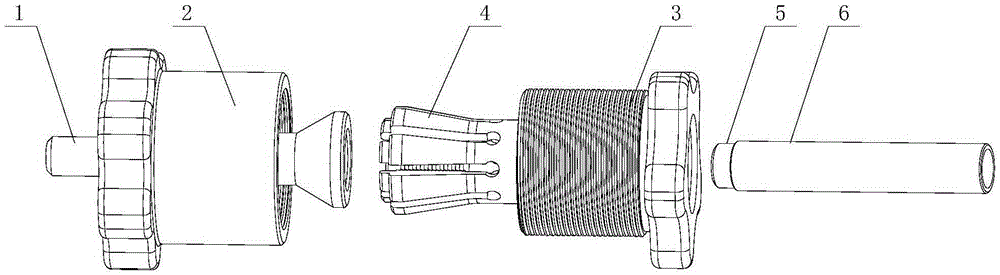

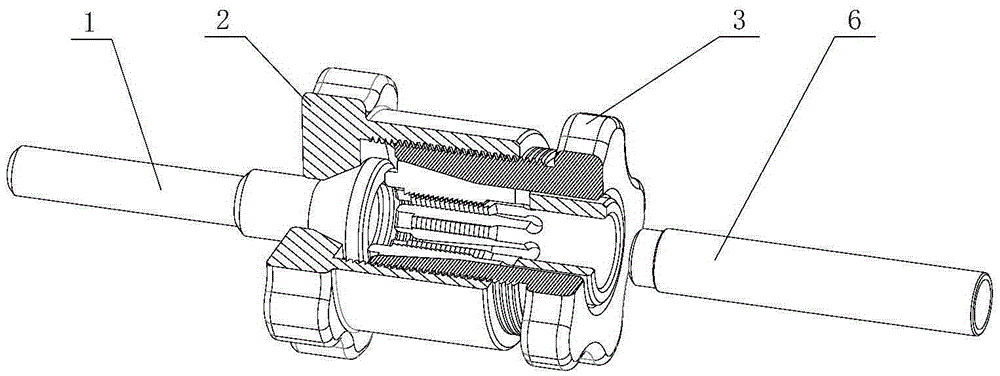

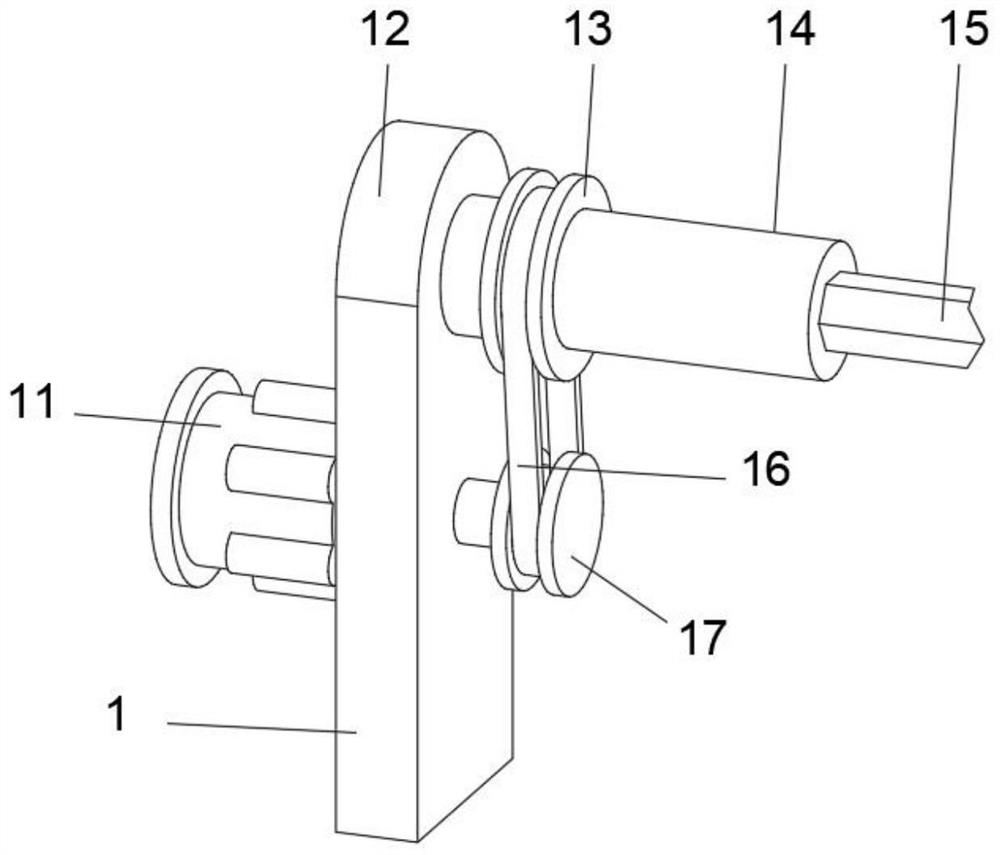

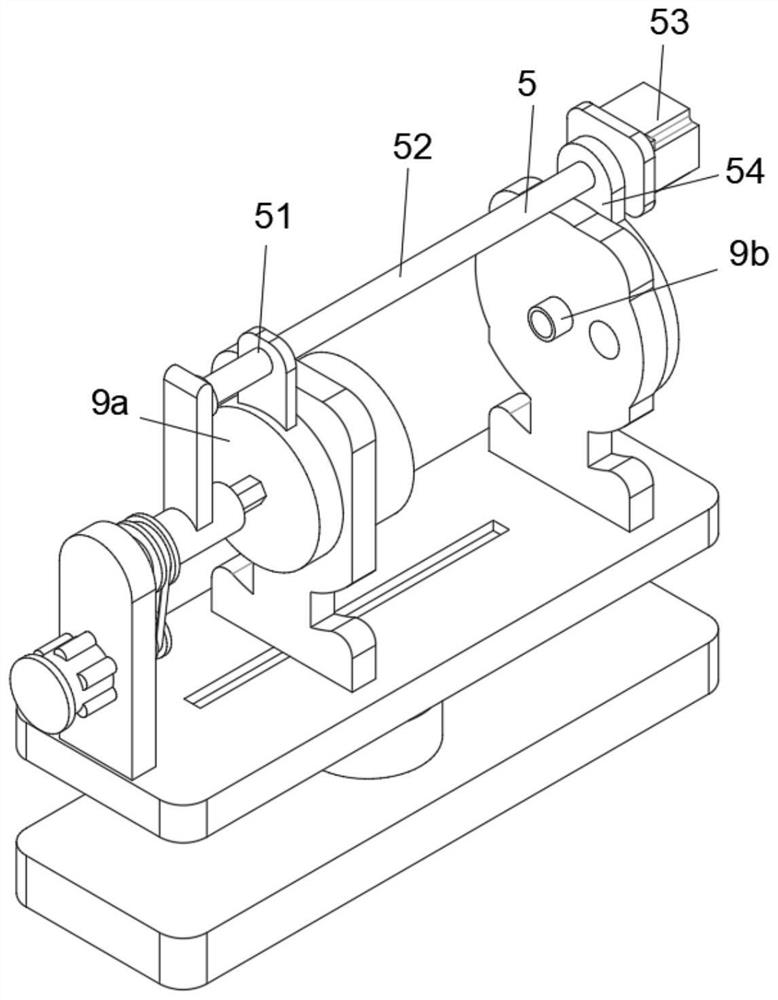

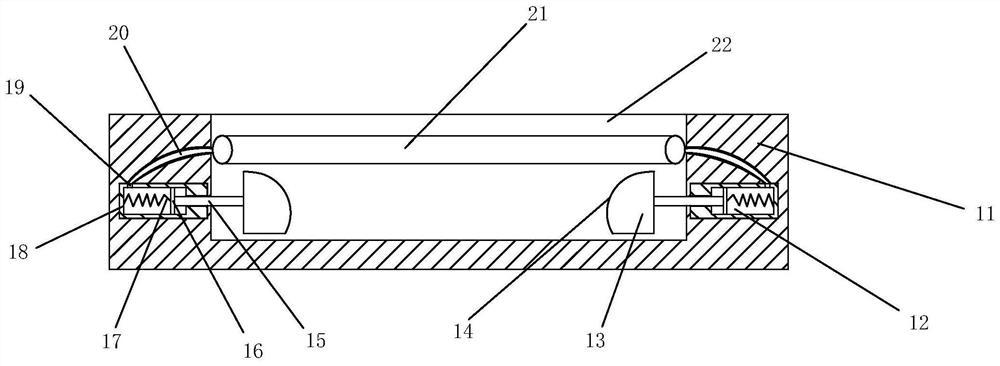

Specimen holder of tube or bar for tension test

ActiveCN105388062AReduce frictionReduce wearInvestigating material ductilityEngineeringConical surface

The invention discloses a specimen holder of a tube or a bar for a tension test. The specimen holder comprises a tension handle, a locking part, a holding seat and a holder body, wherein the holder body comprises a cylinder body and a circular truncated cone body which are integrally formed; the maximum external diameter of the circular truncated cone body is greater than the external diameter of the cylinder body; the whole circular truncated cone body is provided with at least two grooves along the axial direction, and the two grooves are used for segmenting the circular truncated cone body into holding blocks; a holding part for holding a test specimen is arranged on the inner surface of each clamping block; the holding seat sleeves the outside of the holder body and is connected with the holder body in a matching way; the holding seat is provided with a first conical surface matched with the circular truncated cone body; the front end of the locking part is connected with the holding seat through a spiral structure; the tension handle is connected with the rear end of the locking part. The specimen holder disclosed by the invention is small in size, convenient in disassembly and assembly and uniform and reliable in holding force; the specimen holder realizes automatic centering in a clamping process, is uniform, quick and reliable in clamping, and is particularly suitable for being used in a high-low temperature environmental cabinet with compact structure and small space.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

