Clamping and positioning tool for inner hole of thin-wall shell part

A thin-walled shell, clamping and positioning technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of low clamping force, inappropriate clamping and positioning tooling, and lack of clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The present invention will be further described below with reference to the accompanying drawings and specific examples.

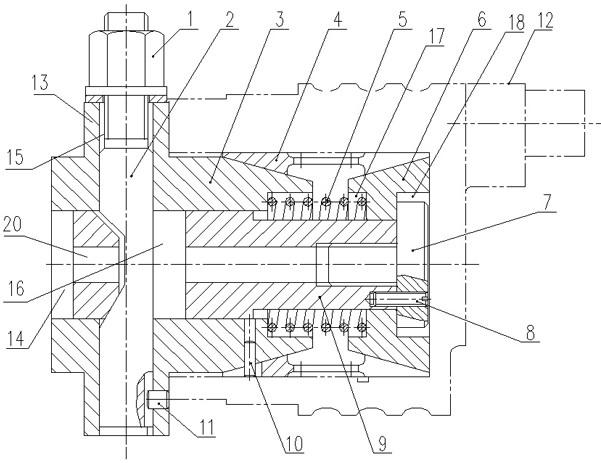

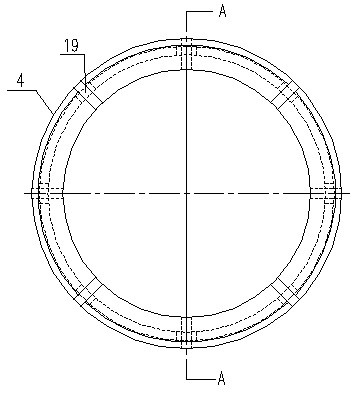

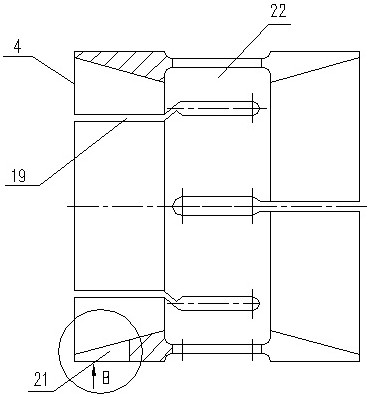

[0014]Such asfigure 1 ,figure 2 ,image 3 withFigure 4As shown, the present embodiment includes a main body 3, a clamping shaft 2, a nut, a tie rod 9, a spring 5, a jacket 4, a tapered block 6, and a push-pull block 7 with a connecting rod. The outer circle of the main body 3 matches the inner hole of the workpiece 12, extending into a tapered shape, the left end portion has a circle projection 13, and the center is opened with the inner hole I14 that matches the outer circle of the pulley 9, the right end of the inner hole I14 The diameter is large to accommodate the spring 5. An inner hole II15 is perpendicular to the inner holes I14 in the protrusions of the main body 3 and in combination with the clamping shaft 2. The pull rod 9 is in the position of the inner holes I14 and II15, and the clamping shaft mounting hole 16 is formed, the left end is thick, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com