Clamping device for off-line detection of motor gearbox of new energy automobile

A new energy vehicle and clamping device technology, applied in workpiece clamping devices, machine gear/transmission mechanism testing, manufacturing tools, etc. Increase the limitations of the device and other issues to achieve the effect of being conducive to off-line detection, reducing the probability of indentation or even failure, and reducing the probability of indentation or even damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

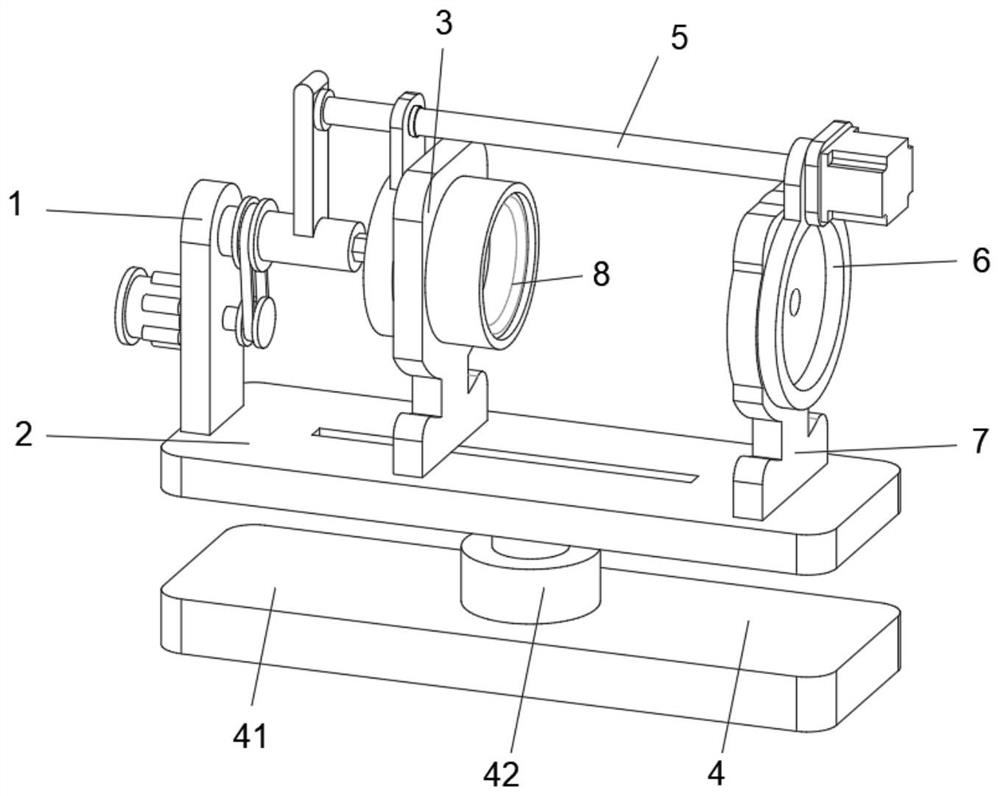

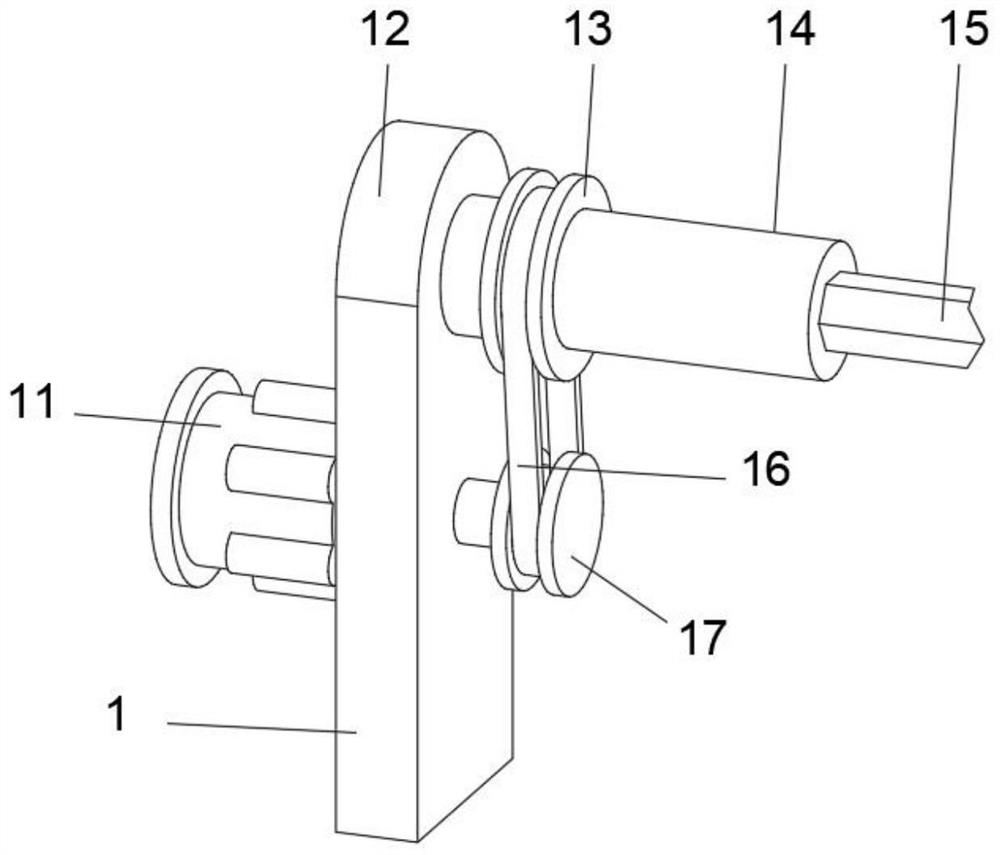

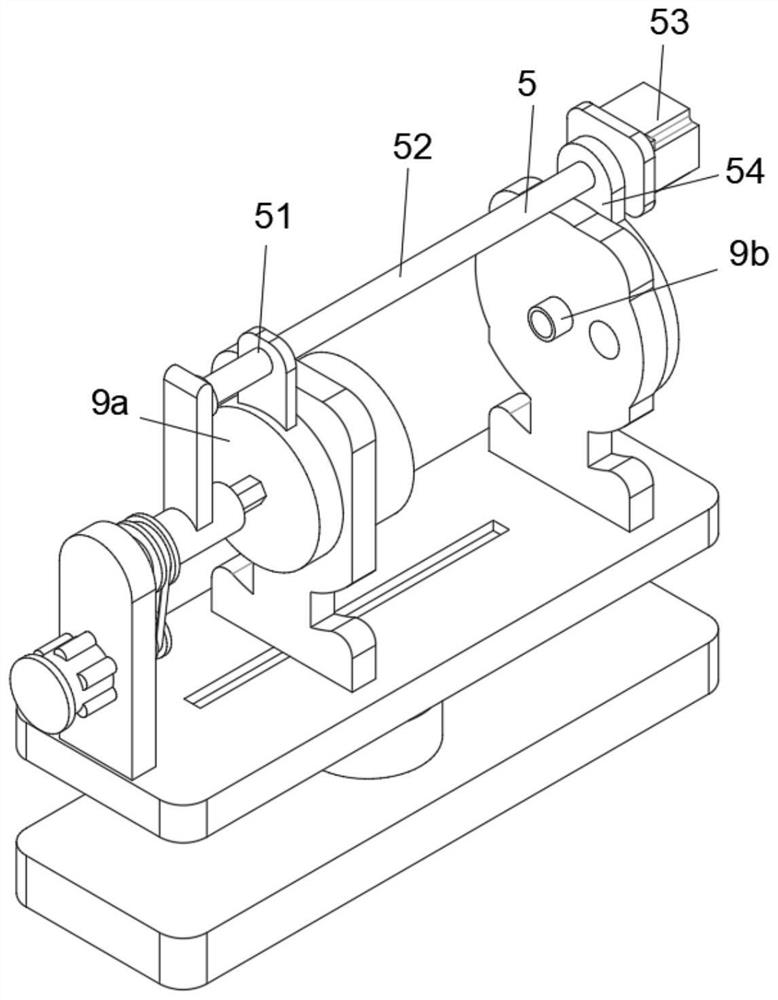

[0026] Please refer to Figure 1 to Figure 6 , a clamping device for off-line detection of a new energy vehicle motor gearbox includes: a mounting plate 2, a fixed splint 7 and a movable splint 3 that are matched and arranged above the mounting plate 2; the fixed splint 7 and the movable splint The upper surface of the mounting plate 2 is fixedly connected, and the movable splint 3 is slidingly connected with the upper surface of the mounting plate 2; the surface of the fixed splint 7 opposite to the movable splint 3 is fixedly connected with an output shaft positioning for positioning the output shaft of the gearbox cover 9b, and the surface opposite to the fixed splint 7 and the movable splint 3 is rotatably connected with a rotating ring 6 through a plane bearing; 9a, and the movable splint 3 is provided with a plurality of slots 9c in a uniform cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com