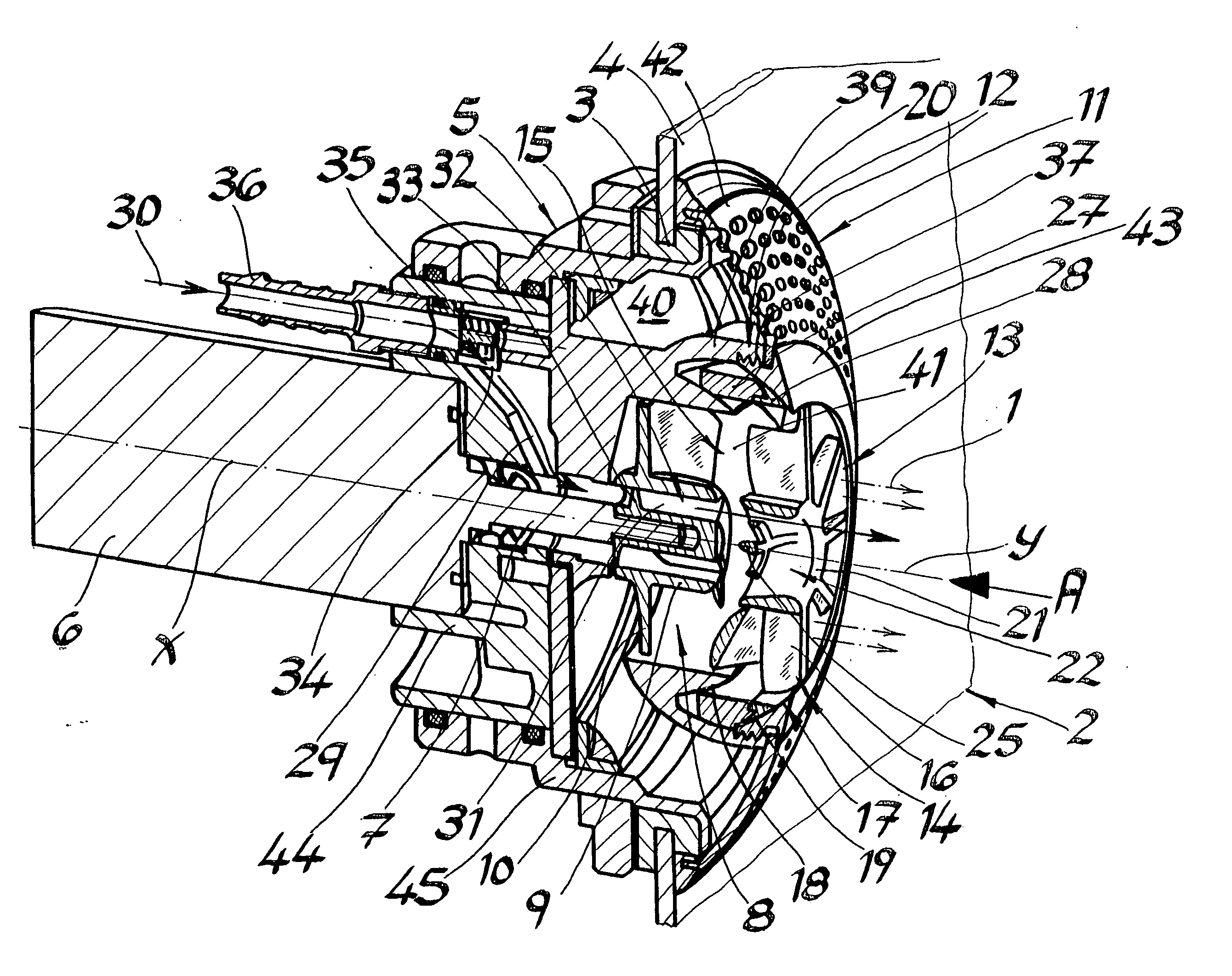

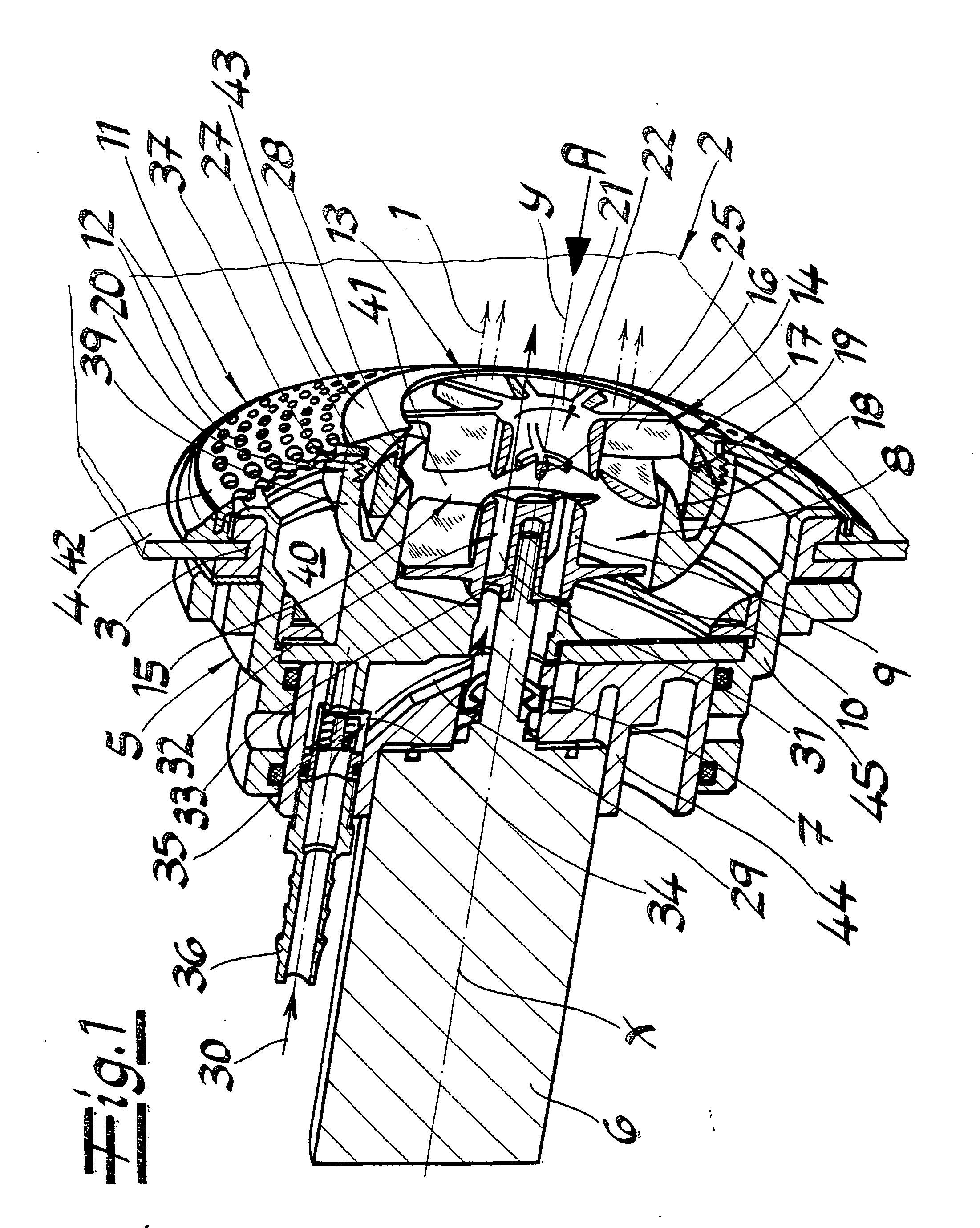

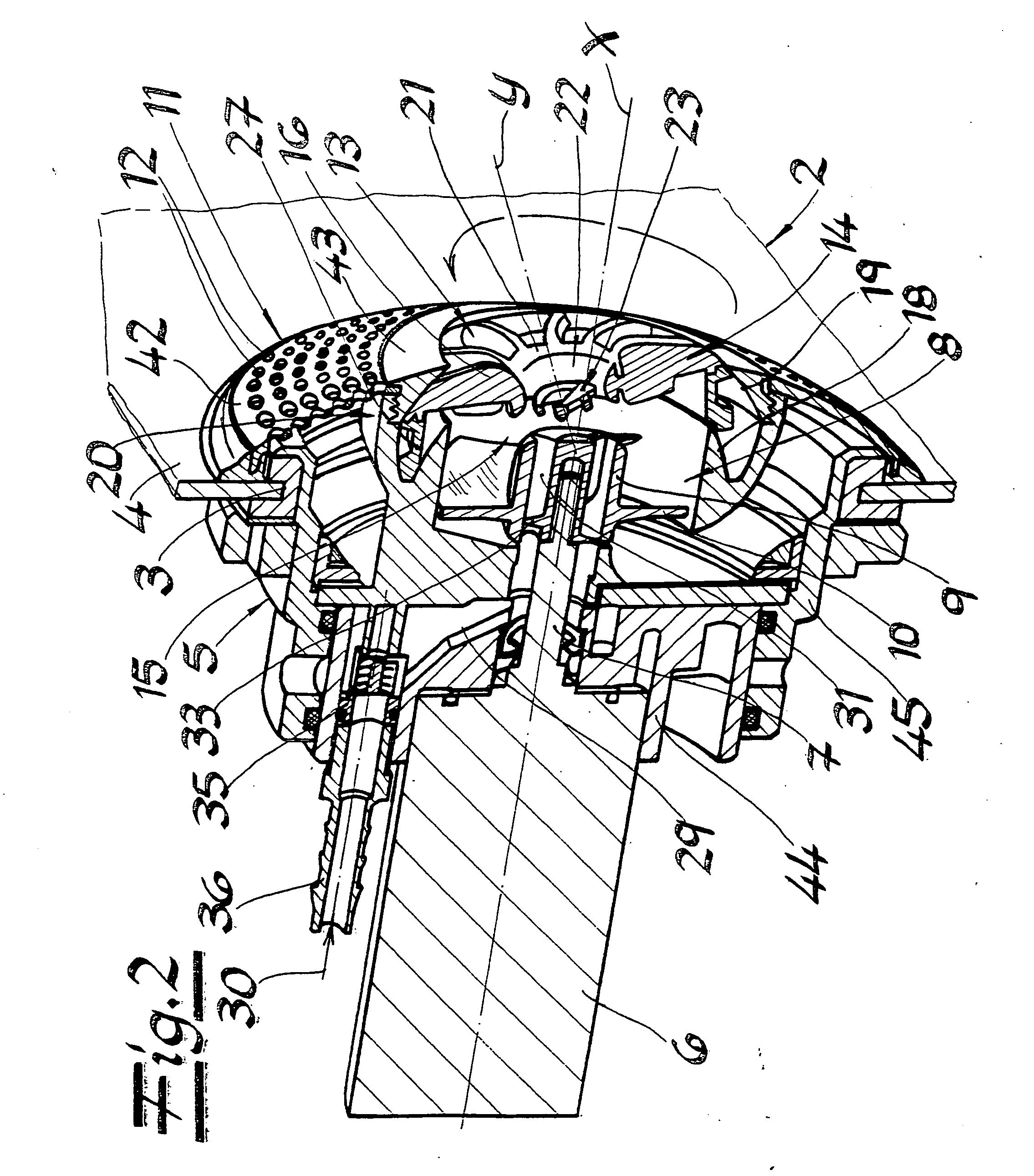

Device for generating a massage stream in a sanitary tub

A device for generating a massage stream in a sanitary tub has an accommodation device that can be attached to an opening in the tub body of the sanitary tub, for accommodating an electric motor having a drive shaft, a propeller having a hub attached to the drive shaft and vanes arranged radially about the hub. There is a rosette arranged on the accommodation device, positioned within the sanitary tub, having edge-side inflow openings, as well as a central outlet opening. The propeller draws water located in the sanitary tub in through the inflow openings, and subsequently transports it back into the sanitary tub, through a guide element arranged in the outlet opening, which can be pivoted relative to the hub axis. The guide element is configured as a guide vane ring and has a ring-shaped bearing shell at the outer end of the guide vanes. The shell moves between a glide surface of the accommodation device that is configured as a sphere surface segment, and a concave contact surface of the rosette.

Owner:FRANZ KALDEWEI

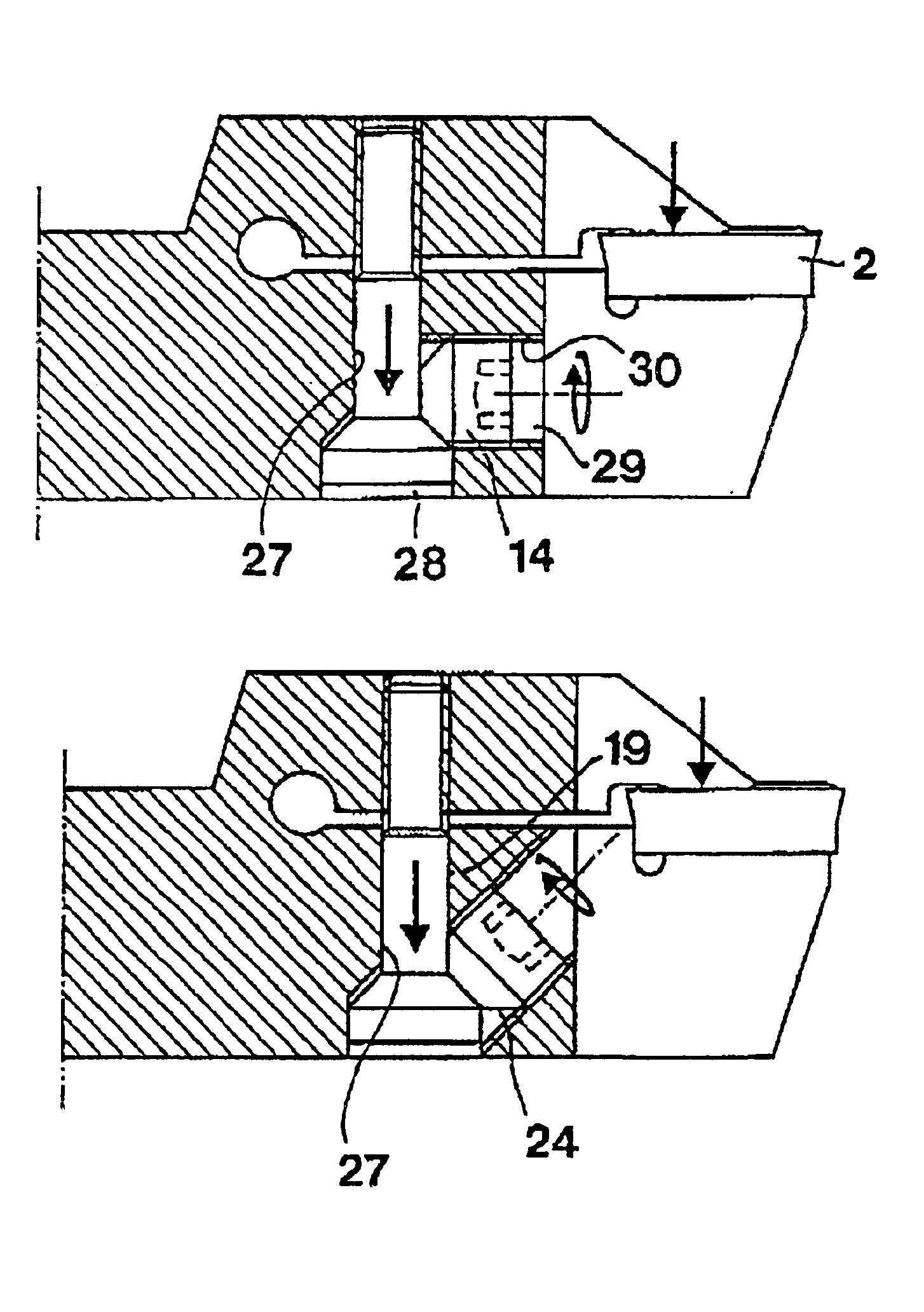

Insert holder for parting and grooving operations

InactiveUS20020154959A1Conveniently accessibleEliminate disadvantagesCutting insertsTurning toolsEngineeringAbutment

