Combination driving-type compound die mechanism of full electric injection molding machine

A technology of hybrid drive and mold clamping mechanism, applied in the field of mold clamping mechanism, can solve the problems of high oil circuit and sealing system requirements, difficult to change output characteristics, and high cost of servo motor, and achieve accurate mold clamping force, high speed, and saving. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing, the patent of the present invention is described in detail as follows:

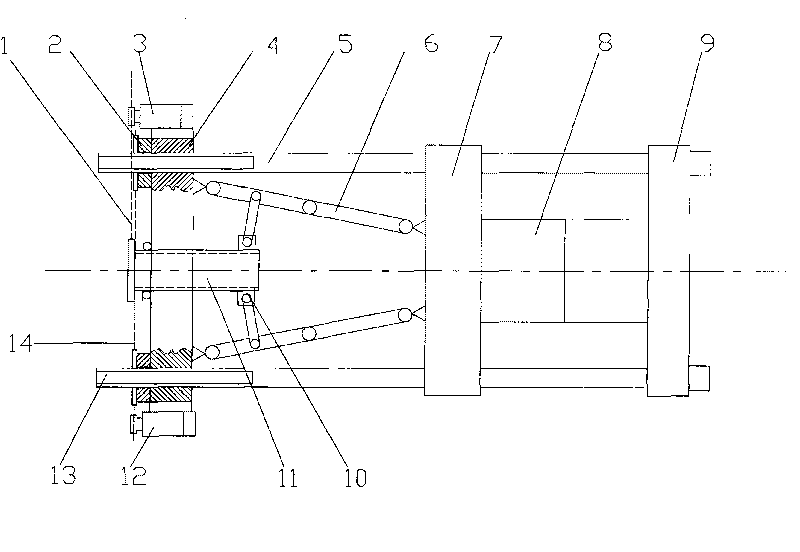

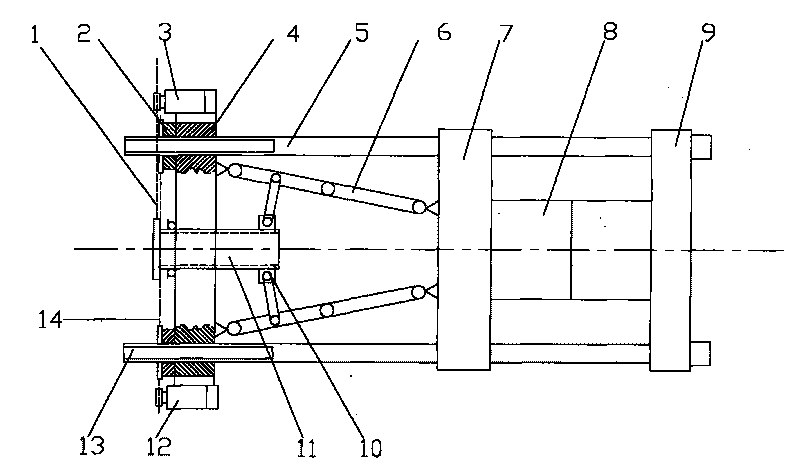

[0014] like figure 1 As shown, the present invention is a hybrid-driven mold clamping mechanism for an all-electric injection molding machine, including a toggle mechanism 6 , a support plate 4 , a tie rod 5 , a threaded crosshead 11 , an adjusting nut 2 , a moving platen 7 and a fixed platen 9 . There may be multiple tie rods 5, which are center-symmetrically distributed, i.e. diagonally symmetrical, triangularly symmetrical or other centrally symmetrical shapes. The support plate 4 is screwed to the threaded tie rod part 13, and the fixed template 9 is fixedly mounted on the tie rod 5. The movable template 7 is installed on the pull rod 5 and can move along the pull rod 5 . A threaded crosshead 11 is installed in the middle of the support plate 4, and the two are threaded. The conventional motor 3 acts on one end of the threaded crosshead 11 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com