Metal belt-type stepless transmission target clamping force calculation method based on reserved clamping force

A continuously variable transmission, metal belt technology, applied in the direction of elements with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of difficult testing and not the only clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

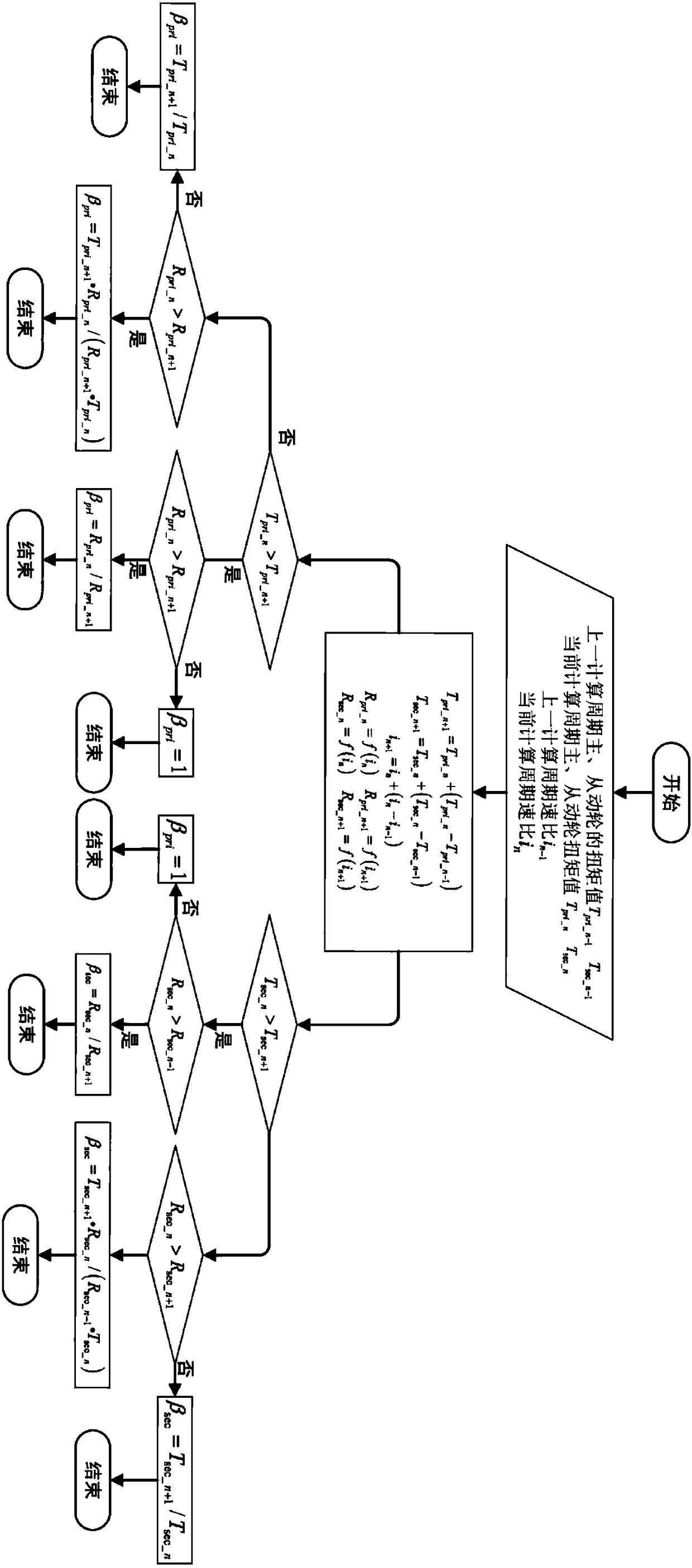

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0064] The invention provides a target clamping force calculation method, and the calculation method of the invention is applied to a metal belt type continuously variable transmission device.

