Electronic garbage recovery treatment equipment

A technology of recycling and electronic waste, applied in the direction of electronic waste recycling, grain processing, recycling technology, etc., can solve the problems of high feeding port, waste of physical strength, unfavorable work efficiency, etc., to achieve unbreakable, convenient and labor-saving feeding, and convenient follow-up The effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

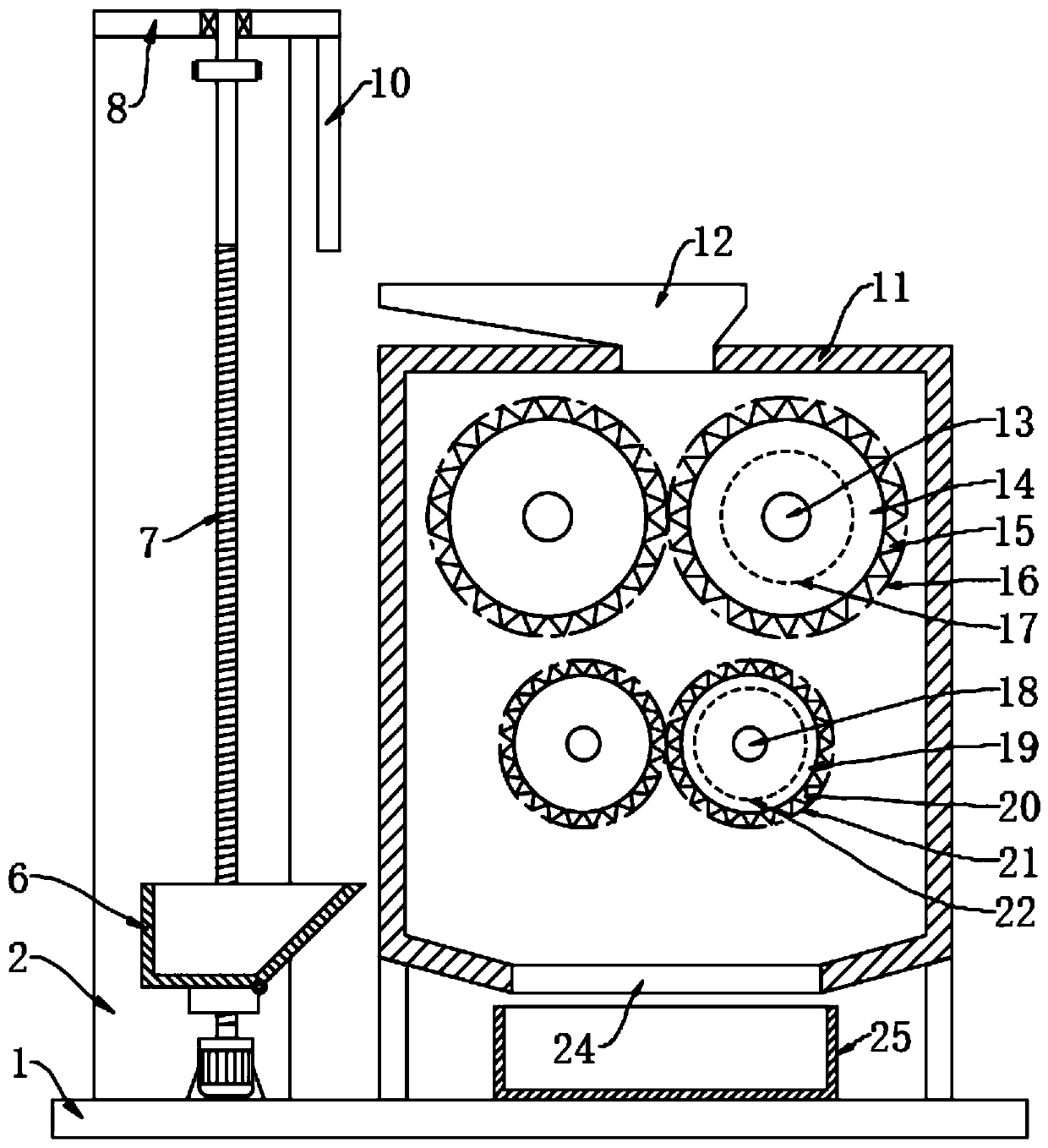

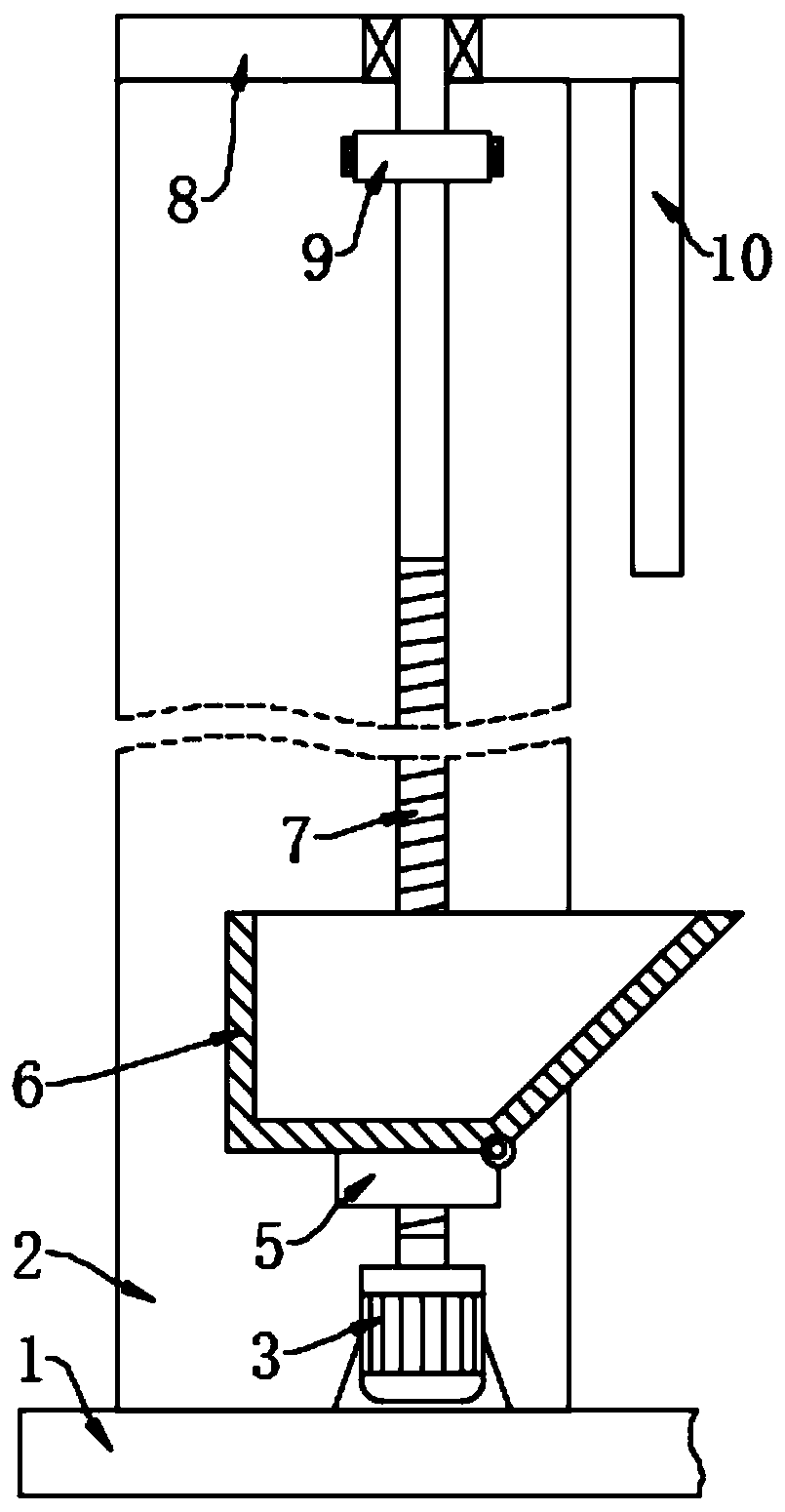

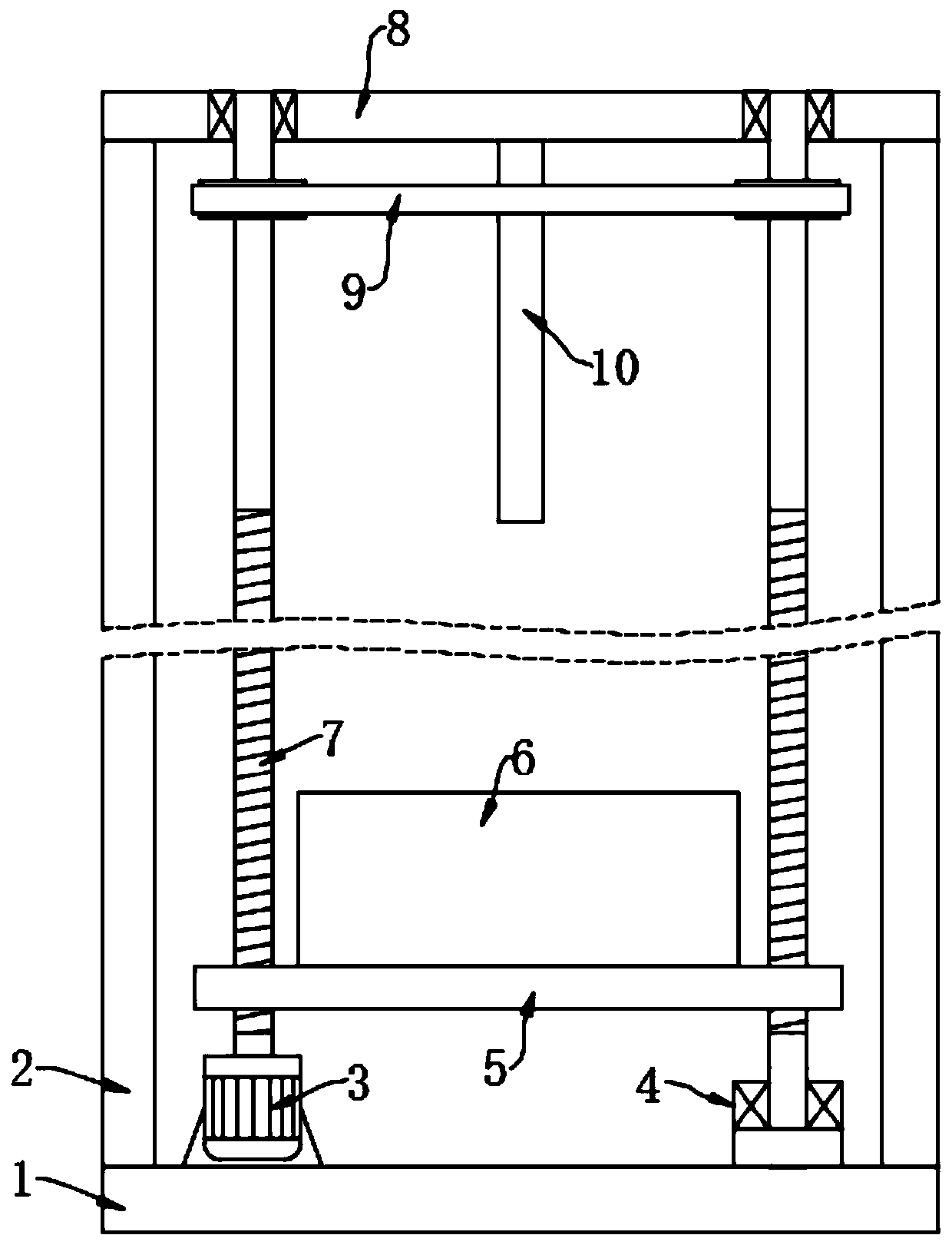

[0027] see Figure 1~4 , in an embodiment of the present invention, an electronic waste recycling and processing device includes a base 1, the top of the base 1 is fixed with a crushing box 11 through a bracket, the top of the crushing box 11 is provided with a