A holder is designed to receive a cutting insert intended for parting and grooving operations. The insert is clampable in a seat formed between a blade tongue and a clamping finger which respectively extend from lower and upper front parts of the holder. A gap separates those front parts in order to enable those parts to be forced towards each other by means of a clamping mechanism mounted in the holder. The clamping mechanism comprises a drawbar, a first end portion of which is movable within a bore formed in one of the front parts, and a second end portion of which is fixed in the other front part. The first end portion of the drawbar includes a head having a frusto-conical abutment surface. A tightening screw is threadedly mounted in the same front part as the head and is arranged to contact the abutment surface to displace the drawbar in a direction forcing the clamping finger and the tongue together to clamp the cutting insert in place.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

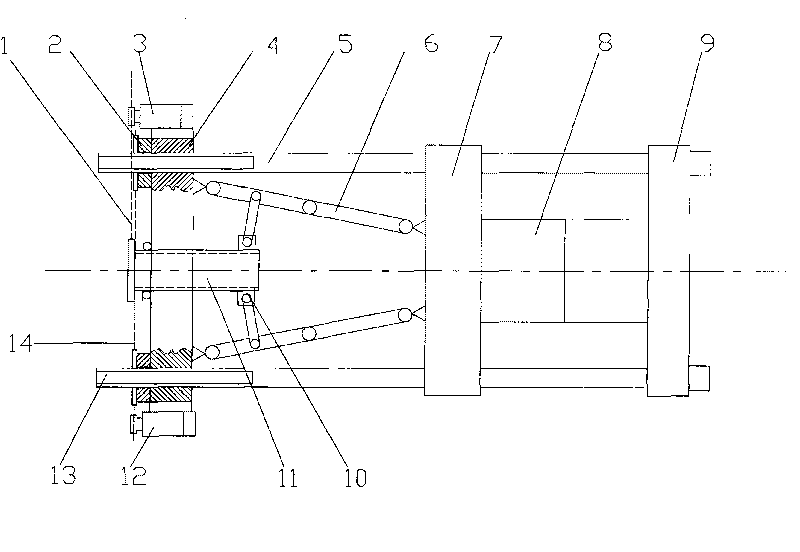

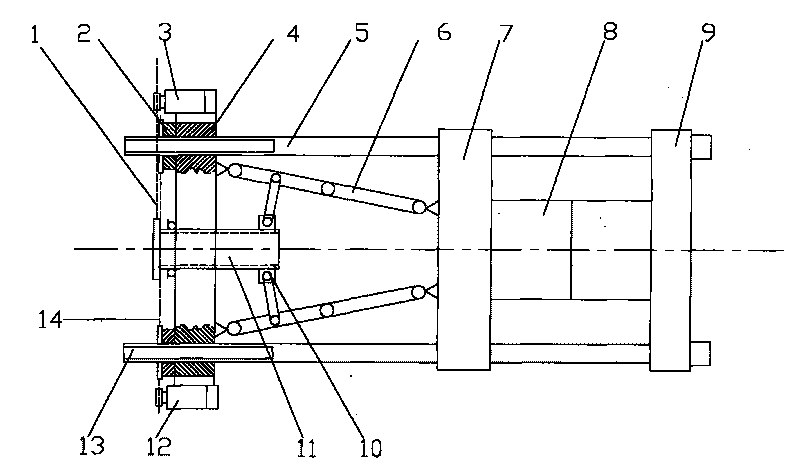

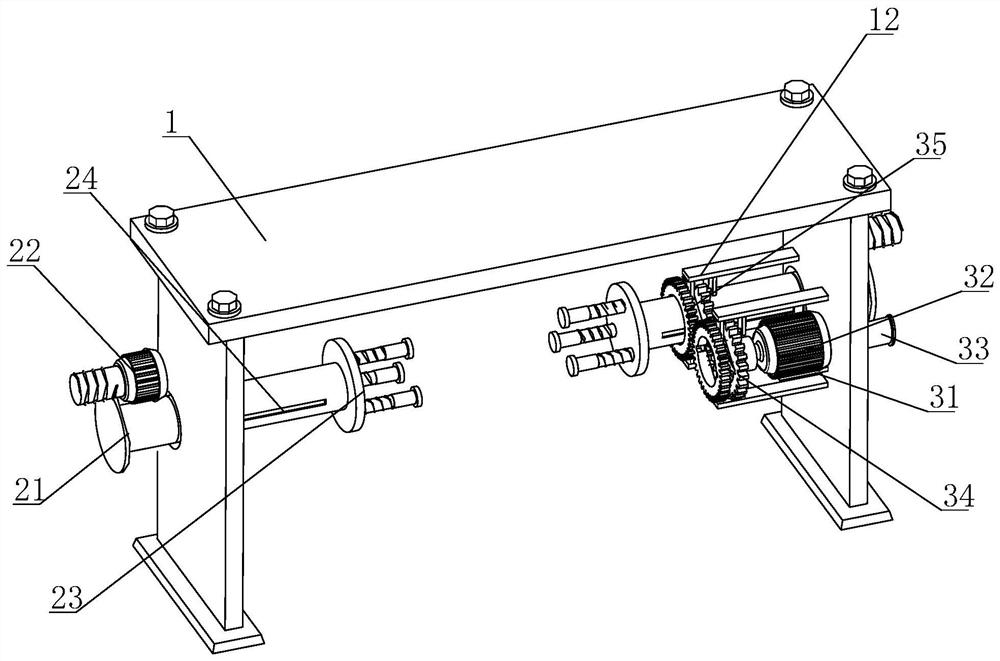

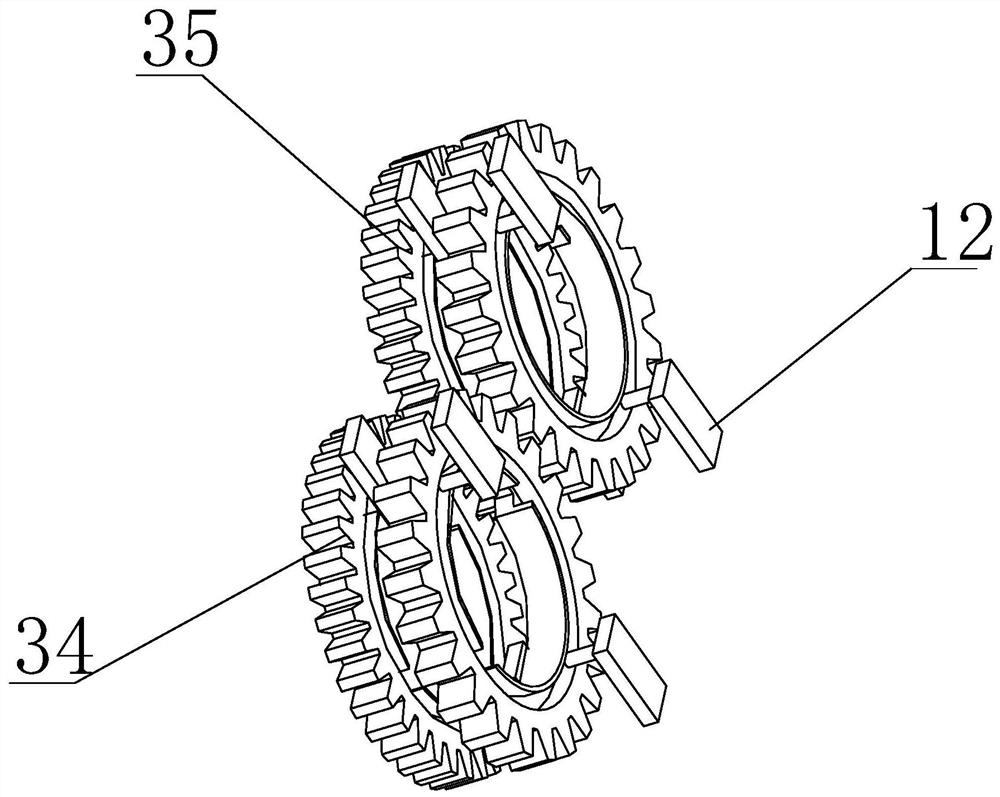

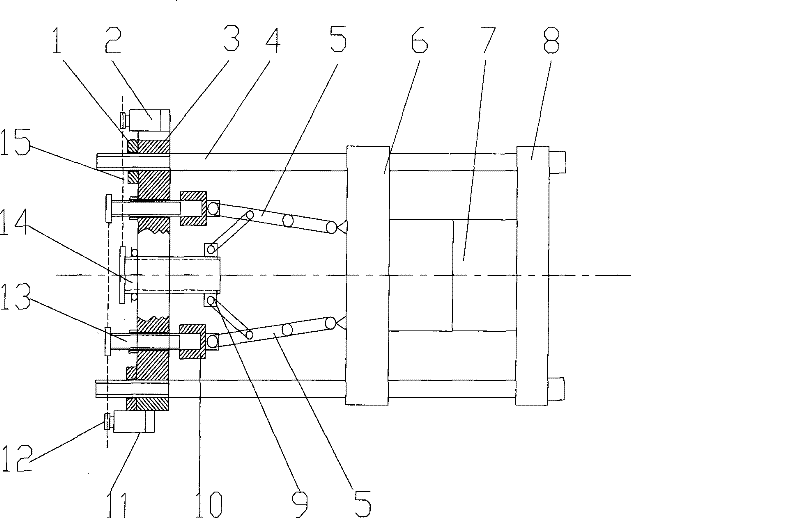

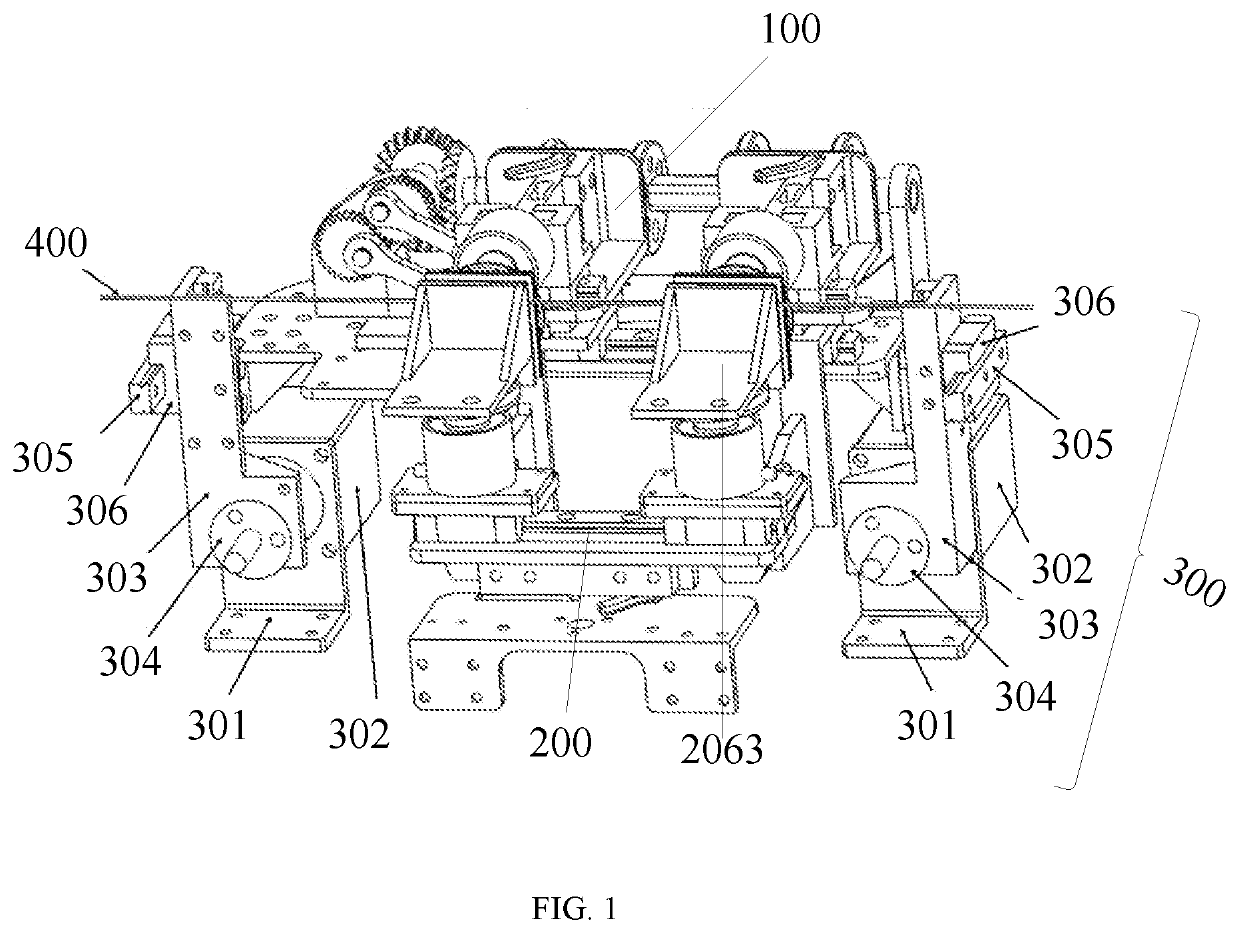

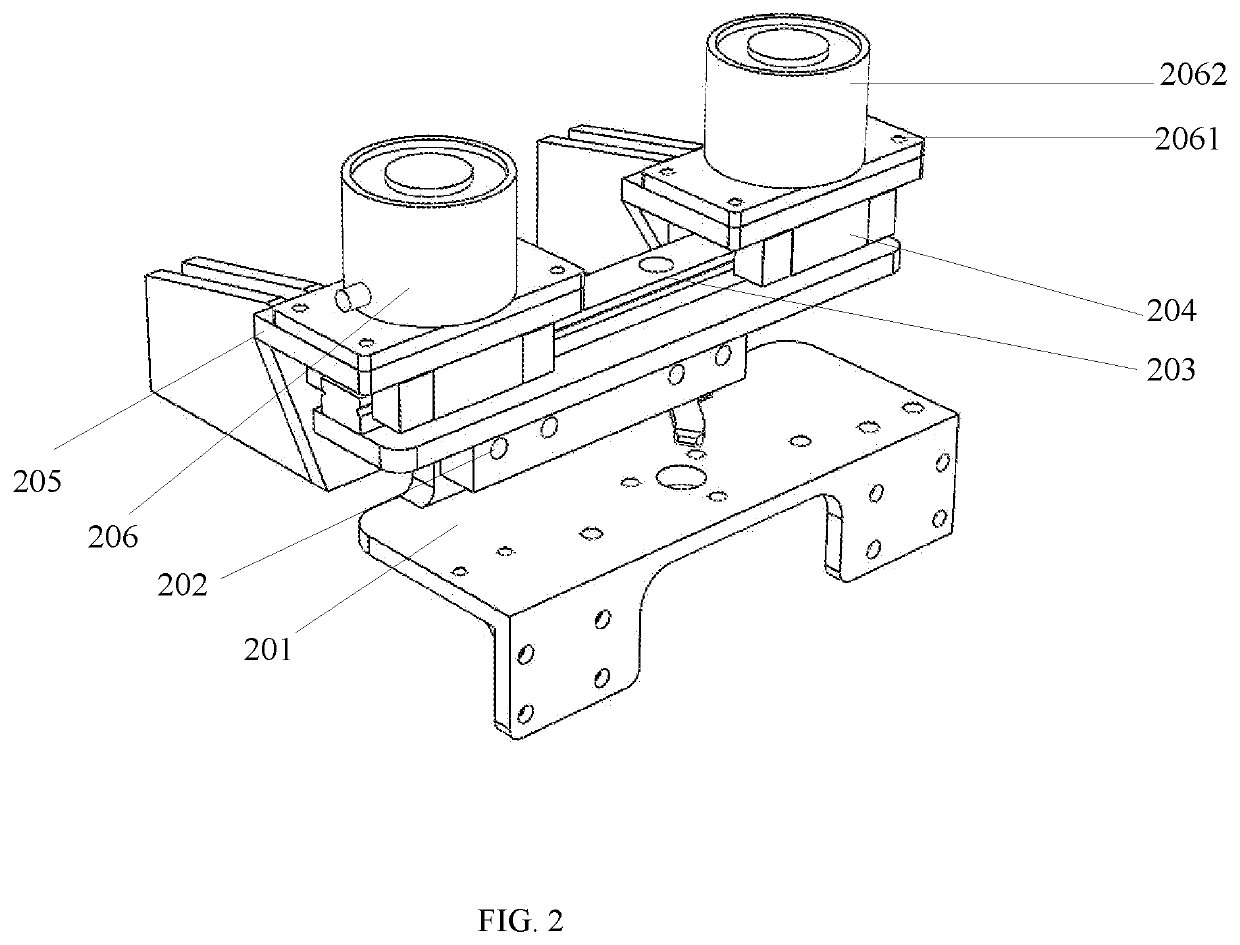

