Batch pushing and distributing device for board-loaded materials

A material distribution device and material technology, which is applied in the field of batch pushing and material distribution devices for plate-mounted materials, and can solve the problems that automatic material distribution and feeding cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

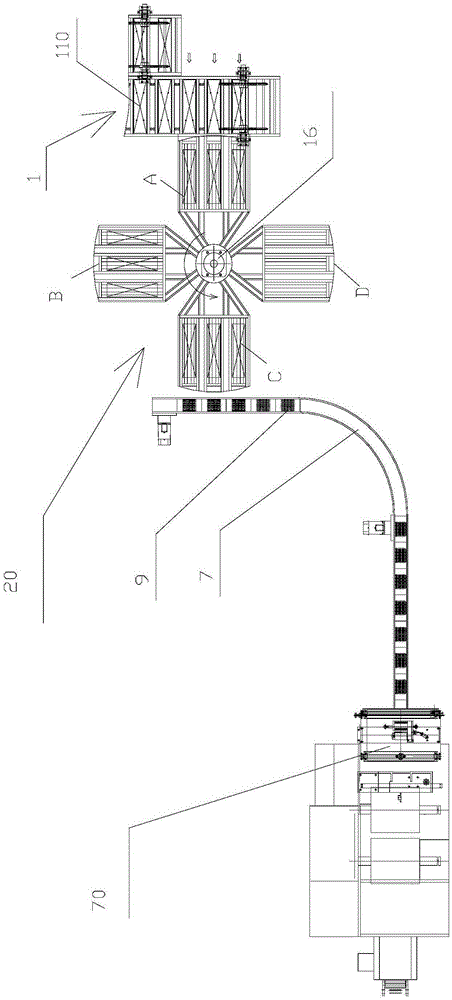

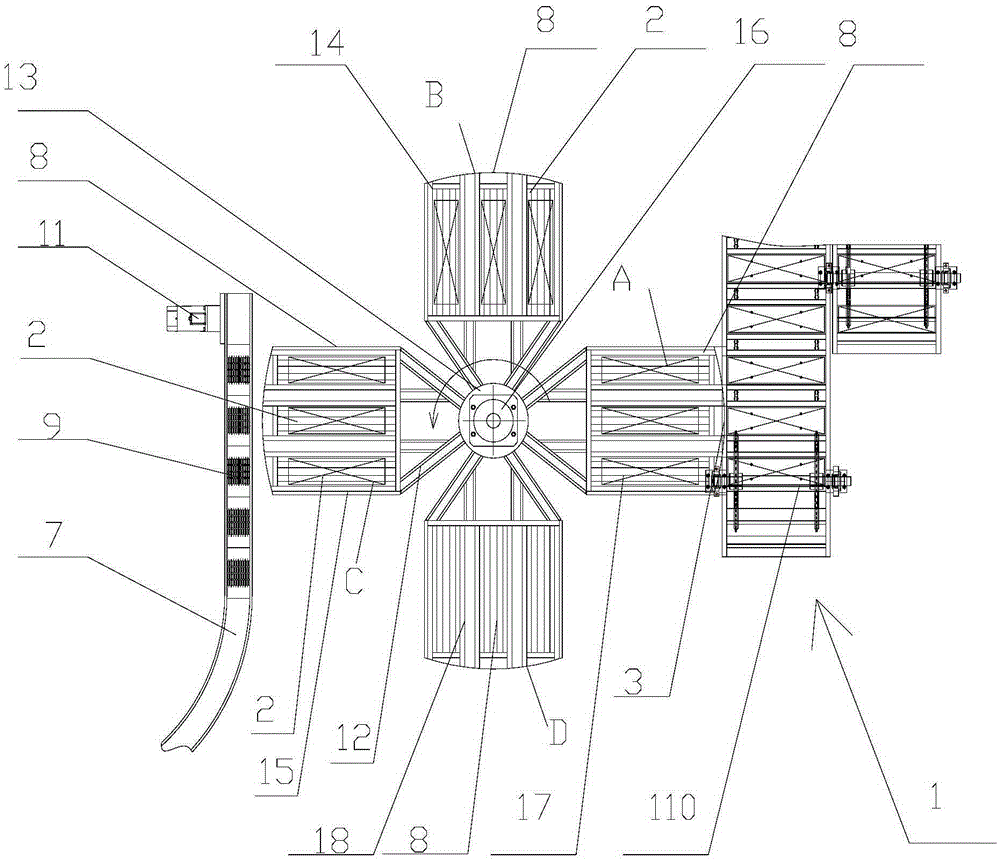

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

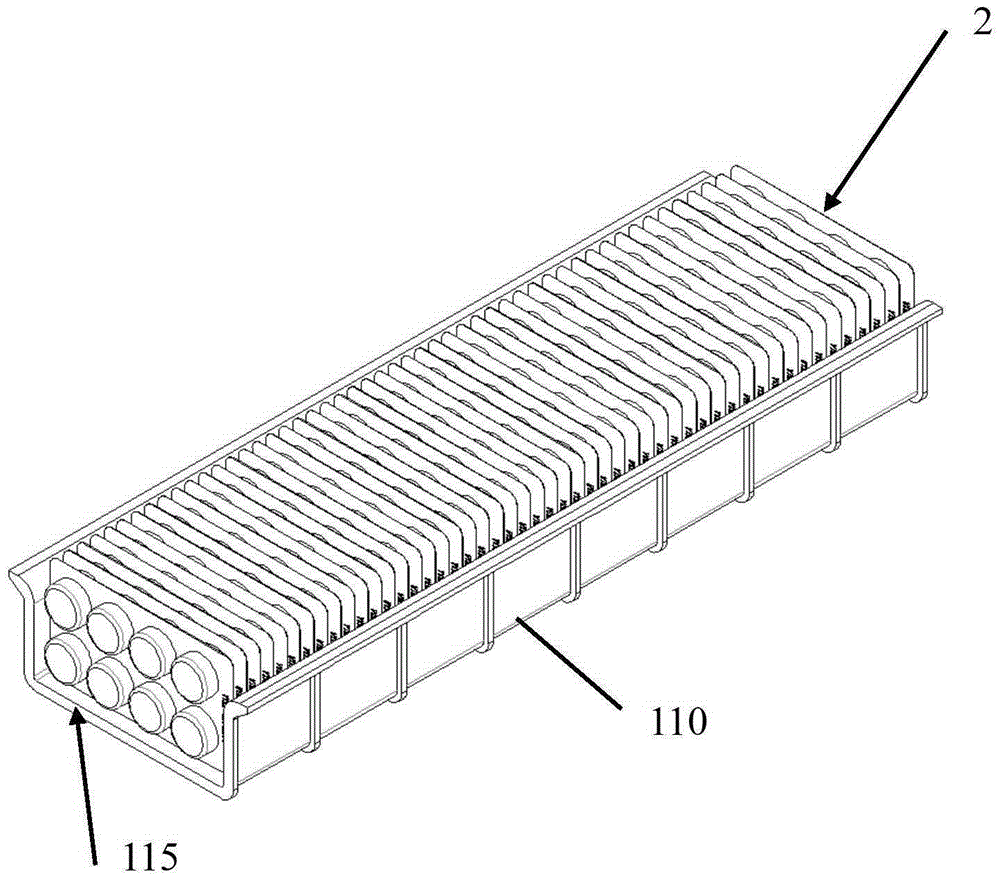

[0042] Such as figure 2 with image 3 As shown, the batch pushing and distributing device for plate-mounted materials according to the embodiment of the present invention is used to divide the m pieces of plate-mounted materials contained in the feeding frame on the feeding line into n groups of plate-mounted materials, and the plate-mounted materials can be plate-mounted materials Milk tablets or board-packed tablets or other materials, each group of board-packed materials contains k pieces of board-packed materials, n=m / k, in the embodiment of the present invention, n=5, m=50, k=10;

[0043] The embodiment of the present invention is used to divide the 50 pieces of board materials 2 in the material holding frame into 5 groups of board materials 9, and each group o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com