A rotary core type circumferential flow distribution device for a reciprocating plunger pump

A plunger pump and plunger technology, which is applied in the field of rotary core type circumferential flow distribution device for reciprocating plunger pumps, can solve the problems of large pressure loss, high cost, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

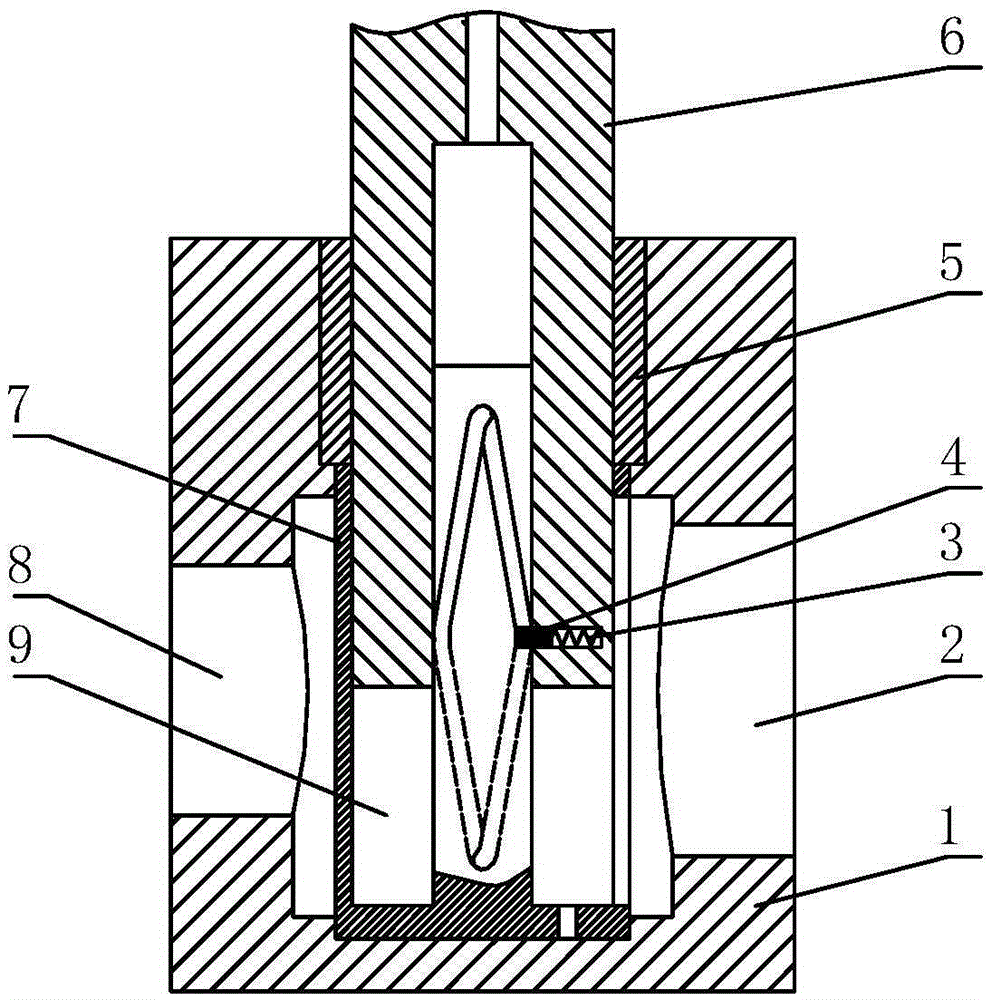

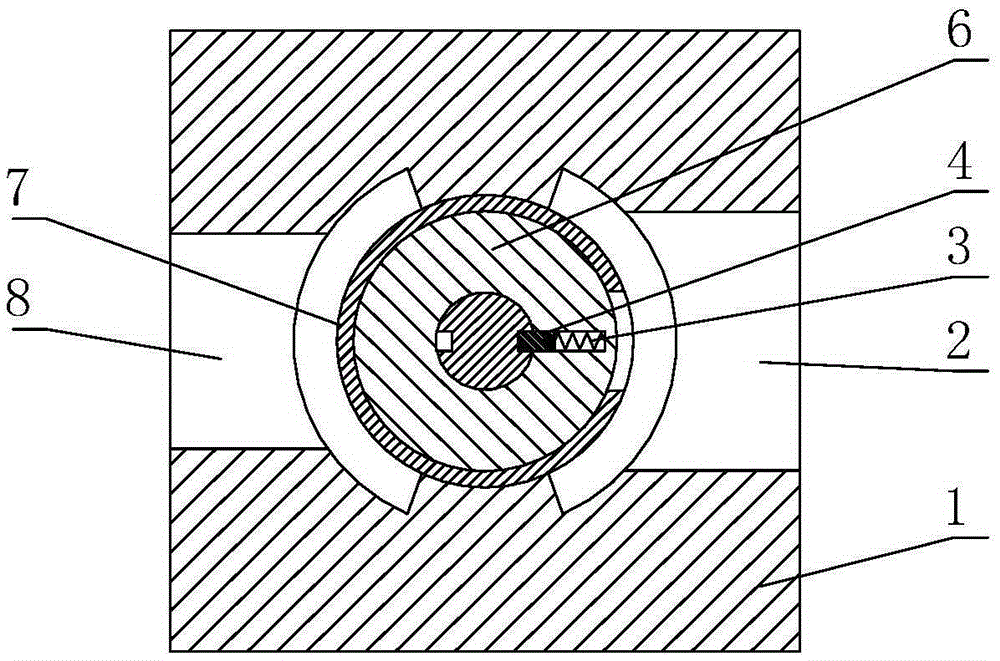

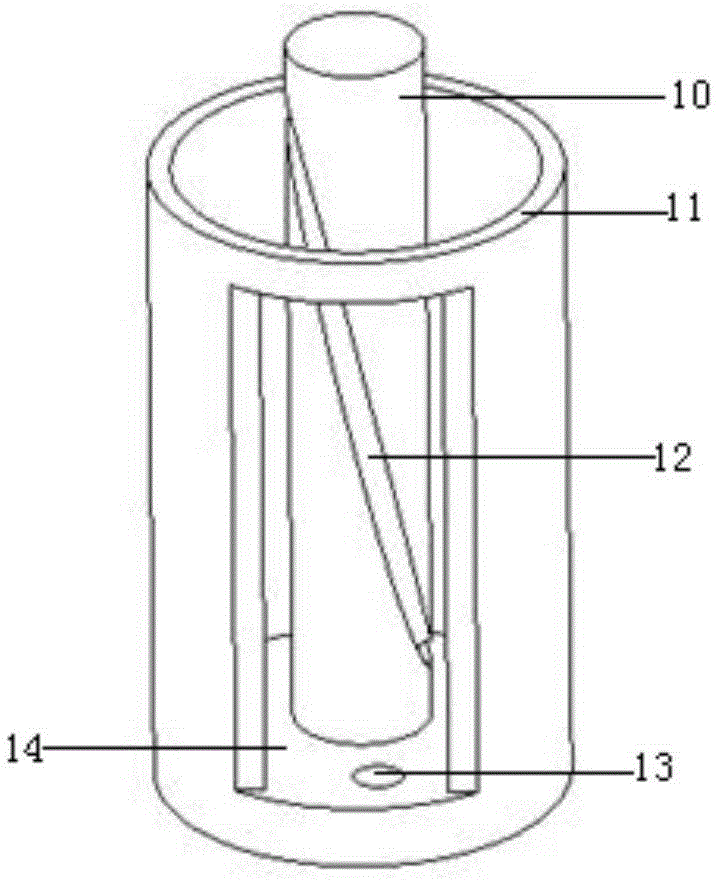

[0013] The main structure of the present embodiment is a pump body 1, a fluid inlet 2, a compression spring 3, a driven pin 4, a sliding sleeve 5, a plunger 6, a valve core 7, a fluid outlet 8 and a pump chamber 9, wherein the valve core 7 includes a valve core Center shaft 10, spool peripheral wall 11, cam groove 12, spool hole 13 and distribution hole 14; the shape of the pump body 1, which plays a supporting and connecting role, is designed according to the environment and equipment requirements of the pump body 1; the hollow cylindrical structure The plunger 6 is fixedly installed in the cavity of the pump body 1, and the sliding sleeve 5 made of wear-resistant or self-lubricating material is embedded in the pump body 1 to guide the plunger 6; the sliding sleeve 5 and the plunger 6 Close fit, the plunger 6 reciprocates in the axial direction in the sliding sleeve 5 under the action of external force; the circular inner cavity of the plunger 6 is provided with air holes comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com