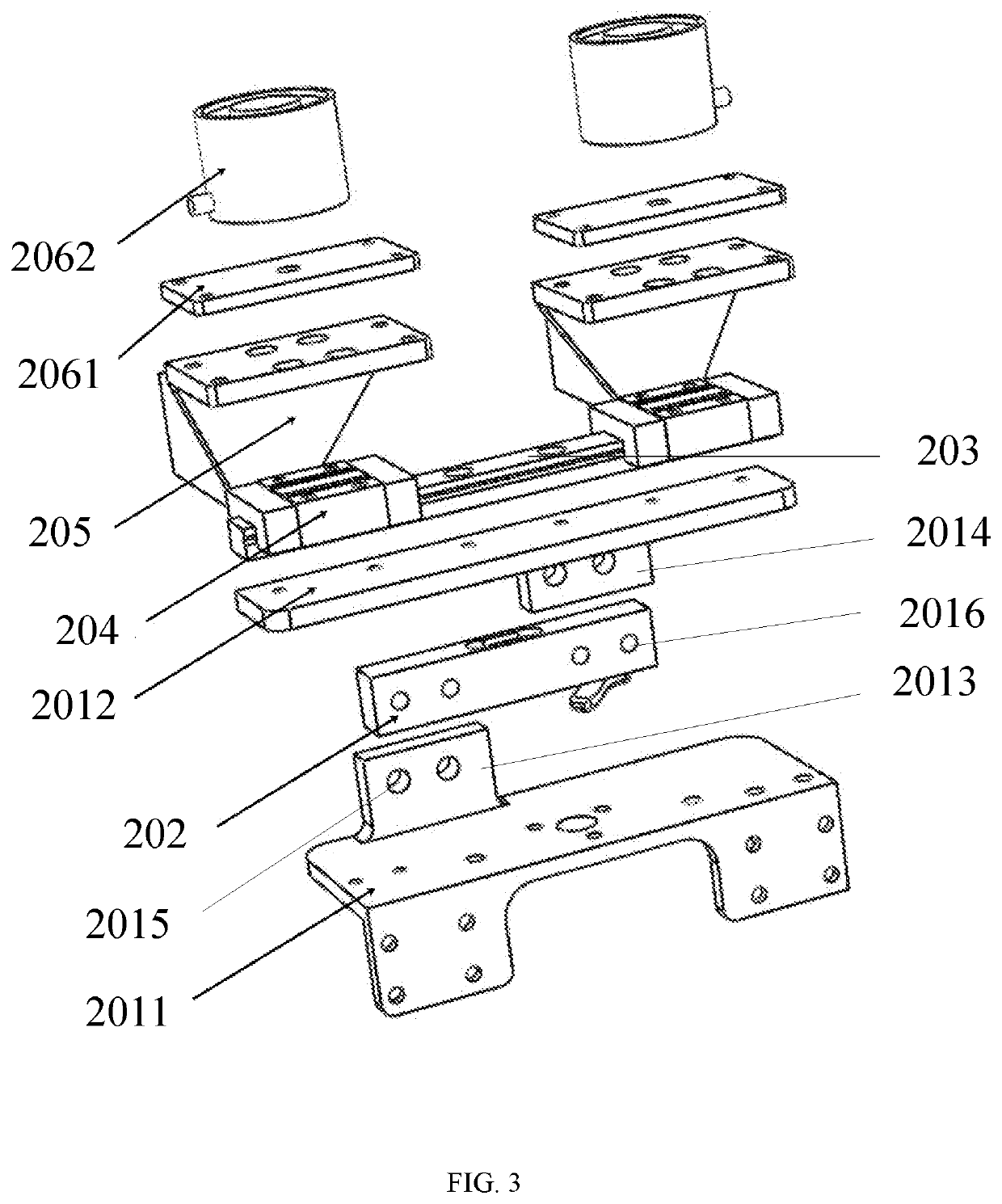

Combination driving-type compound die mechanism of full electric injection molding machine

The invention relates to a combination driving-type compound die mechanism of a full electric injection molding machine, belonging to the field of compound die mechanism, comprising an external synchronous belt, an adjusting screw nut, a conventional motor, a support plate, a pull rod, a toggle rod mechanism, a movable platen, a mould, a fixed die plate, a support angle, a screw thread crosshead, a servo motor, a screw-threaded draw bar and an internal synchronous belt. The compound die mechanism adopts combination drive principle to design, and the power source is the servo motor and the conventional motor. Output motion of the servo motor, linear motion of the support plate and output motion generated by the conventional motor, linear motion of the supporting angle are synthesized through a toggle rod mechanism of two degrees of freedom to generate programmable output motion. The system combines the advantages of a traditional mechanical system and a total servo electromechanical system, can realize flexible output motion, has the characteristics of high loading capacity, rapid operational speed and low cost.

