A sample fixture for pipe or bar for tensile test

A sample fixture and tensile test technology, which is applied in the direction of testing the ductility of materials, analyzing materials, instruments, etc., can solve the problems of inability to disassemble and reuse, insufficient test force, uneven clamping force, etc., to improve clamping and Efficiency in disassembly, avoiding breakage in abnormal positions, uniform, fast and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

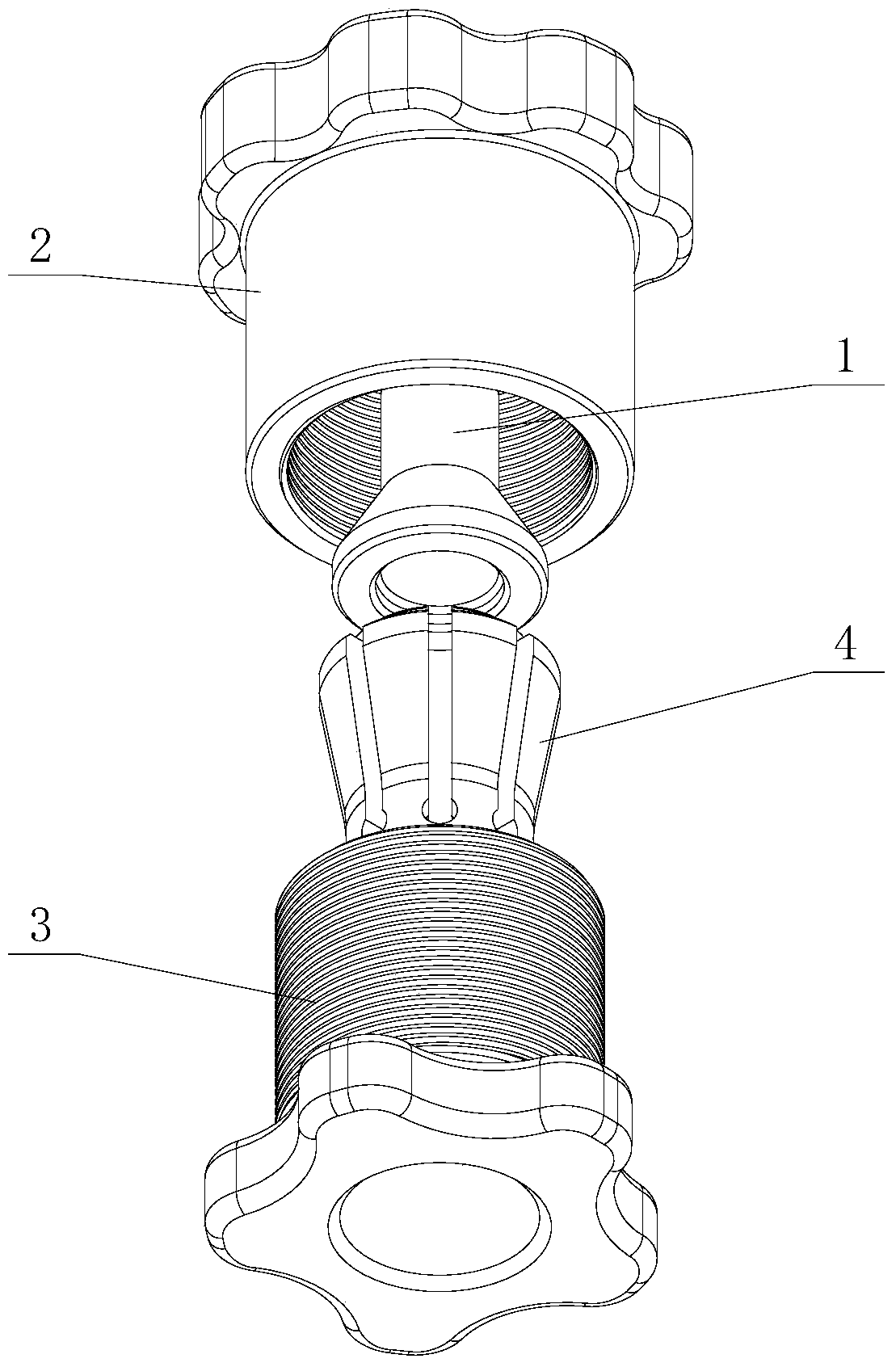

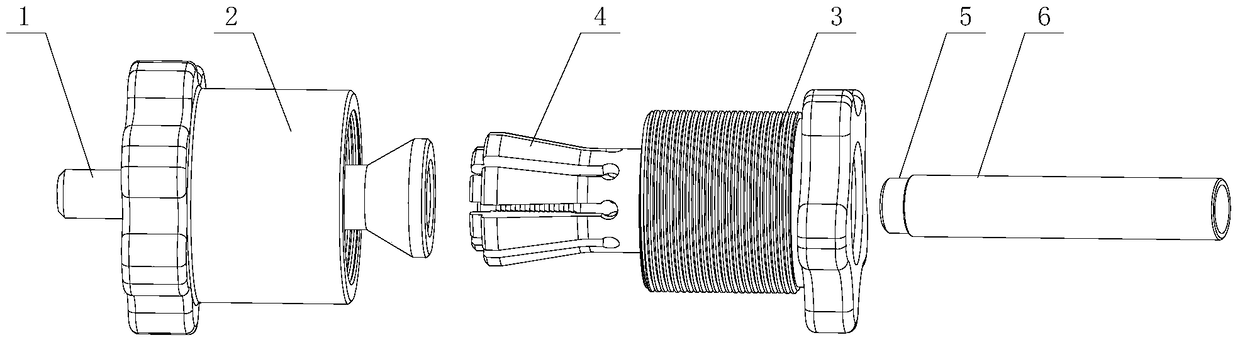

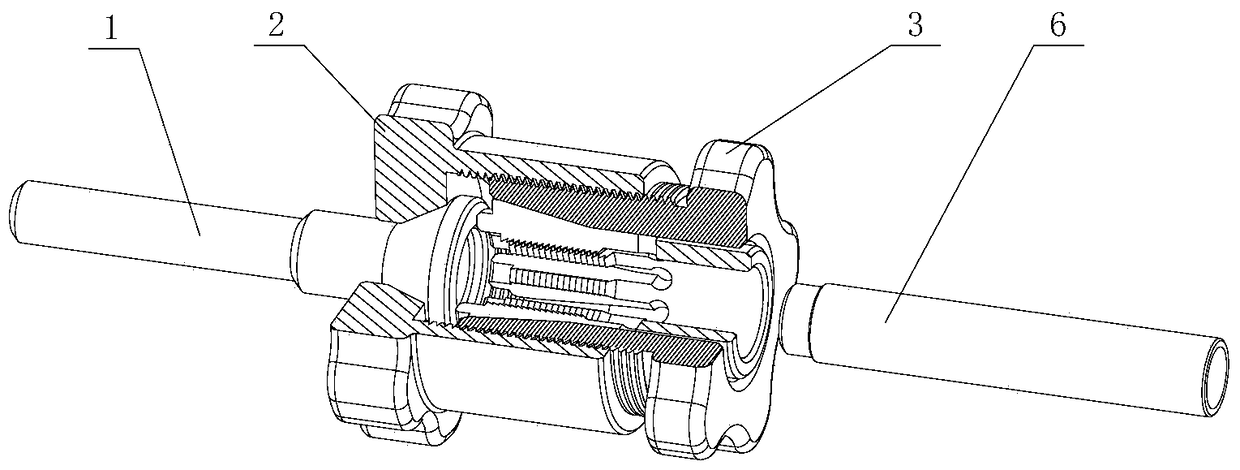

[0051] like figure 1 shown, combined with Figure 5-Figure 9 According to the embodiment of the present invention, a sample holder for a pipe or bar for a tensile test includes a tensile handle 1, a locking member 2, a clamping seat 3, and a holder 4, and the holder 4 is a hollow structure To allow the test piece sample 6 to be clamped therein, the holder 4 includes an integrally formed cylindrical body 41 and a conical body 42, the maximum outer diameter of the conical body 42 is greater than the outer diameter of the cylindrical body 41, the The whole body of the truncated cone 42 is provided with at least two grooves 43 in the axial direction, so as to divide the truncated cone 42 into clamping blocks 421, and the inner surface of the clamping block 421 has clamps for clamping the test piece sample 6. The holding part; the clamping seat 3 is sleeved on the outside of the clamper 4, and is connected with the clamping device. The clamping seat 3 has a first tapered surface 3...

Embodiment 2

[0070] like Figure 2-4 As shown, on the basis of Embodiment 1, a clamping core is also included, and the clamping core is embedded and installed at the clamping end of the sample sample to provide internal support for the sample sample to prevent the test sample from The sample is clamped and deformed.

[0071] Further, the clamping core and the test piece sample adopt transition fit or interference fit, which not only enables the clamping core to be fixed at the end of the test piece sample, but also effectively ensures that the test piece sample is clamped. When the holding force is applied, the shape of the specimen is kept unchanged.

[0072]Preferably, the end face of the umbrella structure 11 is provided with a circular concave portion 12, the diameter of the concave portion 12 is larger than the inner diameter of the test piece sample 6, and smaller than the outer diameter of the boss 422, so that the The clamping core 5 can be placed in the concave portion 12 , and ...

Embodiment 3

[0078] This embodiment provides a tensile test device, which includes the above-mentioned pipe or bar sample fixtures for tensile tests, preferably two sets of pipe or bar sample fixtures for tensile tests, and are installed centrally.

[0079] When in use, a set of pipe or bar sample clamps for tensile testing is used on both arms of the test equipment, that is, on both sides of the test piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com