Automatic rotation mechanism for cosmetic box conveyance

An automatic conveying and rotating mechanism technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low efficiency and poor effect, and achieve high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

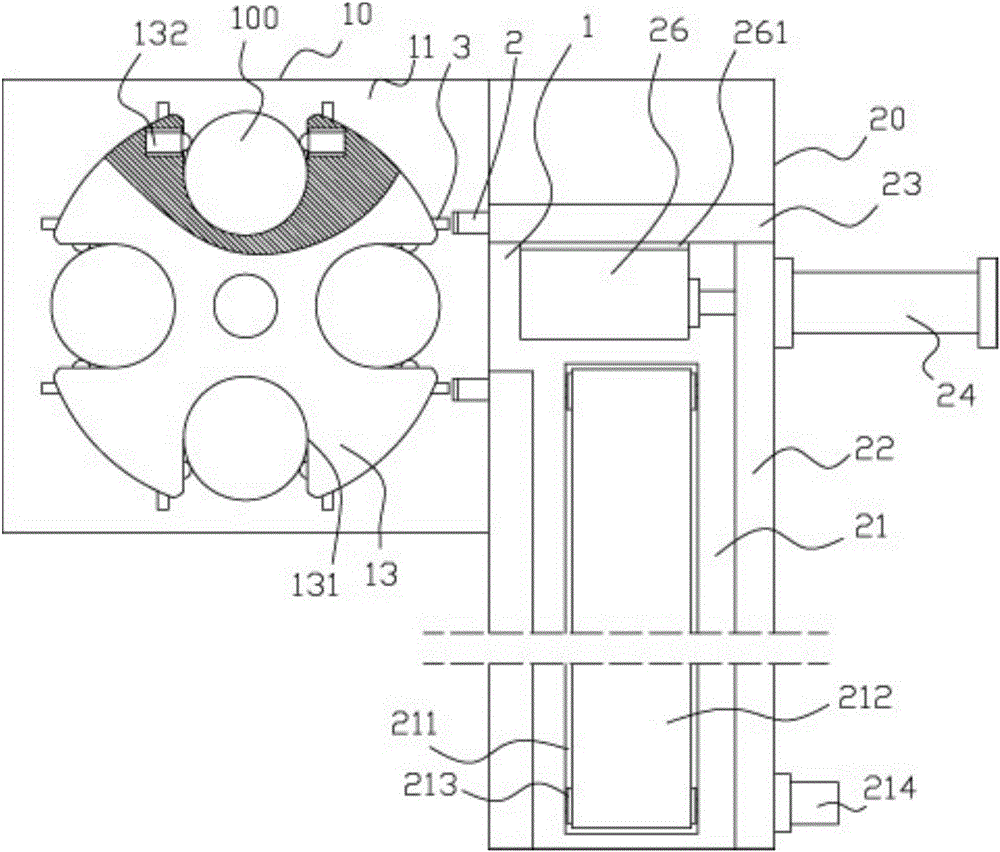

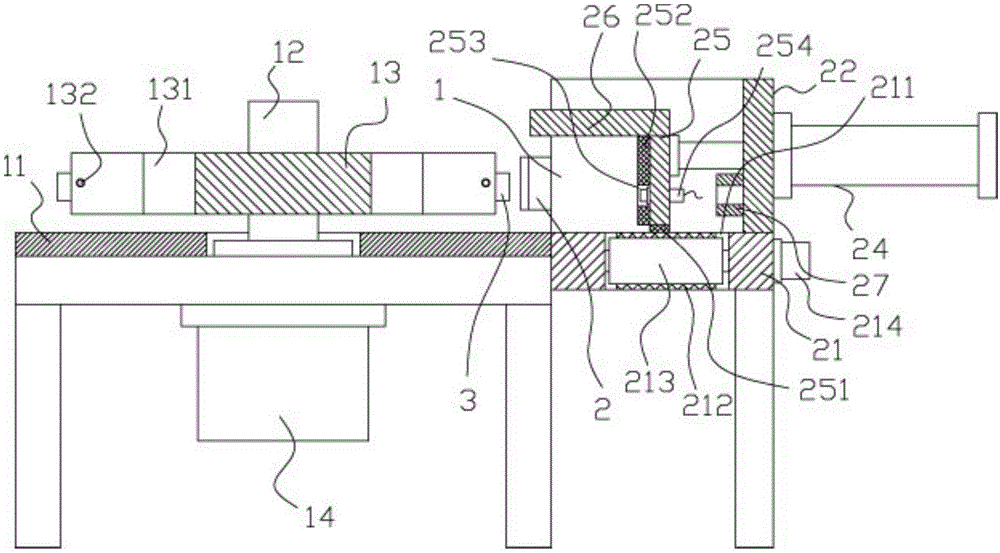

[0023] Example: see Figure 1 to Figure 2 Shown, a kind of cosmetic box body automatic conveying rotation mechanism, comprises rotating frame 10 and conveying frame 20, the right side of described rotating frame 10 is fixed with conveying frame 20, and the top surface of the top plate of rotating frame 10 is fixed with automatic Lubricate the sliding plate 11, the front left side wall of the conveying top plate 21 of the conveying frame 20 is close to the right side wall of the self-lubricating sliding plate 11, the top surface of the conveying top plate 21 is flat with the top surface of the self-lubricating sliding plate 11, and the top surface of the conveying top plate 21 Left and right side top surfaces are all fixed with guide plate 22, and the middle part of conveying top plate 21 has conveying channel 211, and conveyor belt 212 is in conveying channel 211, and conveyor belt 212 is stretched on two transmission rollers 213, and transmission roller The two ends of 213 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com