Owner:BEIJING UNIV OF CHEM TECH +1

Clamping device and method for controlling clamping force on workpiece through linear motor

PendingCN113500621AHigh Precision Motion ControlImprove motor controlGripping headsElectric machineControl cell

The invention discloses a clamping device and method for controlling the clamping force on a workpiece through a linear motor. The clamping device comprises a base, the linear motor, a telescopic rod, a control unit, a transmission mechanism and a clamping jaw mechanism; the clamping jaw mechanism comprises friction force sensing jaws and mechanical clamping jaws, and friction force sensors are arranged on the contact faces of the friction force sensing jaws and the workpiece; the linear motor is connected with the telescopic rod; and the control unit sends an electric signal, the linear motor drives the telescopic rod to move, and then the transmission mechanism is driven to control opening and closing of the clamping jaw mechanism. According to the clamping device, the friction force sensing jaws are in contact with the workpiece, so that the friction force sensors sense vertical friction force generated when the workpiece is in contact with the friction force sensing jaws; and the friction force sensors process and judge the vertical friction force and feeds back the vertical friction force to a CPU, the CPU controls a driving signal of the linear motor and enables the clamping device to provide clamping force according to the friction force generated by relative sliding between the contact faces of the mechanical clamping jaws and the workpiece, and accurate control over the clamping force is achieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

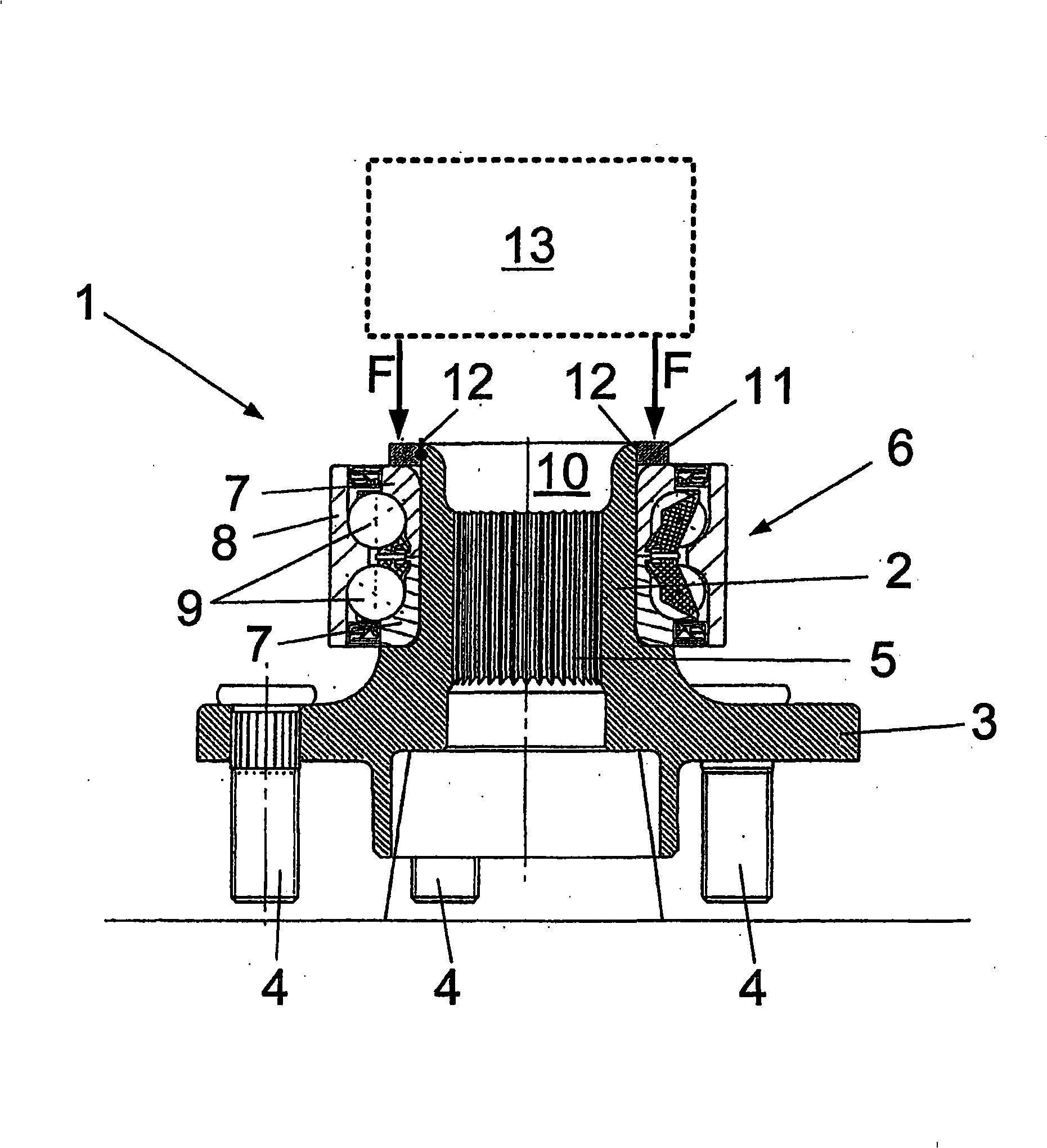

Bearing unit, preferably, wheel bearing unit for a motor vehicle, and method for producing a bearing unit

InactiveCN101287919AReduce radiation exposureGood focusabilityRolling contact bearingsBearing assemblyRolling-element bearingEngineering

The invention relates to a bearing unit, preferably, a wheel bearing unit (1) for a motor vehicle, comprising a hub (2) provided with a wheel-sided securing flange (11), whereon an angular contact anti-friction bearing (6), which comprises at least one inner ring (7) and an outer ring (8), is arranged. In order to produce the bearing unit (1) and to operate it in an economical manner, and also to prevent, for example, deformation and tensions characteristic of known roller riveting units, the securing flange (3) is connected in a material fit to the flange ring (11) in relation to the end (10) of the hub (2), which clamps at least the inner ring (7) to the hub (2).; The invention also relates to a method for producing a bearing unit (1), preferably, a wheel bearing unit for a motor vehicle, comprising a hub (2) which is provided with a wheel-sided securing flange (3) whereon an angular contact anti-friction bearing (6) comprising at least one inner ring (7) and an outer ring (8), is arranged, by means of a device (13) which exerts a clamping force (F) on the bearing unit (1).

Owner:SCHAEFFLER KG

An engine cylinder head turning device

The invention relates to an engine cylinder head overturning device, which includes a mounting frame, and two opposite clamping mechanisms that can precisely control the length for clamping the engine cylinder head are slidingly arranged inside the mounting frame. The side of the clamping mechanism is provided with an overturning mechanism for rotating the clamping mechanism, which can precisely control the overturning angle. The present invention installs a worm at the front end of the first motor, drives the main rod to move through the rotation of the worm, realizes the precise control of the moving length of the main rod, makes the clamping force of the main rod to the engine cylinder head more accurate, and avoids the Too much or too little movement of the main rod will cause unnecessary damage to the engine cylinder head and insufficient clamping force. The present invention also sets two sets of gear sets with different numbers of teeth, and realizes the fineness of different rotation angles through different gears. The control is used to deal with processing devices in different directions and different needs, so as to facilitate the repair and processing of corresponding processing devices.

Owner:WUHU DINGHENG MATERIAL TECH

Electronic part clamp

InactiveCN110883717AAvoid damageAvoid pinchingWork holdersApparatus for force/torque/work measurementEngineeringStructural engineering

An electronic part clamp comprises a bottom plate and two stand columns fixedly connected to the left side and the right side of the upper portion of the bottom plate, and further comprises a plurality of pairs of horizontal electric push rods oppositely arranged in the longitudinal direction. The rod ends of each pair of horizontal push rods are oppositely arranged and fixedly connected with clamping plates, and bases at the rod ends of each pair of horizontal push rods are fixedly connected with the inner side faces of the two stand columns respectively. A pressure sensor is installed on theinner side face of one of the two clamping plates on each pair of horizontal push rods in an attached mode, and each pressure sensor is correspondingly provided with a pressure display instrument, wherein the pressure display instruments are installed on the stand columns. The clamp can effectively fix an electronic product part and can prevent the electronic product part from being damaged by clamping.

Owner:徐州鸿杰电子有限公司

A Calculation Method of Target Clamping Force of Metal Belt Continuously Variable Transmission Based on Reserved Clamping Force

ActiveCN108361367BAccurate calculationAccurate calculation of pulley clamping forceGearing controlEngineeringMechanical engineering

The invention discloses a metal belt-type stepless transmission target clamping force calculation method based on reserved clamping force. The method comprises the steps that according to formulas, the minimum target clamping force F<pri> of a driving belt wheel and the minimum target clamping force F<sec> of a driven belt wheel are calculated; and then according to the current target speed ratioand the corresponding clamping force ratio, the driven belt wheel target clamping force F<sec_KPKS> corresponding to the driving belt wheel and the driving belt wheel target clamping force F<pri_KPKS>corresponding to the driven belt wheel are calculated.

