Liquid filling device and using method thereof

A filling equipment, liquid technology, applied in the direction of liquid bottling, liquid treatment, cleaning methods and utensils, etc., can solve the problems of lack of fixing devices for bottles, reduce filling continuity, and low equipment failure, so as to avoid contamination of machines frame, improve continuity and stability, and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

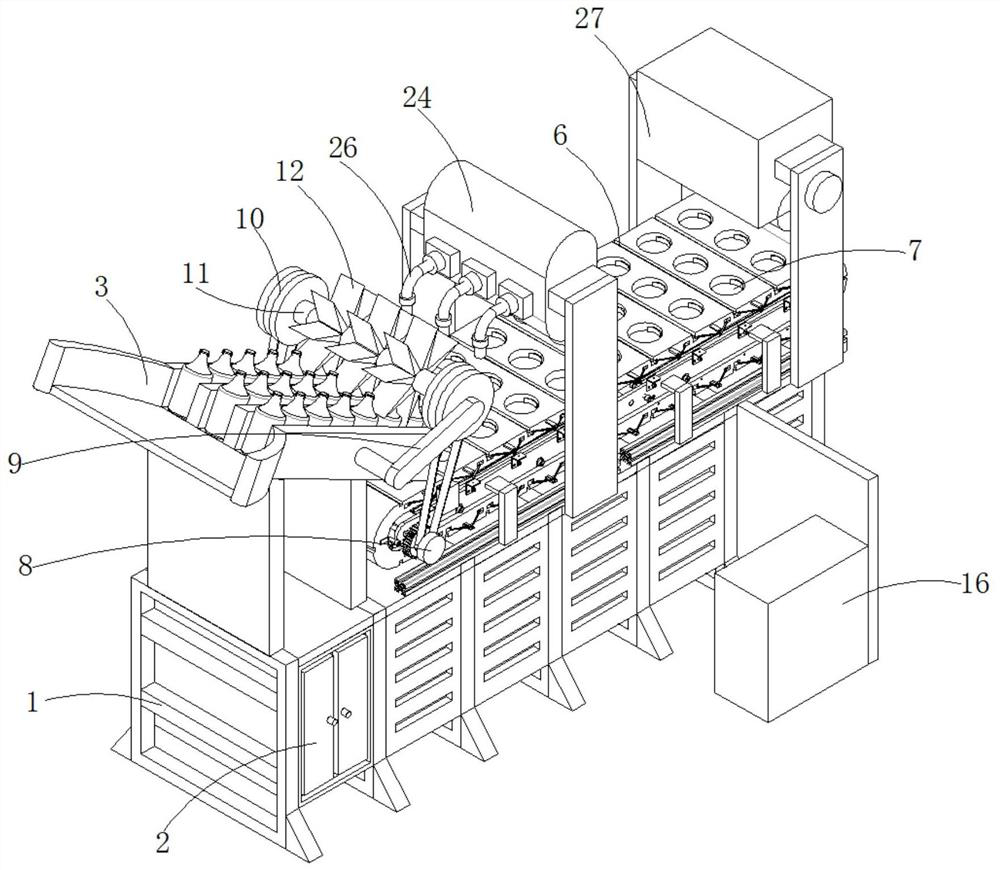

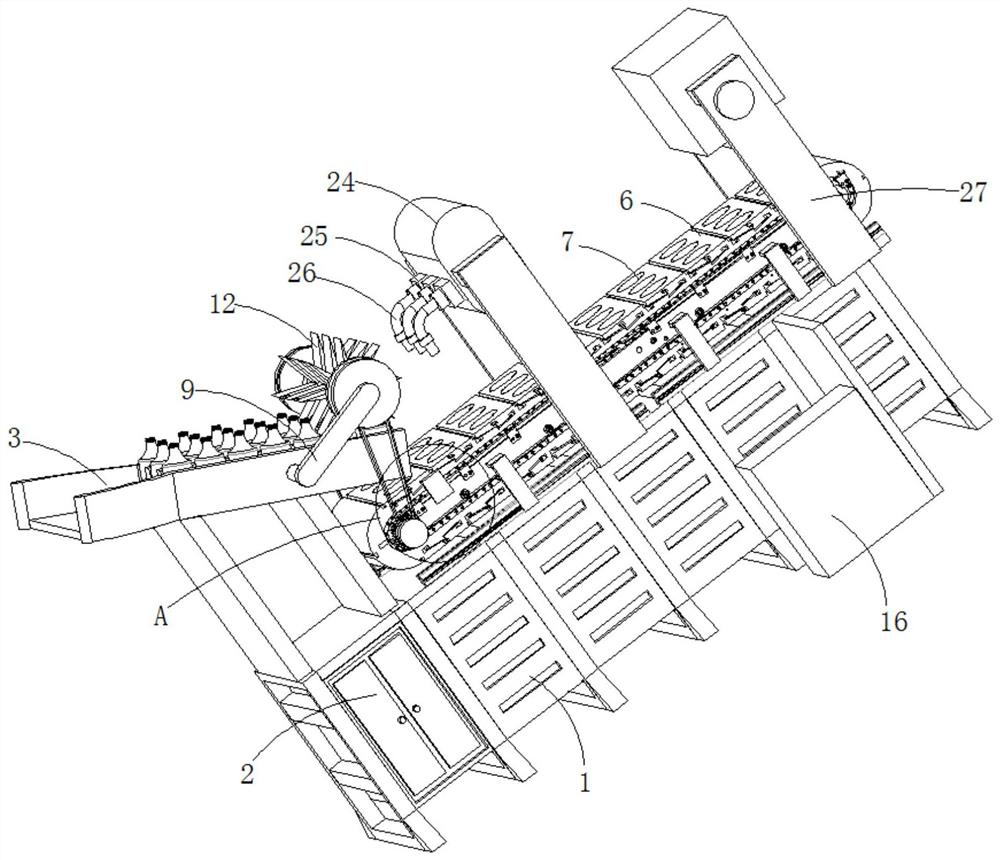

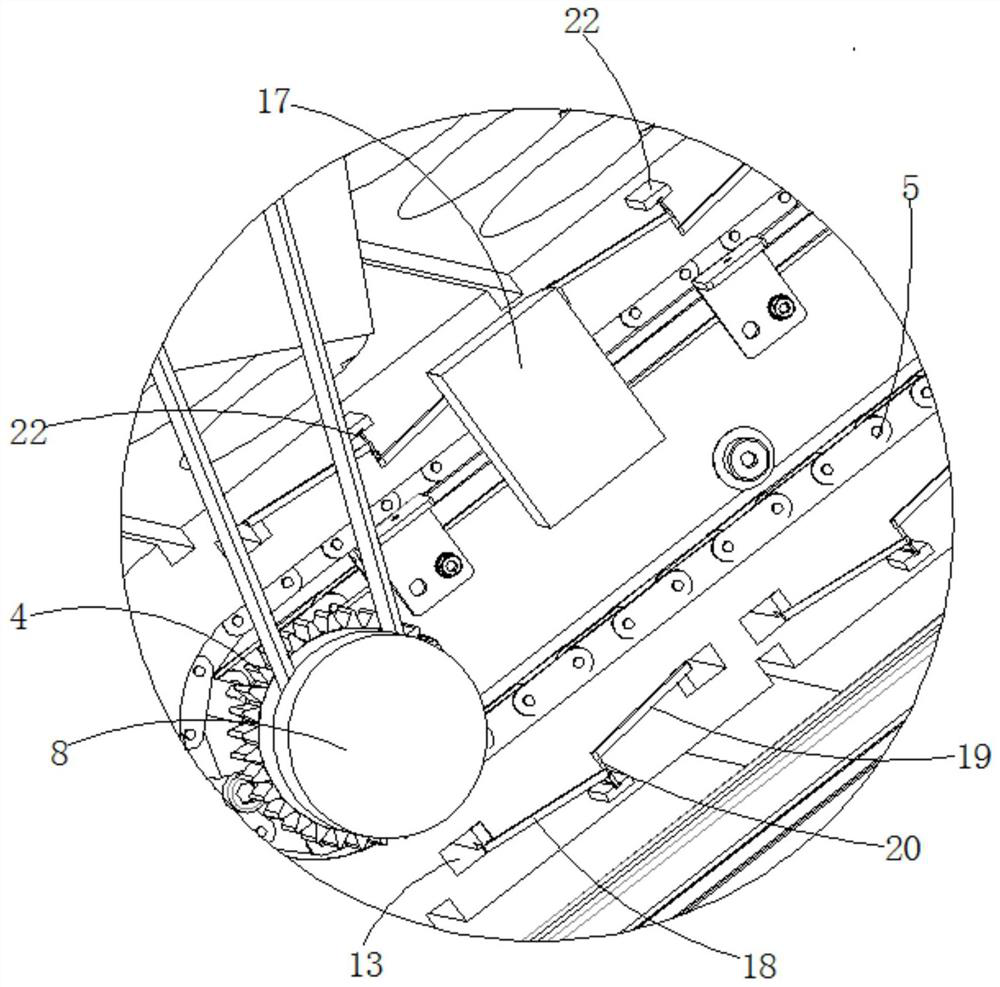

[0040] refer to Figure 1-6 , a liquid filling equipment, comprising a frame 1 and a PLC electric control box 2, the PLC electric control box 2 is installed on the frame 1, and the top of the frame 1 is fixedly connected with the bottle feeding bucket 3 and the drive The roller 4 and the bottom of the bottle feeding bucket 3 are provided with a vibration exciter. The driving roller 4 is driven by a servo motor and controlled by PLC programming. The end of the driving roller 4 is linked with a transmission chain 5, and the driving roller 4 is connected to a conveyor belt through the transmission chain 5. 6. The outer surface of the conveyor belt 6 is provided with evenly distributed positioning grooves 7, the end of the driving roller 4 is fixedly connected with a driving pulley 8, and the outer wall of the bottle feeding bucket 3 is connected with a driven pulley 10 through a rotating rod 9, and the driven pulley The driven roller 11 is fixedly connected between the 10, the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com