feeding hopper 12, and the feeding hopper 12 extends to The upper left side of the crushing box 11 is convenient for adding electronic waste from the left side; the front and rear directions in the crushing box 11 are provided with two first rotating shafts 13 on the left and right, and the left and right first rotating shafts 13 are respectively connected to the front and rear walls of the crushing box 11 in rotation. The rotating shaft 13 located in the crushing box 11 is fixedly equipped with a first crushing roller 14, and the side wall of the first crushing roller 14 is evenly provided with a number of first crushing teeth 15; Two rotating shafts 18, the second rotating shaft 18 is located below the first rotating ...

Embodiment 2

[0030] see Figure 5 , on the basis of Example 1, the bottom of the crushing box 11 is fixedly provided with a screen 26, the screen 26 is inclined downward to the right, and the right end of the screen 26 is fixedly connected with a discharge chute 27, and the discharge chute 27 passes through the The right wall of the crushing box 11 extends to the outside of the crushing box 11; a vibration motor 28 is fixedly installed at the bottom of the screen 26, and the vibration motor 28 drives the screen 26 to vibrate to screen the electronic waste fragments falling on the screen 26. The plastic in the garbage is easily broken and falls through the sieve mesh 26, while the metal in the electronic waste has better toughness and is not easy to break, so it slides to the right, which is beneficial to the classification of the electronic waste and facilitates subsequent processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com