Owner:JILIN UNIV

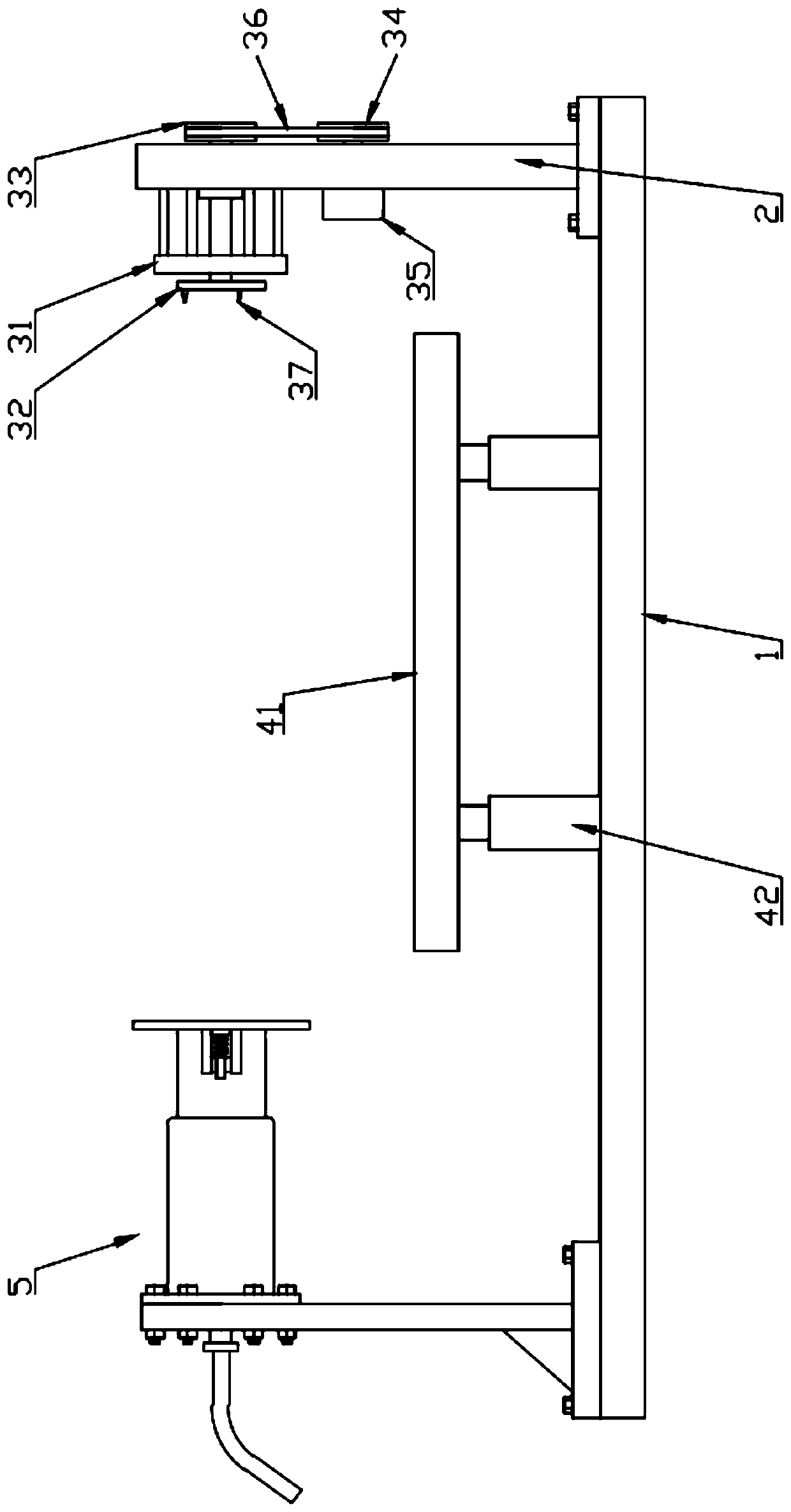

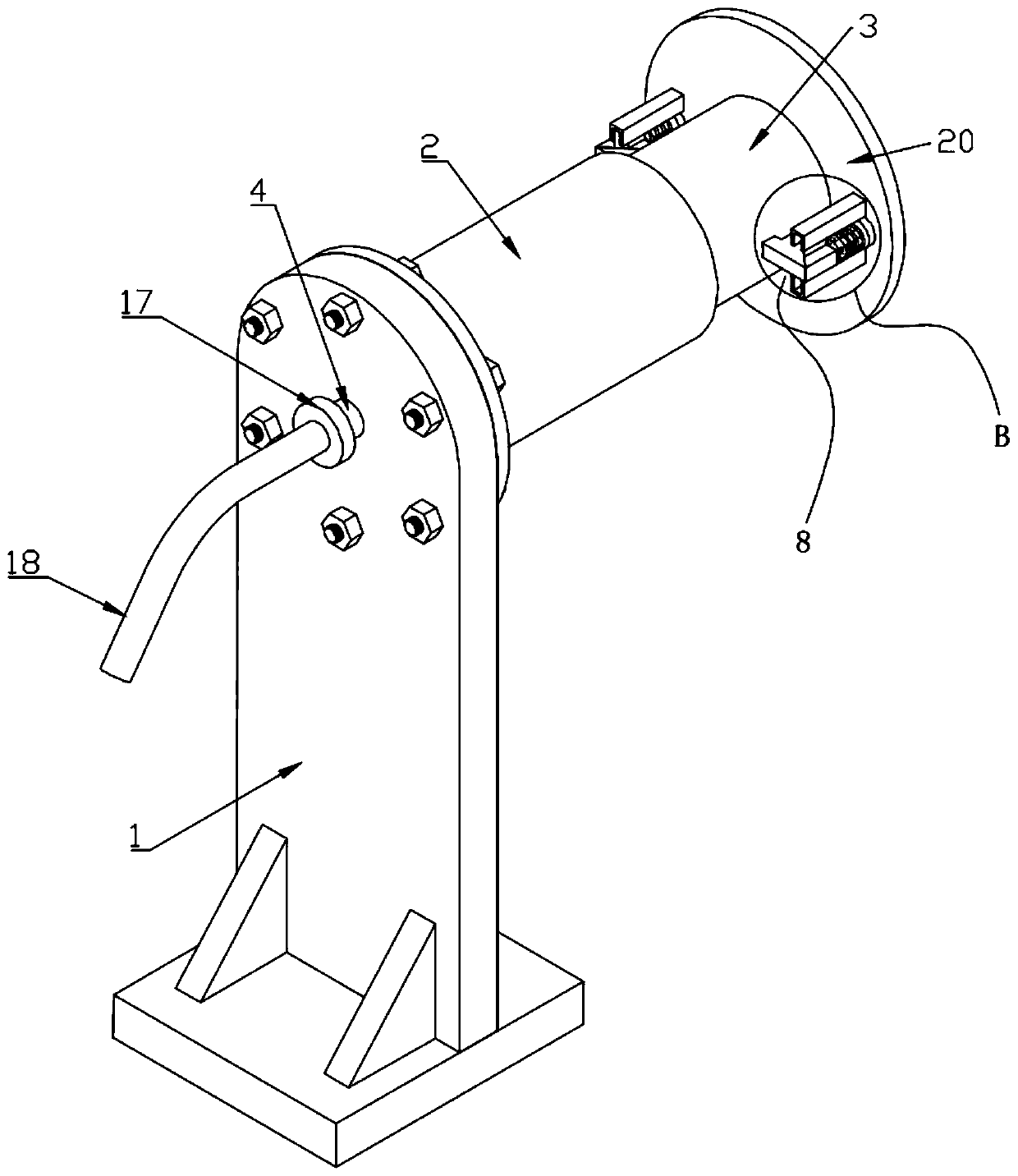

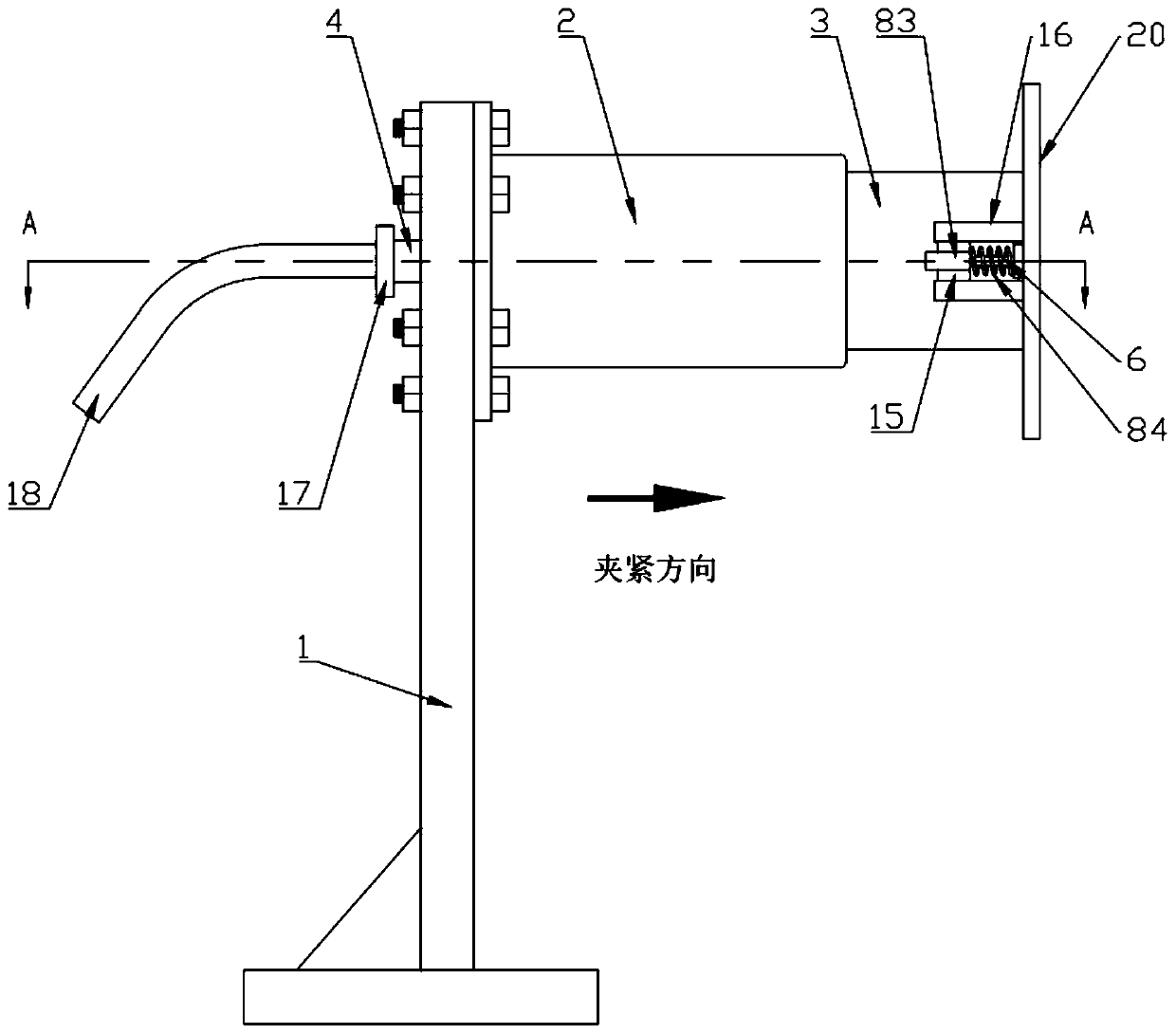

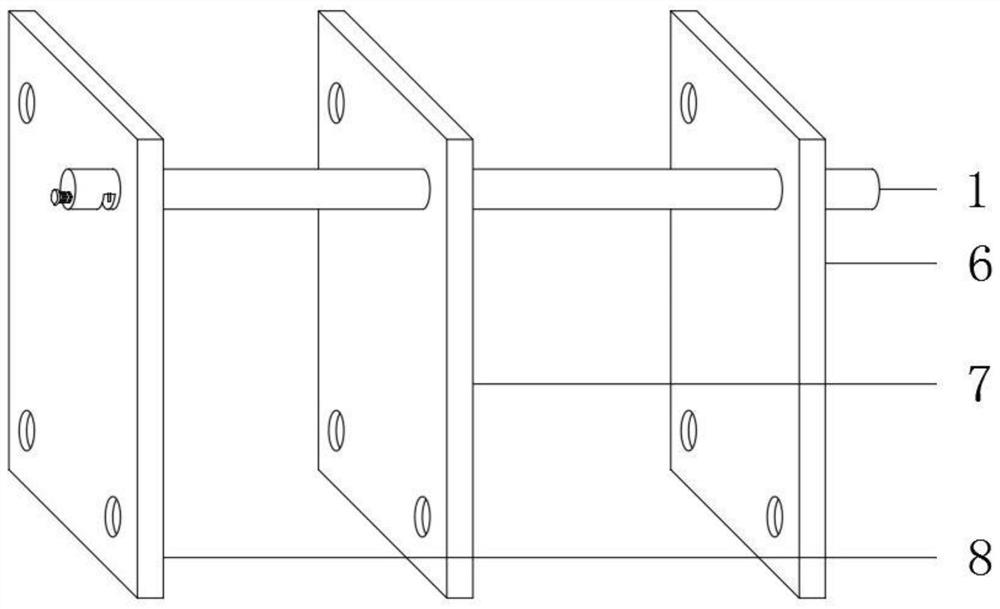

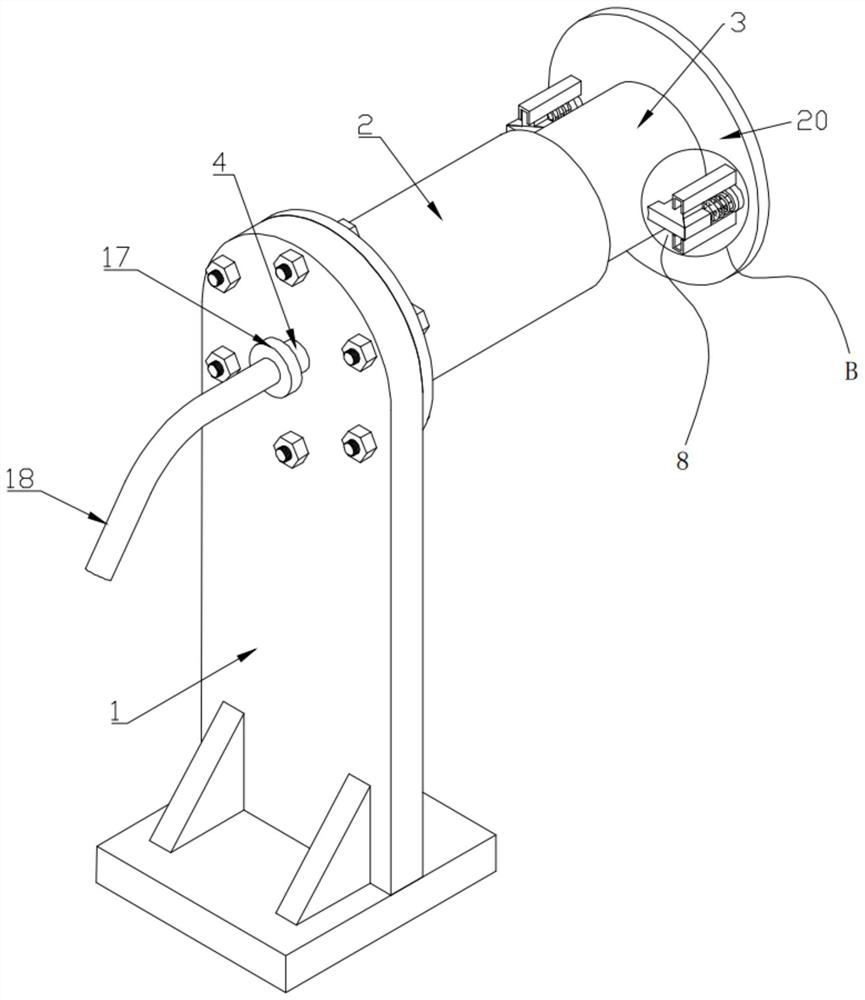

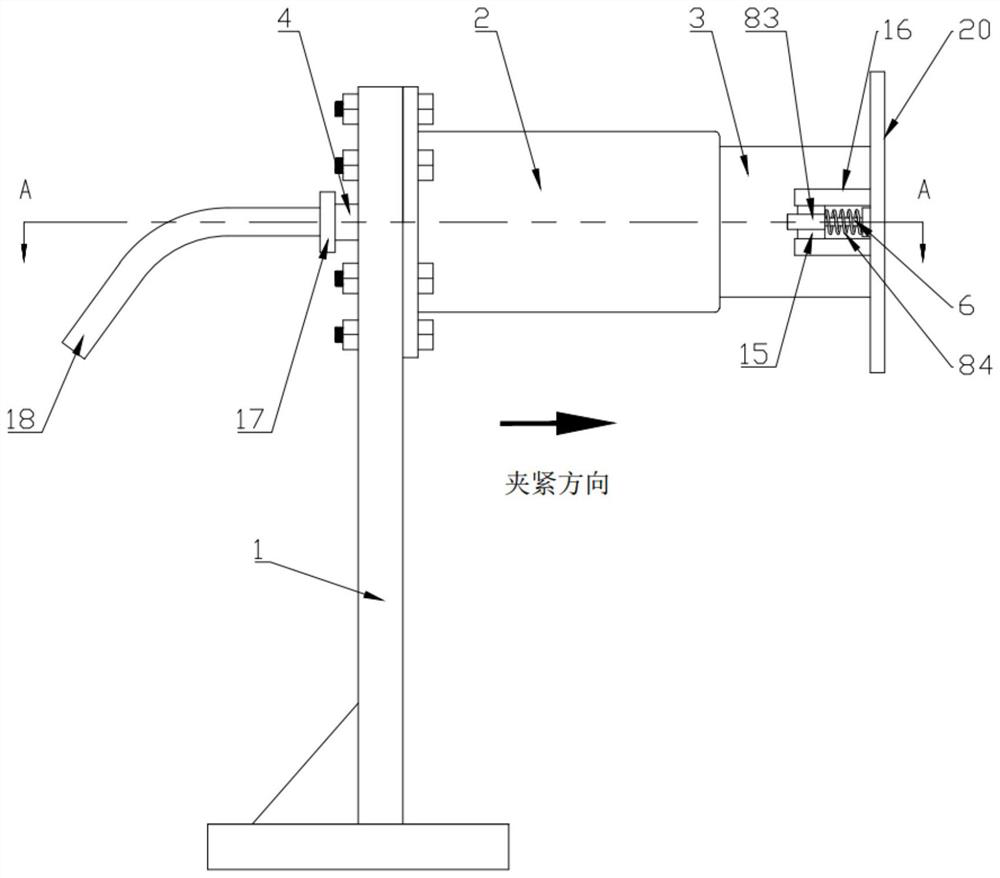

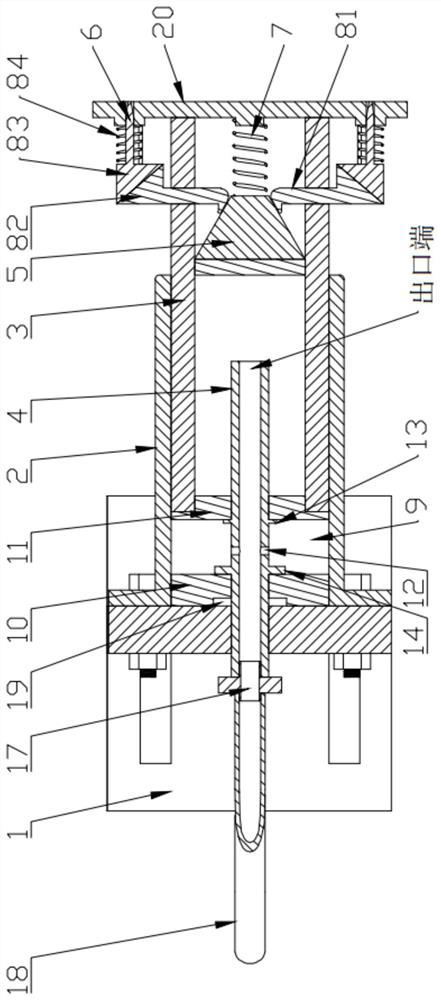

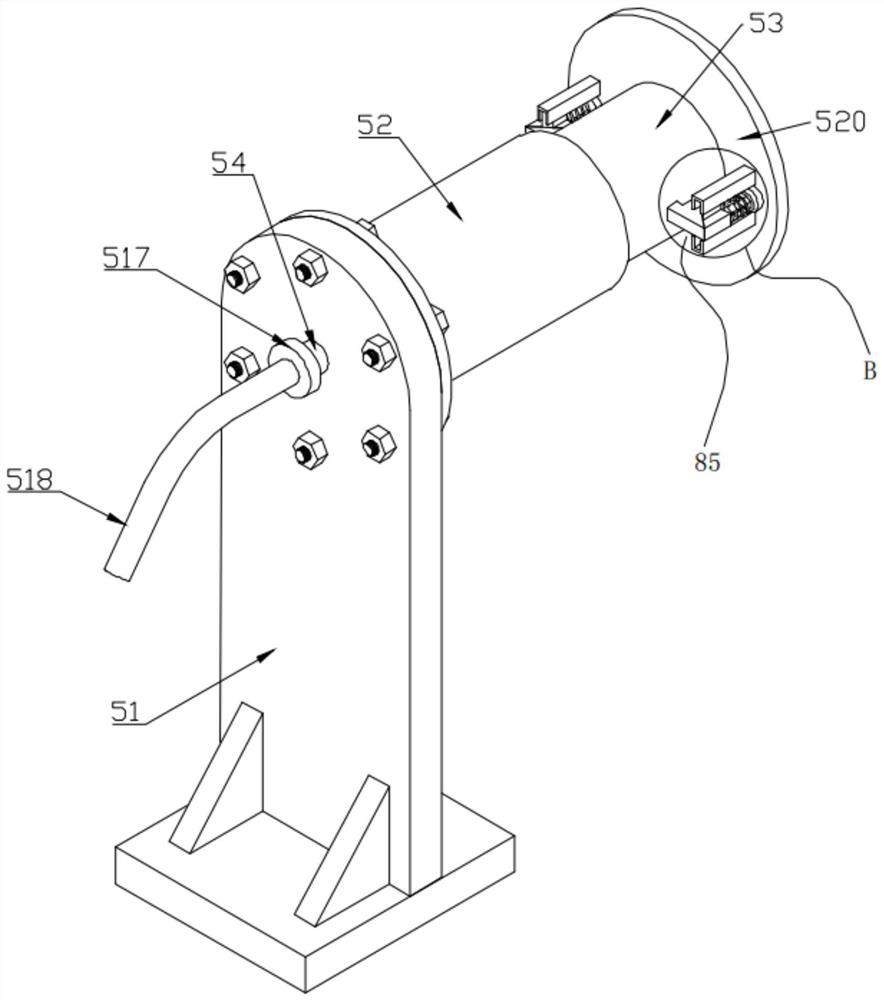

Positioning mechanism for agricultural and forestry large-dimension round timber processing

ActiveCN110843048APrecise positioningSave human effortMulti-purpose machinesTree debarkingAgricultural scienceAgricultural engineering

The invention discloses a positioning mechanism for agricultural and forestry large-dimension round timber processing, and relates to the technical field of wood processing. The positioning mechanismcomprises a bearing frame, an outer sleeve, an inner sleeve, a liquid inlet tube, a piston, an ejector pin and a drive mechanism. Clamping and positioning for one end of wound timber is realized through a way of fixing the bearing frame and moving the inner sleeve; compared with a conventional tail base positioning way, the positioning mechanism does not need to manually shake a rocker handle to realize movement of the tail base, and can realize positioning by only needing to introducing in hydraulic oil, so that a positioning process is simplified, and labor power is saved; meanwhile, a top plate is firstly in contact with the round timber, the round timber is locked by the ejector pin, and is finally pressurized until pressure achieves a set value, so that clamping and positioning of theround timber are realized, and clamping force is more precise; and meanwhile, a rotation condition, caused by too great torque, of the round timber is further prevented.

Owner:芜湖文青机械设备设计有限公司

Novel tiebar on injection molding machine

The invention discloses a novel tiebar on an injection molding machine. The tiebar comprises tiebar bodies, limiting rings are fixed to the tops of the left ends of the tiebar bodies, permanent magnets are arranged at the left ends of the limiting rings, fixing grooves are formed in the bottoms of the ends, away from the limiting rings, of the tiebar bodies, the left end faces of the tiebar bodies are in threaded connection with fixing bolts, mold adjusting plates are arranged at the ends, close to the limiting rings, of the tiebar bodies, movable mold plates are arranged on the sides, away from the limiting rings, of the mold adjusting plates, fixed mold plates are arranged on one sides of the movable mold plates, fixing assemblies are arranged on the right sides of the fixed mold plates, positioning assemblies are arranged on the sides, close to the limiting rings, of the mold adjusting plates, the right end faces of the fixing bolts are provided with clamping grooves, and fixing and locking assemblies are arranged at the tops of the fixing bolts. According to the novel tiebar on the injection molding machine, by arranging the fixing and locking assemblies, the situation that the fixing bolts are loosened after long-time use can be prevented; and through positioning holes, a touch switch and an indicator lamp, whether the tie bar bodies are fixed to the mold adjusting plates or not can be strikingly displayed.

Owner:广东力劲塑机智造股份有限公司

A Greenhouse Vegetable Seedling Cultivation and Transplanting Machine

