Self-moving type termination point hydraulic support based on parallel mechanism and application of termination point hydraulic support

A technology of end hydraulic support and hydraulic support, which is applied to mine roof support, mining equipment, earth-moving drilling, etc. problems, to achieve the effect of large height adjustment range, convenient underground transportation, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

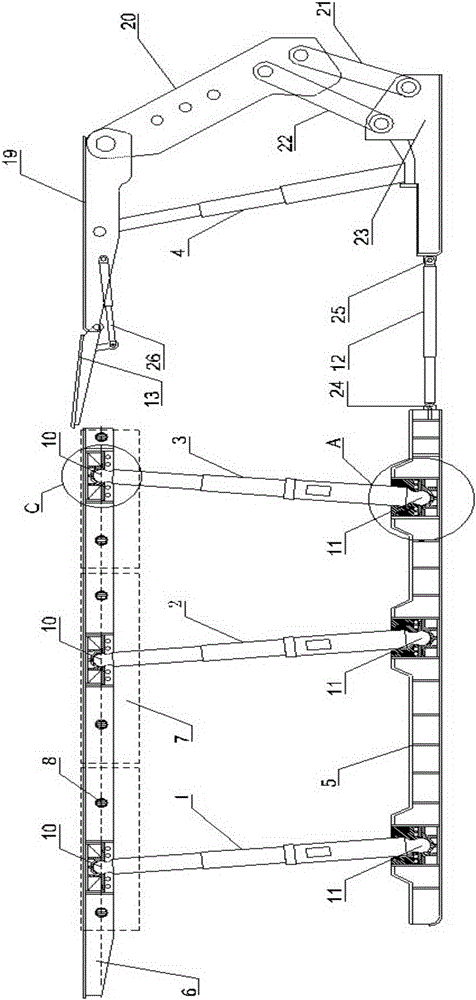

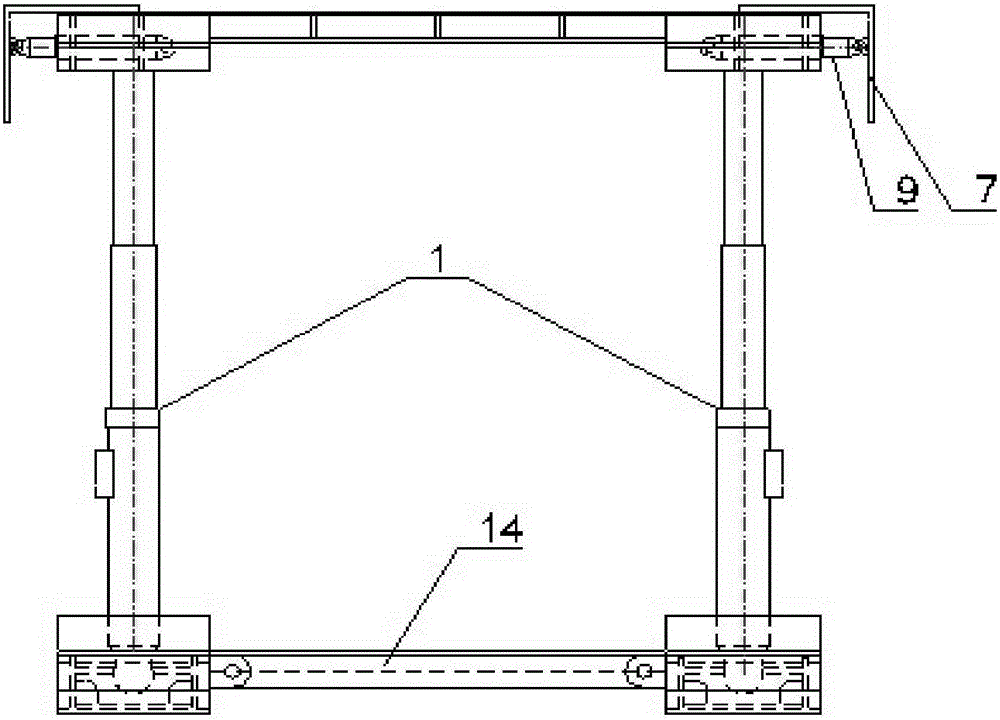

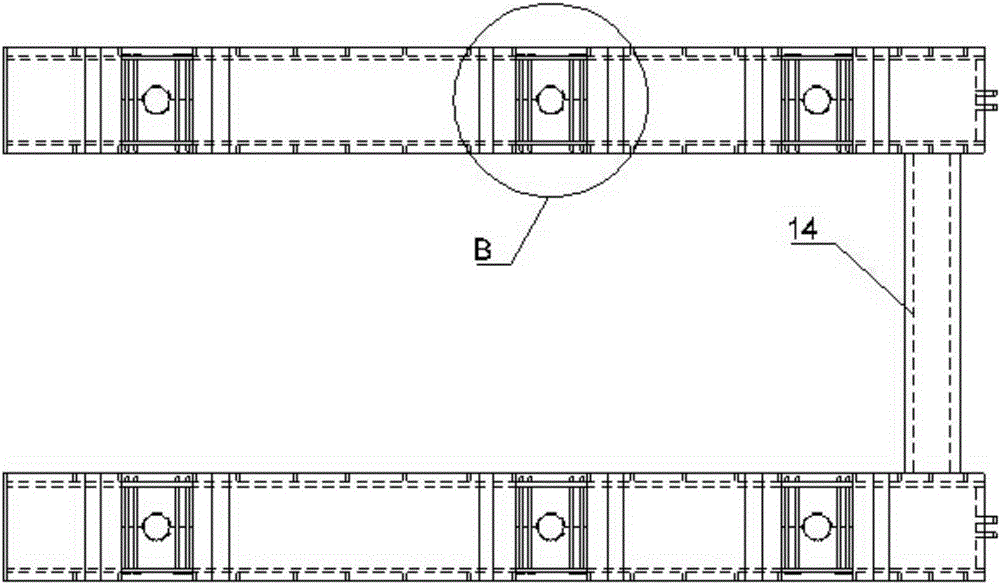

[0042] This embodiment provides a self-moving terminal hydraulic support based on a parallel mechanism, such as figure 1 As shown, it includes a front hydraulic support and a rear hydraulic support; wherein, the front hydraulic support includes two front bases 5, base connecting rods 14, front top beams 6 and front columns arranged in parallel, one of the two front bases 5 The side is fixedly connected by the base connecting rod 14. In this embodiment, the two ends of the base connecting rod 14 are fixedly connected to the two front bases 5 by means of bolt connection, and the two front bases 5 are symmetrically arranged with three rows of Front pillars (including the first row of front pillars 1, the second row of front pillars 2 and the third row of front pillars 3), the two ends of the front pillars are respectively hinged with the front top beam 6 and the front base 5, and the front top beam 6 is connected with the front The base 5 corresponds up and down; the rear hydraul...

Embodiment 2

[0051] This embodiment provides a self-moving terminal hydraulic support based on a parallel mechanism. The structure is as described in Embodiment 1, the difference is that the number of side guards 7 is three, and the three side guards 7 are arranged side by side. On the outer side of the front top beam 6 , each side guard 7 is hinged with two side push jacks 9 , and the side guard 7 is pushed out or pulled back by the two side push jacks 9 .

[0052] The application of the side pusher jack and the side guard can be adapted to the support of the ends of different widths, and the side guard is pushed out by the side pusher jack to contact the mine shaft wall. In addition, during the whole process of the hydraulic support at the end, the side guard can also adjust the walking position of the support. If the position of the front hydraulic support is shifted, the side guard can be pushed out by the side push jack to adjust the position of the front hydraulic support so that the...

Embodiment 3

[0054] This embodiment provides a self-moving terminal hydraulic support based on a parallel mechanism. The structure is as described in Embodiment 2. The difference is that a damping device is provided at the connection between the front column and the column socket, and the damping device is elastic. The limit damping device adopts rubber stopper in the present embodiment, and the damping device can limit the excessive inclination of the front column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com