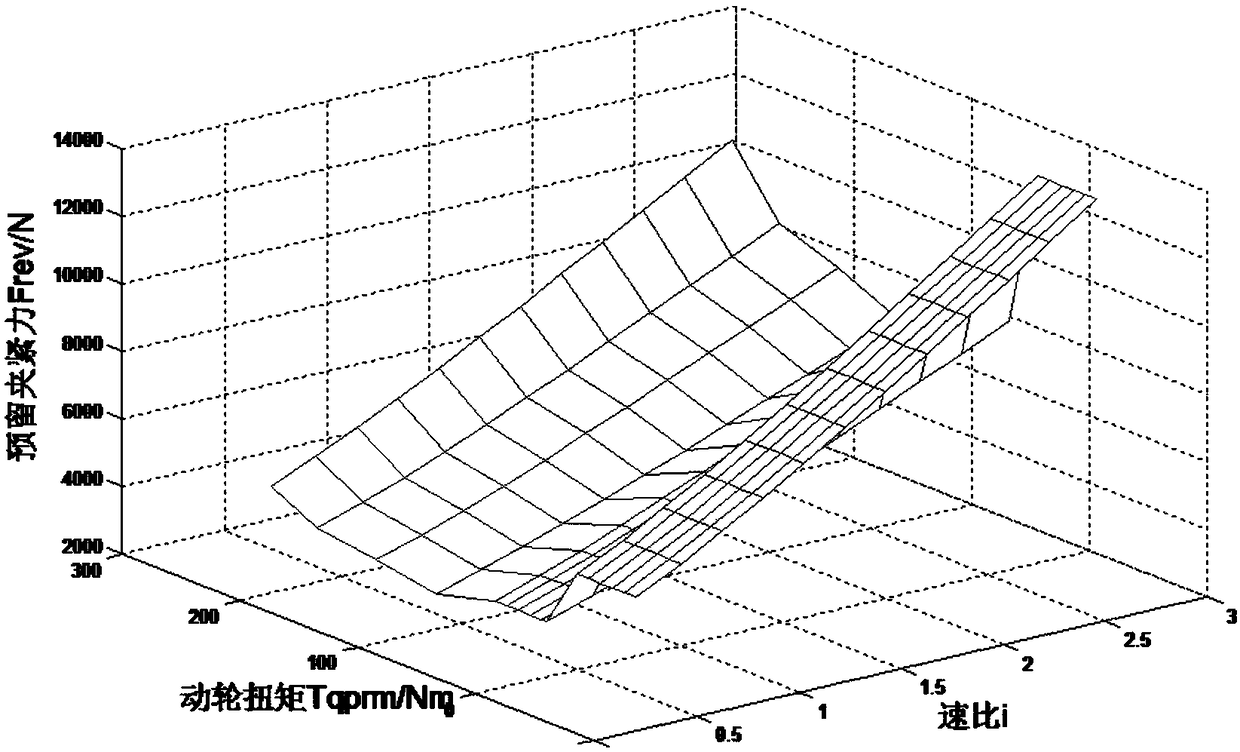

[0065] In the theoretical calculation process, under the premise of ensuring the safe transmission of torque, the required minimum clamping force is shown in formula (1).

[0066]

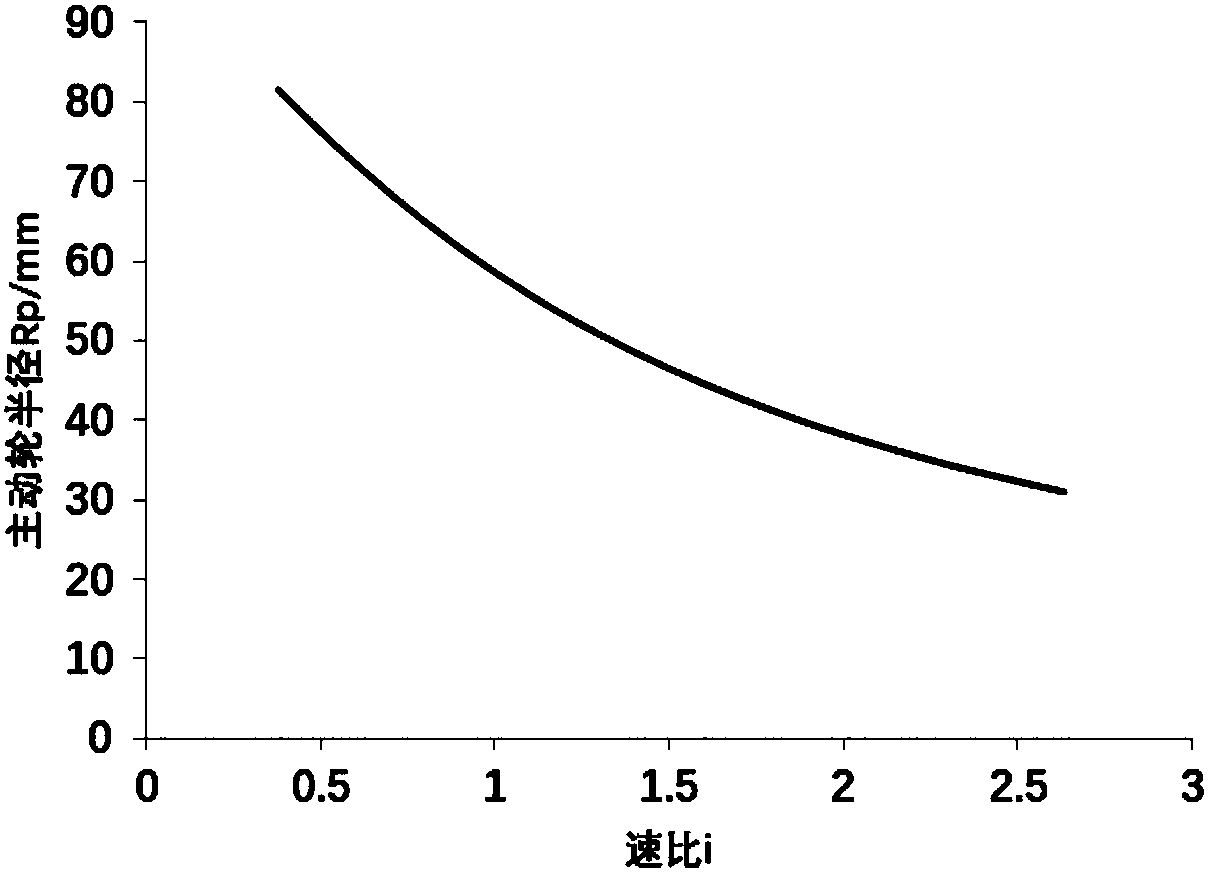

[0067] In the formula, F is the target clamping force of the pulley; T is the torque transmitted by the pulley; α is the half cone angle of the pulley; μ is the friction coefficient between the pulley and the metal belt; R is the working radius of the pulley.

[0068] Considering the anti-drag condition, the torque values in all the formulas in this paper are the absolute values of the torque.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com