The invention discloses a transplanter for greenhouse vegetable seedlings. The transplanter comprises a mechanical arm (1), a mechanical hand (2) and an automatic feeding system; the automatic feeding system comprises a seedling conveying device (3), a steering device (4), an empty tray recovering device (5), a seedling receiving device (6) and a protective pedal (7), wherein the seedling conveying device (3) is connected with the empty tray recovering device (5) through the steering device (4), the mechanical arm (1) is arranged above the seedling conveying device (3), the mechanical hand (2) is installed on the mechanical arm (1), the seedling receiving device (6) is arranged below the seedling conveying device (3), and the protective pedal (7) is arranged above the seedling receiving device (6). The greenhouse vegetable seedlings can be automatically transplanted through the transplanter, the transplanter is used for automatically conveying and receiving the seedlings, collecting seedling trays and conveying planting floating plates in the transplanting process of the greenhouse vegetable seedlings, the transplanting operation is not limited by manual seedling feeding speed and intensity any more, and the production efficiency of greenhouse vegetables is substantially improved.

Owner:WENZHOU UNIVERSITY +1

System and method for automatically regulating clamping force of motor-driven injection molding machine

The invention discloses a system for automatically regulating the clamping force of a motor-driven injection molding machine. The system is characterized in that four draw bars penetrate through a static template, a movable template and a rear template, and the static template is fixed on the draw bar; a five-point toggle mechanism is connected between the movable template and the rear template, and the crosshead thereof penetrates through the rear template and is sleeved outside a ball screw; the ball screw is driven by a spotting motor; the rear template is connected with the four draw bars through four regulating nuts; a bearing is arranged between each regulating nut and the rear template; the peripheries of the regulating nuts are provided with gear teeth; a rack wheel is arranged at the neutral position of the four regulating nuts and is meshed with the gear teeth of the four regulating nuts; the crosshead of the five-point toggle mechanism and the ball screw pass through the center of the rack wheel; the output gear of a mold-adjustment motor is meshed with the rack wheel; and the mold-adjustment motor is connected with an injection molding machine control system. The invention also aims at providing a method for automatically regulating the clamping force of a motor-driven injection molding machine. The invention has the advantages that the mold-adjustment accuracy is high.

Owner:SOUTH CHINA UNIV OF TECH

Clamping device for off-line detection of motor gearbox of new energy automobile

PendingCN114367932AOff-line detection is beneficialAvoid interferenceMachine gearing/transmission testingWork holdersNew energyElectric machinery

The invention provides a clamping device for off-line detection of a motor gearbox of a new energy automobile, and relates to the technical field of off-line detection of motor gearboxes. The clamping device for off-line detection of the motor gearbox of the new energy automobile comprises a mounting plate, and a fixed clamping plate and a movable clamping plate which are arranged in a matched mode are arranged above the mounting plate; the fixed clamping plate is fixedly connected with the upper surface of the mounting plate, and the movable clamping plate is slidably connected with the upper surface of the mounting plate; the opposite faces of the fixed clamping plate and the movable clamping plate are fixedly connected with an output shaft positioning sleeve used for positioning an output shaft of the gearbox, and the opposite faces of the fixed clamping plate and the movable clamping plate are rotationally connected with a rotating ring through a plane bearing. And the opposite surfaces of the movable clamping plate and the fixed clamping plate are rotationally connected with a mounting disc which is concentric with the rotating ring. The clamping device for off-line detection of the motor gearbox of the new energy automobile has the advantage of being small in use limitation.

