Bearing unit, preferably, wheel bearing unit for a motor vehicle, and method for producing a bearing unit

A bearing device, wheel bearing technology, applied in the direction of bearing assembly, rigid support of bearing components, bearings, etc., can solve problems such as high cost and change in clamping force, and achieve the effect of small ray radiation and good focusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

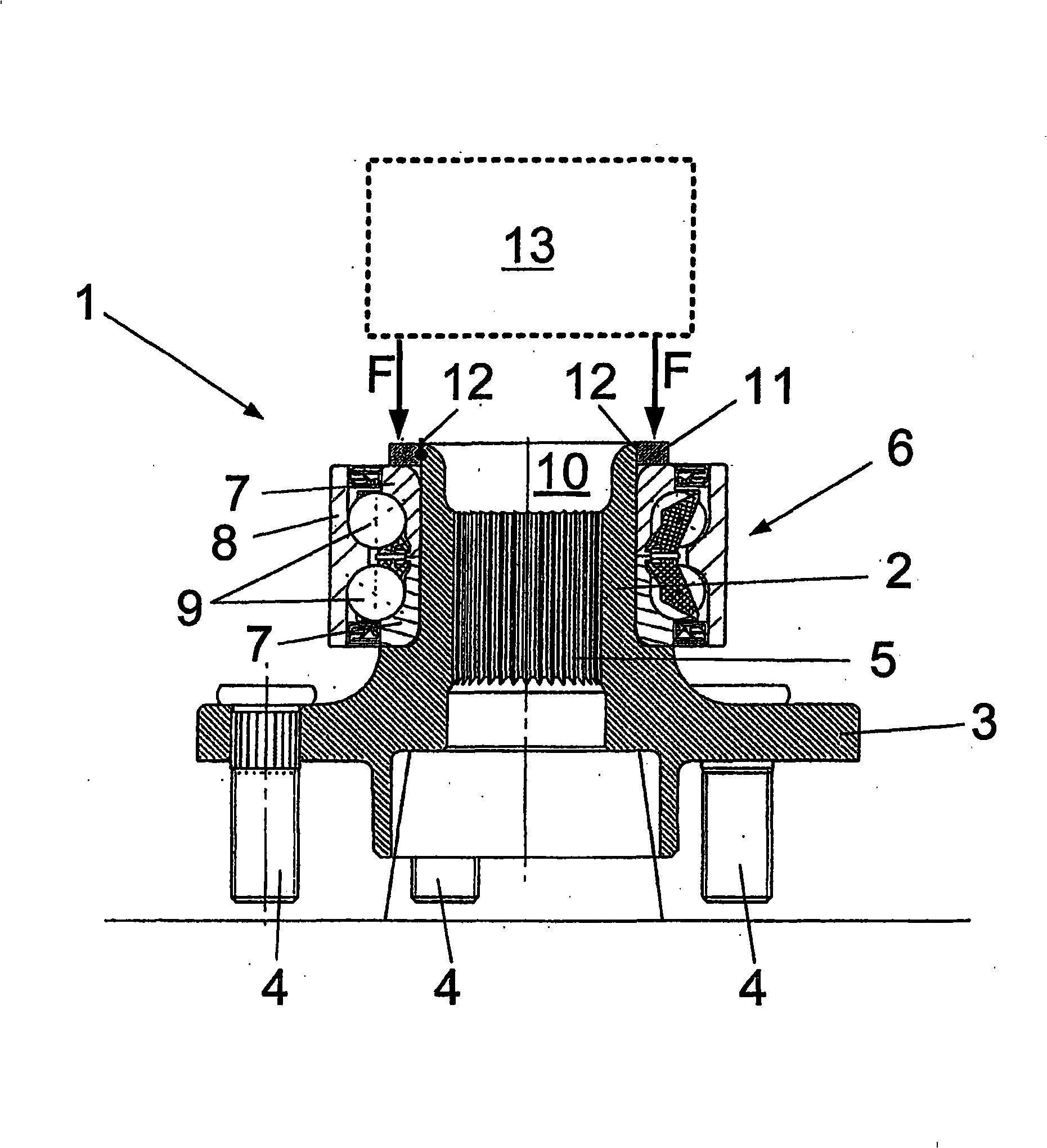

[0030] The wheel bearing arrangement 1 has a wheel hub 2 comprising a wheel-side fastening flange 3, on which a non-illustrated friction body, ie a brake disc and a wheel, are fastened by means of connecting elements 4, for example screws. lock up.

[0031] The hub 2 , as is common for drive shafts, can be connected in a rotationally fixed manner to a drive cardan shaft via an internal toothing 5 in its interior.

[0032] In the case of a hub for a non-driven shaft, which is not shown, the hub has no internal torque-transmitting elements and can be completely solid or have recesses.

[0033] Arranged on the hub 2 is a two-row angular contact rolling bearing 6 , which has a two-piece inner ring 7 and an outer ring 8 , between which two rows of spherical rolling bodies 9 are arranged.

[0034] The end 10 of the hub 2 opposite the fastening flange 3 is connected materially to a flange ring 11 , that is to say by means of welding and preferably by laser welding on the inner circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com