Cylinder packaging barrel conveying device

A technology for conveying devices and packaging barrels, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increased labor, low efficiency, troubles, etc., and achieve good results and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

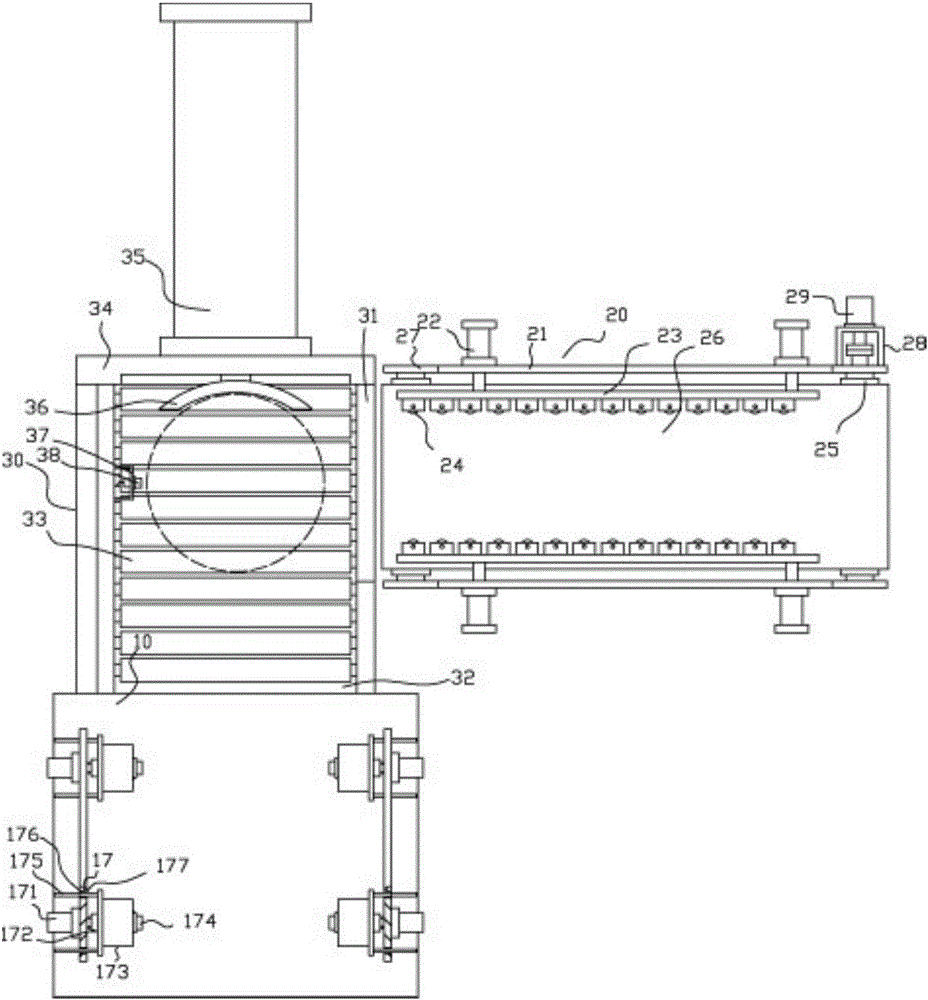

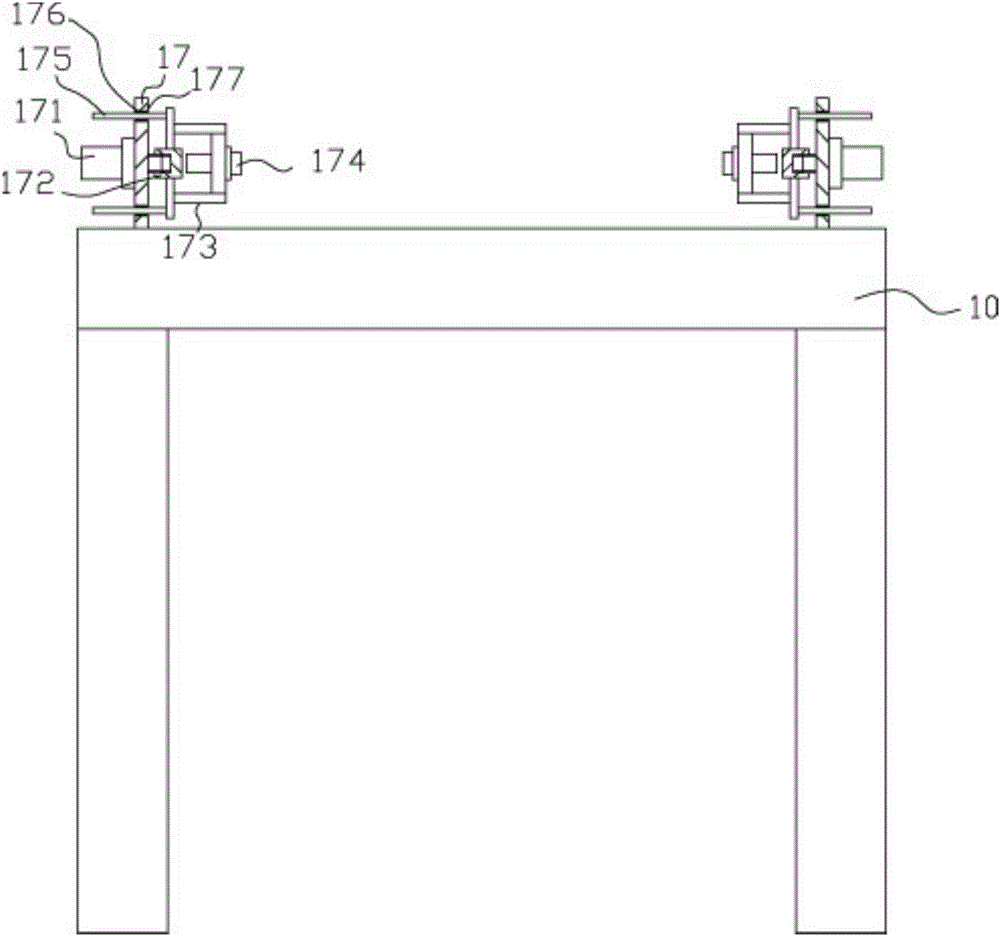

[0025] Example: see Figure 1 to Figure 4 As shown, a cylindrical packaging drum conveying device includes a conveying frame 20 and a rear support frame 30, and the right side of the rear support frame 30 is fixed with a conveying frame 20;

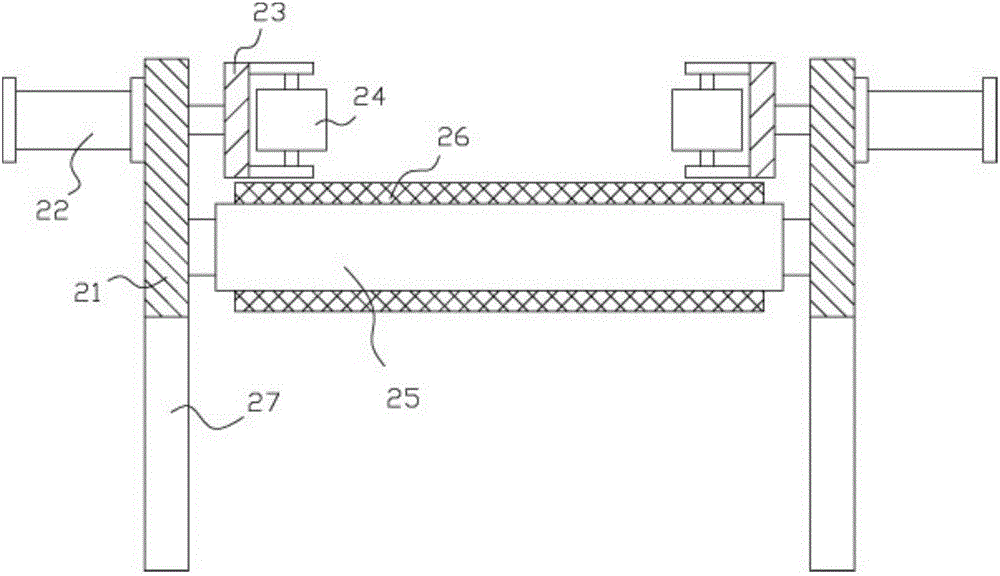

[0026] The left and right ends of the upper part of the crossbeam 21 on the front and rear sides of the delivery frame 20 are all fixed with position adjustment cylinders 22, and the push rods of the two position adjustment cylinders 22 of the crossbeam 21 pass through the crossbeam 21 and are fixed with a side adjustment plate 23, A plurality of side transmission roller bodies 24 are hinged on the side adjustment plate 23, and the side transmission roller bodies 24 of the side adjustment plate 23 on the two beams 21 are opposite to each other left and right, and the left end of the delivery frame 20 is facing the right side of the rear support frame 30. Material outlet 31, the front end of rear support frame 30 has outlet 32, and outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com