Owner:江苏惠博机电科技股份有限公司

A positioning mechanism for processing large-size logs for agriculture and forestry

ActiveCN110843048BPrecise positioningSave human effortTree debarkingMulti-purpose machinesAgricultural scienceCrank

The invention discloses a positioning mechanism for processing large-size logs used in agriculture and forestry, which relates to the technical field of wood processing and includes a support bracket, an outer sleeve, an inner sleeve, a liquid inlet pipe, a piston, a thimble and a driving mechanism. The support bracket is fixed, and the inner sleeve moves to realize the clamping and positioning of one end of the log. Compared with the traditional tailstock positioning method, there is no need to manually shake the handle to realize the movement of the tailstock, only need to pass in hydraulic oil It can be realized, which simplifies the positioning process and saves manpower. At the same time, the top plate first contacts the log, then locks it with the thimble, and finally pressurizes until the pressure reaches the set value to realize the clamping and positioning of the log. The clamping force is more precise, and it also prevents the log from turning due to excessive torque.

Owner:芜湖文青机械设备设计有限公司

A sample fixture for pipe or bar for tensile test

ActiveCN105388062BGuaranteed to be used correctlySolving special problems with test gripsInvestigating material ductilityTensile testingConical surface

The invention discloses a specimen holder of a tube or a bar for a tension test. The specimen holder comprises a tension handle, a locking part, a holding seat and a holder body, wherein the holder body comprises a cylinder body and a circular truncated cone body which are integrally formed; the maximum external diameter of the circular truncated cone body is greater than the external diameter of the cylinder body; the whole circular truncated cone body is provided with at least two grooves along the axial direction, and the two grooves are used for segmenting the circular truncated cone body into holding blocks; a holding part for holding a test specimen is arranged on the inner surface of each clamping block; the holding seat sleeves the outside of the holder body and is connected with the holder body in a matching way; the holding seat is provided with a first conical surface matched with the circular truncated cone body; the front end of the locking part is connected with the holding seat through a spiral structure; the tension handle is connected with the rear end of the locking part. The specimen holder disclosed by the invention is small in size, convenient in disassembly and assembly and uniform and reliable in holding force; the specimen holder realizes automatic centering in a clamping process, is uniform, quick and reliable in clamping, and is particularly suitable for being used in a high-low temperature environmental cabinet with compact structure and small space.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Combination drive type mould clamping mechanism of all-electric injection molding machine

The invention relates to a combination drive type mould clamping mechanism of an all-electric injection molding machine, belonging to the field of mould clamping mechanisms of injection molding machines. The combination drive type mould clamping mechanism of the all-electric injection molding machine comprises mould adjusting nuts, a conventional motor, a support plate, a pull rod, a toggle mechanism, a dynamic mould plate, a mould, a fixed mould plate, a supporting angle, a hinge sleeve, a servo motor, an externally synchronous belt, a threaded screw rod, a threaded crosshead and an internally synchronous belt. The combination drive type mould clamping mechanism is designed by adopting a combination drive principle, and a power source of the combination drive type mould clamping mechanism is the servo motor and the conventional motor; the combination drive type mould clamping mechanism combines input motions generated by the servo motor and the conventional motor through a two-degree of freedom toggle mechanism and then generates programmable output motions; the system combines the advantages of the traditional mechanical system and a full-server electromechanical system, can realize the flexibility of the output motion and has high carrying capacity, fast operation and low cost.

Owner:BEIJING UNIV OF CHEM TECH +1

A Pneumatic Gripper Device with Sensor Control

The invention relates to the field of automatic control of weighing sensor production, in particular to a pneumatic clamp device with sensor control. A pneumatic clamping device with sensor control, comprising a lower base plate and an upper base plate, the lower base plate and the upper base plate are connected by a column, an air cylinder is installed on the upper base plate, and the piston rod of the air cylinder passes through the A top plate is connected behind the upper bottom plate, a sensor for measuring the clamping force of the clamped object is arranged on the lower bottom plate, and a pressure plate for placing the clamped object is arranged on the sensor. The invention has high production efficiency and low cost, and is beneficial to mass production of sensors.

Owner:KELI SENSING TECH NINGBO CO LTD

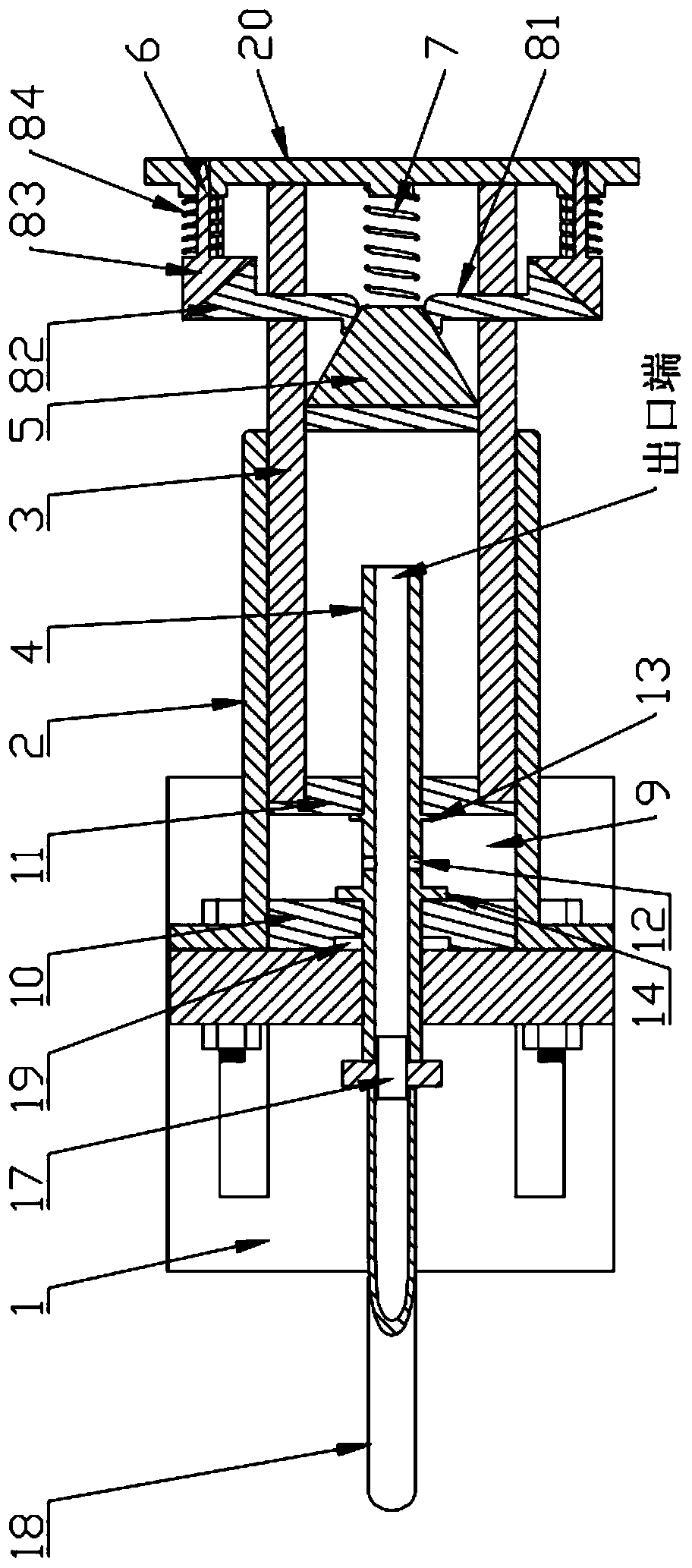

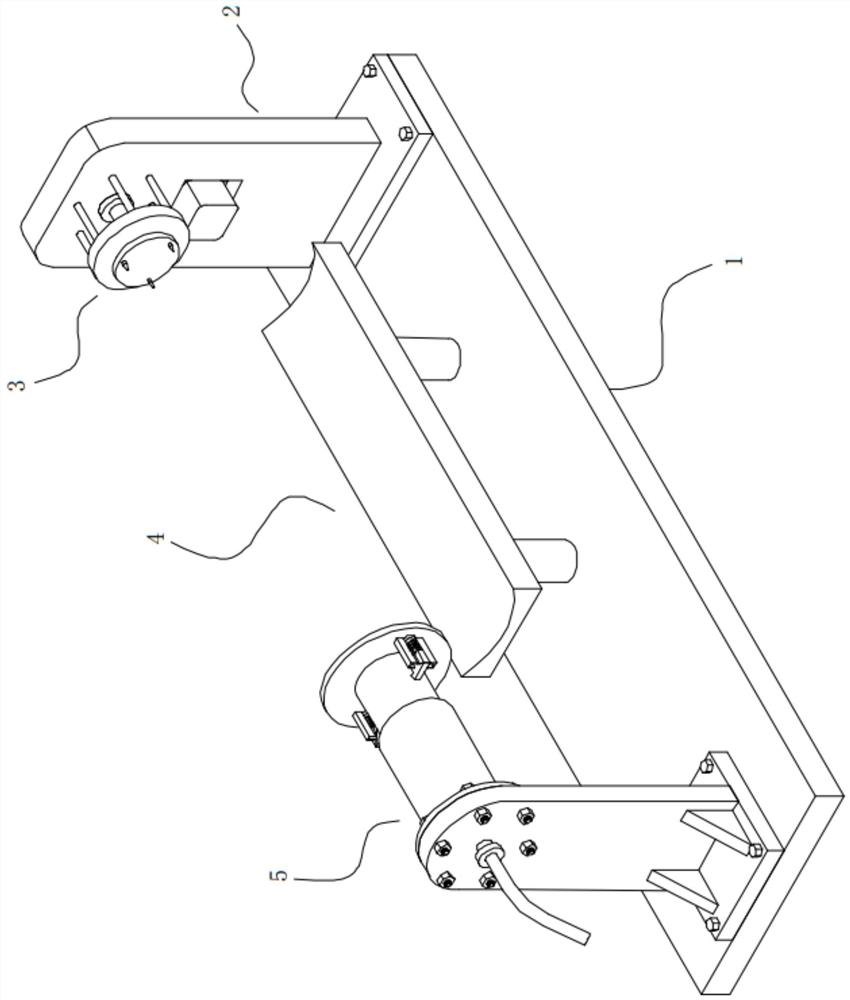

Guide wire clamping force controlling device and method for interventional surgical robot

PendingUS20220133421A1Precise clamping forceImprove performanceDiagnosticsSurgical manipulatorsPhysical medicine and rehabilitationSurgical robot

A guide wire clamping force controlling device and a method for an interventional surgical robot are disclosed. The controlling device includes a driving end, two sides of which are respectively connected with a driving part, and the two driving parts synchronously drive the driving end to move forward or backward along a direction perpendicular to the advancing direction of the vertical guide wire. The driven end includes a connecting plate, a high-precision weighing sensor, a driven end micro liner rail, a driven end slider, a driven end connecting member and a passive thread rolling part. The high-precision weighing sensor is fixed on the side of the connecting plate which is close to the guide wire, and the driven end micro liner rail is fixed on the top side.

Owner:BEIJING WEIMAI MEDICAL EQUIP CO LTD

A large-size log processing equipment for agriculture and forestry

ActiveCN110712254BAchieve axial positioningPrecise positioningMulti-purpose machinesGrinding work supportsAgricultural scienceAgricultural engineering

The invention discloses a large-size round log processing equipment for agriculture and forestry, which relates to the technical field of wood processing and includes a base, a frame, a power assembly, a lifting platform and a positioning mechanism, and the frame and the positioning mechanism are respectively installed at both ends of the base , the power assembly is installed on the frame, the power assembly cooperates with the positioning mechanism and drives the log to rotate around its axis, the lifting platform is installed between the frame and the positioning mechanism and is used to realize the loading and unloading of the log, The invention realizes the surface processing of large-size logs, that is, the drive motor drives the logs to rotate, the positioning mechanism cooperates with the drive plate to realize the axial positioning of the logs, and the bracket is fixed and the inner sleeve moves. The method realizes the clamping and positioning of one end of the log, which can be realized only by feeding hydraulic oil, which simplifies the positioning process, saves manpower, and the clamping force is more accurate. At the same time, it also prevents the rotation of the log due to excessive torque. .

Owner:芜湖文青机械设备设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com